Professional Documents

Culture Documents

Fi-16 - 17-04-23 Spring Dadn

Uploaded by

cms0 ratings0% found this document useful (0 votes)

36 views1 pageOriginal Title

FI-16_17-04-23 SPRING DADN

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

36 views1 pageFi-16 - 17-04-23 Spring Dadn

Uploaded by

cmsCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 1

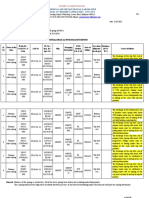

रसायनिक एवं धातुकर्म प्रयोगशाला

CHEMICAL AND METALLURGICAL LABORATORY

(NABL ACCREDITED AS PER ISO/IEC: 17025-2017)

Carriage Repair Workshop, Lower Parel, Mumbai-400013

Phone: 022-676-40012/40576/40160, Email: cmslowerparel@gmail.com No.:

C&M/MI/Carriage/PL Date: 25.04.2023

Sr.CDO/ICD/IND

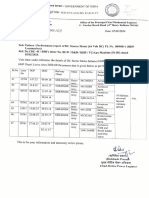

Sub: Metallurgical Investigation Report of failed springs (02 No’s)

Ref: SSE/DADN’s letter no. M 442/ADME/DADN/04/2023 dtd. 09.04.2023

METALLURGICAL INVESTIGATION REPORT

Train No./ PL No./ POH Location Hardness

Sr. Name of Stamping Date of

Coach No. & Lab No. Drg. No./ Spec Mfg. Station, (fitment/ (45-51 Cause of failure

No the item Particulars failure

Code No. Sch. & dt. breakage) RC)

The breakage of the top first coil of

201205 33500356/ CMSTL

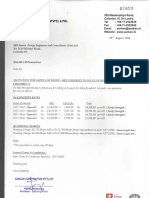

Primary ICF Bottom primary outer spring with about 15%

1 LWLRRM/ FI-16-04-23 1277143 CMSTL 0522 F04 20/03/23

inner spring 11/02/2020 first coil fatigue may be attributed to hitting of

WR RDSO/2017/ N5

coils.

CG-01

The breakage of the top first coil of

33500356/

203055 CMSTL primary outer spring with about 25%

Primary FI-17-04-23 1277143 RCF Bottom

2 LWACCN/ CMSTL 0422 F04 23/01/23 fatigue may be attributed to hitting

inner spring RDSO/2017/ 01/09/2021 first coil

NCR N18 marks, paint peeled off due to hitting

CG-01

of coil with top flat portion.

Remark: Hardness of the springs is satisfactory. All of the above springs have broken due to mutual hitting.

Since spring material bears high notch sensitivity therefore presence of any kind of dent/hitting marks/corrosion pits will make the spring detrimental.

ACMT/PL

C/- Dy. CME(Chg)/CCG

C/- SSE/Ftg-II/PL

You might also like

- Fi-16 - 17-04-23 Spring DadnDocument1 pageFi-16 - 17-04-23 Spring DadncmsNo ratings yet

- Fi-11 - 14-04-23 Spring IndDocument2 pagesFi-11 - 14-04-23 Spring IndcmsNo ratings yet

- Fi-01 - 08-04-23 Spring BDTSDocument2 pagesFi-01 - 08-04-23 Spring BDTScmsNo ratings yet

- FI-15!04!23 Primary Outer Springs ADI BGDocument2 pagesFI-15!04!23 Primary Outer Springs ADI BGcmsNo ratings yet

- Eqt Test RecordsDocument12 pagesEqt Test RecordsBabu Pro50% (2)

- Boletin Tecnico USA Abs FordDocument5 pagesBoletin Tecnico USA Abs FordjuvenildobusinNo ratings yet

- Mill Test Certificate: Customer Name/Address StampDocument1 pageMill Test Certificate: Customer Name/Address StampD S Sagar TripuramalluNo ratings yet

- Amuria FamDocument1 pageAmuria FamOkello StevenNo ratings yet

- 21055-Acoustics India - 15nosDocument27 pages21055-Acoustics India - 15nosgowtham_venkat_4No ratings yet

- 1.20mm T.C - Mehta SteelsDocument1 page1.20mm T.C - Mehta SteelsRonak FireNo ratings yet

- Fi-43 - 48-04-23 SbiDocument2 pagesFi-43 - 48-04-23 SbicmsNo ratings yet

- 1 20mm T C Mehta SteelsDocument1 page1 20mm T C Mehta Steelsmadhav jadhavNo ratings yet

- DDDDDDDocument43 pagesDDDDDDDhanush NairNo ratings yet

- JSW Steel Limited: Test Certificate For Cold Reduced Low Carbon Steel Sheet & StripDocument1 pageJSW Steel Limited: Test Certificate For Cold Reduced Low Carbon Steel Sheet & StripVenkatesh KumarNo ratings yet

- Performance Report of DC Starter MotorDocument1 pagePerformance Report of DC Starter MotorKaushik SahaNo ratings yet

- Scheduled Oil Sampling Report: Customer Information Unit InformationDocument2 pagesScheduled Oil Sampling Report: Customer Information Unit InformationDharmaNugrahaNo ratings yet

- DTHW 005Document1 pageDTHW 005Angga 99No ratings yet

- MTC 2257 SPECTRA 304 HR COIL 8mm X 1250Document1 pageMTC 2257 SPECTRA 304 HR COIL 8mm X 1250Amit Kumar OjhaNo ratings yet

- Mill Test Certificate: Jindal Stainless (Hisar) LimitedDocument1 pageMill Test Certificate: Jindal Stainless (Hisar) Limitedhemantmech099200No ratings yet

- Epcon C8: Steel Reinforcement Fixings For Reinforced ConcreteDocument3 pagesEpcon C8: Steel Reinforcement Fixings For Reinforced ConcreteAhmed Samir SalimNo ratings yet

- TL - Genius - Bulb - CTRL - v1 1Document4 pagesTL - Genius - Bulb - CTRL - v1 1gautamkr15No ratings yet

- GRC COLUMN CASE 2 ReplayDocument11 pagesGRC COLUMN CASE 2 Replayhazem badawyNo ratings yet

- JSW Steel Limited: To M/S, Transpares LimitedDocument4 pagesJSW Steel Limited: To M/S, Transpares LimitedSandeep KashyapNo ratings yet

- 1.5 SCH 40 (B2101104)Document1 page1.5 SCH 40 (B2101104)Mahmoud MetwallyNo ratings yet

- 1913 - 2018 08 04 13 27 21 - 1533369458 PDFDocument1 page1913 - 2018 08 04 13 27 21 - 1533369458 PDFAshish RathodNo ratings yet

- Ford Mondero Tbs 2007Document5 pagesFord Mondero Tbs 2007Vecino CamayNo ratings yet

- HR 3.50MM July 2019Document1 pageHR 3.50MM July 2019satrughana patraNo ratings yet

- Corrections Track Record Cum PTR SheetDocument11 pagesCorrections Track Record Cum PTR SheetParag WadekarNo ratings yet

- MTC For BoltDocument2 pagesMTC For Boltrizwan40% (5)

- Certificate of Conformity: Applicable Specs / ProceduresDocument99 pagesCertificate of Conformity: Applicable Specs / Proceduresaditya rastogiNo ratings yet

- 9802/5830 F4-3-1 Motor, Swing & Slew RingDocument3 pages9802/5830 F4-3-1 Motor, Swing & Slew RingLiliana GarciaNo ratings yet

- Welding Procedure B69AWDocument2 pagesWelding Procedure B69AWMastram HatheshNo ratings yet

- 304 1.5MM PCDocument1 page304 1.5MM PCsabir hussain100% (1)

- HGR3100 Engine 23augDocument1 pageHGR3100 Engine 23augIndo BemlNo ratings yet

- MON-110-CO-0002-LD, REV1 - Equipment NameplateDocument4 pagesMON-110-CO-0002-LD, REV1 - Equipment NameplateHarol MateusNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOBilal Luhar100% (1)

- 1.5MM 304Document1 page1.5MM 304pankaj kumarNo ratings yet

- Batch 127232 Hexindo BalikpapanDocument2 pagesBatch 127232 Hexindo BalikpapanlilikNo ratings yet

- Service Letter SL2020-701/KNB: Third-Party Spindle Guides and NozzlesDocument2 pagesService Letter SL2020-701/KNB: Third-Party Spindle Guides and NozzlesStathis MoumousisNo ratings yet

- Mill Test Certificate: Jindal Stainless (Hisar) LimitedDocument1 pageMill Test Certificate: Jindal Stainless (Hisar) Limitedhemantmech09920050% (2)

- Non Routine Card-NrcDocument2 pagesNon Routine Card-Nrcpann67% (3)

- Vedanta Limited Cairn Oil & Gas: Integrated Field Plan Execution Services in Satellite Fields in Rj-On 90/1 BLOCKDocument23 pagesVedanta Limited Cairn Oil & Gas: Integrated Field Plan Execution Services in Satellite Fields in Rj-On 90/1 BLOCKPRAKASH PANDEYNo ratings yet

- Sanken: (P/'T) EmailDocument5 pagesSanken: (P/'T) EmailAmila SampathNo ratings yet

- VTI OF Seal-Lock XP and XP-PCDocument3 pagesVTI OF Seal-Lock XP and XP-PCCong BuiNo ratings yet

- Cert ACERO INOX 316L PDFDocument1 pageCert ACERO INOX 316L PDFCarlos RomeroNo ratings yet

- JSW Steel LimitedDocument1 pageJSW Steel LimitedVenkatesh Kumar100% (1)

- Plate 25Document1 pagePlate 25Cyril J PadiyathNo ratings yet

- TM GDR-413Document2 pagesTM GDR-413Ahmat RamadaniNo ratings yet

- Technical Service Report: GR454 Komatsu GD 825 A-2 12797 S6D140E-2 40244Document2 pagesTechnical Service Report: GR454 Komatsu GD 825 A-2 12797 S6D140E-2 40244Yusfian TurnerNo ratings yet

- HGR3098 Engine 23augDocument1 pageHGR3098 Engine 23augIndo BemlNo ratings yet

- 6 - Pipe MTCDocument1 page6 - Pipe MTCsnehalmdeshmukh100% (1)

- Date:13-10-2012 Section 1:: A. B. C) CDocument2 pagesDate:13-10-2012 Section 1:: A. B. C) CbalaNo ratings yet

- H - INDTSC - (Te. Report) Ultra Eng - Solar Tracker - PosMAC-490 - Coating IssueDocument2 pagesH - INDTSC - (Te. Report) Ultra Eng - Solar Tracker - PosMAC-490 - Coating Issuerahul srivastavaNo ratings yet

- Stainless Steel P10Document1 pageStainless Steel P10Lucian GrigorasNo ratings yet

- BTL PresentationDocument144 pagesBTL Presentationrihand.satishNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOParesh MehtaNo ratings yet

- Issue (HEC-SR-03542) - 2022/04/25 MIS JEL3 468: 43,5 46 (4 PCS X 11,5 M) Please Manage For Over Issued Material 2,5 MDocument1 pageIssue (HEC-SR-03542) - 2022/04/25 MIS JEL3 468: 43,5 46 (4 PCS X 11,5 M) Please Manage For Over Issued Material 2,5 MAsmin TanaNo ratings yet

- LSK-1055-15 Prov. MNS-030 To 34-15 42.5 N Lucky CementDocument1 pageLSK-1055-15 Prov. MNS-030 To 34-15 42.5 N Lucky CementMuhammad Hasan Anees Muhammad AneesNo ratings yet

- 65X M L - 211224 - 180120 - Converted - by - AbcdpdfDocument1 page65X M L - 211224 - 180120 - Converted - by - AbcdpdfVidhyarthi Photocopy KhargoneNo ratings yet

- Ijrcm 2 Cvol 2 Issue 9Document181 pagesIjrcm 2 Cvol 2 Issue 9com-itNo ratings yet

- CPS Fitting Stations by County - 22 - 0817Document33 pagesCPS Fitting Stations by County - 22 - 0817Melissa R.No ratings yet

- Sendik's Oconomowoc Press AnnouncementDocument2 pagesSendik's Oconomowoc Press AnnouncementTMJ4 NewsNo ratings yet

- Volkswagen Passat R Line Price ListDocument2 pagesVolkswagen Passat R Line Price ListDr Uvarani Sp Care Rawang TinNo ratings yet

- 2019 Book TheEBMTHandbookDocument688 pages2019 Book TheEBMTHandbook88tk6rccsmNo ratings yet

- Order ID 4148791009Document1 pageOrder ID 4148791009SHUBHAM KUMARNo ratings yet

- Enidine Wire Rope IsolatorsDocument52 pagesEnidine Wire Rope IsolatorsJocaNo ratings yet

- Persons Digests For 090613Document10 pagesPersons Digests For 090613pyriadNo ratings yet

- PEL 20161201 Dec 2016Document76 pagesPEL 20161201 Dec 2016RémiNo ratings yet

- Flight Eticket - PdfaaaDocument3 pagesFlight Eticket - PdfaaaIgnacio Gonzalez PastranoNo ratings yet

- LFT - Development Status and Perspectives: Prof. DR Michael SchemmeDocument7 pagesLFT - Development Status and Perspectives: Prof. DR Michael SchemmeabiliovieiraNo ratings yet

- Goran BULDIOSKI THINK TANKS IN CENTRAL AND EASTERN EUROPE AND THE QUALITY OF THEIR POLICY RESEARCHDocument31 pagesGoran BULDIOSKI THINK TANKS IN CENTRAL AND EASTERN EUROPE AND THE QUALITY OF THEIR POLICY RESEARCHCentre for Regional Policy Research and Cooperation StudiorumNo ratings yet

- 18c Effective Telephone CommunicationDocument78 pages18c Effective Telephone CommunicationJan Cleo Cerdiña QuijanoNo ratings yet

- Handling and Working With Analytical StandardsDocument6 pagesHandling and Working With Analytical StandardsPreuz100% (1)

- Safety Data Sheet: Armohib Ci-28Document21 pagesSafety Data Sheet: Armohib Ci-28SJHEIK AbdullahNo ratings yet

- KUTAI MCCB Circuit Breaker Transfer Switch With Remote Monitoring OptionsDocument11 pagesKUTAI MCCB Circuit Breaker Transfer Switch With Remote Monitoring OptionsJanice LuNo ratings yet

- Schindler's List Theme Sheet Music For Piano, Violin (Solo)Document1 pageSchindler's List Theme Sheet Music For Piano, Violin (Solo)Sara SzaboNo ratings yet

- Rosie Revere Teaching GuideDocument5 pagesRosie Revere Teaching GuideAbrams Books100% (1)

- Warm Mix Asphalt: "National Perspective"Document46 pagesWarm Mix Asphalt: "National Perspective"Royhan RizkyNo ratings yet

- ANT A794517R0 1470 DatasheetDocument2 pagesANT A794517R0 1470 DatasheetRobertNo ratings yet

- Door LockDocument102 pagesDoor LockNicolás BozzoNo ratings yet

- Service Manual: Super Audio CD/DVD ReceiverDocument88 pagesService Manual: Super Audio CD/DVD Receiveralvhann_1No ratings yet

- TD 3.6 L4 TCD 3.6 L4: Operation ManualDocument72 pagesTD 3.6 L4 TCD 3.6 L4: Operation ManualMajd50% (2)

- Jacob Engine Brake Aplicación PDFDocument18 pagesJacob Engine Brake Aplicación PDFHamilton MirandaNo ratings yet

- LT32567 PDFDocument4 pagesLT32567 PDFNikolayNo ratings yet

- Practice Questions SheetDocument4 pagesPractice Questions Sheetsaif hasanNo ratings yet

- Questionnaire For National Security Positions: Purpose of This FormDocument36 pagesQuestionnaire For National Security Positions: Purpose of This Formadad1lqNo ratings yet

- Peri Komponentu Katalogas Pastoliams 2015 enDocument372 pagesPeri Komponentu Katalogas Pastoliams 2015 enLim Yew KwangNo ratings yet

- JavaDocument14 pagesJavaGANESH REDDYNo ratings yet

- Masonry: Department of EducationDocument6 pagesMasonry: Department of EducationFatima AdilNo ratings yet