Professional Documents

Culture Documents

Roll Making

Uploaded by

Tejesh MannemOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Roll Making

Uploaded by

Tejesh MannemCopyright:

Available Formats

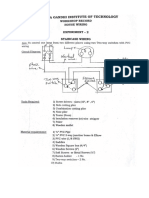

CHISEL MAKING

CHISEL MAKING

Aim:

To convert a cylindrical rod of 12mm diameter and 85mmm length to a square head

chisel.

Equipment and Tools Required:

Hearth, Round Tongs, Sledge Hammer, Flattener, Anvil, Brass Rule, and Poker Rod etc.

Sequence of operation:

Heating the specimen.

Step 1-Round to Square

Step 2-Round to Chisel Edge

Heating:

1. First the forge is fired and the blower air valve is regulated to ensure proper air supply

for uniform firing.

2. The given material is held in furnace and heated to red hot temperature (12000c)

3. Care should be taken to avoid melting off the metal rod due to overheating.

Step Ⅰ-Round to Square:

1. After the material attains the required hot condition in the furnace it is held by means

of tongs and placed on anvil.

2. By using sledge hammer and flattener required force is applied on the material so that

the round rod is deformed into square rod and length is increase due to the reduction

in diameter

3. The Force applied should be uniform on the material to form a square shape and fine

finish.

4. This operation is continued until the square shape is obtained.

Step Ⅱ-Round to chisel edge:

1. The other half of work piece is heated to form Tapered shape by using sledge hammer

and flattener.

2. Do the Same operation in another side and check the Dimension.

Result:

Thus the 12mm diameter and 85mm length cylindrical rod is converted as square head

chisel.

You might also like

- Chisel Making: Name: Anirudh Murale Reg No:RA2011003040054Document2 pagesChisel Making: Name: Anirudh Murale Reg No:RA2011003040054Anirudh MuraleNo ratings yet

- ChiselDocument2 pagesChiselVamsi Krishna BalagaNo ratings yet

- Round RingDocument2 pagesRound RingVamsi Krishna BalagaNo ratings yet

- Forging MaterialDocument51 pagesForging MaterialRoyalmechNo ratings yet

- Smith ForgingDocument7 pagesSmith Forgingsenel pereraNo ratings yet

- Background/ Profile of CompanyDocument8 pagesBackground/ Profile of Companyethiopia ethiopiaNo ratings yet

- N 51 e 62 e 9 Ea 2045Document28 pagesN 51 e 62 e 9 Ea 2045TECH RISHABH 07No ratings yet

- Smithy Forging PCTEIETDocument2 pagesSmithy Forging PCTEIETSurjit Kumar GandhiNo ratings yet

- Addis Ababa Science and Techology University: of Electrical and EnginneringDocument9 pagesAddis Ababa Science and Techology University: of Electrical and Enginneringethiopia ethiopiaNo ratings yet

- EXP Write UpDocument28 pagesEXP Write UpIndrani ChakrabortyNo ratings yet

- Basic Machining Facing and TurningDocument17 pagesBasic Machining Facing and TurningKedar NathNo ratings yet

- Diploma Workshop Practice IDocument11 pagesDiploma Workshop Practice IRAKESH KUMARNo ratings yet

- 02 - 2020MEB1267 - Group C (MONDAY)Document3 pages02 - 2020MEB1267 - Group C (MONDAY)ankur bharaliNo ratings yet

- Assignment 2Document17 pagesAssignment 2AakarshNo ratings yet

- MS-II Lab ManualDocument18 pagesMS-II Lab ManualdibyenindusNo ratings yet

- EXP Write UpDocument28 pagesEXP Write UpSoumyajit NandiNo ratings yet

- Design of A Diesel Fired Heat-Treatment FurnaceDocument11 pagesDesign of A Diesel Fired Heat-Treatment FurnaceKhin Aung ShweNo ratings yet

- Mya Myint Mo (Workshop)Document12 pagesMya Myint Mo (Workshop)ytzqddnd58No ratings yet

- Coursework Smith ForgingDocument8 pagesCoursework Smith ForgingJethro JeyarajNo ratings yet

- Workshop Practice DE-42 Mechatronics: SyndicateDocument5 pagesWorkshop Practice DE-42 Mechatronics: SyndicateibrahimNo ratings yet

- Workshop Report (1) 2C25 (1588)Document8 pagesWorkshop Report (1) 2C25 (1588)Thazin LinnNo ratings yet

- Black Smithy ShopDocument3 pagesBlack Smithy ShopAmarjeet Singh (Assistant Professor- Mechanical Engineer)No ratings yet

- MR Sunil Kumar Ojha: Assistant Professor Mechanical Engineering Department JRE Group of Institutions Greater NoidaDocument61 pagesMR Sunil Kumar Ojha: Assistant Professor Mechanical Engineering Department JRE Group of Institutions Greater NoidaGurjinderSinghDoshanjhNo ratings yet

- Aluminum Cylinder Having Diameter 0Document2 pagesAluminum Cylinder Having Diameter 0asocarras1No ratings yet

- Forging A Cold Chisel WorksheetDocument2 pagesForging A Cold Chisel WorksheetdaveNo ratings yet

- .Archivetemptest 2 - Softening Point of BitumenDocument6 pages.Archivetemptest 2 - Softening Point of BitumenSadon B AsyNo ratings yet

- Pipe Bending-Hot BendingDocument4 pagesPipe Bending-Hot Bendingamulbaby31100% (1)

- CASTINGS: The Products Made by Casting Process Are KnownDocument11 pagesCASTINGS: The Products Made by Casting Process Are KnownbernabasNo ratings yet

- Spring For Hanging Egg ChairDocument5 pagesSpring For Hanging Egg ChairMuhammad AsimNo ratings yet

- Heat Treatment ShopDocument2 pagesHeat Treatment Shopyogendra singhNo ratings yet

- Engineering Practices Lab Manual (Group A) FINAL VERSION 59 PDFDocument2 pagesEngineering Practices Lab Manual (Group A) FINAL VERSION 59 PDFJayaram R S [MECH]No ratings yet

- EED Presentation1-1Document18 pagesEED Presentation1-1HansrajNo ratings yet

- Smithy ManualDocument11 pagesSmithy ManualSeattle MountaineerNo ratings yet

- Workshop Hammer ReportDocument14 pagesWorkshop Hammer ReportJoshua Chong67% (3)

- Forging: ObjectivesDocument5 pagesForging: ObjectivesLeeladhar SharmaNo ratings yet

- Job Report - Rikzan Kurnia AzrifulDocument6 pagesJob Report - Rikzan Kurnia AzrifulRikzanNo ratings yet

- Lathe Report Sem 1 DegDocument9 pagesLathe Report Sem 1 DegTarmizi Bahari74% (27)

- Chapter 14.1 To 14.4,14.6Document20 pagesChapter 14.1 To 14.4,14.6Lhekha RaviendranNo ratings yet

- Report TrainingDocument15 pagesReport TrainingGaurav AkotkarNo ratings yet

- Forging 2Document39 pagesForging 2ssukhmeet551No ratings yet

- 4 - Sem Lab Manual: Spur Gear MillingDocument10 pages4 - Sem Lab Manual: Spur Gear MillingPRASSAN SHAHNo ratings yet

- Practical 18,19,20Document9 pagesPractical 18,19,20Muhammad AwaisNo ratings yet

- Heat TreatmentDocument5 pagesHeat TreatmentLaxman GautamNo ratings yet

- HeatingDocument44 pagesHeatingKilaru Sai KiranNo ratings yet

- Electric Heating and Welding - Lec 24Document31 pagesElectric Heating and Welding - Lec 24Sajid NaseebNo ratings yet

- Shisha Charcoal and Honeycomb Process FlowDocument12 pagesShisha Charcoal and Honeycomb Process FlowDhiangga JauharyNo ratings yet

- PI Lecture 16Document7 pagesPI Lecture 16pk2003158No ratings yet

- Surya Black SmithyDocument11 pagesSurya Black Smithy2K20B671 Shivam GargNo ratings yet

- Milling MCDocument27 pagesMilling MCapi-19775783100% (1)

- Unit IIIDocument167 pagesUnit IIIJG MohanNo ratings yet

- Workshop - List of Experements and Its Procedure PDFDocument29 pagesWorkshop - List of Experements and Its Procedure PDFAdhi SheshuNo ratings yet

- me8361-MT 1 LabmanualDocument37 pagesme8361-MT 1 LabmanualHOD ITNo ratings yet

- Softening Point of BitumenDocument5 pagesSoftening Point of BitumenDleen ONo ratings yet

- Metal SpinningDocument22 pagesMetal SpinningthirumalaikumaranNo ratings yet

- Heat Pipe PresentationDocument20 pagesHeat Pipe PresentationMaria TabbutNo ratings yet

- Butt JointDocument2 pagesButt JointAyush RanjanNo ratings yet

- Study and Analysis On Heat Treatment Process and Microstructure of Low Carbon SteelDocument6 pagesStudy and Analysis On Heat Treatment Process and Microstructure of Low Carbon SteelIJARTESNo ratings yet

- Black Smithy Shop: 1-Supporting Tools: Leg ViceDocument10 pagesBlack Smithy Shop: 1-Supporting Tools: Leg ViceAashish KushwahaNo ratings yet

- Knife Making: The Beginner's Guide of Blacksmithing and Making KnivesFrom EverandKnife Making: The Beginner's Guide of Blacksmithing and Making KnivesNo ratings yet

- Gas Welding: Butt JointDocument5 pagesGas Welding: Butt JointTejesh MannemNo ratings yet

- Electrical Arc Welding Lap Joint: PreparationDocument5 pagesElectrical Arc Welding Lap Joint: PreparationTejesh MannemNo ratings yet

- Step FittingDocument6 pagesStep FittingTejesh MannemNo ratings yet

- 6.a. Design and Implementation of Binary To Gray Code Converters Using Logic GatesDocument11 pages6.a. Design and Implementation of Binary To Gray Code Converters Using Logic GatesTejesh MannemNo ratings yet

- Schrodinger Equation-Introduction and Derivation: Lecture-S1 12-04-2021Document38 pagesSchrodinger Equation-Introduction and Derivation: Lecture-S1 12-04-2021Tejesh MannemNo ratings yet

- Switch MakingDocument5 pagesSwitch MakingTejesh MannemNo ratings yet

- Application FormDocument3 pagesApplication FormTejesh MannemNo ratings yet