Professional Documents

Culture Documents

Self-priming dewatering pumps coupled with IE2 motor

Uploaded by

vivek dhadwalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Self-priming dewatering pumps coupled with IE2 motor

Uploaded by

vivek dhadwalCopyright:

Available Formats

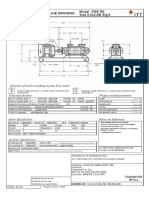

SELF PRIMING

DEWATERING

PUMPS

COUPLED WITH IE2 MOTOR

SP BS SP M SP COUPLED

KIRLOSKAR BROTHERS LIMITED Service Toll- Free No.

A Kirloskar Group Company KIRLOSKAR BROTHERS LIMITED

Established 1888 1800 103 4443 A Kirloskar Group Company

Registered Office & Global Headquarters : “Yamuna”, Survey No. 98 /(3 to7), Plot No. 3, Baner, Pune 411 045, State Maharashtra, India.

Tel.: +91 (20) 2721 4444 Fax: +91 (20) 67211060 Email: marketing@kbl.co.in Website: www.kirloskarpumps.com CIN No.: L29113PN1920PLC000670

Established 1888

KIRLOSKAR PUMPS KIRLOSKAR PUMPS

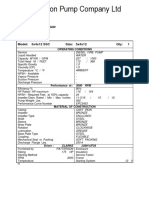

TECHNICAL SPECIFICATION

SP BARE SHAFT/MOTOR COUPLED SP MONOBLOC

Head Range : Upto 44 metres Upto 24 metres

Discharge Range : Upto 80 lps Upto 17.5 lps

Power Rating : 0.75 - 18.7 kW 0.37 - 3.7 kW

(1 - 25 HP) Motor Coupled* (0.5 - 5 HP)

Voltage Range : 415±10% 300 - 440V (Three Phase)

(For motor coupled only) 180 - 240V (Single Phase)

Class of Insulation : F Class (Motor coupled only) B / F Class

Protection : IP 55 IP 44 / IP 55

*Energy Efficient IE2 Motor

MATERIAL OF CONSTRUCTION

SP BARE SHAFT SP MONOBLOC SP MOTOR COUPLED

Impeller : Cast Iron / Stainless Steel/ Bronze Cast iron / Stainless Steel/ Bronze Cast Iron / Stainless Steel/ Bronze

Motor Body : - Cast Iron Cast Iron

Delivery Casing : Cast Iron Cast Iron Cast Iron

Shaft : Carbon Steel / Stainless Steel Carbon Steel / Stainless Steel Carbon Steel / Stainless Steel

Shaft Sleeve : Stainless Steel Stainless Steel (Bronze –SP-3LM+) Stainless Steel

Sealing : Gland Packed / Mechanical Seal Gland Packed / Mechanical Seal Gland Packed / Mechanical Seal

APPLICATIONS

Ÿ Handling chemicals, effluents, sewage, ash-water

Ÿ Dewatering foundation, trenches and pits

Ÿ Flood water handling

Ÿ Pumping water from docks, ports, vessels

Ÿ Dewatering from basements, multi-storeys, shopping malls, godowns

Ÿ Cooling water for marine engines and shovels

FEATURES

Self Priming

No need of foot valve and priming pumpset every time for quicker operations.

Non clog Impeller

Non clog impeller to handle suspended soft solids upto 60 MM in size made it suitable for sewage and dewatering applications.

Flatter Efficiency Curve

Minimum variations in efficiency during entire operating range increases the utility of pumpset for variable conditions.

Designed to Prevent Overloading

Lesser chances of motor burning as the motor does not get overloaded even if the pump is operated at a head lower than recommended, thus

ensuring substantial cost savings due to low maintenance and breakdown.

Dynamically Balanced Rotating Parts

Minimum vibrations protect components from damages during the operations, thus ensuring consistent performance as concentricity is

maintained.

Replaceable Wearing Parts

All wearing parts within the pumps are easily accessible and replaceable which facilitates ease of maintenance thereby extending the life of the

pump.

Easy Maintainable Designs

Easy maintainable design and better interchangeability of components so that pump can be serviced even at remote locations by semi-skilled

technicians.

You might also like

- MarlinDocument28 pagesMarlincumpio425428No ratings yet

- MAGA Training ReportDocument56 pagesMAGA Training ReportChaturanga WagaArachchige67% (3)

- DE712-014 Parts Manual - 712014 1 en Rev 1Document248 pagesDE712-014 Parts Manual - 712014 1 en Rev 1Emi DominguezNo ratings yet

- KCS 05 T A Hydraulic gear pumps and motors Compact line featuresDocument68 pagesKCS 05 T A Hydraulic gear pumps and motors Compact line featuresrenankeybNo ratings yet

- Ssangyong Actyon D20DT Manual de Reparacion de Los DiferencialesDocument24 pagesSsangyong Actyon D20DT Manual de Reparacion de Los DiferencialesHugo VillcaNo ratings yet

- Engine Service Specifications: © 1998-2009 American Honda Motor Co., Inc. - All Rights Reserved AHMDocument42 pagesEngine Service Specifications: © 1998-2009 American Honda Motor Co., Inc. - All Rights Reserved AHMazry_alqadry0% (1)

- L1 Finding Nemo Teacher Notes American EnglishDocument9 pagesL1 Finding Nemo Teacher Notes American Englishcris_simescuNo ratings yet

- Manual stack emission monitoring standardDocument29 pagesManual stack emission monitoring standardsantisal11No ratings yet

- Give Me Five 6 Pupils BookDocument129 pagesGive Me Five 6 Pupils BookAdrian Gonzalez100% (5)

- MSV40 MAX Manual de PartesDocument7 pagesMSV40 MAX Manual de PartesLenny SosaNo ratings yet

- Patterson Pump Company LTD: Model: 5x4x12 SSC Size: 5x4x12 Qty: 1Document25 pagesPatterson Pump Company LTD: Model: 5x4x12 SSC Size: 5x4x12 Qty: 1Ahmad Salah100% (2)

- Self Priming Dewatering Pumps: SP Bs SP Coupled SPMDocument2 pagesSelf Priming Dewatering Pumps: SP Bs SP Coupled SPMAK0909No ratings yet

- KU4 4 Inchs Borewell Submersible PumpsDocument2 pagesKU4 4 Inchs Borewell Submersible PumpsPrakNo ratings yet

- Kirloskar Brothers Limited: A Kirloskar Group Company Established 1888Document2 pagesKirloskar Brothers Limited: A Kirloskar Group Company Established 1888Mohan CharanchathNo ratings yet

- KDS Three Phase Monobloc PumpDocument2 pagesKDS Three Phase Monobloc PumpvimalmailbookNo ratings yet

- Section 5Document67 pagesSection 5Rafael EquihuaNo ratings yet

- 2013-03 (P) - Revision A - Evinrude E-TEC 40-300 High Pressure Fuel Pump Kits PDFDocument1 page2013-03 (P) - Revision A - Evinrude E-TEC 40-300 High Pressure Fuel Pump Kits PDFElvin HernándezNo ratings yet

- PDFDocument12 pagesPDFRavi AgrawalNo ratings yet

- Dongfeng Diesel Gensets 220-460 kVADocument2 pagesDongfeng Diesel Gensets 220-460 kVAMuhammad rizkiNo ratings yet

- Catalog f9 05 40Document3 pagesCatalog f9 05 40Leydiivonne Cortes NorbertoNo ratings yet

- 12-10G GH-3VCMDocument1 page12-10G GH-3VCMMamiherintsoa Issaia RanaivoarimananaNo ratings yet

- EVOSTA Wet Rotor CirculatorsDocument3 pagesEVOSTA Wet Rotor Circulatorsmky_roNo ratings yet

- 0.1 General PointsDocument96 pages0.1 General PointsSergeyNo ratings yet

- Motor BrandDocument2 pagesMotor Brandabid kazmiNo ratings yet

- Turbo BlowerDocument2 pagesTurbo BlowerMoedji WidyantoNo ratings yet

- Workshop Stock ListDocument16 pagesWorkshop Stock ListRachit100% (1)

- Condenser-HX-Expanders - 2018Document17 pagesCondenser-HX-Expanders - 2018Mohammed Ahmed NasherNo ratings yet

- DS 4NNTL-FDocument2 pagesDS 4NNTL-FgrobedNo ratings yet

- KV DVDocument2 pagesKV DVAbdullaKakkadKarumbilNo ratings yet

- SPbloc & SPnormDocument18 pagesSPbloc & SPnormsmita reddyNo ratings yet

- Kirloskar: Swing Check Type Multi-Door Reflux (Non Return) ValvesDocument3 pagesKirloskar: Swing Check Type Multi-Door Reflux (Non Return) ValvesWrt BillNo ratings yet

- A4 Vs C ClassDocument2 pagesA4 Vs C Classroshanbehra2023No ratings yet

- Mercedes / Knorr / Wabco / Bendix / Clayton / Volvo / RenualtDocument6 pagesMercedes / Knorr / Wabco / Bendix / Clayton / Volvo / RenualtForceFieldNo ratings yet

- 220kV LINESDocument9 pages220kV LINESNitin KumarNo ratings yet

- Model 3355 RS Pump Outline DrawingDocument1 pageModel 3355 RS Pump Outline DrawingDavidNo ratings yet

- Catalogo Bomba SchwingDocument16 pagesCatalogo Bomba SchwingDavid MusanNo ratings yet

- 004 Specs-Test-ValuesDocument6 pages004 Specs-Test-Valueselnynios100% (1)

- TW500W 1 20327Document1 pageTW500W 1 20327WilberZangaNo ratings yet

- Audi Q3 Vs BMW X1 Vs Mercedes-Benz Gla Vs Volvo Xc40Document2 pagesAudi Q3 Vs BMW X1 Vs Mercedes-Benz Gla Vs Volvo Xc40roshanbehra2023No ratings yet

- 10 - OdinDocument3 pages10 - OdinUsman ANo ratings yet

- BL2.0 Mechanical Diaphragm Price ListDocument1 pageBL2.0 Mechanical Diaphragm Price Listarijit mukhkerjeeNo ratings yet

- API 610 Pump Specification and DrawingDocument1 pageAPI 610 Pump Specification and DrawingPablo SantisNo ratings yet

- GM EngineDocument66 pagesGM EngineSSE Control MBNo ratings yet

- 004 - Specs & Test ValuesDocument6 pages004 - Specs & Test ValuesHenry Valeriano MaqueraNo ratings yet

- RFQ For Maxon Oven Pak ItemsDocument2 pagesRFQ For Maxon Oven Pak ItemsvadivelankgNo ratings yet

- Submersible Pump: Model S8D1 E275Document2 pagesSubmersible Pump: Model S8D1 E275frank rodriguezNo ratings yet

- 65598-Gd Cutsheet Template Pah 2015 LRDocument2 pages65598-Gd Cutsheet Template Pah 2015 LRAngheluță Dănuț ȘtefanNo ratings yet

- D and T-Series-masterDocument12 pagesD and T-Series-masterJavier PerezNo ratings yet

- Engine Flywheel: Power Take-Off Sae Type 1Document6 pagesEngine Flywheel: Power Take-Off Sae Type 1GdadbhhNo ratings yet

- Kirloskar Canned Motor PumpsDocument14 pagesKirloskar Canned Motor Pumpswesleyjames007No ratings yet

- Bbas Agua CalienteDocument12 pagesBbas Agua CalienteErich ThomasNo ratings yet

- Masons - Industrial - MBW - 18-45W - 50HzDocument4 pagesMasons - Industrial - MBW - 18-45W - 50HzGogaNo ratings yet

- SAAM Towage Fleet - Copia A Equipo Perú - FinalDocument27 pagesSAAM Towage Fleet - Copia A Equipo Perú - FinalRuben RodriguezNo ratings yet

- MCR PC300-7 (KLR 301)Document1 pageMCR PC300-7 (KLR 301)lilikNo ratings yet

- Catalogo KSB SPBlocDocument8 pagesCatalogo KSB SPBlocRuddy Fabrizio Galvez Justiniano0% (1)

- Curvas Bombas Banco HieloDocument20 pagesCurvas Bombas Banco HieloJohanNo ratings yet

- 1 - Thorn 1Document4 pages1 - Thorn 1Usman ANo ratings yet

- Gate Valve Data Sheet ProjectDocument4 pagesGate Valve Data Sheet ProjectSandeepNBabuNo ratings yet

- List of Part-3Document2,000 pagesList of Part-3Gỗ MộcNo ratings yet

- Engine InventoryDocument7 pagesEngine InventoryArif Mulyasyahputra2No ratings yet

- Bomba Gorman T4A3S-BDocument2 pagesBomba Gorman T4A3S-BToshiro HitsugayaNo ratings yet

- Honda spark plug price listDocument2 pagesHonda spark plug price listmomoNo ratings yet

- Technical specifications of a 125cc vehicleDocument6 pagesTechnical specifications of a 125cc vehiclekapil jatNo ratings yet

- FIre Hydrant SupliersDocument15 pagesFIre Hydrant SupliersKarthick MahadevanNo ratings yet

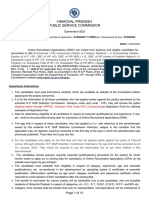

- Tech Docs Ksew Wss JJM Jmu Item2 RKB 50 15e 7stg 45kc2 180m 36.36m3 07 09 2023Document5 pagesTech Docs Ksew Wss JJM Jmu Item2 RKB 50 15e 7stg 45kc2 180m 36.36m3 07 09 2023vivek dhadwalNo ratings yet

- HRTC Conductor 360 Post Notification 2023 Apply OnlineDocument12 pagesHRTC Conductor 360 Post Notification 2023 Apply Onlinevivek dhadwalNo ratings yet

- Performance Curve of Kirloskar Brothers Limited Pumpset Model KS8B-4505Document1 pagePerformance Curve of Kirloskar Brothers Limited Pumpset Model KS8B-4505vivek dhadwalNo ratings yet

- Ks6ea 2020RDocument1 pageKs6ea 2020Rvivek dhadwalNo ratings yet

- Phe Technical AnnexureDocument1 pagePhe Technical Annexurevivek dhadwalNo ratings yet

- Ks8e 2006Document1 pageKs8e 2006vivek dhadwalNo ratings yet

- Performance Curve - KS6F-1509RDocument1 pagePerformance Curve - KS6F-1509Rvivek dhadwalNo ratings yet

- D.K.Pandey: Lecture 1: Growth and Decay of Current in RL CircuitDocument5 pagesD.K.Pandey: Lecture 1: Growth and Decay of Current in RL CircuitBBA UniversityNo ratings yet

- Brazed Tool ArDocument5 pagesBrazed Tool ArRoni MustafiqNo ratings yet

- SignaLink USB Product Guide - 02.2018Document22 pagesSignaLink USB Product Guide - 02.2018Rafael D. B. AnellaNo ratings yet

- Ipra IrrDocument58 pagesIpra IrrMac Manuel100% (1)

- Farha WCM Project-1Document110 pagesFarha WCM Project-1a NaniNo ratings yet

- 52 Blower StoryDocument7 pages52 Blower StoryBentley SpottingNo ratings yet

- Fiat Type 199 Punto Evo 3 PDFDocument9 pagesFiat Type 199 Punto Evo 3 PDFGestione SportivaNo ratings yet

- Footing BiaxialDocument33 pagesFooting BiaxialSanthoshkumar RayavarapuNo ratings yet

- CCTmanual 56Document226 pagesCCTmanual 56Jim Barrón GarcíaNo ratings yet

- Schutz - Subnotes PDFDocument47 pagesSchutz - Subnotes PDFJarryd RastiNo ratings yet

- SOLAR DRYER v1Document43 pagesSOLAR DRYER v1Maria Angelica Borillo100% (1)

- Wiring Diagrams Model Yk (Style G) Liquid Chillers Optiview Control Center With SSS, LV VSD W/ Modbus, & MV VSDDocument30 pagesWiring Diagrams Model Yk (Style G) Liquid Chillers Optiview Control Center With SSS, LV VSD W/ Modbus, & MV VSDAbdulSattarNo ratings yet

- CIB 357th MeetingDocument49 pagesCIB 357th MeetingbarkhaNo ratings yet

- Namma Kalvi 12th Maths Book Back 1 Mark Questions em 216251Document29 pagesNamma Kalvi 12th Maths Book Back 1 Mark Questions em 21625111B CHARAN ANANDNo ratings yet

- MTD Big Bore Engines 78 277cc 83 357cc 90 420cc Repair Manual PDFDocument136 pagesMTD Big Bore Engines 78 277cc 83 357cc 90 420cc Repair Manual PDFGiedrius MalinauskasNo ratings yet

- Hydrocarbon ReactionsDocument2 pagesHydrocarbon ReactionsJessa Libo-onNo ratings yet

- Pacemaker 180508042454Document86 pagesPacemaker 180508042454padmaNo ratings yet

- Providence Anadime Chorus Adc3Document1 pageProvidence Anadime Chorus Adc3wplaisNo ratings yet

- Hoist by TechnologyDocument6 pagesHoist by TechnologyAnonymous ntE0hG2TPNo ratings yet

- SG PB Imds1350Document103 pagesSG PB Imds1350zky0108No ratings yet

- The Task of 5-Axis Milling PDFDocument4 pagesThe Task of 5-Axis Milling PDFManikanda PrabhucNo ratings yet

- Math Story FlowersDocument3 pagesMath Story Flowerstoxic_angel_love958No ratings yet

- Agribusiness ManagementDocument20 pagesAgribusiness Managementronald_leabresNo ratings yet

- 456/1 Mathematics Paper 1 June /july 2012 HoursDocument4 pages456/1 Mathematics Paper 1 June /july 2012 HoursBaguma MichaelNo ratings yet