Professional Documents

Culture Documents

14-FEB - JSA - SA - GHWP - Relay Module Connection Change Work

14-FEB - JSA - SA - GHWP - Relay Module Connection Change Work

Uploaded by

osama sheikhCopyright:

Available Formats

You might also like

- Risk Assessment For Installation of Fan Coil UnitsDocument18 pagesRisk Assessment For Installation of Fan Coil UnitsAnandu Ashokan67% (3)

- Jobs Safety Analysis (JSA)Document8 pagesJobs Safety Analysis (JSA)uttam mishra100% (1)

- Aramco Safety Questions & AnswersDocument24 pagesAramco Safety Questions & AnswersGulfam ShahzadNo ratings yet

- Temporary Works Update Thursday, 21 November 2019Document25 pagesTemporary Works Update Thursday, 21 November 2019r_awadhiya100% (2)

- 39 Jha On Blok Masonary WorkDocument4 pages39 Jha On Blok Masonary WorkDheeraj KumarNo ratings yet

- Erection Dismantling of Scaffolding - JsaDocument3 pagesErection Dismantling of Scaffolding - JsaJixtha SaintNo ratings yet

- Jobs Safety Analysis (JSA)Document4 pagesJobs Safety Analysis (JSA)uttam mishraNo ratings yet

- Job Safety Analysis (JSA) Stringing WorkDocument4 pagesJob Safety Analysis (JSA) Stringing WorkSivaram Dasari100% (1)

- Jsa R B 6 ForkliftDocument3 pagesJsa R B 6 Forkliftoscar67% (3)

- Jsa R B 6 ForkliftDocument3 pagesJsa R B 6 ForkliftsinghajitbNo ratings yet

- Job Hazard Analysis Form Stripping Forms: ReferenceDocument2 pagesJob Hazard Analysis Form Stripping Forms: ReferenceReden Mejico PedernalNo ratings yet

- Safety at Construction SiteDocument18 pagesSafety at Construction SiteShikhin GargNo ratings yet

- OSHA Regulations 1926 Subpart L ScaffoldsDocument34 pagesOSHA Regulations 1926 Subpart L ScaffoldsfiercecatNo ratings yet

- 14-FEB - JSA - NR - GHWP - Control Valve Auto Mode CheckingDocument2 pages14-FEB - JSA - NR - GHWP - Control Valve Auto Mode Checkingosama sheikhNo ratings yet

- 14-FEB - JSA - NR - GH&H - L&S-WP - Chiller Room ICW & CTW Line Erection WorkDocument2 pages14-FEB - JSA - NR - GH&H - L&S-WP - Chiller Room ICW & CTW Line Erection Workosama sheikhNo ratings yet

- JSA Scaffolding WAHDocument1 pageJSA Scaffolding WAHNilamSanjeev Kumar SinghNo ratings yet

- 14-FEB - JSA - NR - GHWP - Fabrication Shop EXTDocument2 pages14-FEB - JSA - NR - GHWP - Fabrication Shop EXTosama sheikhNo ratings yet

- Jobs Safety Analysis (JSA) : JOB/ACTIVITY NAME: Scaffolding Erection, Dismantling Work, Work at Height, Welding WorkDocument4 pagesJobs Safety Analysis (JSA) : JOB/ACTIVITY NAME: Scaffolding Erection, Dismantling Work, Work at Height, Welding Workuttam mishraNo ratings yet

- JHA PaintingDocument12 pagesJHA Paintingeast100% (1)

- Jsa For Piping and Erection RevisedDocument1 pageJsa For Piping and Erection RevisedDr AnwarNo ratings yet

- Attachemnt RA Work at HeightDocument4 pagesAttachemnt RA Work at Heightathul subashNo ratings yet

- JSADocument18 pagesJSADeshbandhu Aman PandeyNo ratings yet

- 12 Scaffolding WorkDocument5 pages12 Scaffolding WorkKoneti JanardhanaraoNo ratings yet

- Job Safety Analysis: Work at HeightDocument2 pagesJob Safety Analysis: Work at Heightmuhammad imtiazNo ratings yet

- Work at Height JsaDocument2 pagesWork at Height JsanabeelNo ratings yet

- Risk Assessments For FormworkDocument1 pageRisk Assessments For FormworkQays YousefNo ratings yet

- JSA PilingDocument1 pageJSA PilingNilamSanjeev Kumar SinghNo ratings yet

- Job Safety Analysis: Page 1 of 4Document4 pagesJob Safety Analysis: Page 1 of 4RakeshkasarlaNo ratings yet

- Method Statement For Transmission Line Lanco PDFDocument37 pagesMethod Statement For Transmission Line Lanco PDFAmar WadoodNo ratings yet

- Shoring 55Document7 pagesShoring 55Mohamed Hasafy100% (1)

- ERECTION METHOD STATEMENT Part 2Document6 pagesERECTION METHOD STATEMENT Part 2joseph chewNo ratings yet

- Risk Assessments - PageDocument1 pageRisk Assessments - PageQays YousefNo ratings yet

- Instruction ManualDocument14 pagesInstruction Manualmohamad zakwanNo ratings yet

- Use of Stepladders 05Document1 pageUse of Stepladders 05cardyNo ratings yet

- IPM - MOS - 005 - Mobile ScaffoldDocument6 pagesIPM - MOS - 005 - Mobile ScaffoldmohdnurasyraafNo ratings yet

- Job Hazard Analysis For Working at HeigthsDocument1 pageJob Hazard Analysis For Working at Heigthsjayboygulles02No ratings yet

- JSA For Scaffolding Erection Removal Around AT-911Document1 pageJSA For Scaffolding Erection Removal Around AT-911Equipment Materials100% (1)

- User Instructions Extension Single LaddersDocument11 pagesUser Instructions Extension Single LaddersTryfon KarachaliosNo ratings yet

- Risk Mitigation Plan 1Document25 pagesRisk Mitigation Plan 1Omar BahakimNo ratings yet

- 03 WMS - ScaffoldingDocument5 pages03 WMS - ScaffoldingHimanshu NiveriyaNo ratings yet

- Jha For Painting Works Repainting of Control Room and Guard House at Switchyard (External)Document1 pageJha For Painting Works Repainting of Control Room and Guard House at Switchyard (External)Jonas GonzalesNo ratings yet

- ASPECT HAZARD ASSESSMENT FORM FOR CONTRACTORS (Read Only)Document1 pageASPECT HAZARD ASSESSMENT FORM FOR CONTRACTORS (Read Only)Takumina ServicesNo ratings yet

- 0503 Geda Hoist InstructionsDocument6 pages0503 Geda Hoist InstructionsBoruida MachineryNo ratings yet

- Concrete Placement - FootingsDocument2 pagesConcrete Placement - Footingsadelin TinIndoNo ratings yet

- Target Working at HeightsDocument8 pagesTarget Working at HeightsMang Doros EsquilloNo ratings yet

- Shoring ModifedDocument15 pagesShoring ModifedMohamed HasafyNo ratings yet

- JHA Hot WorkDocument1 pageJHA Hot WorkNilamSanjeev Kumar SinghNo ratings yet

- Safety Poster of CTMDocument1 pageSafety Poster of CTMyashNo ratings yet

- Job Safety Analysis For Dismantling of WorkshopDocument10 pagesJob Safety Analysis For Dismantling of WorkshopShaheer AhmedNo ratings yet

- CTS Sterlite MergedDocument20 pagesCTS Sterlite MergedAvidip DeyNo ratings yet

- Pole Unit Install JhaDocument2 pagesPole Unit Install JhafatimahNo ratings yet

- Jsa Roof Sheeting & Wall CladdingDocument23 pagesJsa Roof Sheeting & Wall Claddingsamir ranjan dhalNo ratings yet

- Job Safety Analysis FormDocument2 pagesJob Safety Analysis FormAbhaySngh100% (1)

- NippleupDocument4 pagesNippleupali abbasNo ratings yet

- Duty of Care Act: Occupational Health and Safety Act 1984Document24 pagesDuty of Care Act: Occupational Health and Safety Act 1984Hoanghon BacNo ratings yet

- Risk Assessment What Work Excavation Work With Help of JCB Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDDocument2 pagesRisk Assessment What Work Excavation Work With Help of JCB Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDhemant yadav0% (2)

- Fall Control User Instructions: Procedure BP-FCL-0096-01Document24 pagesFall Control User Instructions: Procedure BP-FCL-0096-01soffi3No ratings yet

- MechanicalPipeLifte Issue 1Document6 pagesMechanicalPipeLifte Issue 1Bram ANo ratings yet

- Risk AssesmentDocument3 pagesRisk Assesmentmrogers72100% (4)

- Sunmow Jha 001Document3 pagesSunmow Jha 001Douglas DellyNo ratings yet

- Jha - Hot Works FenceDocument2 pagesJha - Hot Works Fencevannixs caindoyNo ratings yet

- Tubular Steel Tubular Aluminium Alloy Timber BambooDocument17 pagesTubular Steel Tubular Aluminium Alloy Timber Bambooillya amyraNo ratings yet

- HOUSEKEEPERDocument1 pageHOUSEKEEPERosama sheikhNo ratings yet

- Checklist For Full Body Safety Harness (Monthly) : Date of CheckDocument3 pagesChecklist For Full Body Safety Harness (Monthly) : Date of Checkosama sheikhNo ratings yet

- TimeDocument1 pageTimeosama sheikhNo ratings yet

- UntitledDocument1 pageUntitledosama sheikhNo ratings yet

- 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 RemarksDocument2 pages1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 Remarksosama sheikhNo ratings yet

- UntitledDocument1 pageUntitledosama sheikhNo ratings yet

- Work Start: (Tick Applicable)Document1 pageWork Start: (Tick Applicable)osama sheikhNo ratings yet

- 14-FEB - JSA - NR - GHWP - Fabrication Shop EXTDocument2 pages14-FEB - JSA - NR - GHWP - Fabrication Shop EXTosama sheikhNo ratings yet

- 14-FEB - JSA - NR - GH&H - L&S-WP - Chiller Room ICW & CTW Line Erection WorkDocument2 pages14-FEB - JSA - NR - GH&H - L&S-WP - Chiller Room ICW & CTW Line Erection Workosama sheikhNo ratings yet

- 14-FEB - JSA - NR - GHWP - Control Valve Auto Mode CheckingDocument2 pages14-FEB - JSA - NR - GHWP - Control Valve Auto Mode Checkingosama sheikhNo ratings yet

- Scaffolding in The Ancient World: Construction Repair Buildings Metal Pipes Bamboo Asian People's Republic of ChinaDocument7 pagesScaffolding in The Ancient World: Construction Repair Buildings Metal Pipes Bamboo Asian People's Republic of ChinaJoanna YengNo ratings yet

- BambooDocument60 pagesBamboorahul sulakheNo ratings yet

- Sccafolding Safety+ DM Code of ConstructionDocument11 pagesSccafolding Safety+ DM Code of ConstructionGodwin0% (1)

- Method Statement: Outline Demolition Method Statement 34 Springvale Avenue Walsall Ws5 3QbDocument27 pagesMethod Statement: Outline Demolition Method Statement 34 Springvale Avenue Walsall Ws5 3QbSHopkinsonNo ratings yet

- Interview: Safety Officers & SupervisorsDocument25 pagesInterview: Safety Officers & SupervisorsVaibhav Vithoba Naik0% (1)

- E175 PDFDocument570 pagesE175 PDFyeelingsNo ratings yet

- Demolition RISK AssessmentDocument15 pagesDemolition RISK AssessmentAli KaziNo ratings yet

- Scaffolding ExamplesDocument10 pagesScaffolding ExamplesSarin100% (1)

- Scaffolding Awareness Rev 01 - 12 Mar 09Document22 pagesScaffolding Awareness Rev 01 - 12 Mar 09Raghavendra KiranNo ratings yet

- WP1323 Working Near Overhead and Underground Electric Lines V2Document31 pagesWP1323 Working Near Overhead and Underground Electric Lines V2Jake SternNo ratings yet

- Working MethodDocument16 pagesWorking MethodHendrias Ari SujarwoNo ratings yet

- TG13 03 Non-Standard Boarded PlatformsDocument4 pagesTG13 03 Non-Standard Boarded PlatformsDaniel SarmientoNo ratings yet

- Proposed Construction of 3 No. Classrooms Block and 2 No. Eco Toilet Blocks at KiamwathiDocument49 pagesProposed Construction of 3 No. Classrooms Block and 2 No. Eco Toilet Blocks at Kiamwathiyamanta_rajNo ratings yet

- Cuplok Access Scaffold System-11Document24 pagesCuplok Access Scaffold System-11JijithpillaiNo ratings yet

- 306 SunsuriaDocument7 pages306 Sunsurianurma ramdanNo ratings yet

- Ischebeck Push Pull PropDocument12 pagesIschebeck Push Pull PropMohammed HafizNo ratings yet

- Scafollding StandardsDocument2 pagesScafollding StandardsMustofa0% (1)

- Guidelines On The Design and Construction of Bamboo ScaffoldsDocument24 pagesGuidelines On The Design and Construction of Bamboo ScaffoldsRizwan MirzaNo ratings yet

- AuV Alum Stage 600 2013enDocument12 pagesAuV Alum Stage 600 2013enArdamitNo ratings yet

- Factories and Machinery (Building Operations and Works of Engineering Construction) (Safety) Regulations, 1986 Ve - Pua328 - 1986Document46 pagesFactories and Machinery (Building Operations and Works of Engineering Construction) (Safety) Regulations, 1986 Ve - Pua328 - 1986Exsan Othman100% (1)

- Peri Up FlexDocument18 pagesPeri Up FlexRandom Stuff and StuffNo ratings yet

- HSE SWP 033 Ladders Scaffold SafetyDocument4 pagesHSE SWP 033 Ladders Scaffold SafetyGia Minh Tieu TuNo ratings yet

- Work at Heights StandardDocument1 pageWork at Heights Standardananthu.uNo ratings yet

- White Paper: SCIA ScaffoldingDocument35 pagesWhite Paper: SCIA ScaffoldingGiorgi KOGOSHVILINo ratings yet

- SA Scaffold Tag SystemDocument36 pagesSA Scaffold Tag SystemJunard M. Lu Hap100% (6)

- MATH TERMS 4 RefresherDocument2 pagesMATH TERMS 4 Refreshercat buenafeNo ratings yet

14-FEB - JSA - SA - GHWP - Relay Module Connection Change Work

14-FEB - JSA - SA - GHWP - Relay Module Connection Change Work

Uploaded by

osama sheikhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

14-FEB - JSA - SA - GHWP - Relay Module Connection Change Work

14-FEB - JSA - SA - GHWP - Relay Module Connection Change Work

Uploaded by

osama sheikhCopyright:

Available Formats

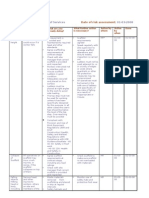

PROJECT ELEPHANT

JOB SAFETY ANALYSIS

Name of Contractor: M/s Canter Engineers Pvt. Ltd.

JSA For workpermit Number:

Date Valid from:

Work permit time: 09 Am To 09 Pm

Location of work: 0 mtr. Level, Grid 09-25 (F-I), Welding Room and Dai/Mould Clean room.

Nature of activity: FAS Relay Module Connection Change work. by scaffolding (05 mtr. Height)

Sr. No. Description of work Hazard associated with the job Action Taken

* Only inducted worker shall be deputed at the workplace.

* Untrained Worker. * All the engaged workers should be medically examined as per the BOCW state

1 Manpower Engage * Un-fit worker rule 2007 rule 250C.

* Un Trained person * TBT must be conduct prior to start the work.

* Only trained & physically fit personals will be allowed to execute the activity.

Manual Material shifting to the work place *Housekeeping should be done before starting the work.

2 *Slip, Trip & Fall hazard

(Scaffolding Material, Hand tools, Relay Module Etc.) *Area should be clean & free from any obstruction before starting of the activity.

*On or above 1.2 meter height, every one should use double lanyard FBSH while erection of scaffolding.

*Fall from height

*Scaffolding should be properly erected, inspected by the job supervisor & tagged before use.

3 Scaffolding erection (Max height 05 mtr.) *Scaffolding colapes

*If scaffolding is not in use same should be red tagged.

*Improper scaffolding

*1.3 ratio should be maintained, while erection of the scaffolding.

*Only trained and fit workers shall be deploying for work at height.

* Area to be barricaded to restrict unwanted personnel entry.

* Use inspected FBSH with safe and proper anchor point.

* Provide toe board to protect fall of materials.

* Provide Top rail on 1 meter and mid rail 500mm height and 150mm toe board to prevent falling object.

* Provide proper access to scaffold.

* Fall of person

* Provide outriggers to protect of scaffold to collapse.

* Fall of materials

* Platform shall be fully covered and tied.

* Collapse of scaffold

FAS Relay Module Connection Change work. * Don’t put over weight on scaffold platform.

4 * Overhead obstructions

By scaffolding (Max height 05 mtr.) * Ensure overhead obstruction while move of scaffold.

* Over weight

* Wheel should be always locked while work is going on scaffold.

* Over reaching on scaffold

* Don’t overreach on scaffold.

* Unsafe scaffold

* Material shall not be thrown, Rope shall be providing to shift the materials.

* Inspection shall be done by job supervisor.

* Scaffolding shall not be pulled /pushed when workmen present on the scaffolding. Don’t allow any

unknown party near to scaffold.

* Green tag shall be display on safe scaffold.

* Area shall be barricade; Sign board shall be displayed.

*Area should be clean, housekeeping should be done after completing the activity.

After the work *All the unwanted material(Scaffolding material, pipe cut piece, Cutting dust, hand tools etc.) should be

5 Area Housekeeping *Slip, Trip & Fall hazard removed from the work place.

Unwanted material remove *After compleating the work area housekeeping should be done & pictures should be shared in whatsapp

group as instructed by PTdCS Safety.

* Emergency Path way & Assembly Point shall be clean, clear& communicated.

* Panic situation * Access should be clear from obstruction.

6 In Case of Emergency

* Confusion * Ensure emergency vehicle is readily available at all time.

* Awareness of emergency contact.

Remarks:

Signature: Signature: Signature: Signature:

Name: Name: Name: Name:

Job Initator(PTdCS) Project Manager (contractor) Section Incharge (Datwyler) Safety Manager(PTdCS)

Signature: Signature: Signature: Signature:

Name: Name: Osama Zakir Name: Name:

Contractor Job supervisor Safety Manager(Contractor) Area owner(Datwyler) Safety Manager(Datwyler)

You might also like

- Risk Assessment For Installation of Fan Coil UnitsDocument18 pagesRisk Assessment For Installation of Fan Coil UnitsAnandu Ashokan67% (3)

- Jobs Safety Analysis (JSA)Document8 pagesJobs Safety Analysis (JSA)uttam mishra100% (1)

- Aramco Safety Questions & AnswersDocument24 pagesAramco Safety Questions & AnswersGulfam ShahzadNo ratings yet

- Temporary Works Update Thursday, 21 November 2019Document25 pagesTemporary Works Update Thursday, 21 November 2019r_awadhiya100% (2)

- 39 Jha On Blok Masonary WorkDocument4 pages39 Jha On Blok Masonary WorkDheeraj KumarNo ratings yet

- Erection Dismantling of Scaffolding - JsaDocument3 pagesErection Dismantling of Scaffolding - JsaJixtha SaintNo ratings yet

- Jobs Safety Analysis (JSA)Document4 pagesJobs Safety Analysis (JSA)uttam mishraNo ratings yet

- Job Safety Analysis (JSA) Stringing WorkDocument4 pagesJob Safety Analysis (JSA) Stringing WorkSivaram Dasari100% (1)

- Jsa R B 6 ForkliftDocument3 pagesJsa R B 6 Forkliftoscar67% (3)

- Jsa R B 6 ForkliftDocument3 pagesJsa R B 6 ForkliftsinghajitbNo ratings yet

- Job Hazard Analysis Form Stripping Forms: ReferenceDocument2 pagesJob Hazard Analysis Form Stripping Forms: ReferenceReden Mejico PedernalNo ratings yet

- Safety at Construction SiteDocument18 pagesSafety at Construction SiteShikhin GargNo ratings yet

- OSHA Regulations 1926 Subpart L ScaffoldsDocument34 pagesOSHA Regulations 1926 Subpart L ScaffoldsfiercecatNo ratings yet

- 14-FEB - JSA - NR - GHWP - Control Valve Auto Mode CheckingDocument2 pages14-FEB - JSA - NR - GHWP - Control Valve Auto Mode Checkingosama sheikhNo ratings yet

- 14-FEB - JSA - NR - GH&H - L&S-WP - Chiller Room ICW & CTW Line Erection WorkDocument2 pages14-FEB - JSA - NR - GH&H - L&S-WP - Chiller Room ICW & CTW Line Erection Workosama sheikhNo ratings yet

- JSA Scaffolding WAHDocument1 pageJSA Scaffolding WAHNilamSanjeev Kumar SinghNo ratings yet

- 14-FEB - JSA - NR - GHWP - Fabrication Shop EXTDocument2 pages14-FEB - JSA - NR - GHWP - Fabrication Shop EXTosama sheikhNo ratings yet

- Jobs Safety Analysis (JSA) : JOB/ACTIVITY NAME: Scaffolding Erection, Dismantling Work, Work at Height, Welding WorkDocument4 pagesJobs Safety Analysis (JSA) : JOB/ACTIVITY NAME: Scaffolding Erection, Dismantling Work, Work at Height, Welding Workuttam mishraNo ratings yet

- JHA PaintingDocument12 pagesJHA Paintingeast100% (1)

- Jsa For Piping and Erection RevisedDocument1 pageJsa For Piping and Erection RevisedDr AnwarNo ratings yet

- Attachemnt RA Work at HeightDocument4 pagesAttachemnt RA Work at Heightathul subashNo ratings yet

- JSADocument18 pagesJSADeshbandhu Aman PandeyNo ratings yet

- 12 Scaffolding WorkDocument5 pages12 Scaffolding WorkKoneti JanardhanaraoNo ratings yet

- Job Safety Analysis: Work at HeightDocument2 pagesJob Safety Analysis: Work at Heightmuhammad imtiazNo ratings yet

- Work at Height JsaDocument2 pagesWork at Height JsanabeelNo ratings yet

- Risk Assessments For FormworkDocument1 pageRisk Assessments For FormworkQays YousefNo ratings yet

- JSA PilingDocument1 pageJSA PilingNilamSanjeev Kumar SinghNo ratings yet

- Job Safety Analysis: Page 1 of 4Document4 pagesJob Safety Analysis: Page 1 of 4RakeshkasarlaNo ratings yet

- Method Statement For Transmission Line Lanco PDFDocument37 pagesMethod Statement For Transmission Line Lanco PDFAmar WadoodNo ratings yet

- Shoring 55Document7 pagesShoring 55Mohamed Hasafy100% (1)

- ERECTION METHOD STATEMENT Part 2Document6 pagesERECTION METHOD STATEMENT Part 2joseph chewNo ratings yet

- Risk Assessments - PageDocument1 pageRisk Assessments - PageQays YousefNo ratings yet

- Instruction ManualDocument14 pagesInstruction Manualmohamad zakwanNo ratings yet

- Use of Stepladders 05Document1 pageUse of Stepladders 05cardyNo ratings yet

- IPM - MOS - 005 - Mobile ScaffoldDocument6 pagesIPM - MOS - 005 - Mobile ScaffoldmohdnurasyraafNo ratings yet

- Job Hazard Analysis For Working at HeigthsDocument1 pageJob Hazard Analysis For Working at Heigthsjayboygulles02No ratings yet

- JSA For Scaffolding Erection Removal Around AT-911Document1 pageJSA For Scaffolding Erection Removal Around AT-911Equipment Materials100% (1)

- User Instructions Extension Single LaddersDocument11 pagesUser Instructions Extension Single LaddersTryfon KarachaliosNo ratings yet

- Risk Mitigation Plan 1Document25 pagesRisk Mitigation Plan 1Omar BahakimNo ratings yet

- 03 WMS - ScaffoldingDocument5 pages03 WMS - ScaffoldingHimanshu NiveriyaNo ratings yet

- Jha For Painting Works Repainting of Control Room and Guard House at Switchyard (External)Document1 pageJha For Painting Works Repainting of Control Room and Guard House at Switchyard (External)Jonas GonzalesNo ratings yet

- ASPECT HAZARD ASSESSMENT FORM FOR CONTRACTORS (Read Only)Document1 pageASPECT HAZARD ASSESSMENT FORM FOR CONTRACTORS (Read Only)Takumina ServicesNo ratings yet

- 0503 Geda Hoist InstructionsDocument6 pages0503 Geda Hoist InstructionsBoruida MachineryNo ratings yet

- Concrete Placement - FootingsDocument2 pagesConcrete Placement - Footingsadelin TinIndoNo ratings yet

- Target Working at HeightsDocument8 pagesTarget Working at HeightsMang Doros EsquilloNo ratings yet

- Shoring ModifedDocument15 pagesShoring ModifedMohamed HasafyNo ratings yet

- JHA Hot WorkDocument1 pageJHA Hot WorkNilamSanjeev Kumar SinghNo ratings yet

- Safety Poster of CTMDocument1 pageSafety Poster of CTMyashNo ratings yet

- Job Safety Analysis For Dismantling of WorkshopDocument10 pagesJob Safety Analysis For Dismantling of WorkshopShaheer AhmedNo ratings yet

- CTS Sterlite MergedDocument20 pagesCTS Sterlite MergedAvidip DeyNo ratings yet

- Pole Unit Install JhaDocument2 pagesPole Unit Install JhafatimahNo ratings yet

- Jsa Roof Sheeting & Wall CladdingDocument23 pagesJsa Roof Sheeting & Wall Claddingsamir ranjan dhalNo ratings yet

- Job Safety Analysis FormDocument2 pagesJob Safety Analysis FormAbhaySngh100% (1)

- NippleupDocument4 pagesNippleupali abbasNo ratings yet

- Duty of Care Act: Occupational Health and Safety Act 1984Document24 pagesDuty of Care Act: Occupational Health and Safety Act 1984Hoanghon BacNo ratings yet

- Risk Assessment What Work Excavation Work With Help of JCB Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDDocument2 pagesRisk Assessment What Work Excavation Work With Help of JCB Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDhemant yadav0% (2)

- Fall Control User Instructions: Procedure BP-FCL-0096-01Document24 pagesFall Control User Instructions: Procedure BP-FCL-0096-01soffi3No ratings yet

- MechanicalPipeLifte Issue 1Document6 pagesMechanicalPipeLifte Issue 1Bram ANo ratings yet

- Risk AssesmentDocument3 pagesRisk Assesmentmrogers72100% (4)

- Sunmow Jha 001Document3 pagesSunmow Jha 001Douglas DellyNo ratings yet

- Jha - Hot Works FenceDocument2 pagesJha - Hot Works Fencevannixs caindoyNo ratings yet

- Tubular Steel Tubular Aluminium Alloy Timber BambooDocument17 pagesTubular Steel Tubular Aluminium Alloy Timber Bambooillya amyraNo ratings yet

- HOUSEKEEPERDocument1 pageHOUSEKEEPERosama sheikhNo ratings yet

- Checklist For Full Body Safety Harness (Monthly) : Date of CheckDocument3 pagesChecklist For Full Body Safety Harness (Monthly) : Date of Checkosama sheikhNo ratings yet

- TimeDocument1 pageTimeosama sheikhNo ratings yet

- UntitledDocument1 pageUntitledosama sheikhNo ratings yet

- 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 RemarksDocument2 pages1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 Remarksosama sheikhNo ratings yet

- UntitledDocument1 pageUntitledosama sheikhNo ratings yet

- Work Start: (Tick Applicable)Document1 pageWork Start: (Tick Applicable)osama sheikhNo ratings yet

- 14-FEB - JSA - NR - GHWP - Fabrication Shop EXTDocument2 pages14-FEB - JSA - NR - GHWP - Fabrication Shop EXTosama sheikhNo ratings yet

- 14-FEB - JSA - NR - GH&H - L&S-WP - Chiller Room ICW & CTW Line Erection WorkDocument2 pages14-FEB - JSA - NR - GH&H - L&S-WP - Chiller Room ICW & CTW Line Erection Workosama sheikhNo ratings yet

- 14-FEB - JSA - NR - GHWP - Control Valve Auto Mode CheckingDocument2 pages14-FEB - JSA - NR - GHWP - Control Valve Auto Mode Checkingosama sheikhNo ratings yet

- Scaffolding in The Ancient World: Construction Repair Buildings Metal Pipes Bamboo Asian People's Republic of ChinaDocument7 pagesScaffolding in The Ancient World: Construction Repair Buildings Metal Pipes Bamboo Asian People's Republic of ChinaJoanna YengNo ratings yet

- BambooDocument60 pagesBamboorahul sulakheNo ratings yet

- Sccafolding Safety+ DM Code of ConstructionDocument11 pagesSccafolding Safety+ DM Code of ConstructionGodwin0% (1)

- Method Statement: Outline Demolition Method Statement 34 Springvale Avenue Walsall Ws5 3QbDocument27 pagesMethod Statement: Outline Demolition Method Statement 34 Springvale Avenue Walsall Ws5 3QbSHopkinsonNo ratings yet

- Interview: Safety Officers & SupervisorsDocument25 pagesInterview: Safety Officers & SupervisorsVaibhav Vithoba Naik0% (1)

- E175 PDFDocument570 pagesE175 PDFyeelingsNo ratings yet

- Demolition RISK AssessmentDocument15 pagesDemolition RISK AssessmentAli KaziNo ratings yet

- Scaffolding ExamplesDocument10 pagesScaffolding ExamplesSarin100% (1)

- Scaffolding Awareness Rev 01 - 12 Mar 09Document22 pagesScaffolding Awareness Rev 01 - 12 Mar 09Raghavendra KiranNo ratings yet

- WP1323 Working Near Overhead and Underground Electric Lines V2Document31 pagesWP1323 Working Near Overhead and Underground Electric Lines V2Jake SternNo ratings yet

- Working MethodDocument16 pagesWorking MethodHendrias Ari SujarwoNo ratings yet

- TG13 03 Non-Standard Boarded PlatformsDocument4 pagesTG13 03 Non-Standard Boarded PlatformsDaniel SarmientoNo ratings yet

- Proposed Construction of 3 No. Classrooms Block and 2 No. Eco Toilet Blocks at KiamwathiDocument49 pagesProposed Construction of 3 No. Classrooms Block and 2 No. Eco Toilet Blocks at Kiamwathiyamanta_rajNo ratings yet

- Cuplok Access Scaffold System-11Document24 pagesCuplok Access Scaffold System-11JijithpillaiNo ratings yet

- 306 SunsuriaDocument7 pages306 Sunsurianurma ramdanNo ratings yet

- Ischebeck Push Pull PropDocument12 pagesIschebeck Push Pull PropMohammed HafizNo ratings yet

- Scafollding StandardsDocument2 pagesScafollding StandardsMustofa0% (1)

- Guidelines On The Design and Construction of Bamboo ScaffoldsDocument24 pagesGuidelines On The Design and Construction of Bamboo ScaffoldsRizwan MirzaNo ratings yet

- AuV Alum Stage 600 2013enDocument12 pagesAuV Alum Stage 600 2013enArdamitNo ratings yet

- Factories and Machinery (Building Operations and Works of Engineering Construction) (Safety) Regulations, 1986 Ve - Pua328 - 1986Document46 pagesFactories and Machinery (Building Operations and Works of Engineering Construction) (Safety) Regulations, 1986 Ve - Pua328 - 1986Exsan Othman100% (1)

- Peri Up FlexDocument18 pagesPeri Up FlexRandom Stuff and StuffNo ratings yet

- HSE SWP 033 Ladders Scaffold SafetyDocument4 pagesHSE SWP 033 Ladders Scaffold SafetyGia Minh Tieu TuNo ratings yet

- Work at Heights StandardDocument1 pageWork at Heights Standardananthu.uNo ratings yet

- White Paper: SCIA ScaffoldingDocument35 pagesWhite Paper: SCIA ScaffoldingGiorgi KOGOSHVILINo ratings yet

- SA Scaffold Tag SystemDocument36 pagesSA Scaffold Tag SystemJunard M. Lu Hap100% (6)

- MATH TERMS 4 RefresherDocument2 pagesMATH TERMS 4 Refreshercat buenafeNo ratings yet