Professional Documents

Culture Documents

Fi-01 - 08-04-23 Spring BDTS

Uploaded by

cmsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fi-01 - 08-04-23 Spring BDTS

Uploaded by

cmsCopyright:

Available Formats

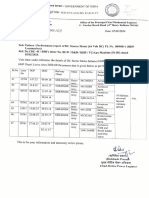

रसायनिक एवं धातक

ु र्म प्रयोगशाला

CHEMICAL AND METALLURGICAL LABORATORY

(NABL ACCREDITED AS PER ISO/IEC: 17025-2017)

Carriage Repair Workshop, Lower Parel, Mumbai-400013 No.:

Phone: 022-676-40012/40576/40160, Email: cmslowerparel@gmail.com

C&M/MI/Carriage/PL Date: 25.04.2023

Sr.CDO-BDTS

Sub: Metallurgical Investigation Report of failed LHB springs (08 No’s)

Ref: Sr. CDO/BDTS’s letter no. S/BDTS/13 C(II), dtd 31.03.2023

METALLURGICAL INVESTIGATION REPORT

Train No./ PL No./ POH Location Hardness

Sr. Name of the Stamping Date of

Coach No. & Lab No. Drg. No./ Mfg. Station, (fitment/ (45-51 Cause of failure

No item Particulars failure

Code Spec No. Sch. & dt. breakage) RC)

The breakage of the top first coil of

19037/

33500678/ CMICF primary outer spring with about 20%

Primary 203095 ICF Top first

1 FI-01-04-23 LG01100/ CMICF 0320 F07 28/03/23 fatigue mode may be attributed to

outer spring LWSCN/ 19/08/2020 coil

RDSO/ R07 hitting marks due to hitting of the coil

WR

2017/CG-01 with end tip of top flat portion.

The breakage of the bottom first coil

19037/ 33500678/ of primary outer spring with about

CMSTL

Primary 217114 FI-02-04-23 LG01100/ ICF Bottom 35% progressive fatigue mode may be

2 CMSTL 0622 F07 26/03/23

outer spring LWS/ RDSO/ 11/2021 first coil attributed to hitting marks due to

N56

WR 2017/CG-01 hitting of the coil with end tip of

bottom flat portion.

The breakage of the Top first coil of

primary outer spring with about 20%

22922/ 33500678/

CMICF & 55% progressive fatigue mode

Primary 217111 FI-03-04-23 LG01100/ ICF Top first

3 CMICF 0721 F07 24/03/23 respectively may be attributed to

outer spring LSLRD/ RDSO/ 30/11/2021 coil

17 hitting marks, severe biting marks due

WR 2017/CG-01

to hitting of the coils with top flat

portions.

The breakage of the bottom first coil

12907/ 33503035/

CMSTL of primary outer spring with about

Primary 211060 FI-04-04-23 1267411/ MCF Bottom

4 CMSTL 1119 F03 21/03/23 20% fatigue mode may be attributed

outer spring LWCBAC/ RDSO/ 23/01/2021 first coil

N9 to hitting marks due to hitting of the

WR 2017/CG-01

coil with bottom centering disc.

The breakage of the top first coil of

19037/ 33503035/

CMSTL primary outer spring with about 10%

Primary 196221 FI-05-04-23 1267411/ PL Top first

5 CMSTL 1119 F03 28/03/23 fatigue mode may be attributed to

outer spring LWCBAC/ RDSO/ 21/10/2022 coil

N02 hitting marks due to hitting of the coil

WR 2017/CG-01

with top flat portion.

The breakage of the Top first coil of

19037/ 33503035/ primary outer spring with about 15%

CMSTL

Primary 196221 FI-06-04-23 1267411/ PL Top first progressive fatigue mode may be

6 CMSTL 1119 F03 28/03/23

outer spring LWCBAC/ RDSO/ 21/10/2022 coil attributed to hitting marks due to

902

WR 2017/CG-01 hitting of the coils with top flat

portions.

The breakage of the top first coil of

19037/ 33503035/

CMSTL primary outer spring with about 50%

Primary 196221 FI-07-04-23 1267411/ PL Top first

7 CMSTL 1018 F03 28/03/23 fatigue mode may be attributed to

outer spring LWCBAC/ RDSO/ 21/10/2022 coil

91 hitting marks due to hitting of the coil

WR 2017/CG-01

with top flat portion.

The breakage of the top first coil of

19037/ 33500666/ primary inner spring with about 45%

CMICF

Primary 203095 FI-08-04-23 LG01101/ ICF Top first fatigue mode may be attributed to

8 CMICF 0320 F06 28/03/23

inner spring LWSCN/ RDSO/ 19/08/2020 coil hitting marks due to hitting of the

22

WR 2017/CG-01 coil, near vicinity of end tip of top flat

portion.

Remark: Hardness of the springs is satisfactory. All of the above springs have broken due to hitting marks/biting marks.

Since spring material bears high notch sensitivity therefore presence of any kind of dent/hitting marks/corrosion pits will make the spring detrimental.

ACMT/PL

C/- Dy. CME (Chg)/CCG

C/- SSE/Ftg-II/PL

You might also like

- Failed Springs Investigation ReportDocument2 pagesFailed Springs Investigation ReportcmsNo ratings yet

- Fi-16 - 17-04-23 Spring DadnDocument1 pageFi-16 - 17-04-23 Spring DadncmsNo ratings yet

- Metallurgical Investigation Report of Failed Springs Highlights Fatigue Caused by HittingDocument1 pageMetallurgical Investigation Report of Failed Springs Highlights Fatigue Caused by HittingcmsNo ratings yet

- FI-15!04!23 Primary Outer Springs ADI BGDocument2 pagesFI-15!04!23 Primary Outer Springs ADI BGcmsNo ratings yet

- Vedanta Limited Integrated Field Plan Inspection ReportsDocument23 pagesVedanta Limited Integrated Field Plan Inspection ReportsPRAKASH PANDEYNo ratings yet

- Unit Estimate of ATDocument3 pagesUnit Estimate of ATSSE TRD JabalpurNo ratings yet

- Bof Lab Daily Production Report: TotalDocument2 pagesBof Lab Daily Production Report: TotalBinod Kumar PadhiNo ratings yet

- Performance Report of DC Starter MotorDocument1 pagePerformance Report of DC Starter MotorKaushik SahaNo ratings yet

- Mill Test Certificate: Customer Name/Address StampDocument1 pageMill Test Certificate: Customer Name/Address StampD S Sagar TripuramalluNo ratings yet

- 21055-Acoustics India - 15nosDocument27 pages21055-Acoustics India - 15nosgowtham_venkat_4No ratings yet

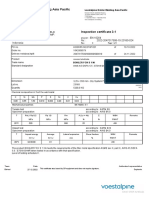

- Inspection Certificate 3.1Document1 pageInspection Certificate 3.1YUDI IRMAWANTONo ratings yet

- TL - Genius - Bulb - CTRL - v1 1Document4 pagesTL - Genius - Bulb - CTRL - v1 1gautamkr15No ratings yet

- Shift-Wise Production Report (Under Ground) Form 1 - ADocument2 pagesShift-Wise Production Report (Under Ground) Form 1 - Aagrawalharshit27No ratings yet

- PIN LI-CQA-104-F-02Document11 pagesPIN LI-CQA-104-F-02MOHD SUHAILNo ratings yet

- Newly Prepared BbsDocument5 pagesNewly Prepared BbsMOHD SUHAILNo ratings yet

- PO SR - No.8, HEL REPORT 120004Document4 pagesPO SR - No.8, HEL REPORT 120004Agni DuttaNo ratings yet

- Electrical Cable SizesDocument2 pagesElectrical Cable Sizesanand OraseNo ratings yet

- Yokogawa: Y/17B6 Pneumatic Buoyancy Transmitter User's ManualDocument5 pagesYokogawa: Y/17B6 Pneumatic Buoyancy Transmitter User's ManualRabah AmidiNo ratings yet

- BOF Daily Production ReportDocument3 pagesBOF Daily Production ReportBinod Kumar PadhiNo ratings yet

- Precision Equipments (Chennai) Pvt. LTD.: Design Data Tema TypeDocument2 pagesPrecision Equipments (Chennai) Pvt. LTD.: Design Data Tema TypeAnonymous AyDvqgNo ratings yet

- VT23 - Workshop Laundry Swb. - 20.10Document6 pagesVT23 - Workshop Laundry Swb. - 20.10TamNo ratings yet

- Crompton Motor Datasheet 0.75EN4 - 06dec23182720Document7 pagesCrompton Motor Datasheet 0.75EN4 - 06dec23182720Suhas KambleNo ratings yet

- MB 0094 2e - Mx23aDocument7 pagesMB 0094 2e - Mx23aThomas JoseNo ratings yet

- Welder Qualification Test Parameter Sheet: Weld LayerDocument16 pagesWelder Qualification Test Parameter Sheet: Weld Layergulu padhanNo ratings yet

- Corrections Track Record Cum PTR SheetDocument11 pagesCorrections Track Record Cum PTR SheetParag WadekarNo ratings yet

- Boletin Tecnico USA Abs FordDocument5 pagesBoletin Tecnico USA Abs FordjuvenildobusinNo ratings yet

- Cementing ProgrammeDocument11 pagesCementing ProgrammeAutumn Assirem TrefoilNo ratings yet

- 1.5MM 304Document1 page1.5MM 304pankaj kumarNo ratings yet

- Speed vs Current CurveDocument7 pagesSpeed vs Current CurveRahesh MNo ratings yet

- Surge DiverterDocument2 pagesSurge DiverterKa TranNo ratings yet

- MTC 2257 SPECTRA 304 HR COIL 8mm X 1250Document1 pageMTC 2257 SPECTRA 304 HR COIL 8mm X 1250Amit Kumar OjhaNo ratings yet

- Maxstar 200 SD, DX, and LX: CE and Non-CE Models (Including Optional Cart and Cooler)Document16 pagesMaxstar 200 SD, DX, and LX: CE and Non-CE Models (Including Optional Cart and Cooler)Noe AriasNo ratings yet

- Operation Bulletin (Production Guide Line) : Flamingo Fashions Limited (Lingerie)Document3 pagesOperation Bulletin (Production Guide Line) : Flamingo Fashions Limited (Lingerie)Jahangir Alam SohagNo ratings yet

- Fi-43 - 48-04-23 SbiDocument2 pagesFi-43 - 48-04-23 SbicmsNo ratings yet

- Epcon C8: Steel Reinforcement Fixings For Reinforced ConcreteDocument3 pagesEpcon C8: Steel Reinforcement Fixings For Reinforced ConcreteAhmed Samir SalimNo ratings yet

- R.K Steel Udyog PVT - LTD: Test Certificate For High Strength Deformed Steel Bars and Wires For Concrete ReinforcementDocument2 pagesR.K Steel Udyog PVT - LTD: Test Certificate For High Strength Deformed Steel Bars and Wires For Concrete Reinforcementnanda kishopre100% (4)

- Kde5000ta PDFDocument36 pagesKde5000ta PDFJoaquim MoraisNo ratings yet

- KDE5000TADocument6 pagesKDE5000TANelson PrillesNo ratings yet

- 267-MAINTENANCE REPORT 2 BR en USDocument4 pages267-MAINTENANCE REPORT 2 BR en USAndré AmorimNo ratings yet

- zs11 Tso BsoDocument177 pageszs11 Tso BsoRAMSEVAK SINGHNo ratings yet

- RATESDocument33 pagesRATESNagaraju NayakNo ratings yet

- GRC COLUMN CASE 2 ReplayDocument11 pagesGRC COLUMN CASE 2 Replayhazem badawyNo ratings yet

- Corrosion Resistant Steel JFE-SIP - OT1 For Bottom Plate of Cargo Oil Tanks of Crude Oil TankersDocument3 pagesCorrosion Resistant Steel JFE-SIP - OT1 For Bottom Plate of Cargo Oil Tanks of Crude Oil TankersSami KahtaniNo ratings yet

- Schedule of Rate for Standard Stock Materials Common SR 2021-22 (11 kV SystemDocument27 pagesSchedule of Rate for Standard Stock Materials Common SR 2021-22 (11 kV SystemkaleemNo ratings yet

- HF-632 (1) Magnetic CompassDocument16 pagesHF-632 (1) Magnetic CompassAndrey ZhmurkoNo ratings yet

- CG Power and Industrial Solutions Limited: Dimensional DrawingDocument7 pagesCG Power and Industrial Solutions Limited: Dimensional DrawingRahesh MNo ratings yet

- Running Account BillDocument9 pagesRunning Account Billashish1100100% (2)

- Final inspection and test reportsDocument7 pagesFinal inspection and test reportssami maNo ratings yet

- Ford Mondero Tbs 2007Document5 pagesFord Mondero Tbs 2007Vecino CamayNo ratings yet

- Jyoti Engineering Works: Chemical AnalysisDocument8 pagesJyoti Engineering Works: Chemical AnalysisKristin CrawfordNo ratings yet

- Project Title: Detailed Engineering of Methanol Export Line To New Liquid JettyDocument3 pagesProject Title: Detailed Engineering of Methanol Export Line To New Liquid JettypavanNo ratings yet

- Compressor Failure ReportDocument11 pagesCompressor Failure ReportudbarryNo ratings yet

- Int. Concc.Document28 pagesInt. Concc.Vivek Kumar GopeNo ratings yet

- Example #3-Sdr-23-052-A662 - Nrc20-Panel 481 Al and 471ar DamagedDocument3 pagesExample #3-Sdr-23-052-A662 - Nrc20-Panel 481 Al and 471ar Damagedtanloc.tfcNo ratings yet

- Schedule of Rate For Standard Stock Materials Common SR 2021-22 (11 KV System)Document161 pagesSchedule of Rate For Standard Stock Materials Common SR 2021-22 (11 KV System)sagar mukulNo ratings yet

- Eqt Test RecordsDocument12 pagesEqt Test RecordsBabu Pro50% (2)

- ME 303 - 09 - Machining IIIDocument50 pagesME 303 - 09 - Machining IIITt OwnsqqNo ratings yet

- PROJECT LOAD DETAILSDocument1 pagePROJECT LOAD DETAILSzfrlNo ratings yet

- Delivery OrderDocument2 pagesDelivery OrderKANISHK KOHLINo ratings yet

- Bonny Norton Peirce - Social Identity and InvestmentDocument24 pagesBonny Norton Peirce - Social Identity and InvestmentAllie SANo ratings yet

- Perspective Homework RubricDocument2 pagesPerspective Homework Rubricapi-244578825No ratings yet

- Aspen Separation Unit-OpsDocument25 pagesAspen Separation Unit-Opsedwin dableoNo ratings yet

- Holes Human Anatomy and Physiology 12Th Edition Shier Test Bank Full Chapter PDFDocument53 pagesHoles Human Anatomy and Physiology 12Th Edition Shier Test Bank Full Chapter PDFJakeOwensbnpm100% (9)

- UX DesignDocument96 pagesUX DesignParisa Zarifi100% (3)

- Kma 252 Exam 18 NewstyleDocument19 pagesKma 252 Exam 18 NewstyleSebin GeorgeNo ratings yet

- Phillips Petroleum Co. v. Mississippi, 484 U.S. 469 (1988)Document21 pagesPhillips Petroleum Co. v. Mississippi, 484 U.S. 469 (1988)Scribd Government DocsNo ratings yet

- The Impact of Interest Rates On Economic Growth in KenyaDocument41 pagesThe Impact of Interest Rates On Economic Growth in KenyaSAMUEL KIMANINo ratings yet

- 40 Inventive Principles Applied to Service OperationsDocument16 pages40 Inventive Principles Applied to Service Operationssina yadegariNo ratings yet

- Case StudiesDocument19 pagesCase StudiesSorin MarkovNo ratings yet

- Macalloy Corporate Brochure September 2018 LR PDFDocument12 pagesMacalloy Corporate Brochure September 2018 LR PDFsampathkumarNo ratings yet

- Michigan English TestDocument22 pagesMichigan English TestLuisFelipeMartínezHerediaNo ratings yet

- Paratech Brochures RSSDocument12 pagesParatech Brochures RSSTatiana Andrea Carvajal GutierrezNo ratings yet

- Demolition and excavation worksDocument30 pagesDemolition and excavation worksHafizan Hanafiah100% (3)

- KORT RENZO C. BESARIO BS NURSING LESSON REVIEWDocument3 pagesKORT RENZO C. BESARIO BS NURSING LESSON REVIEWDummy AccountNo ratings yet

- Literature Review On OscilloscopeDocument5 pagesLiterature Review On Oscilloscopedhjiiorif100% (1)

- Ritual and Religion Course at University of EdinburghDocument10 pagesRitual and Religion Course at University of EdinburghRenata DC MenezesNo ratings yet

- Does Cash App Have Business Accounts - Google SeaDocument1 pageDoes Cash App Have Business Accounts - Google SeaAdedayo CrownNo ratings yet

- Prenatal DevelopmentDocument23 pagesPrenatal DevelopmentLF90No ratings yet

- StressesDocument61 pagesStressesMuhammad MusaNo ratings yet

- Leaders Eat Last - Book Summary - VWS - v2.0Document23 pagesLeaders Eat Last - Book Summary - VWS - v2.0REEM HAMDY100% (1)

- BS 0812-114 - 1989Document12 pagesBS 0812-114 - 1989عمر عمرNo ratings yet

- Resume Dianne Ostrander 4-27-06-09Document2 pagesResume Dianne Ostrander 4-27-06-09api-12400587No ratings yet

- Business Ethics Q3 Mod2 Foundations of The Principles of Business1Document5 pagesBusiness Ethics Q3 Mod2 Foundations of The Principles of Business1Julie CabusaoNo ratings yet

- 2Tafseer2019Sep4 17 24oc1 8 29nov5 262020jan7 21F11 18 25Document96 pages2Tafseer2019Sep4 17 24oc1 8 29nov5 262020jan7 21F11 18 25Aroob YaseenNo ratings yet

- Cbs BookDocument294 pagesCbs Bookadmiralninja100% (1)

- Y10 ICT End of TermDocument7 pagesY10 ICT End of TermIvy Atuhairwe BisoborwaNo ratings yet

- Superb Estate: PricesDocument10 pagesSuperb Estate: PricesReal GandeaNo ratings yet

- Mental Health Awareness and PFA Training ReportDocument4 pagesMental Health Awareness and PFA Training ReportSHEILA MAE PERTIMOS100% (14)

- Negros IslandDocument18 pagesNegros IslandGrace AmaganNo ratings yet