Professional Documents

Culture Documents

MNKF

Uploaded by

Mouzy Mcthy0 ratings0% found this document useful (0 votes)

17 views4 pagesLUCJK

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentLUCJK

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views4 pagesMNKF

Uploaded by

Mouzy McthyLUCJK

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 4

MBEYA UNIVERSITY OF SCIENCE AND TECHNOLOGY

DEPARTMENT: ELECTRICAL AND POWER ENGINEERING

COURSE NAME: ELECTRICAL MAINTENANCE

COURSE CODE: EE 8110

GROUP NO: 03

TASK: GROUP ASSIGNMENT

GROUP PARTICIPANTS

SN NAME CA NO SIGNATURE

1 JOSEPH R JOSEPH CA/BEEE/20/10346

2 EMMANUEL M SAMA CA/BEEE/20/7258

3 JACKSON G LUVANDA CA/BEEE/20/7184S

4 MISUNGWI K JULIUS CA/BEEE/20/7164

5 MRISHO M RUBASE CA/BEEE/20/

6 MACHIBULA M JOSEPH CA/BEEE/20/10347

7 MUSTAPHA M SALUM CA/BEEE/20/7257

8 SAID KH SAID CA/BEEE/20/7255

9 EVA J SHABAN CA/BEEE/20/7265

10 FELISTA E JONAS CA/BEEE/20/7162

A. List down and briefly explain the four reasons of carrying maintenance.?

To increase functional reliability of production facilities. Aimed at performing

maintenance to increases performance of the device or machine , e.g. changing oil on

a car machine

To maximize useful life of the equipment. Proper regular maintenance increases the

lifespan of an equipment hence runs efficiently during its usual life cycle.

To enhance the safety of the manpower. Regular maintenance of devices and

equipment expose hidden faults which can be fixed thus preventing any sort of man

power loss e.g. Airplanes must be regularly undergoes electrical as well as mechanical

maintenance that when damaged or experience any kind of fault the can cause

accidents that leads to the loss of man power

To minimize the total production cost . Maintenance of production equipment in

industry or a factory increases the life span of a the equipment being used thus

reducing the need to buy new equipment as a result of failures, the same equipment

can be used for a lo0ng period of time with maximum efficiency

B. Explain the key conditions to monitor in condition monitoring maintenance.?

(i). Knowing what to listen for;

-: Machines contains partially or totally mechanical moving parts which produce

noise(sound &vibration); a healthy operating machine produce no or minimum sound and

vibration which abruptly changes or increase as a result of fault or damage to some machinery

parts, The change in vibration and sound produced maybe an indicator that the machinery is

experiencing some faults in the system which can be fixed early.

(ii). How to interpret it:

-: After listening to a vibration /sound changes produced by the machine, vibration are

interpreted through its magnitude in order to detect the path/location where the fault might be.

(iii) when to put the knowledge to use:

-: This knowledge can be put into use when maintenance of the instrument or machine

C. State any three Advantages of condition monitoring.?

1. Enables the repair of problem component prior to failure

2. Helps plant personnel to reduce the possibility catastrophic failure

3. Increases lifespan of machinery

4. Lowering maintenance

5. Maximizing production output

D. Discuss the two ways of troubleshooting elimination .

1. The serial method

: - Is the technique used by troubleshooter to check for frequently encountered or easily

tested conditions first Example, Checking to ensure that a printer light is on and that its cable is

firmly seated at both ends.

2. The half-splitting method

:- Is a technique used in fault finding to locate defects with a few measurements. Essentially the

technique involves splitting the circuit path into halves and troubleshooting from the middle of

the first half then the second and so on.

You might also like

- Machine Condition Monitoring and Fault DiagnosticsDocument28 pagesMachine Condition Monitoring and Fault Diagnosticsزيد فؤاد اليافعيNo ratings yet

- CH 1 MaintenanceDocument26 pagesCH 1 MaintenanceTewodros DereseNo ratings yet

- Introduction of MaintenanceDocument35 pagesIntroduction of Maintenanceekhwan82100% (1)

- Ijmet: International Journal of Mechanical Engineering and Technology (Ijmet)Document8 pagesIjmet: International Journal of Mechanical Engineering and Technology (Ijmet)IAEME PublicationNo ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Local Presentation On CBM - Iipm, IndiaDocument54 pagesLocal Presentation On CBM - Iipm, IndiaFreddie Asiedu LarbiNo ratings yet

- Maintenance Engineering Q&a PDFDocument27 pagesMaintenance Engineering Q&a PDFRaviggg100% (3)

- MaintenanceDocument89 pagesMaintenancelp mishra100% (5)

- Kakrapar Atomic Power StationDocument15 pagesKakrapar Atomic Power StationMurtaza PatrawalaNo ratings yet

- 20-05 Industrial Maintenance & Safety (In)Document1 page20-05 Industrial Maintenance & Safety (In)thirukumaran25No ratings yet

- Fault Diagnostics - Report-2Document12 pagesFault Diagnostics - Report-2Mohamed MostafaNo ratings yet

- Analysis of Breakdown and Imp in PM On 1000ton Hyd PressDocument10 pagesAnalysis of Breakdown and Imp in PM On 1000ton Hyd PressSundar Kumar Vasantha GovindarajuluNo ratings yet

- Bharathiyar College of Engineering and Technology Karaikal Department of Mechanical Engineering Subject: Maintenance and Safety Engineering Two Marks Questions With AnswerDocument14 pagesBharathiyar College of Engineering and Technology Karaikal Department of Mechanical Engineering Subject: Maintenance and Safety Engineering Two Marks Questions With AnswerM.ThirunavukkarasuNo ratings yet

- Standard Training Module (STM) : Mechanical MaintenanceDocument19 pagesStandard Training Module (STM) : Mechanical Maintenanceuday245No ratings yet

- Maintenance Management AssignmentDocument50 pagesMaintenance Management AssignmentViswanatha Sastry83% (6)

- Basic 9 Basic Tech 3RD Term E-NotesDocument17 pagesBasic 9 Basic Tech 3RD Term E-NotesAkinyemi Odunayo100% (1)

- Topic 1 - Maintenance System LatestDocument77 pagesTopic 1 - Maintenance System LatestAfhnan TemiziNo ratings yet

- Discuss Clearly About Two Inspection Methods For Checking of Machines and EquipmentDocument4 pagesDiscuss Clearly About Two Inspection Methods For Checking of Machines and Equipmentmuhaba muhamedNo ratings yet

- Mill Maintenance: Maintenance Can Be Defined As The Activity Undertaken To Allow Continued Use of Buildings andDocument5 pagesMill Maintenance: Maintenance Can Be Defined As The Activity Undertaken To Allow Continued Use of Buildings andNijam JabbarNo ratings yet

- Breakdown MaintenanceDocument4 pagesBreakdown MaintenanceSankalp Sharma0% (1)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Maintenance Schedule For Induction Motor Microproject ReportDocument18 pagesMaintenance Schedule For Induction Motor Microproject Report44 Tejas JadhavNo ratings yet

- List 4 Importance of Electrical SafetyDocument2 pagesList 4 Importance of Electrical SafetyMohd RizwanNo ratings yet

- Chapter 10 Maintenance ManagementDocument23 pagesChapter 10 Maintenance ManagementShafayet JamilNo ratings yet

- Evaluation of Machine DowntimeDocument5 pagesEvaluation of Machine DowntimeRickle Vincent PilongoNo ratings yet

- Industral Training ReportDocument22 pagesIndustral Training ReportuditNo ratings yet

- CNC Machines and Automation: Problems in CNC MachineDocument21 pagesCNC Machines and Automation: Problems in CNC Machinerahul bhattNo ratings yet

- Southern Range Nyanza LTDDocument17 pagesSouthern Range Nyanza LTDspindles2No ratings yet

- Lecture 3A MaintenanceDocument43 pagesLecture 3A Maintenancemoyo josephNo ratings yet

- Maintenance ManagementDocument7 pagesMaintenance ManagementNadeemNo ratings yet

- Unit 1 - 15 Marks, EasyDocument3 pagesUnit 1 - 15 Marks, EasyBipul VermaNo ratings yet

- Introduction To Maintenance and RepairingDocument32 pagesIntroduction To Maintenance and RepairingR.W. SaputraNo ratings yet

- Basics of TestingDocument47 pagesBasics of TestingEE166Srushti Vibhute.No ratings yet

- Chapitre 01Document6 pagesChapitre 01marouakheira.benaissa.etdNo ratings yet

- Topic 1 - DJJ50203 Maintenance and TroubleshootingDocument37 pagesTopic 1 - DJJ50203 Maintenance and TroubleshootingNazuan NazriNo ratings yet

- Unit 3 IcmDocument17 pagesUnit 3 IcmPalak JioNo ratings yet

- TRABAJOFINAL Ingles Tecnico.Document5 pagesTRABAJOFINAL Ingles Tecnico.mariano joseNo ratings yet

- 16 - Predictive Management TecsDocument3 pages16 - Predictive Management TecsnasdaqtexasNo ratings yet

- Introduction To Maintenance: SMJ 4812 Proj. Management & Maintenance Engrg. Sem.I 2003/2004Document31 pagesIntroduction To Maintenance: SMJ 4812 Proj. Management & Maintenance Engrg. Sem.I 2003/2004NatrajiNo ratings yet

- Type of MaintenancDocument10 pagesType of MaintenancMohammed ShantiNo ratings yet

- IntroductionDocument12 pagesIntroductionHemed hafidhNo ratings yet

- Topic 1 Maintenance: Unit 1 Understand The Maintenance SystemDocument13 pagesTopic 1 Maintenance: Unit 1 Understand The Maintenance SystemMohamad HizamiNo ratings yet

- Section No.: 7 / Title: Condition Based MaintenanceDocument5 pagesSection No.: 7 / Title: Condition Based Maintenancekrishna_14893No ratings yet

- MEM AssignmentDocument17 pagesMEM AssignmentDibyanshu GuruNo ratings yet

- Introduction To MaintenanceDocument38 pagesIntroduction To MaintenancemarianaNo ratings yet

- Chemical IndustriesDocument10 pagesChemical IndustriessunliasNo ratings yet

- Exp 6Document10 pagesExp 6Sayali PatilNo ratings yet

- Exp 05Document6 pagesExp 05Sayali PatilNo ratings yet

- Intro To MaintenanceDocument31 pagesIntro To Maintenancesharif339No ratings yet

- Design-Out Maintenance On Frequent Failure of Motor Ball Bearings-2-3 PDFDocument10 pagesDesign-Out Maintenance On Frequent Failure of Motor Ball Bearings-2-3 PDFIAEME PublicationNo ratings yet

- Nhà M 9Document7 pagesNhà M 9Zuy NguyenNo ratings yet

- M10 RewindingDocument124 pagesM10 RewindinggmnatigizawNo ratings yet

- Vibration Based Condition Monitoring of Rotating MDocument18 pagesVibration Based Condition Monitoring of Rotating MNidhal Ben KhalifaNo ratings yet

- Ueeneee110A Develop and Implement Energy Sector Maintenance Programs Assessment1 Maintenance Program DevelopmentDocument3 pagesUeeneee110A Develop and Implement Energy Sector Maintenance Programs Assessment1 Maintenance Program Developmentamrit palasaurNo ratings yet

- Maintenance of Equipment: Philippine Society of Mechanical Engineers Professional Development CourseDocument23 pagesMaintenance of Equipment: Philippine Society of Mechanical Engineers Professional Development CourseAngel Silva VicenteNo ratings yet

- Gas Turbine ModelsDocument11 pagesGas Turbine ModelsEngr Mubeen100% (1)

- Vibration BookDocument152 pagesVibration Bookrez_babu7430No ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Machine Reliability and Condition Monitoring: A Comprehensive Guide to Predictive Maintenance PlanningFrom EverandMachine Reliability and Condition Monitoring: A Comprehensive Guide to Predictive Maintenance PlanningRating: 4.5 out of 5 stars4.5/5 (2)

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- Electrical Maintenance L1Document57 pagesElectrical Maintenance L1Mouzy McthyNo ratings yet

- Logic Gates 3 NewDocument29 pagesLogic Gates 3 NewMouzy McthyNo ratings yet

- Maintenance AssingmentDocument3 pagesMaintenance AssingmentMouzy McthyNo ratings yet

- Small Signal Amplifire Lecture 1Document24 pagesSmall Signal Amplifire Lecture 1Mouzy McthyNo ratings yet

- UntitledDocument1 pageUntitledMouzy McthyNo ratings yet

- Question Majaliwa AssngmntDocument2 pagesQuestion Majaliwa AssngmntMouzy McthyNo ratings yet

- Lecture 5 - Teaching MethodsDocument37 pagesLecture 5 - Teaching MethodsMouzy Mcthy100% (1)

- PROJECTDocument1 pagePROJECTMouzy McthyNo ratings yet

- Course Outline Education Bachelor 2022Document3 pagesCourse Outline Education Bachelor 2022Mouzy McthyNo ratings yet

- Mechanics TestDocument4 pagesMechanics TestMouzy McthyNo ratings yet

- Wiska Varitain - 0912Document18 pagesWiska Varitain - 0912Anonymous hHWOMl4FvNo ratings yet

- Training Design SprintDocument11 pagesTraining Design Sprintardi wiantoNo ratings yet

- TCGRX BullsEye Tablet SplitterDocument2 pagesTCGRX BullsEye Tablet SplittermalucNo ratings yet

- Citrus Information Kit-Update: Reprint - Information Current in 1998Document53 pagesCitrus Information Kit-Update: Reprint - Information Current in 1998hamsa sewakNo ratings yet

- 2396510-14-8EN - r1 - Service Information and Procedures Class MDocument2,072 pages2396510-14-8EN - r1 - Service Information and Procedures Class MJuan Bautista PradoNo ratings yet

- Half Yearly Examination, 2017-18: MathematicsDocument7 pagesHalf Yearly Examination, 2017-18: MathematicsSusanket DuttaNo ratings yet

- Project Report For Tunnel ExcavationDocument19 pagesProject Report For Tunnel ExcavationAbhishek Sarkar50% (2)

- Brochure - OasisDocument24 pagesBrochure - OasisVivek RNo ratings yet

- Sustainable Strategic Management BarbosaDocument11 pagesSustainable Strategic Management BarbosapurwawardhaniNo ratings yet

- GNSS COrs SystemDocument20 pagesGNSS COrs SystemKostPutriMalangNo ratings yet

- Or HandoutDocument190 pagesOr Handoutyared haftu67% (6)

- Exemption in Experience & Turnover CriteriaDocument4 pagesExemption in Experience & Turnover CriteriaVivek KumarNo ratings yet

- The Other Twelve Part 1Document5 pagesThe Other Twelve Part 1vv380100% (2)

- All Nobel Prizes in LiteratureDocument16 pagesAll Nobel Prizes in LiteratureMohsin IftikharNo ratings yet

- Construction Claims and Contract Admin CPDDocument40 pagesConstruction Claims and Contract Admin CPDCraig FawcettNo ratings yet

- DatuinMA (Activity #5 - NSTP 10)Document2 pagesDatuinMA (Activity #5 - NSTP 10)Marc Alen Porlaje DatuinNo ratings yet

- CLT Apllications NewestDocument49 pagesCLT Apllications NewestMackBrideNo ratings yet

- Pipe Freezing StudyDocument8 pagesPipe Freezing StudymirekwaznyNo ratings yet

- The Perception of Luxury Cars MA Thesis 25 03Document60 pagesThe Perception of Luxury Cars MA Thesis 25 03Quaxi1954No ratings yet

- Te-Chemical Sem5 CPNM-CBCGS Dec19Document2 pagesTe-Chemical Sem5 CPNM-CBCGS Dec19Mayank ShelarNo ratings yet

- 한국항만 (영문)Document38 pages한국항만 (영문)hiyeonNo ratings yet

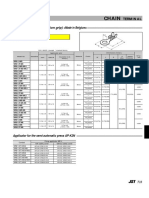

- Chain: SRB Series (With Insulation Grip)Document1 pageChain: SRB Series (With Insulation Grip)shankarNo ratings yet

- Pre-Paid Customer Churn Prediction Using SPSSDocument18 pagesPre-Paid Customer Churn Prediction Using SPSSabhi1098No ratings yet

- Sips 1328Document64 pagesSips 1328Jean Claude De AldánNo ratings yet

- The Teacher Research Movement: A Decade Later: Cite This PaperDocument13 pagesThe Teacher Research Movement: A Decade Later: Cite This PaperAlexandre NecromanteionNo ratings yet

- Su Poder en El Espiritu Santo Your Power in The Holy Spirit Spanish Edition by John G Lake PDFDocument4 pagesSu Poder en El Espiritu Santo Your Power in The Holy Spirit Spanish Edition by John G Lake PDFRodrigo MendezNo ratings yet

- Bassoon (FAGOT) : See AlsoDocument36 pagesBassoon (FAGOT) : See Alsocarlos tarancón0% (1)

- Maskote WB Zinc Stop-OffDocument7 pagesMaskote WB Zinc Stop-OffbondsivamaniNo ratings yet

- Oral Communication in ContextDocument19 pagesOral Communication in ContextAzory ZelleNo ratings yet