Professional Documents

Culture Documents

Kirloskar Brothers Limited: A Kirloskar Group Company Established 1888

Uploaded by

Mohan CharanchathOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kirloskar Brothers Limited: A Kirloskar Group Company Established 1888

Uploaded by

Mohan CharanchathCopyright:

Available Formats

KDI

THREE PHASE

MONOBLOC PUMPS

KIRLOSKAR BROTHERS LIMITED

A Kirloskar Group Company

Service Toll- Free No.

KIRLOSKAR BROTHERS LIMITED

Established 1888 1800 103 4443 A Kirloskar Group Company

Registered Office & Global Headquarters : “Yamuna”, Survey No. 98 /(3 to7), Plot No. 3, Baner, Pune 411 045, State Maharashtra, India.

Tel.: +91 (20) 2721 4444 Fax: +91 (20) 67211060 Email: marketing@kbl.co.in Website: www.kirloskarpumps.com CIN No.: L29113PN1920PLC000670 Established 1888

KIRLOSKAR PUMPS KIRLOSKAR PUMPS

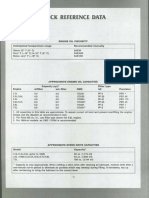

TECHNICAL SPECIFICATION

Head Range : Upto 76 metres

Discharge Range : Upto 39 lps

Power Ratings : 1.5 to 22 kW

(2 to 30 HP)

Voltage Range : 350 to 440 Volts

(Three Phase)

Insulation : F Class

Protection : IP 55

MATERIAL OF CONSTRUCTION

Impeller : Cast Iron / Bronze /

Stainless Steel

Delivery Casing : Cast Iron

Motor Body : Cast Iron

Pump Shaft : Stainless Steel

Sealing : Mechanical Seal

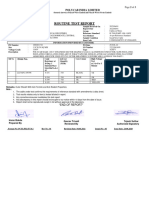

APPLICATIONS

Ÿ Air conditioning and refrigeration systems

Ÿ Cooling towers

Ÿ Clear water handling at high pressure in industries

Ÿ Irrigation in horticulture & agriculture

Ÿ Fire fighting systems

FEATURES

Flatter Efficiency Curve

Minimum variations in efficiency during entire operating range increases the utility of pumpset for variable conditions.

Wide Voltage Design

The motor is designed to withstand wide voltage fluctuations from 350 to 440 volts and reduces motor burning in case of low voltage.

Designed to Prevent Overloading

Lesser chances of motor burning as the motor does not get overloaded even if the pump is operated at a head lower than recommended, thus

ensuring substantial cost savings due to low maintenance and breakdown.

Replaceable Wearing Parts

All wearing parts within the pumps are easily accessible and replaceable which facilitates ease of maintenance thereby extending the life of the pump.

Dynamically Balanced Rotating Parts

Minimum vibrations protect components from damages during the operations, thus ensuring consistent performance as concentricity is maintained.

CED – Cathodic Electro Deposition

CED is the latest coating technology for corrosion resistance with uniform coating. It provides 5 times more protection over conventional painting,

resulting in longer life. All major CI parts of Kirloskar pumps coming in contact with the water are CED coated.

Automatic Air Release

Automatically releases air when the pump starts which ensures swifter and smoother operations, thus eliminating the necessity of operating air

release cock and ensures swifter and smoother operations.

Mechanical Seal

Superior quality of mechanical seal ensures zero leakage, lower friction loss, protects from wearing of shaft, thus resulting in easy maintenance and

longer life.

You might also like

- KDS Three Phase Monobloc PumpDocument2 pagesKDS Three Phase Monobloc PumpvimalmailbookNo ratings yet

- Self Priming Dewatering Pumps: SP Bs SP Coupled SPMDocument2 pagesSelf Priming Dewatering Pumps: SP Bs SP Coupled SPMAK0909No ratings yet

- Self-priming dewatering pumps coupled with IE2 motorDocument2 pagesSelf-priming dewatering pumps coupled with IE2 motorvivek dhadwalNo ratings yet

- KU4 4 Inchs Borewell Submersible PumpsDocument2 pagesKU4 4 Inchs Borewell Submersible PumpsPrakNo ratings yet

- 1Document2 pages1waseemybNo ratings yet

- JOS Openwell Submersible Pumpset UpdatedDocument2 pagesJOS Openwell Submersible Pumpset UpdatedGaurav SoNiNo ratings yet

- KV DVDocument2 pagesKV DVAbdullaKakkadKarumbilNo ratings yet

- MODIFIED TenderNotice RFX 10633 Oil LeakagesDocument2 pagesMODIFIED TenderNotice RFX 10633 Oil Leakages4D EngineeringNo ratings yet

- Reliable Fire Pumpsets for Lifesaving ProtectionDocument4 pagesReliable Fire Pumpsets for Lifesaving ProtectionnaseerpashaNo ratings yet

- Kirloskar Canned Motor PumpsDocument14 pagesKirloskar Canned Motor Pumpswesleyjames007No ratings yet

- Kirloskar Brothers Limited: A Kirloskar Group Company Established 1888Document2 pagesKirloskar Brothers Limited: A Kirloskar Group Company Established 1888design jyotihydrotech.comNo ratings yet

- Ministry of Commerce & Industry: RillingDocument3 pagesMinistry of Commerce & Industry: RillingMick DelantorNo ratings yet

- Adobe Scan Dec 30, 2021Document6 pagesAdobe Scan Dec 30, 2021Omkar MurthyNo ratings yet

- Request For Quotation Local Purchase Section: RFQ NumberDocument3 pagesRequest For Quotation Local Purchase Section: RFQ NumberAkhil Geo BijuNo ratings yet

- Engine InventoryDocument7 pagesEngine InventoryArif Mulyasyahputra2No ratings yet

- Web Work PDFDocument39 pagesWeb Work PDFCharles JacobNo ratings yet

- F10 03-H-MergedDocument6 pagesF10 03-H-MergedLokeshNo ratings yet

- Berger Paints India LimitedDocument2 pagesBerger Paints India LimiteddipeshlodhiqseplNo ratings yet

- Synergy-Infra 3A91 Capacity 200TRDocument9 pagesSynergy-Infra 3A91 Capacity 200TRSiva NagendraNo ratings yet

- Swivel Joint CalatogueDocument6 pagesSwivel Joint CalatoguejlbarretoaNo ratings yet

- Megha 1640233741Document2 pagesMegha 1640233741anvesh anviNo ratings yet

- Dokumentation Energoutil 2015-35370 - enDocument37 pagesDokumentation Energoutil 2015-35370 - enbrctlnNo ratings yet

- Bbas Agua CalienteDocument12 pagesBbas Agua CalienteErich ThomasNo ratings yet

- Temp - Measuring ProbeDocument1 pageTemp - Measuring ProbeSudhan SudhanPowerTechNo ratings yet

- Volume3A Mech PDFDocument321 pagesVolume3A Mech PDFSayee Krishnan100% (1)

- Vessel's Info Form - BunkerDocument2 pagesVessel's Info Form - BunkerFilip NikolevskiNo ratings yet

- Pro-Analysis Learnings - Mist SprayerDocument4 pagesPro-Analysis Learnings - Mist SprayerJISHAN ALAMNo ratings yet

- Pentagon TurbineDocument6 pagesPentagon TurbinePatel PriteshNo ratings yet

- Kashima (M) SDN Presentation 25.01.21 (English)Document10 pagesKashima (M) SDN Presentation 25.01.21 (English)Dhruv TrivediNo ratings yet

- 0./u!s Limited: SLLLLFBMDocument3 pages0./u!s Limited: SLLLLFBMc.hloeabe.le.07No ratings yet

- STD Specs of FLP MotorDocument9 pagesSTD Specs of FLP Motordheeraj1993No ratings yet

- Nre BBLDocument2 pagesNre BBLRammurthy JVNo ratings yet

- Internship Sheme in Coal India LTDDocument16 pagesInternship Sheme in Coal India LTDSahil SokhalNo ratings yet

- Al Jazeera Steel Products MTC ReportDocument1 pageAl Jazeera Steel Products MTC ReportKyNo ratings yet

- Kirloskar Brothers Limited: A Kirloskar Group Company Established 1888Document2 pagesKirloskar Brothers Limited: A Kirloskar Group Company Established 1888ANJANEYA SHARMANo ratings yet

- DVX30 Kat BC HVT2125 (28-10-2013) PDFDocument191 pagesDVX30 Kat BC HVT2125 (28-10-2013) PDFJohnson James100% (1)

- Test Certificate No.: 0000524871: Chemical Analysis Mechanical PropertiesDocument1 pageTest Certificate No.: 0000524871: Chemical Analysis Mechanical PropertiesSuman Jana100% (1)

- Global Synthetic Power Steering FluidDocument2 pagesGlobal Synthetic Power Steering FluidRafael AguileraNo ratings yet

- Koel Fire Pump Engine Heat ExchangerDocument9 pagesKoel Fire Pump Engine Heat Exchangerhanushukla1735No ratings yet

- Dossier Merla - ODB 4604279Document33 pagesDossier Merla - ODB 4604279Indira briceñoNo ratings yet

- Omc Cobra 86 93 Quick References DataDocument6 pagesOmc Cobra 86 93 Quick References DataJean-Baptiste MontfortNo ratings yet

- Dedicated To Quality OCM Services in Middle East Since 1992: Analysis ReportDocument2 pagesDedicated To Quality OCM Services in Middle East Since 1992: Analysis ReportMohamed ElnagdyNo ratings yet

- New Complete Company Profile-2020Document88 pagesNew Complete Company Profile-2020OGTC Reports100% (1)

- Merlin Diesel Systems Ltd injector calibration and testing documentationDocument126 pagesMerlin Diesel Systems Ltd injector calibration and testing documentationLucas Man100% (2)

- Metal Cutting GasDocument21 pagesMetal Cutting GasSuyog ShingareNo ratings yet

- BMCG Presentation Cii08012010mDocument21 pagesBMCG Presentation Cii08012010mSHRINIVASNo ratings yet

- TorqueDocument6 pagesTorqueRavindra PawarNo ratings yet

- BMCG PresentationDocument21 pagesBMCG PresentationmarkandeyaNo ratings yet

- Quotation: Dmi Diesel Offshore (S) Pte LTD Dmi SingaporeDocument3 pagesQuotation: Dmi Diesel Offshore (S) Pte LTD Dmi SingaporeŞenol MemişNo ratings yet

- Mitra Roof Treatment CentreDocument4 pagesMitra Roof Treatment CentreSudip MitraNo ratings yet

- 375 - 50WT Cat 3Document2 pages375 - 50WT Cat 3ATF PrécisionNo ratings yet

- VW AZX IN T3Document6 pagesVW AZX IN T3Edward MainaNo ratings yet

- RFQ PDFDocument1 pageRFQ PDFakashdruva892No ratings yet

- Job Work Order: For JSW Steel LimitedDocument5 pagesJob Work Order: For JSW Steel LimitedabcNo ratings yet

- Job Work Order: For JSW Steel LimitedDocument5 pagesJob Work Order: For JSW Steel LimitedabcNo ratings yet

- Electromat CatalogueDocument24 pagesElectromat Cataloguekvramanan_1No ratings yet

- EMP 4 Pipes - 001 Nov 2023Document16 pagesEMP 4 Pipes - 001 Nov 2023Nithin GNo ratings yet

- 150 X3.5 C RTCDocument1 page150 X3.5 C RTCnitinNo ratings yet

- Ship Survey Status: Tirumala GasDocument27 pagesShip Survey Status: Tirumala GasHoa LuuNo ratings yet

- Es-219-Ab-6000-M43-7.5kw + CR219DDocument1 pageEs-219-Ab-6000-M43-7.5kw + CR219DMohan CharanchathNo ratings yet

- VHS-C en 0217 Edit PDFDocument4 pagesVHS-C en 0217 Edit PDFArielNo ratings yet

- Installation & Maintenance ManualDocument5 pagesInstallation & Maintenance ManualMohan CharanchathNo ratings yet

- Sling Angles and LoadsDocument1 pageSling Angles and LoadsMohan CharanchathNo ratings yet

- CR 45-8 A-F-A-E-HQQE - 96122811 - DrawingDocument1 pageCR 45-8 A-F-A-E-HQQE - 96122811 - DrawingMohan CharanchathNo ratings yet

- Calculating Sling Angles - Instruction and ExamplesDocument1 pageCalculating Sling Angles - Instruction and ExamplesMohan CharanchathNo ratings yet

- Sling Capacity and Sling Angle Calculation FormulaDocument1 pageSling Capacity and Sling Angle Calculation FormulaMohan CharanchathNo ratings yet

- Es-168-Ab-6000-M43-4kw+ CR168DDocument1 pageEs-168-Ab-6000-M43-4kw+ CR168DMohan CharanchathNo ratings yet

- Introduction To Sling Load Tension Calculations.: February 2015Document14 pagesIntroduction To Sling Load Tension Calculations.: February 2015tomicdaneNo ratings yet

- Electricity Fog Cannon Spray MachineDocument1 pageElectricity Fog Cannon Spray MachineMohan CharanchathNo ratings yet

- Simple Sling TensionDocument2 pagesSimple Sling TensionMohan CharanchathNo ratings yet

- Underground mining crane technical specificationsDocument3 pagesUnderground mining crane technical specificationsMohan CharanchathNo ratings yet

- KDS Monobloc Pump Single PhaceDocument2 pagesKDS Monobloc Pump Single PhaceMohan CharanchathNo ratings yet

- Easily Calculate SWL of Wire SlingDocument1 pageEasily Calculate SWL of Wire SlingMohan CharanchathNo ratings yet

- Calculating Sling Angles and StressDocument1 pageCalculating Sling Angles and StressMohan CharanchathNo ratings yet

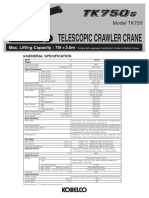

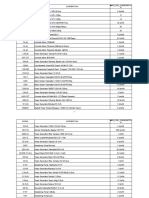

- Telescopic Crawler Crane: Model TK750Document6 pagesTelescopic Crawler Crane: Model TK750Mohan CharanchathNo ratings yet

- SCC750A: Crawler Crane 75 Tons Lifting Capacity 75 Tons Lifting CapacityDocument17 pagesSCC750A: Crawler Crane 75 Tons Lifting Capacity 75 Tons Lifting CapacityMohan CharanchathNo ratings yet

- AccumulatorDocument5 pagesAccumulatorMohan CharanchathNo ratings yet

- AdvantagesDocument5 pagesAdvantagesMohan CharanchathNo ratings yet

- Reservoirs, Strainers and FiltersDocument16 pagesReservoirs, Strainers and FiltersMohan CharanchathNo ratings yet

- ZF 9S 109 PDFDocument62 pagesZF 9S 109 PDFMohan Charanchath100% (3)

- Instruction Manual For BG25Document183 pagesInstruction Manual For BG25Mohan Charanchath100% (1)

- Hydraulic Actuators: Linear and Rotary TypesDocument18 pagesHydraulic Actuators: Linear and Rotary TypesMohan CharanchathNo ratings yet

- Hydraulic Crawler Crane: Model: BMS1000Document20 pagesHydraulic Crawler Crane: Model: BMS1000Mohan CharanchathNo ratings yet

- J Engine PDFDocument128 pagesJ Engine PDFMohan CharanchathNo ratings yet

- Rear Axle PDFDocument30 pagesRear Axle PDFMohan CharanchathNo ratings yet

- Allcv Service Manual: Propeller ShaftDocument10 pagesAllcv Service Manual: Propeller ShaftMohan CharanchathNo ratings yet

- ZF S5 S6 and S6 OD Gear Box PDFDocument58 pagesZF S5 S6 and S6 OD Gear Box PDFMohan Charanchath75% (4)

- RS 160 Rear Axle PDFDocument31 pagesRS 160 Rear Axle PDFMohan CharanchathNo ratings yet

- Faster pull-down in refrigeration systemsDocument9 pagesFaster pull-down in refrigeration systemsRahul PatilNo ratings yet

- Kirloskar FerrorsI Ndustries LTD (Project)Document53 pagesKirloskar FerrorsI Ndustries LTD (Project)rameshmba100% (6)

- Market Research On Diesel EnginesDocument93 pagesMarket Research On Diesel Enginesarunshivamogga100% (1)

- Kirloskar Brothers Limited, SanandDocument25 pagesKirloskar Brothers Limited, SanandjaydeepsinhNo ratings yet

- Industry ProfileDocument20 pagesIndustry ProfileShanu shriNo ratings yet

- Koel Fire Pump Engine Heat ExchangerDocument9 pagesKoel Fire Pump Engine Heat Exchangerhanushukla1735No ratings yet

- Swot and Pestle Analysis of Kirloskar GroupDocument14 pagesSwot and Pestle Analysis of Kirloskar GroupCharuJagwaniNo ratings yet

- Final SIP Report On 1st JuneDocument36 pagesFinal SIP Report On 1st JuneRicha MittalNo ratings yet

- Machinery Working Status ReportDocument6 pagesMachinery Working Status ReportChetan SohalNo ratings yet

- CPHM PumpsDocument6 pagesCPHM PumpsDeepak ThakkerNo ratings yet

- LIST OF CUSTOMERSDocument8 pagesLIST OF CUSTOMERSTpo OrientalGroupNo ratings yet

- Fire Fighting System Enquiry SpecsDocument56 pagesFire Fighting System Enquiry SpecsVaibhav Sawant100% (1)

- Fuel Consumption Rates of Construction EquipmentDocument11 pagesFuel Consumption Rates of Construction EquipmentDEEPAKNo ratings yet

- KBL Fire Catalogue PDFDocument31 pagesKBL Fire Catalogue PDFmoinulsaqibNo ratings yet

- HA Series1Document2 pagesHA Series1anon_42344729680% (5)

- Kirloskar Iland BrochureDocument3 pagesKirloskar Iland BrochureBiroj JenaNo ratings yet

- KFP Series EngineDocument4 pagesKFP Series EngineJaleel DesionicsNo ratings yet

- Screw Air Compressor Electrical Tank MountedDocument12 pagesScrew Air Compressor Electrical Tank MountedK B TempNo ratings yet

- 872-Kirloskar Mega T-15 Batch TestDocument7 pages872-Kirloskar Mega T-15 Batch TestSelvakumarNo ratings yet

- List of Equipment Available For Disposal 1 / Factory Available For DismantlingDocument58 pagesList of Equipment Available For Disposal 1 / Factory Available For DismantlingRaghu R NaikNo ratings yet

- A Raid Is Ele MissionDocument18 pagesA Raid Is Ele MissionAvijitSinharoyNo ratings yet

- Electro EquipmentsDocument24 pagesElectro Equipmentsgs100% (1)

- Kirloskar PuneDocument18 pagesKirloskar PuneApoorva KolteNo ratings yet

- Case Study of Kirloskar Brothers Ltd TQM ImplementationDocument47 pagesCase Study of Kirloskar Brothers Ltd TQM Implementation2123 Abhinav rajNo ratings yet

- Kirloskar Electric Ltd. Internship ReportDocument41 pagesKirloskar Electric Ltd. Internship ReportPranit Patil100% (5)

- CVP NewDocument23 pagesCVP NewBhaskar ReddyNo ratings yet

- Internship presentation on inventory management at Kirloskar BrothersDocument9 pagesInternship presentation on inventory management at Kirloskar BrothersAyush Chopra100% (1)

- AR - Transformers and Pumps Look Promising PDFDocument85 pagesAR - Transformers and Pumps Look Promising PDFRonak JajooNo ratings yet

- KBL Fire Pumps Meet NFPA, FM, UL StandardsDocument5 pagesKBL Fire Pumps Meet NFPA, FM, UL StandardsguruuptoNo ratings yet

- Kirloskar Integrated Technologies LimitedDocument12 pagesKirloskar Integrated Technologies LimitedBhushan MalsheNo ratings yet