Professional Documents

Culture Documents

ProMAC SDS PDF

Uploaded by

Rian AnshariOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ProMAC SDS PDF

Uploaded by

Rian AnshariCopyright:

Available Formats

ProMAC Multi-Arm Caliper Tools

TM

Available with either HD (High-speed Digital) or PTX

telemetry, the ProMAC series Multi-Arm Caliper tools are

the latest generation of Probe electromechanical cased

hole logging instruments for measuring the internal

profile of the tubing, casing and completion assembly.

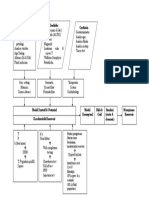

A multi-finger caliper log of the inside of a completion enables operators

to cost-effectively plan work-over and remedial operations, and to keep

historical records of the general condition of tubing and casing in order

to assess any problems associated to corrosion, wear or mechanical

deformation through the life of the well.

A series of independent radial measurements provided by the caliper

arms, also commonly referred to as “fingers”, yields a detailed image of

the inspected well that can be presented in various formats, including

a cross-section of the casing and a 3-dimensional, color-enhanced

visualization.

The ProMAC series tools are available in 24, 40 and 60-finger

configurations with a full range of measurement. The tools come in

1-11/16 in (43.0 mm), 2-3/4 in (69.9 mm) and 3-3/4 in (95.3 mm) O.D. to

log tubulars ranging from 1.75 to 11.75 in (44.5 to 298.4 mm).

As multi-arm caliper tools log the internal profile of the completion, the

actuation of each finger is converted to an individual electrical signal.

The signal is converted into a calibrated radial measurement that is

transmitted in a data frame that consists of a frame identifier, individual

finger channels, electronics temperature data and a checksum, at a

rate of 50 frames per second on HD (or at 10 frames per second on PTX).

Directional data is acquired simultaneously and can also be included in

the log presentation.

The ProMAC series multi-arm caliper tools incorporate mechanical,

electrical and electronic design features that enhance performance and

reliability, ultimately reflecting on customer ROI. Simple to service and

maintain, with interchangeable and common components between

different sizes. The ProMAC tools also incorporate robust temperature

compensation stability thanks to our patent-pending DVRTs. Surface

Read-Out capable with a Warrior™ cased-hole logging panel, or Memory

capable (only with HD telemetry), downhole data is plotted and

processed using Warrior™ software for all telemetry options.

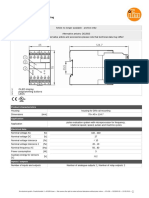

SPECIFICATIONS Well Integrity

MAC24 MAC40 MAC60

Mechanical Specifications

Outside diameter, in [mm] 1.69 [43.0] 2.75 [69.85] 3.75 [95.25]

Length, ft [m] 5.1 [1.55] 5.3 [1.62] 7.46 [1.66]

Weight, lb [kg] 25 [11.3] 80 [36.3] 135 [61.2]

Temperature rating, °F [°C] 350 [177] 350 [177] 350 [177]

Pressure rating, psi [MPa] 15,000 [103] 20,000 [138] 20,000 [138]

Number of fingers 24 40 60

Measurement Specifications

Diameter Range, in [mm] 1.75 – 7.0 [44.45 – 177.8] 3.0 – 9.63 [76.2 – 244.6] 4.0 – 11.75 [101.6 – 298.4]

Output Primary: 24, 40 or 60 Internal casing radii, inclination and rotation

Secondary: Head voltage, internal temperature

Logging speed, ft/min [m/min] Recommended: 30 [9.14], Maximum: 60 [18.28]

PTX HD

Vertical resolution, in [mm]

0.3 [7.6] 0.12 [3.0]

(at recommended logging speed)

Radial resolution, in [mm] 0.001 [0.025]

Radial accuracy, in [mm] +/- 0.02 [+/- 0.5]

Sampling rate (frames per second) 10 50

All PTX tools: All HD tools:

Combinability

GR, CCL, iQ, RADii GR, CCL, iQ, RADii, RAS, PLT

Sensor Type Caliper: DVRT Inclinometer: 3-axis accelerometer

Electrical Specifications

PTX HD

SRO 120 50

Voltage, V DC

Memory N/A 19.2

© 2020 Probe Technologies Holdings, Inc. All rights reserved.

ProMAC 2020.04.01

You might also like

- Toolmaster TM10 eDocument8 pagesToolmaster TM10 eMaskub Ulul KhrtNo ratings yet

- RSOP19 ReceivingDocument2 pagesRSOP19 ReceivingRian AnshariNo ratings yet

- EXCEL Shortcut KeysDocument4 pagesEXCEL Shortcut Keysruzsi07No ratings yet

- UL - Kobishi Horn & Strobe & Bell (DD 20200603)Document1 pageUL - Kobishi Horn & Strobe & Bell (DD 20200603)Chong JiazhenNo ratings yet

- Motorized Free Point Tool: Titan Division - InstrumentsDocument2 pagesMotorized Free Point Tool: Titan Division - InstrumentsCamilo CajiaoNo ratings yet

- Surface Roughness Tester Page 1Document1 pageSurface Roughness Tester Page 1SatyamEngNo ratings yet

- Wenzel Technical Data Sheet LH 1210 1512 Premium SelectDocument4 pagesWenzel Technical Data Sheet LH 1210 1512 Premium SelectBoris 'Junior' BorisovNo ratings yet

- Seniorsonicmarkiii WITH PROFILER or CPA 50EDocument8 pagesSeniorsonicmarkiii WITH PROFILER or CPA 50EmontanovillarroelfabiolalourdeNo ratings yet

- Thermal Analysis PDFDocument62 pagesThermal Analysis PDFGonzalo BenavidesNo ratings yet

- StratosH 2300 Scanner BrochureDocument2 pagesStratosH 2300 Scanner BrochureJohnny BarcodeNo ratings yet

- Smar Measument MF 8000Document4 pagesSmar Measument MF 8000Yerson JuarezNo ratings yet

- UHT Dimension - 2020-01a PDFDocument2 pagesUHT Dimension - 2020-01a PDFRian AnshariNo ratings yet

- DS Linear Motors P02-23Sx80Document19 pagesDS Linear Motors P02-23Sx80Arturo GomezNo ratings yet

- Samsung Gtn32se Chassis Le32a43tDocument140 pagesSamsung Gtn32se Chassis Le32a43tfaroltek100% (3)

- DuraMax - 60 - 022 - 273 I - eDocument4 pagesDuraMax - 60 - 022 - 273 I - eUmair HashamNo ratings yet

- RVP510 01 - en UsDocument4 pagesRVP510 01 - en UsJose Ernesto AcevedoNo ratings yet

- DM3058 Datasheet SaeligDocument8 pagesDM3058 Datasheet SaeligWilliamNo ratings yet

- Brochure LaserglowDocument1 pageBrochure LaserglowsheshidharrajubNo ratings yet

- Force Control DatasheetDocument2 pagesForce Control DatasheetDaniel P SaldiasNo ratings yet

- Tinius MeltPlastometerDocument6 pagesTinius MeltPlastometerHafiani HichamNo ratings yet

- DM3058 Datasheet PDFDocument8 pagesDM3058 Datasheet PDFmasrinaNo ratings yet

- DM3058 DatasheetDocument8 pagesDM3058 DatasheetmasrinaNo ratings yet

- General Specifications: Daqstation DX1000Document23 pagesGeneral Specifications: Daqstation DX1000Michael DouglasNo ratings yet

- Ficha Tecnica Vieojet Nuevo Ss-3130-UsDocument2 pagesFicha Tecnica Vieojet Nuevo Ss-3130-UsJhon RodriguezNo ratings yet

- Ramsey Micro-Tech 9101 Scale Electronics - ENDocument2 pagesRamsey Micro-Tech 9101 Scale Electronics - ENAlejandro SegoviaNo ratings yet

- 2.75IN HT 6-8 Sectors Radial Incremented Flyer 2021.01.22Document2 pages2.75IN HT 6-8 Sectors Radial Incremented Flyer 2021.01.22Adrian MartínezNo ratings yet

- Datasheet DD2603Document3 pagesDatasheet DD2603RONALD TERRAZASNo ratings yet

- 2012 DSC Brochure r1Document18 pages2012 DSC Brochure r1Harish Kumar KannepalliNo ratings yet

- BTU - LandisGyr-Ultraheat-Ultracold-T550-UH50Document6 pagesBTU - LandisGyr-Ultraheat-Ultracold-T550-UH50ahmed abdellahNo ratings yet

- Claa154wb03 An ChunghwapicturetubesDocument27 pagesClaa154wb03 An ChunghwapicturetubesNoel Alejandro Cordova RangelNo ratings yet

- Corector RometDocument2 pagesCorector RometJose Manuel CastroNo ratings yet

- CPT Claa080ua01 7.97'' PDFDocument23 pagesCPT Claa080ua01 7.97'' PDFxyc0nNo ratings yet

- FD201BDocument3 pagesFD201BVictor SandovalNo ratings yet

- 600 Configurable Controller Gefran ManualDocument29 pages600 Configurable Controller Gefran ManualAdrian GozarNo ratings yet

- J Control - DX 9100 Digital ControllerDocument104 pagesJ Control - DX 9100 Digital Controlleramhosny640% (1)

- Manual ElektrotanyaDocument18 pagesManual ElektrotanyaliviucatalinNo ratings yet

- TS Imcw2Document4 pagesTS Imcw2Guadalupe CondoriNo ratings yet

- Cat Electronic Technician 2017A v1.0 Product Status ReportDocument8 pagesCat Electronic Technician 2017A v1.0 Product Status ReportGlaidsonNo ratings yet

- Siemens 64slices CT - OdtDocument3 pagesSiemens 64slices CT - OdtDhon de CastroNo ratings yet

- Claa154wb03an ChunghwapicturetubesDocument21 pagesClaa154wb03an Chunghwapicturetubesadrian PușcașuNo ratings yet

- Yotta Cat EngDocument18 pagesYotta Cat EngMarcelo ChocaNo ratings yet

- HMT370EX Datasheet B211825ENDocument6 pagesHMT370EX Datasheet B211825ENAristo MNo ratings yet

- Videojet 3340: Laser Marking SystemDocument2 pagesVideojet 3340: Laser Marking Systemjoe dermawanNo ratings yet

- 100HSX Jul 2013Document2 pages100HSX Jul 2013roshanmechNo ratings yet

- Md71thd Sys Ds v05r00Document2 pagesMd71thd Sys Ds v05r00ABDUL ALIM100% (1)

- Valeport Midas CTDDocument67 pagesValeport Midas CTDXhuLE7oNo ratings yet

- Aries Laser PointerDocument2 pagesAries Laser PointersheshidharrajubNo ratings yet

- Druck - Adts 403Document4 pagesDruck - Adts 403bugoff700No ratings yet

- ProH CD700R300 PrecimeterDocument2 pagesProH CD700R300 PrecimetermaximeNo ratings yet

- Protherma PTS 2019.11.25Document2 pagesProtherma PTS 2019.11.25Rian AnshariNo ratings yet

- LINEAR MOTORS P01-48x240F-HP: DOC-NO. 0185-0110-D / VERSION 1V0 Subject To AlterationsDocument26 pagesLINEAR MOTORS P01-48x240F-HP: DOC-NO. 0185-0110-D / VERSION 1V0 Subject To Alterationsoctavinavarro8236No ratings yet

- 2010 Sanwa en PDFDocument35 pages2010 Sanwa en PDFh1k0No ratings yet

- MPU 800c: MPU Gas Ultrasonic FlowmeterDocument10 pagesMPU 800c: MPU Gas Ultrasonic FlowmeterKamal SkNo ratings yet

- MFC24C-A Operation Manual PDFDocument30 pagesMFC24C-A Operation Manual PDFJuan Mejia OspinaNo ratings yet

- DD2503 00 - en GBDocument2 pagesDD2503 00 - en GBGoran MladenovicNo ratings yet

- Optrex TCG057QVLGA G00-3181863Document22 pagesOptrex TCG057QVLGA G00-3181863May OchoaNo ratings yet

- RS-WZ3WZ1-N01-1 Operation Manual of Temperature Vibration Transmitter (RS485Type)Document14 pagesRS-WZ3WZ1-N01-1 Operation Manual of Temperature Vibration Transmitter (RS485Type)Vendas BPSNo ratings yet

- PTU300 Datasheet B210954EN HDocument5 pagesPTU300 Datasheet B210954EN HMarlon Zambrano PalmaNo ratings yet

- MicroESystems Mercury3000VSi DataSheetDocument10 pagesMicroESystems Mercury3000VSi DataSheetElectromateNo ratings yet

- Spesifikasi Mobile ListemDocument2 pagesSpesifikasi Mobile ListemnanirakalaNo ratings yet

- Practical Embedded Controllers: Design and Troubleshooting with the Motorola 68HC11From EverandPractical Embedded Controllers: Design and Troubleshooting with the Motorola 68HC11No ratings yet

- Protherma PTS 2019.11.25Document2 pagesProtherma PTS 2019.11.25Rian AnshariNo ratings yet

- Ras003 Reservoir Analysis Sonde Sigma Only PDFDocument2 pagesRas003 Reservoir Analysis Sonde Sigma Only PDFRian AnshariNo ratings yet

- Ras002 Reservoir Analysis Sonde Sigma Co PDFDocument2 pagesRas002 Reservoir Analysis Sonde Sigma Co PDFRian AnshariNo ratings yet

- Spectral Gamma Ray CCL Tool 275 PDFDocument2 pagesSpectral Gamma Ray CCL Tool 275 PDFRian Anshari100% (1)

- Protherma PTS 2019.11.25Document2 pagesProtherma PTS 2019.11.25Rian AnshariNo ratings yet

- UHT Dimension - 2020-01a PDFDocument2 pagesUHT Dimension - 2020-01a PDFRian AnshariNo ratings yet

- Production Logging SolutionsDocument4 pagesProduction Logging SolutionsRian AnshariNo ratings yet

- Probe - Kuster K10 Geothermal PTS (Sro)Document1 pageProbe - Kuster K10 Geothermal PTS (Sro)Rian AnshariNo ratings yet

- CET 2021 ProvisionalDocument1 pageCET 2021 ProvisionalRian AnshariNo ratings yet

- XS-XL-working DocumentDocument2 pagesXS-XL-working DocumentRian AnshariNo ratings yet

- Video Instruments 2020 Flodim PDFDocument2 pagesVideo Instruments 2020 Flodim PDFRian AnshariNo ratings yet

- UNSPSCDocument2,058 pagesUNSPSCBagus TriwantoroNo ratings yet

- EZ Cutter - G3 2020 Flodim PDFDocument2 pagesEZ Cutter - G3 2020 Flodim PDFRian AnshariNo ratings yet

- Paper Casing Design Geothermal FIX2Document25 pagesPaper Casing Design Geothermal FIX2Rian AnshariNo ratings yet

- Point - VIVID (Slide)Document41 pagesPoint - VIVID (Slide)Rian AnshariNo ratings yet

- Form RequestDocument1 pageForm RequestRian AnshariNo ratings yet

- RSOP34 Food Safety Training ProgramDocument1 pageRSOP34 Food Safety Training ProgramRian AnshariNo ratings yet

- New Well TestDocument5 pagesNew Well TestRian AnshariNo ratings yet

- HSE-01 Evaluating and Improving: Health, Safety & Environment ManualDocument7 pagesHSE-01 Evaluating and Improving: Health, Safety & Environment ManualRian AnshariNo ratings yet

- Integrated Reservoir Information System in Kamojang, IndonesiaDocument7 pagesIntegrated Reservoir Information System in Kamojang, IndonesiaRian AnshariNo ratings yet

- HSE-01 Evaluating and Improving: Health, Safety & Environment ManualDocument7 pagesHSE-01 Evaluating and Improving: Health, Safety & Environment ManualRian AnshariNo ratings yet

- RSOP34a Annual Training CalendarDocument1 pageRSOP34a Annual Training CalendarRian AnshariNo ratings yet

- Geothermal Reservoir Management in Iceland: As A Renewable EnergyDocument6 pagesGeothermal Reservoir Management in Iceland: As A Renewable EnergyRian AnshariNo ratings yet

- Geothermal Reservoir Management in Iceland: As A Renewable EnergyDocument6 pagesGeothermal Reservoir Management in Iceland: As A Renewable EnergyRian AnshariNo ratings yet

- Flow Chart GOOODocument1 pageFlow Chart GOOORian AnshariNo ratings yet

- Peralatan PemboranDocument25 pagesPeralatan PemboranRian AnshariNo ratings yet

- Daftar PustakaDocument1 pageDaftar PustakaRian AnshariNo ratings yet

- Gothermal HandbookDocument89 pagesGothermal HandbookRian AnshariNo ratings yet

- Introduction To Boolean LogicDocument5 pagesIntroduction To Boolean LogicTapaswiniNo ratings yet

- (M5-M7) PHPDocument96 pages(M5-M7) PHPAngelo PayodNo ratings yet

- 04 U2000 ATAE IntroductionDocument16 pages04 U2000 ATAE IntroductionHung NguyenNo ratings yet

- Globacom Hybid Power Solution Installation Guide Cosmos-LibreDocument18 pagesGlobacom Hybid Power Solution Installation Guide Cosmos-LibreLuis MadridNo ratings yet

- F15 Depron PDFDocument2 pagesF15 Depron PDFKarlieNo ratings yet

- 03 - Performing Security AssessmentsDocument78 pages03 - Performing Security AssessmentsDoraemonNo ratings yet

- Use Case ModelingDocument31 pagesUse Case ModelingpacharneajayNo ratings yet

- An Analysis of The Cloud Computing Security ProblemDocument8 pagesAn Analysis of The Cloud Computing Security ProblemKarthik KrishnamurthiNo ratings yet

- Multi-Dimensional Information-Driven Many-Objective Software Remodularization ApproachDocument18 pagesMulti-Dimensional Information-Driven Many-Objective Software Remodularization ApproachIoana SoraNo ratings yet

- Sample BOS IoT Lite BMS Topology DiagramDocument2 pagesSample BOS IoT Lite BMS Topology DiagramWalter BarbaNo ratings yet

- Lenovo Watch 9 User Guide EnglishDocument2 pagesLenovo Watch 9 User Guide EnglishKhairulAshraafNo ratings yet

- K200 and FIL 2 Errors. Case No. DC119429Document62 pagesK200 and FIL 2 Errors. Case No. DC119429Mikal SmithNo ratings yet

- Internal Attachment ReportDocument12 pagesInternal Attachment ReportDaniel50% (2)

- Ospf Lab GuidDocument3 pagesOspf Lab Guidfalaad64No ratings yet

- Introduction To Accounting Data Analytics and Visualization Module 1Document55 pagesIntroduction To Accounting Data Analytics and Visualization Module 1Tareq AzizNo ratings yet

- CTR 8500-8300 3.6.0 TACACS+ CLI Commands - July2018Document16 pagesCTR 8500-8300 3.6.0 TACACS+ CLI Commands - July2018Bryan Delfín Aguirre OrtegaNo ratings yet

- UntitledDocument13 pagesUntitledSonu KumarNo ratings yet

- Mathematical Model and System Identification To Optimize Inputs Conditions For Plant Design of CyclohexaneDocument28 pagesMathematical Model and System Identification To Optimize Inputs Conditions For Plant Design of CyclohexaneBüşraNo ratings yet

- Ey Hfs Top 10 Application Modernization Services 2022 Ey Excerpt PDFDocument36 pagesEy Hfs Top 10 Application Modernization Services 2022 Ey Excerpt PDFSowmya MuraliNo ratings yet

- The Rise of Linux - The Battle For The Operating System MarketDocument18 pagesThe Rise of Linux - The Battle For The Operating System MarketNikhil BhaskarNo ratings yet

- DBMS Lab - Manual Dec 15, 2020Document22 pagesDBMS Lab - Manual Dec 15, 2020harshNo ratings yet

- Dokumen - Tips Ericsson Rbs Ret Alarms Troubleshooting Guide Flow Chart v2Document1 pageDokumen - Tips Ericsson Rbs Ret Alarms Troubleshooting Guide Flow Chart v2Oscar GonzalezNo ratings yet

- Interfacing Python To MysqlDocument20 pagesInterfacing Python To MysqlmalathiNo ratings yet

- Workflows For Depth-Converting KINGDOM Project DataDocument10 pagesWorkflows For Depth-Converting KINGDOM Project DataSoltani AkRêmNo ratings yet

- HNS Level IIIDocument34 pagesHNS Level IIIAbebe Gosu100% (3)

- Standard Data Formats For Analytical Systems: Status and ChallengesDocument1 pageStandard Data Formats For Analytical Systems: Status and ChallengeschatNo ratings yet

- Conducting Research in A PandemicDocument23 pagesConducting Research in A PandemicRech SarzabaNo ratings yet

- Lesson Plan Ict 5Document5 pagesLesson Plan Ict 5api-278398808No ratings yet