Professional Documents

Culture Documents

Exercices Fundamentals of SC V1 Hyb

Uploaded by

iMANE ELBENNANIOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Exercices Fundamentals of SC V1 Hyb

Uploaded by

iMANE ELBENNANICopyright:

Available Formats

ESITH – LI3

Exercises

Fundamentals of

Supply Chain

Mme L. BOUSFIHA Fundamentals of SCM V1 HYB - 1

CHAPTER 1

Introduction to Supply

Chain Management

Mme L. BOUSFIHA Fundamentals of SCM V1 HYB - 2

Mme Loubna BOUSFIHA Fundamentals of Supply Chain / 1

ESITH – LI3

Exercise 1

Classify these industrial companies :

Production

Process Environnement MTS ETO / ATO or MTO

Choices

FLOW

INTERMITTANT

PROJECT

Ships Manufacturing Mechanical subcontracting Manufacturing of skis

Refineries Ready-to-wear clothing Satellites

Assembly of car Collective housing Milk manufacturing

Mme L. BOUSFIHA Fundamentals of SCM V1 HYB - 3

Exercise 2

Product Layout vs. Process Layout :

Product Process

Capital cost

Flexibility

Annual setup cost

Run cost

Work-in-process inventory

Production and inventory control costs

Lead time

Mme L. BOUSFIHA Fundamentals of SCM V1 HYB - 4

Mme Loubna BOUSFIHA Fundamentals of Supply Chain / 2

ESITH – LI3

CHAPTER 2

Demand Management

Mme L. BOUSFIHA Fundamentals of SCM V1 HYB - 5

Exercise 3

Given the following data, calculate the three-month

moving average forecasts for months 4, 5, 6, and 7.

Month Actual Demand Forecast

1 60

2 70

3 40

4 50

5 70

6 65

7

Mme L. BOUSFIHA Fundamentals of SCM V1 HYB - 6

Mme Loubna BOUSFIHA Fundamentals of Supply Chain / 3

ESITH – LI3

Exercise 4

Weekly demand for an item averaged 100 units over the past year. Actual demand

for the next eight weeks is shown in what follows:

a. Plot the data on graph paper.

b. Letting α = 0.25 , calculate the smoothed forecast for each week.

c. Comment on how well the forecast is tracking actual demand. Is it lagging or

leading actual demand?

Week Actual Demand Forecast

1 103 100

2 112

3 113

4 120

5 126

6 128

7 138

8 141

Mme L. BOUSFIHA 9 Fundamentals of SCM V1 HYB - 7

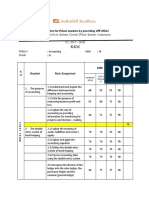

Exercise 5

A company uses a tracking signal trigger of +-4 to decide whether a

forecast should be reviewed. Given the following history, calculate

the MAD and determine in which period the forecast should be

reviewed.

Cumulative Absolute Tracking

Period Forecast Actual Deviation

Deviation Deviation Signal

1 100 110

2 105 90

3 110 85

4 115 110

5 120 105

6 125 95

Mme L. BOUSFIHA Fundamentals of SCM V1 HYB - 8

Mme Loubna BOUSFIHA Fundamentals of Supply Chain / 4

ESITH – LI3

CHAPTER 3

Master Planning

Mme L. BOUSFIHA Fundamentals of SCM V1 HYB - 9

Exercise 6

A company wants to develop a level production plan for a family of

products. The opening inventory is 100 units, and an increase to 160

units is expected by the end of the plan.

The demand for each period is given in what follows. How much

should the company produce each period? What will be the ending

inventories in each period? All periods have the same number of

working days.

Mme L. BOUSFIHA Fundamentals of SCM V1 HYB - 10

Mme Loubna BOUSFIHA Fundamentals of Supply Chain / 5

ESITH – LI3

Exercise 7

A company wants to develop a level production plan for a family of

products. The opening inventory is 600 units, and a decrease to 200

units is expected by the end of the plan.

The demand for each of the months is given in what follows. How

much should the company produce each month? What will be the

ending inventory in each month? Do you see any problems with the

plan?

Mme L. BOUSFIHA Fundamentals of SCM V1 HYB - 11

Exercise 8

A company wants to develop a level production plan. The beginning

inventory is zero. Demand for the next four periods is given in what follows.

a. What production rate per period will give a zero inventory at the end of

period 4?

b. When and in what quantities will back orders occur?

c. What level production rate per period will avoid back orders? What will

be the ending inventory in period 4?

d. If the cost of carrying inventory is $50 per unit per period, the production

cost is $20 per unit and stockouts cost $500 per unit, what will be the cost of

the plan developed in a? What will be the cost of the plan developed in c?

f. What are your comments ?

Mme L. BOUSFIHA Fundamentals of SCM V1 HYB - 12

Mme Loubna BOUSFIHA Fundamentals of Supply Chain / 6

ESITH – LI3

Exercise 9

Because of its labor contract, a company must hire enough labor for

100 units of production per week on one shift or 200 units per week

on two shifts. It cannot hire, lay off, or assign overtime. During the

fourth week, workers will be available from another department

to work part or all of an extra shift (up to 100 units). There is a

planned shutdown for maintenance in the second week, which will

cut production to half. Develop a production plan. The opening

inventory is 200 units, and the desired ending inventory is 300 units.

Mme L. BOUSFIHA Fundamentals of SCM V1 HYB - 13

Exercise 10

Based on the following information , Calculate the total resource

requirements for the cycle product families for July:

Bill of Resources

Product Families: July prod. plan

Product Labor Cycles

Families: Steel (tons) (standard

Cycles hrs) Unicycle 500

Unicycle 0.00030 .40 Bicycles 2,500

Bicycle 0.00055 .60 Tricycles 1,000

Tricycle 0.00035 .30

Based on the following information , Calculate the total resource

requirements for the cycle product families for July

If the capacity available for the cycle product families in terms of

Labor for July is = 1900 hours; can we accept this plan ?

Mme L. BOUSFIHA Fundamentals of SCM V1 HYB - 14

Mme Loubna BOUSFIHA Fundamentals of Supply Chain / 7

ESITH – LI3

Exercise 11

The Wicked Witch Whisk Company manufactures a line of broomsticks. The most popular

is the 36-inch model, and the sales department has prepared a forecast for 6 weeks. The

opening inventory is 30.

As master scheduler, you must prepare an MPS. The brooms are manufactured in lots of

100.

Week 1 2 3 4 5 6

Forecast Sales 10 50 25 50 10 15

Projected Available

Balance 30

MPS

Mme L. BOUSFIHA Fundamentals of SCM V1 HYB - 15

Exercise 12

Worldwide Can-Openers, Inc., makes a family of two hand-operated can openers. The

production plan is based on months and is stated to 16000 dozen for the next month.

The MPS is made using weekly periods. The forecast and projected available balance for

the two models follow. The lot size for both models is 1000 dozen. Calculate the

production plan and the MPS for each item.

Model A

Week 1 2 3 4 Total

Forecast Sales 2000 2000 2500 2000

Projected Available

1500

Balance

MPS

Model B

Week 1 2 3 4 Total

Forecast Sales 1000 1500 1000 2000

Projected Available

500

Balance

MPS

Mme L. BOUSFIHA Fundamentals of SCM V1 HYB - 16

Mme Loubna BOUSFIHA Fundamentals of Supply Chain / 8

ESITH – LI3

Exercise 13

Complete the following problem. There are 20 on hand. The lot size is 60.

Period 1 2 3 4 5 6

Forecast 20 21 22 20 28 25

Customer Orders 19 18 20 18 30 22

Projected

Available Balance 20

MPS

ATP

Mme L. BOUSFIHA Fundamentals of SCM V1 HYB - 17

Exercise 14

The Acme Widget Company makes widgets in two models, and the bottleneck operation is

in work center 10. Following is the resource bill (in hours per part).

Hours per Part

Work

Model A Model B

Center

10 2,5 3,3

The master production schedule for the next 5 weeks is:

Week 1 2 3 4 5

Model A 70 50 50 60 45

Model B 20 40 55 30 45

a. Using the resource bill and the master production schedule, calculate the number of

hours required in work center 10 for each of the 5 weeks.

b. If the available capacity at workstation 10 is 260 hours per week, suggest possible ways

of meeting the demand in week 3.

Mme L. BOUSFIHA Fundamentals of SCM V1 HYB - 18

Mme Loubna BOUSFIHA Fundamentals of Supply Chain / 9

ESITH – LI3

CHAPTER 4

Material Requirement

Planning

Mme L. BOUSFIHA Fundamentals of SCM V1 HYB - 19

Case Study N°1

A company makes tables (servantes); the bill of material for table A is as follows:

Period W1 W2 W3 W4 W5 W6

The MPS for the table A is as follow: MPS 65 70 55 60

For each product, we know the following :

Product On Hand Scheduled Receipt Lead Time (weeks) Lot Size

Servante A 25 70 on W2 1 Batch of 70

Support B 0 105 on W1 2 Lot for Lot

Plateau C 100 1 Lot for Lot

Grande traverse D 50 1 With a Safety Stock of 50 Minimum of 100

Petite traverse E 120 1 Batch of 100

Pied F 400 2 Batch of 200

Mme L. BOUSFIHA Fundamentals of SCM V1 HYB - 20

Mme Loubna BOUSFIHA Fundamentals of Supply Chain / 10

ESITH – LI3

Case Study N°1

Fill the following grids

Weeks 1 2 3 4 5 6

Gross requirements

Scheduled receipts

Servante A Projected available balance

Planned order receipt

Planned order release

Weeks 1 2 3 4 5 6

Gross requirements

Scheduled receipts

Support B Projected available balance

Planned order receipt

Planned order release

Weeks 1 2 3 4 5 6

Gross requirements

Scheduled receipts

Plateau C Projected available balance

Planned order receipt

Planned order release

Weeks 1 2 3 4 5 6

Gross requirements

Grande Scheduled receipts

traverse D Projected available balance

Planned order receipt

Planned order release

Mme L. BOUSFIHA Fundamentals of SCM V1 HYB - 21

Case Study N°1

Weeks 1 2 3 4 5 6

Gross requirements

Petite Scheduled receipts

traverse E Projected available balance

Planned order receipt

Planned order release

Weeks 1 2 3 4 5 6

Gross requirements

Scheduled receipts

Pied F Projected available balance

Planned order receipt

Planned order release

Mme L. BOUSFIHA Fundamentals of SCM V1 HYB - 22

Mme Loubna BOUSFIHA Fundamentals of Supply Chain / 11

ESITH – LI3

Case Study N°2

The BonneRoute SA company manufactures two models of GPS. The entry-level

model G1000 is aimed at the general public, while the sophisticated model G2000

is aimed at delivery professionals.

• The G1000 consists of one unit of "A" and 2 of "B".

• The G2000 consists of 3 units of "A", one of "C" and 4 of "D".

• "A" is made from 4 units of "E" and one of "F". "B" is made up of 2 units of "G"

and one of "F". Finally, "D" is made up of two units of "H" and 3 of "G".

Since the holidays are coming, the company expects large orders in the next few

weeks, especially for the G1000 model. According to production schedules, the

demands for the G1000 will be 400 units in week 8 and 280 units in week 9. For the

G2000 model, it will be 150 units in week 8 and 160 units in week 10.

Final assembly takes a week for the entry-level model and two weeks for the

sophisticated model. The rule size for both models is lot for lot.

Information about the different items used for the manufacture of the two models

can be found in the table below:

Mme L. BOUSFIHA Fundamentals of SCM V1 HYB - 23

Case Study N°2

Component Lead time (LT) Lot size On Hand Scheduled Receipts

A 2 Lot for Lot - -

B 2 Lot for Lot - -

C 2 60 10 -

D 1 80 40 -

E 1 Lot for Lot - 100 in week4

F 3 Lot for Lot 80 -

G 2 Lot for Lot - 160 in week2

H 1 30 100 90 in week 3

Draw the tree bill of material for product G1000 and G2000 and fill in the following grids:

Week 1 2 3 4 5 6 7 8 9 10

Gross Requirements

Scheduled Receipts

G1000

Projected Available

Planned Order Receipt

Planned Order Release

Week 1 2 3 4 5 6 7 8 9 10

Gross Requirements

Scheduled Receipts

G2000

Projected Available

Planned Order Receipt

Planned Order Release

Mme L. BOUSFIHA Fundamentals of SCM V1 HYB - 24

Mme Loubna BOUSFIHA Fundamentals of Supply Chain / 12

ESITH – LI3

Case Study N°2

Week 1 2 3 4 5 6 7 8 9 10

Gross Requirements

Scheduled Receipts

A

Projected Available

Planned Order Receipt

Planned Order Release

Week 1 2 3 4 5 6 7 8 9 10

Gross Requirements

Scheduled Receipts

B

Projected Available

Planned Order Receipt

Planned Order Release

Week 1 2 3 4 5 6 7 8 9 10

Gross Requirements

Scheduled Receipts

C

Projected Available

Planned Order Receipt

Planned Order Release

Week 1 2 3 4 5 6 7 8 9 10

Gross Requirements

Scheduled Receipts

D

Projected Available

Planned Order Receipt

Planned Order Release

Mme L. BOUSFIHA Fundamentals of SCM V1 HYB - 25

Case Study N°2

Week 1 2 3 4 5 6 7 8 9 10

Gross Requirements

Scheduled Receipts

E

Projected Available

Planned Order Receipt

Planned Order Release

Week 1 2 3 4 5 6 7 8 9 10

Gross Requirements

Scheduled Receipts

F

Projected Available

Planned Order Receipt

Planned Order Release

Week 1 2 3 4 5 6 7 8 9 10

Gross Requirements

Scheduled Receipts

G

Projected Available

Planned Order Receipt

Planned Order Release

Week 1 2 3 4 5 6 7 8 9 10

Gross Requirements

Scheduled Receipts

H

Projected Available

Planned Order Receipt

Planned Order Release

Mme L. BOUSFIHA Fundamentals of SCM V1 HYB - 26

Mme Loubna BOUSFIHA Fundamentals of Supply Chain / 13

ESITH – LI3

CHAPTER 6

Inventory

Management

Mme L. BOUSFIHA Fundamentals of SCM V1 HYB - 27

Exercise 15

An importer operates a small warehouse that has the following annual costs.

Wages for purchasing are $45,000, purchasing expenses are $30,000, customs and

brokerage costs are $25 per order, the cost of financing the inventory is 8%, storage

costs are 6%, and the risk costs are 10%. The average inventory is $250,000, and

5000 orders are placed in a year.

a. What is the annual ordering costs?

b. What is the annual carrying costs?

Exercise 16

If the annual cost of goods sold is $12,000,000 and the average inventory is

$2,500,000:

a. What is the inventory turns ratio?

b. What would be the reduction in average inventory if, through better materials

management, inventory turns were increased to 10 times per year?

c. If the cost of carrying inventory is 20% of the average inventory, what is the

annual savings?

Mme L. BOUSFIHA Fundamentals of SCM V1 HYB - 28

Mme Loubna BOUSFIHA Fundamentals of Supply Chain / 14

ESITH – LI3

Exercise 17

An SKU costing $10 is ordered in quantities of 500 units, annual demand is 5200

units, carrying costs are 20%, and the cost of placing an order is $50. Calculate the

following:

a. Average inventory.

b. Number of orders placed per year.

c. Annual inventory carrying cost.

d. Annual ordering cost.

e. Annual total cost.

Exercise 18

A regional warehouse orders items once a week from a central warehouse. The

truck arrives 3 days after the order is placed. The warehouse operates 5 days a

week. For a particular brand and size of chicken soup, the demand is fairly steady

at 20 cases per day. Safety stock is set at 2 days’ supply.

a. What is the target level?

b. If the quantity on hand is 90 cases, how many should be ordered?

Mme L. BOUSFIHA Fundamentals of SCM V1 HYB - 29

Mme Loubna BOUSFIHA Fundamentals of Supply Chain / 15

You might also like

- Internal Audit Reports Post Sarbanes-Oxley: A Guide to Process-Driven ReportingFrom EverandInternal Audit Reports Post Sarbanes-Oxley: A Guide to Process-Driven ReportingNo ratings yet

- Chapter 5 MasProductionDocument21 pagesChapter 5 MasProductionNHI HUỲNH PHƯỢNGNo ratings yet

- Modern Pricing of Interest-Rate Derivatives: The LIBOR Market Model and BeyondFrom EverandModern Pricing of Interest-Rate Derivatives: The LIBOR Market Model and BeyondRating: 4 out of 5 stars4/5 (2)

- SCM - StudyNotes - Chps - 1 - 2 - Prof PrabhuDocument23 pagesSCM - StudyNotes - Chps - 1 - 2 - Prof PrabhukittutanmayNo ratings yet

- CS29016 Beringuier BoherDocument5 pagesCS29016 Beringuier BoherManishaNo ratings yet

- CHAPTER 3i Creating The Responsive Supply Chain - Edited - AHMRDocument29 pagesCHAPTER 3i Creating The Responsive Supply Chain - Edited - AHMRSITI NORADLINA ROSLINo ratings yet

- 4BHM - Sem4Document23 pages4BHM - Sem4NISHANTHNo ratings yet

- Ims 11Document8 pagesIms 11Alessandro PazNo ratings yet

- IEC61511 HFT RedundancyDocument10 pagesIEC61511 HFT RedundancySamNo ratings yet

- LMHL-HEMA-BCC3600 Operating Procedure-006Document5 pagesLMHL-HEMA-BCC3600 Operating Procedure-006Steve KabambeNo ratings yet

- Inventory ControlDocument9 pagesInventory ControlAbhijeetLaturkarNo ratings yet

- Subject Grade: Education For Future Leaders by Providing LIFE SKILLSDocument4 pagesSubject Grade: Education For Future Leaders by Providing LIFE SKILLSririn indahyanyNo ratings yet

- GBE LSC 2 001 00 Lean Supply Chain OverviewDocument61 pagesGBE LSC 2 001 00 Lean Supply Chain OverviewEduardo MaganaNo ratings yet

- Pacs Analysis Corrections Tsr-710341 - Set2-1Document6 pagesPacs Analysis Corrections Tsr-710341 - Set2-1Berihun TsegayeNo ratings yet

- Measuring The Bullwhip Effect in The Supply ChainDocument13 pagesMeasuring The Bullwhip Effect in The Supply ChainEurico NetoNo ratings yet

- Introduction To Supply Chain ConceptsDocument9 pagesIntroduction To Supply Chain ConceptsNaresh TeluNo ratings yet

- 6 Best Practices. Emilyne T. KidayanDocument3 pages6 Best Practices. Emilyne T. KidayanEmieNo ratings yet

- Job Method of Statement For QCF List On Paga SystemDocument4 pagesJob Method of Statement For QCF List On Paga SystemKhairul IdhamNo ratings yet

- 02 Legacy Communication Protocols PDFDocument59 pages02 Legacy Communication Protocols PDFsridhar30481647No ratings yet

- A Win Win Solution For The Bullwhip ProblemDocument11 pagesA Win Win Solution For The Bullwhip Problemcid leana moralesNo ratings yet

- 970803B Meter Fact. LinearDocument4 pages970803B Meter Fact. Linearsyed jeelani ahmedNo ratings yet

- Programme Name: M.B.A. (Media & Event Management)Document35 pagesProgramme Name: M.B.A. (Media & Event Management)Vipul PartapNo ratings yet

- 1 Understanding The Supply ChainDocument23 pages1 Understanding The Supply Chaineeman kNo ratings yet

- BSBWHS501 At3Document5 pagesBSBWHS501 At3Utpann SolutionsNo ratings yet

- A Further Test of The Influence of Leading Indicators On The Probability of Us Business Cycle Phase ShiftsDocument8 pagesA Further Test of The Influence of Leading Indicators On The Probability of Us Business Cycle Phase Shiftsgogayin869No ratings yet

- Lean Supply ChainsDocument5 pagesLean Supply ChainsĐoàn NgọcNo ratings yet

- L-2-2-Establishing Product Function: BITS PilaniDocument19 pagesL-2-2-Establishing Product Function: BITS PilaniSandhyaNo ratings yet

- ABMDocument26 pagesABMashagsNo ratings yet

- MRF 03Document411 pagesMRF 03engrshoaib2308No ratings yet

- Switching Operators Manual DistributionDocument338 pagesSwitching Operators Manual DistributionJames GeorgeNo ratings yet

- BHMCT 230915Document43 pagesBHMCT 230915RAJNATH YADAVNo ratings yet

- Harmony Evolution Options: For Process Industries UsersDocument66 pagesHarmony Evolution Options: For Process Industries UsersmohdthasthakirNo ratings yet

- Innovating To Create IT-Based New Business Opportunities at UPSDocument17 pagesInnovating To Create IT-Based New Business Opportunities at UPSjieminaNo ratings yet

- Piecing Together The Supply Chain ConceptDocument7 pagesPiecing Together The Supply Chain ConceptSolange TCNo ratings yet

- MBA AgribusinessDocument52 pagesMBA AgribusinessNihal PatilNo ratings yet

- A3report 603bweldingDocument1 pageA3report 603bweldingdonnymayNo ratings yet

- Single Event Effects Radiation Test ReportDocument15 pagesSingle Event Effects Radiation Test ReportRahul SushruthNo ratings yet

- SCM Q BankDocument18 pagesSCM Q BankNisha PradeepaNo ratings yet

- Ericsson IMS Call - Flows PDFDocument13 pagesEricsson IMS Call - Flows PDFJuan Ulises CapellanNo ratings yet

- SCM Feature StrategyDocument18 pagesSCM Feature Strategyfahrur_rozi_5No ratings yet

- IMSP 21 Operational Control EMSDocument3 pagesIMSP 21 Operational Control EMSEvonne LeeNo ratings yet

- Policy For Live Work On System OPSAF-01-001 Issue 4Document7 pagesPolicy For Live Work On System OPSAF-01-001 Issue 4Ahmad YaseenNo ratings yet

- Module 2 - Lect 5 - Forecasting PDFDocument36 pagesModule 2 - Lect 5 - Forecasting PDFMhmd KaramNo ratings yet

- Bba Accounting Fa15Document2 pagesBba Accounting Fa15tamiratNo ratings yet

- I Et 0000.00 0000 972 1al 023 E - Complementary Quality Requirement For Valves 16175681Document6 pagesI Et 0000.00 0000 972 1al 023 E - Complementary Quality Requirement For Valves 16175681Manoel LeviNo ratings yet

- SPS Section 6 V3.1 EnglishDocument20 pagesSPS Section 6 V3.1 EnglishjustinNo ratings yet

- Analysis of Kanban Warehouses-Flextronics Doumen CampusDocument21 pagesAnalysis of Kanban Warehouses-Flextronics Doumen CampusJonahNo ratings yet

- (Subject To Adjustments Due To Uncontrolled Circumstances) : Ac 2401 Class Agenda Guide/MwDocument3 pages(Subject To Adjustments Due To Uncontrolled Circumstances) : Ac 2401 Class Agenda Guide/Mwcresha mae necesarioNo ratings yet

- Ban Iko Pilipinas: SentralDocument3 pagesBan Iko Pilipinas: SentralMaya Julieta Catacutan-EstabilloNo ratings yet

- Basics of Supply Chain Managment (Lesson 2)Document26 pagesBasics of Supply Chain Managment (Lesson 2)Pharmacotherapy96% (25)

- Twelve Years A SlaveDocument58 pagesTwelve Years A SlaveVansham AggarwalNo ratings yet

- Measuring The Bullwhip Effect in The Supply Chain: Research PaperDocument12 pagesMeasuring The Bullwhip Effect in The Supply Chain: Research PaperJohn AcidNo ratings yet

- Instruction Pipelining (Ii) : Reducing Pipeline Branch PenaltiesDocument5 pagesInstruction Pipelining (Ii) : Reducing Pipeline Branch PenaltiesvinnisharmaNo ratings yet

- 50 Ic30 Gen 016 A HMP Material ControlDocument3 pages50 Ic30 Gen 016 A HMP Material ControlnguyencaohuygmailNo ratings yet

- Congestion Cell Report: Imanager U2000 MBB Network Management System Virtual Product Documentation (Suse)Document2 pagesCongestion Cell Report: Imanager U2000 MBB Network Management System Virtual Product Documentation (Suse)Николай ЯковенкоNo ratings yet

- Industrial In-Plant TrainingDocument20 pagesIndustrial In-Plant TrainingHemant WaniNo ratings yet

- Presentation - NaCN Facility FEED (60% Review) - Nov-10-2022 - Rev00Document15 pagesPresentation - NaCN Facility FEED (60% Review) - Nov-10-2022 - Rev00Rodger SenaNo ratings yet

- Step 3 - Fundamental AnalysisDocument31 pagesStep 3 - Fundamental AnalysisjaneNo ratings yet

- Financial Accounting 9th Edition Weygandt Solutions Manual DownloadDocument97 pagesFinancial Accounting 9th Edition Weygandt Solutions Manual DownloadHelen Belcher100% (17)

- Tsa Booklet Om 244 DT 17062020Document19 pagesTsa Booklet Om 244 DT 17062020ANURAG SINGHNo ratings yet

- (Bruno Bettelheim) Symbolic Wounds Puberty RitesDocument196 pages(Bruno Bettelheim) Symbolic Wounds Puberty RitesAmbrose66No ratings yet

- 3E Hand Over NotesDocument3 pages3E Hand Over NotesAshutosh MaiidNo ratings yet

- Gandhi and The Non-Cooperation MovementDocument6 pagesGandhi and The Non-Cooperation MovementAliya KhanNo ratings yet

- Turner Et Al. 1991 ASUDS SystemDocument10 pagesTurner Et Al. 1991 ASUDS SystemRocio HerreraNo ratings yet

- Passage Planning: Dr. Arwa HusseinDocument15 pagesPassage Planning: Dr. Arwa HusseinArwa Hussein100% (3)

- Or HandoutDocument190 pagesOr Handoutyared haftu67% (6)

- DC Generator - Construction, Working Principle, Types, and Applications PDFDocument1 pageDC Generator - Construction, Working Principle, Types, and Applications PDFGokul GokulNo ratings yet

- Citrus Information Kit-Update: Reprint - Information Current in 1998Document53 pagesCitrus Information Kit-Update: Reprint - Information Current in 1998hamsa sewakNo ratings yet

- Task of ProjectDocument14 pagesTask of ProjectAbdul Wafiy NaqiuddinNo ratings yet

- Baby DedicationDocument3 pagesBaby DedicationLouriel Nopal100% (3)

- 1en 02 PDFDocument96 pages1en 02 PDFAndrey100% (2)

- Lab 1Document51 pagesLab 1aliNo ratings yet

- Royal British College Dancesport TeamDocument10 pagesRoyal British College Dancesport TeamAnna rose CabatinganNo ratings yet

- AN44061A Panasonic Electronic Components Product DetailsDocument3 pagesAN44061A Panasonic Electronic Components Product DetailsAdam StariusNo ratings yet

- The Sandbox Approach and Its Potential For Use inDocument13 pagesThe Sandbox Approach and Its Potential For Use invalentina sekarNo ratings yet

- Gold Loan Application FormDocument7 pagesGold Loan Application FormMahesh PittalaNo ratings yet

- Amerex Ansul Badger Ul Catalogo Por PartesDocument37 pagesAmerex Ansul Badger Ul Catalogo Por PartesPuma De La Torre ExtintoresNo ratings yet

- RESEARCHDocument5 pagesRESEARCHroseve cabalunaNo ratings yet

- AIP 2020 FINAL JuneDocument5 pagesAIP 2020 FINAL JuneVINA ARIETANo ratings yet

- Half Yearly Examination, 2017-18: MathematicsDocument7 pagesHalf Yearly Examination, 2017-18: MathematicsSusanket DuttaNo ratings yet

- Taylorism vs. FordismDocument2 pagesTaylorism vs. FordismLiv Maloney67% (3)

- Chudamani Women Expecting ChangeDocument55 pagesChudamani Women Expecting ChangeMr AnantNo ratings yet

- STW 44 3 2 Model Course Leadership and Teamwork SecretariatDocument49 pagesSTW 44 3 2 Model Course Leadership and Teamwork Secretariatwaranchai83% (6)

- Gigabyte Ga b85m Ds3h A r10 PDFDocument30 pagesGigabyte Ga b85m Ds3h A r10 PDFMartha Lorena TijerinoNo ratings yet

- Introduction: Meaning of HypothesisDocument8 pagesIntroduction: Meaning of HypothesisMANISH KUMARNo ratings yet

- Nursing Assessment in Family Nursing PracticeDocument22 pagesNursing Assessment in Family Nursing PracticeHydra Olivar - PantilganNo ratings yet

- Some Studies On Structure and Properties of Wrapped Jute (Parafil) YarnsDocument5 pagesSome Studies On Structure and Properties of Wrapped Jute (Parafil) YarnsVedant MahajanNo ratings yet

- Operation and Maintenance Manual Compressor Models: P105WJD, P130DWJD, P160DWJD, P175DWJDDocument70 pagesOperation and Maintenance Manual Compressor Models: P105WJD, P130DWJD, P160DWJD, P175DWJDManuel ParreñoNo ratings yet

- LT3845ADocument26 pagesLT3845Asoft4gsmNo ratings yet

- CLT Apllications NewestDocument49 pagesCLT Apllications NewestMackBrideNo ratings yet