0% found this document useful (0 votes)

188 views10 pagesAutomotive Risk Assessment Guide

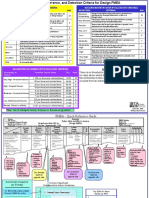

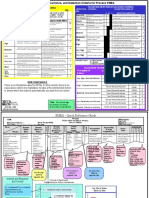

The document describes criteria for ranking potential failure modes in a product or manufacturing process. Failure modes that affect safety or violate regulations are ranked 10. Loss of primary vehicle function is ranked 8. Loss of secondary or comfort functions is ranked 6. Appearance issues noticed by most customers are ranked 4. Detection likelihood is also considered, with no detection opportunity ranked 10 and error prevention through design ranked 1.

Uploaded by

Vijayamalar AmruthalingamCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

188 views10 pagesAutomotive Risk Assessment Guide

The document describes criteria for ranking potential failure modes in a product or manufacturing process. Failure modes that affect safety or violate regulations are ranked 10. Loss of primary vehicle function is ranked 8. Loss of secondary or comfort functions is ranked 6. Appearance issues noticed by most customers are ranked 4. Detection likelihood is also considered, with no detection opportunity ranked 10 and error prevention through design ranked 1.

Uploaded by

Vijayamalar AmruthalingamCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd