Professional Documents

Culture Documents

TM GDR-413

Uploaded by

Ahmat RamadaniCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TM GDR-413

Uploaded by

Ahmat RamadaniCopyright:

Available Formats

PT.

Tekenomiks Indonesia

Office : Jl. Jend Sudirman No. 58 RT 29 Balikpapan, 76114 Indonesia

PROBLEM

TECHNICAL ADVANCE FOR ECONOMIC GAIN

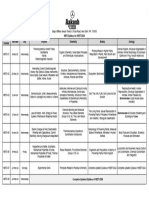

Wear Metal Report: 02049290

Client: PT. SEFAS PELINDOTAMA - BALIKPAPAN

Attention: PT. SENTOSA LAJU SEJAHTERA SITE TGM

Address BALIKPAPAN

Machine: CATERPILLAR 120NG ID No: GDR413-TGM

Oil Name: SHELL SPIRAX S4 CX 30

Visc@40°C: 93.9 Visc@100°C: 10.9 TBN: 0

Compartm't: TRANSMISSION S/N: -

Sample Date: - - - - 31/08/2023 22/09/2023

Received Date - - - - 12/09/2023 26/09/2023

Analysis Date: - - - - 12/09/2023 26/09/2023

Reported Date - - - - 14/09/2023 29/09/2023

Sample no: - - - - 02040102 02049290

SMU:(hrs) - - - - 992 1232

Oil Hrs: - - - - 1000 1000

Oil Changed: - - - - Yes No

Component Hours - - - - - -

Wear Metal Rate - - - - 0.13 0.17

Wear Metals METHOD RESULT Caut High Comments on elevated results

lead (Pb)(mg/kg) ASTM D5185 n/a n/a n/a n/a 12.6 13.7 3 4 Viskositas oli normal. PQ meningkat. Pb Fe

Cu di level tinggi. Kemungkinan dari wear

iron (Fe)(mg/kg) ASTM D5185 n/a n/a n/a n/a 27.4 52.4 28 35 Pump housing Gears bearings Clutch plates

aluminium (Al)(mg/kg) ASTM D5185 n/a n/a n/a n/a 4.3 4.5 9 10 Splines Shafts Diff lock-up Spider gear

copper (Cu)(mg/kg) ASTM D5185 n/a n/a n/a n/a 80.7 101.0 40 55 bushings Thrust washers Cooler Pressure

plate dan debu. Cek level oli dan kondisi oli.

chromium (Cr)(mg/kg) ASTM D5185 n/a n/a n/a n/a 0.6 1.8 3 4 Cek monitor magnetic screen dan filter cut.

tin (Sn)(mg/kg) ASTM D5185 n/a n/a n/a n/a 0.1 0.1 3 4 Cek pressur transmission. Cek excessive

nickel (Ni)(mg/kg) ASTM D5185 n/a n/a n/a n/a 0.1 0.5

noise. Cek slippage atau problem shifting.

0 0

Lakukan pemeriksaan. Disarankan ganti oli

Contaminants dan flushing. by(Supian)

silicon (Si)(mg/kg) ASTM D5185 n/a n/a n/a n/a 3.0 5.0 8 9

sodium (Na)(mg/kg) ASTM D5185 n/a n/a n/a n/a 8.0 4.2 0 0

Oil Additives

magnesium (Mg)(mg/kg) ASTM D5185 n/a n/a n/a n/a 9 9 0 0

zinc (Zn)(mg/kg) ASTM D5185 n/a n/a n/a n/a 949 849 0 0

molybdenum (Mo)(mg/kg) ASTM D5185 n/a n/a n/a n/a 1 0 0 0

calcium (Ca)(mg/kg) ASTM D5185 n/a n/a n/a n/a 3966 2938

Approved by : Ita Saronika ( Manager Lab )

0 0

phosphorous (P)(mg/kg) ASTM D5185 n/a n/a n/a n/a 698 858 0 0

boron (B)(mg/kg) ASTM D5185 n/a n/a n/a n/a 2 2 0 0

Infra Red

TBN(mgKOH/g) ASTM D4739 n/a n/a n/a n/a n/a n/a -0% -0%

TAN(mgKOH/g) ASTM D974 n/a n/a n/a n/a n/a n/a 0 0

soot(Abs/cm) ASTM E2412 n/a n/a n/a n/a n/a n/a 0 0

glycol(% vol) ASTM E2412 n/a n/a n/a n/a n/a n/a 0 0

oxidation((x.100)abs/0.1mm) ASTM E2412 n/a n/a n/a n/a n/a n/a 0 0

nitration((x.100)abs/0.1mm) ASTM E2412 n/a n/a n/a n/a n/a n/a 0 0

sulphation((x.100)abs/0.1mm) ASTM E2412 n/a n/a n/a n/a n/a n/a 0 0

Physical Tests Particle Cleanliness Analysis

water(ppm) ASTM D6304 n/a n/a n/a n/a n/a n/a 0 0 ISO 4406 - 04 | -

fuel dilution(% vol) In-house n/a n/a n/a n/a n/a n/a 0 0 ISO 4406 - 06 | -

water(%) ASTM E2412 n/a n/a n/a n/a 0.00 0.00 0 0 ISO 4406 - 14 | -

F.debris(mg Fe/L) ASTM D8120 n/a n/a n/a n/a 14 31 0 0 Count 1ml | -

visc @ 100oC(mm2/s) ASTM D445 n/a n/a n/a n/a n/a n/a +-0 0

visc @ 40oC(mm2/s) ASTM D445 n/a n/a n/a n/a 93.18 95.98 +-10 +-30

Iso Code (Part/mL)() ISO 4406 -/-/- -/-/- -/-/- -/-/- -/-/- -/-/- 0 0

Element Trends Graph

For enquiries: Tekenomiks Balikpapan, email : Labbpn@techenomics.com, phone : 0542-762226 fax : 0542-762256 mobile : 0542-764681

This wear analysis and oil condition report should be used in conjunction with normal maintenance and evaluated from sample to sample. Every care will be taken in processing samples but no express or implied guarantee is furnished in

regard to the continuing operation or condition of this machinery or any part thereof.

The Result of Analysis is only related to the sample analyzed.

PT. Tekenomiks Indonesia

Office : Jl. Jend Sudirman No. 58 RT 29 Balikpapan, 76114 Indonesia

PROBLEM

TECHNICAL ADVANCE FOR ECONOMIC GAIN

Wear Metal Report: 02057937

Client: PT. SENTOSA LAJU SEJAHTERA

Attention: PT. SENTOSA LAJU SEJAHTERA SITE TGM

Address

Machine: CATERPILLAR 120NG ID No: GDR-413

Oil Name: SHELL SPIRAX S4 CX 30

Visc@40°C: 93.9 Visc@100°C: 10.9 TBN: 0

Compartm't: TRANSMISSION S/N: -

Sample Date: - - - 10/07/2023 09/08/2023 07/10/2023

Received Date - - - 14/07/2023 18/08/2023 12/10/2023

Analysis Date: - - - 14/07/2023 18/08/2023 12/10/2023

Reported Date - - - 15/07/2023 19/08/2023 13/10/2023

Sample no: - - - 02003824 02024757 02057937

SMU:(hrs) - - - 511 749 1519

Oil Hrs: - - - 250 250 500

Oil Changed: - - - No No Yes

Component Hours - - - - - -

Wear Metal Rate - - - 0.44 0.55 0.55

Wear Metals METHOD RESULT Caut High Comments on elevated results

lead (Pb)(mg/kg) ASTM D5185 n/a n/a n/a 13.7 9.7 14.0 3 4 Pb Fe Cu Sn Si naik tinggi dan PQ

meningkat. Keausan Gears Bearings Clutch

iron (Fe)(mg/kg) ASTM D5185 n/a n/a n/a 27.6 30.1 67.8 28 35 plates Splines Shafts Pressure plate wear

aluminium (Al)(mg/kg) ASTM D5185 n/a n/a n/a 4.2 3.4 8.0 9 10 Discs Cooler dan monitor dari dirt. cek level

copper (Cu)(mg/kg) ASTM D5185 n/a n/a n/a 63.0 92.0 178.2 40 55 dan kondisi oli. cek rating filter dan screen.

cek drain plug dari debris. Monitor

chromium (Cr)(mg/kg) ASTM D5185 n/a n/a n/a 1.8 1.1 0.6 3 4 kebocoran dan kontaminasi. cek seal

tin (Sn)(mg/kg) ASTM D5185 n/a n/a n/a 0.1 0.1 8.4 3 4 breather. Cek Transmissi noise. cek shifting

nickel (Ni)(mg/kg) ASTM D5185 n/a n/a n/a 0.7 0.1 0.3

performance. lakukan pemeriksaan. (arman)

0 0

Contaminants

silicon (Si)(mg/kg) ASTM D5185 n/a n/a n/a 4.4 3.4 9.7 8 9

sodium (Na)(mg/kg) ASTM D5185 n/a n/a n/a 6.9 7.6 2.8 0 0

Oil Additives

magnesium (Mg)(mg/kg) ASTM D5185 n/a n/a n/a 9 9 8 0 0

zinc (Zn)(mg/kg) ASTM D5185 n/a n/a n/a 959 929 1277 0 0

molybdenum (Mo)(mg/kg) ASTM D5185 n/a n/a n/a 2 0 0 0 0

calcium (Ca)(mg/kg) ASTM D5185 n/a n/a n/a 3538 3227 3225 0 0

phosphorous (P)(mg/kg) ASTM D5185 n/a n/a n/a 723 993 919 0 0

Approved by : Ita Saronika ( Manager Lab )

boron (B)(mg/kg) ASTM D5185 n/a n/a n/a 3 2 24 0 0

Infra Red

TBN(mgKOH/g) ASTM D4739 n/a n/a n/a n/a n/a n/a -0% -0%

TAN(mgKOH/g) ASTM D974 n/a n/a n/a n/a n/a n/a 0 0

soot(Abs/cm) ASTM E2412 n/a n/a n/a n/a n/a n/a 0 0

glycol(% vol) ASTM E2412 n/a n/a n/a n/a n/a n/a 0 0

oxidation((x.100)abs/0.1mm) ASTM E2412 n/a n/a n/a n/a n/a n/a 0 0

nitration((x.100)abs/0.1mm) ASTM E2412 n/a n/a n/a n/a n/a n/a 0 0

sulphation((x.100)abs/0.1mm) ASTM E2412 n/a n/a n/a n/a n/a n/a 0 0

Physical Tests Particle Cleanliness Analysis

water(ppm) ASTM D6304 n/a n/a n/a n/a n/a n/a 0 0 ISO 4406 - 04 | -

fuel dilution(% vol) In-house n/a n/a n/a n/a n/a n/a 0 0 ISO 4406 - 06 | -

water(%) ASTM E2412 n/a n/a n/a 0.00 0.00 0.00 0 0 ISO 4406 - 14 | -

F.debris(mg Fe/L) ASTM D8120 n/a n/a n/a 13 16 38 0 0 Count 1ml | -

visc @ 100oC(mm2/s) ASTM D445 n/a n/a n/a n/a n/a n/a +-0 0

visc @ 40oC(mm2/s) ASTM D445 n/a n/a n/a 92.72 93.41 92.10 +-10 +-30

Iso Code (Part/mL)() ISO 4406 -/-/- -/-/- -/-/- -/-/- -/-/- -/-/- 0 0

Element Trends Graph

For enquiries: Tekenomiks Balikpapan, email : Labbpn@techenomics.com, phone : 0542-762226 fax : 0542-762256 mobile : 0542-764681

This wear analysis and oil condition report should be used in conjunction with normal maintenance and evaluated from sample to sample. Every care will be taken in processing samples but no express or implied guarantee is furnished in

regard to the continuing operation or condition of this machinery or any part thereof.

The Result of Analysis is only related to the sample analyzed.

You might also like

- DTHW 005Document1 pageDTHW 005Angga 99No ratings yet

- HGR3098 Engine 23augDocument1 pageHGR3098 Engine 23augIndo BemlNo ratings yet

- HGR3100 Engine 23augDocument1 pageHGR3100 Engine 23augIndo BemlNo ratings yet

- Batch 127232 Hexindo BalikpapanDocument2 pagesBatch 127232 Hexindo BalikpapanlilikNo ratings yet

- DT1342 EngineDocument1 pageDT1342 EnginedayatNo ratings yet

- DT2407 DifferentialDocument1 pageDT2407 DifferentialdayatNo ratings yet

- t345 Engine UpdateDocument1 paget345 Engine Updatearif adi saputraNo ratings yet

- Batch 124232 Pt. Kerta Bumi Teknindo - PLTD TinaboganDocument5 pagesBatch 124232 Pt. Kerta Bumi Teknindo - PLTD Tinaboganamin ghozaliNo ratings yet

- DT2872 Final Drive Center RHDocument1 pageDT2872 Final Drive Center RHdayatNo ratings yet

- HDTL 025Document1 pageHDTL 025Angga 99No ratings yet

- NKL-967 (0126 - Hpu-Mca) - Hydraulic - 2111 - Ob2324031 - BDocument2 pagesNKL-967 (0126 - Hpu-Mca) - Hydraulic - 2111 - Ob2324031 - BMUHAMMAD LUTHFINo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- SKL-1155 (0132 - Hpu-Mca) - Hydraulic - 2111 - Ob2324030 - BDocument2 pagesSKL-1155 (0132 - Hpu-Mca) - Hydraulic - 2111 - Ob2324030 - BMUHAMMAD LUTHFINo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- Sterntube - Man. AstaDocument1 pageSterntube - Man. AstacahyoNo ratings yet

- Lube and Fuel Lab Consultant ReportDocument1 pageLube and Fuel Lab Consultant Reportabdul rahmatNo ratings yet

- Pdf24 MergedDocument9 pagesPdf24 MergedauliaadyaksaNo ratings yet

- RD 217 - Transmission - 3110 - Ob2226660 - CDocument2 pagesRD 217 - Transmission - 3110 - Ob2226660 - Copen hartigNo ratings yet

- Lube and Fuel Lab Consultant ReportDocument1 pageLube and Fuel Lab Consultant Reportopen hartigNo ratings yet

- PT Petrolab Services: Test DetailDocument1 pagePT Petrolab Services: Test DetailDiat NorNo ratings yet

- PT Petrolab Oil Analysis ReportDocument1 pagePT Petrolab Oil Analysis ReportJon HermanNo ratings yet

- NiCu-7 solid wire for welding nickel-copper alloysDocument1 pageNiCu-7 solid wire for welding nickel-copper alloyssatnamNo ratings yet

- TDC963REV00Document2 pagesTDC963REV00Chinmaya Kumar DalaiNo ratings yet

- Mycom #1Document1 pageMycom #1Rifky Windya NNo ratings yet

- INSPECTION CERTIFICATE FOR BOLT SETDocument2 pagesINSPECTION CERTIFICATE FOR BOLT SETnam nguyengiangNo ratings yet

- Oil Analysis Report: PT Petrolab ServicesDocument1 pageOil Analysis Report: PT Petrolab ServicesJon HermanNo ratings yet

- Oil Analysis Report: PT Petrolab ServicesDocument1 pageOil Analysis Report: PT Petrolab ServicesJon HermanNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAhmad HisyamNo ratings yet

- Date LCN: Corrective Action Is RequiredDocument1 pageDate LCN: Corrective Action Is RequiredJoel MinafiNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- Standard STD 417-0002: Engine Oil 97487Document7 pagesStandard STD 417-0002: Engine Oil 97487hansiiiNo ratings yet

- RD218 Gardan 3110 Ob2226657 NDocument1 pageRD218 Gardan 3110 Ob2226657 Nopen hartigNo ratings yet

- OJ10641 UO 23 QRDocument1 pageOJ10641 UO 23 QRSubastianNo ratings yet

- MB Trucks Specifications For Engine Oils (Service Fill) V2022.1Document2 pagesMB Trucks Specifications For Engine Oils (Service Fill) V2022.1Olivier DupNo ratings yet

- OJ10639 UO 23 QRDocument1 pageOJ10639 UO 23 QRSubastianNo ratings yet

- Oil Analysis Report: PT Petrolab ServicesDocument1 pageOil Analysis Report: PT Petrolab ServicesJon HermanNo ratings yet

- OJ10640 UO 23 QRDocument1 pageOJ10640 UO 23 QRSubastianNo ratings yet

- BT Oil Lab - Hpu - 09-10.06.2022Document1 pageBT Oil Lab - Hpu - 09-10.06.2022Faizhal ROGNo ratings yet

- PT Petrolab Services: Test DetailDocument2 pagesPT Petrolab Services: Test DetailDaniel Fr SinagaNo ratings yet

- Titanpro 6531 MDocument1 pageTitanpro 6531 MErnesto CheguavaraNo ratings yet

- Lube and Fuel Laboratory Consultant ReportDocument1 pageLube and Fuel Laboratory Consultant Reportopen hartigNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- Test Ce Tificate: C EMI AL OM OS On PercentDocument2 pagesTest Ce Tificate: C EMI AL OM OS On PercentPravin HonmuteNo ratings yet

- OJ10642 UO 23 QRDocument1 pageOJ10642 UO 23 QRSubastianNo ratings yet

- VARILLADocument1 pageVARILLAB. styllshNo ratings yet

- Automig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28Document1 pageAutomig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28satnamNo ratings yet

- FTTLVFLUO AEIA PTE- LTBDocument1 pageFTTLVFLUO AEIA PTE- LTBwawanNo ratings yet

- PT Petrolab Services: Test DetailDocument2 pagesPT Petrolab Services: Test DetailDaniel Fr SinagaNo ratings yet

- Mix Design ComplainceDocument7 pagesMix Design Complainceraja qammar100% (2)

- RD218 - Left Final Drive - 3110 - Ob2226655 - CDocument2 pagesRD218 - Left Final Drive - 3110 - Ob2226655 - Copen hartigNo ratings yet

- DHL30291 C 0Document1 pageDHL30291 C 0Joel MinafiNo ratings yet

- Pds-Aegle 7000 D 15w-40-Api Ci-4Document1 pagePds-Aegle 7000 D 15w-40-Api Ci-4agnovNo ratings yet

- OJ10643 UO 23 QRDocument1 pageOJ10643 UO 23 QRSubastianNo ratings yet

- CWC-BookletF1 15Document1 pageCWC-BookletF1 15satnamNo ratings yet

- Microsoft PowerPoint - Hi-Water Content On Lube Oil FGC EMCLDocument18 pagesMicrosoft PowerPoint - Hi-Water Content On Lube Oil FGC EMCLnjajaljehNo ratings yet

- Optigear 1100 RangeDocument3 pagesOptigear 1100 RangeResistenciaDisidenteNo ratings yet

- Certificado - RAL 9010 - 0.5mmDocument1 pageCertificado - RAL 9010 - 0.5mmTecnico CoberafricaNo ratings yet

- ClinkerDocument1 pageClinkerahmedNo ratings yet

- Nycolube 120Document1 pageNycolube 120Rafael ArevaloNo ratings yet

- Lampiran PAP template monthly MaretDocument2 pagesLampiran PAP template monthly MaretAhmat RamadaniNo ratings yet

- Daily Breakdown Monitoring - SMN 21 MARET 2024Document1 pageDaily Breakdown Monitoring - SMN 21 MARET 2024Ahmat RamadaniNo ratings yet

- Daily Breakdown Monitoring - DMPDocument1 pageDaily Breakdown Monitoring - DMPAhmat RamadaniNo ratings yet

- EXC102-13 CMDocument5 pagesEXC102-13 CMAhmat RamadaniNo ratings yet

- Daily Breakdown Monitoring & Backlog - Site AA - 21 Maret 2024 - 10.33 WITADocument2 pagesDaily Breakdown Monitoring & Backlog - Site AA - 21 Maret 2024 - 10.33 WITAAhmat RamadaniNo ratings yet

- Matrix Trend CM EXC103-1Document2 pagesMatrix Trend CM EXC103-1Ahmat RamadaniNo ratings yet

- PS-11 Fju EngineDocument1 pagePS-11 Fju EngineAhmat RamadaniNo ratings yet

- Matrix Trend CM DZR-218Document1 pageMatrix Trend CM DZR-218Ahmat RamadaniNo ratings yet

- Matrix Trend CM EXC103-1Document2 pagesMatrix Trend CM EXC103-1Ahmat RamadaniNo ratings yet

- Akm-01 - Slk-Akm - Differential FrontDocument1 pageAkm-01 - Slk-Akm - Differential FrontAhmat RamadaniNo ratings yet

- Mtarix PAP ADT-01Document5 pagesMtarix PAP ADT-01Ahmat RamadaniNo ratings yet

- Mtarix PAP ADT-01Document5 pagesMtarix PAP ADT-01Ahmat RamadaniNo ratings yet

- Akm-01 - Slk-Akm - Final Drive Front RHDocument1 pageAkm-01 - Slk-Akm - Final Drive Front RHAhmat RamadaniNo ratings yet

- G22-01 MHS EngineDocument1 pageG22-01 MHS EngineAhmat RamadaniNo ratings yet

- PS-11 Fju EngineDocument1 pagePS-11 Fju EngineAhmat RamadaniNo ratings yet

- R-11 MHS EngineDocument1 pageR-11 MHS EngineAhmat RamadaniNo ratings yet

- PS-11 Fju EngineDocument1 pagePS-11 Fju EngineAhmat RamadaniNo ratings yet

- Exc101-6 Slk-Akm Final Drive RHDocument1 pageExc101-6 Slk-Akm Final Drive RHAhmat RamadaniNo ratings yet

- Exc103-49 - Slk-Akm - Final Drive LHDocument1 pageExc103-49 - Slk-Akm - Final Drive LHAhmat RamadaniNo ratings yet

- Exc101-6 Slk-Akm Final Drive LHDocument1 pageExc101-6 Slk-Akm Final Drive LHAhmat RamadaniNo ratings yet

- Akm-01 - Slk-Akm - Final Drive Front LHDocument1 pageAkm-01 - Slk-Akm - Final Drive Front LHAhmat RamadaniNo ratings yet

- Adt-408 - Slk-Akm - Brake CoolingDocument1 pageAdt-408 - Slk-Akm - Brake CoolingAhmat RamadaniNo ratings yet

- Adt-403 Slk-Akm TransmissionDocument1 pageAdt-403 Slk-Akm TransmissionAhmat RamadaniNo ratings yet

- Exc101-7 - Slk-Akm - Final Drive LHDocument1 pageExc101-7 - Slk-Akm - Final Drive LHAhmat RamadaniNo ratings yet

- Exc101-7 Slk-Akm Final Drive RHDocument1 pageExc101-7 Slk-Akm Final Drive RHAhmat RamadaniNo ratings yet

- Adt-403 Slk-Akm Brake CoolingDocument1 pageAdt-403 Slk-Akm Brake CoolingAhmat RamadaniNo ratings yet

- MML-07 Slk-Akm HydraulicDocument1 pageMML-07 Slk-Akm HydraulicAhmat RamadaniNo ratings yet

- R-40 Slk-Akm EngineDocument1 pageR-40 Slk-Akm EngineAhmat RamadaniNo ratings yet

- MML-07 - Slk-Akm - Final Drive LHDocument1 pageMML-07 - Slk-Akm - Final Drive LHAhmat RamadaniNo ratings yet

- MML-07 - Slk-Akm - Final Drive RHDocument1 pageMML-07 - Slk-Akm - Final Drive RHAhmat RamadaniNo ratings yet

- Pseudo-Chomsky ThreeDocument4 pagesPseudo-Chomsky ThreeTyler ShortNo ratings yet

- EC2204 Signals and Systems University Questions for Five UnitsDocument19 pagesEC2204 Signals and Systems University Questions for Five UnitsCrazy EditingsNo ratings yet

- A Systematic Review of Enablers of Collaboration Among The Participants in Construction ProjectsDocument14 pagesA Systematic Review of Enablers of Collaboration Among The Participants in Construction ProjectsShumank SrivastavaNo ratings yet

- Mesozoic Rock Formations of the South-West Rusca Montana BasinDocument27 pagesMesozoic Rock Formations of the South-West Rusca Montana BasinplanessNo ratings yet

- Moisture Management FinishDocument4 pagesMoisture Management FinishDr. Sanket ValiaNo ratings yet

- Matching TypeDocument26 pagesMatching TypeDiana HernandezNo ratings yet

- UNIT12Document11 pagesUNIT12Jorge Alejandro JuárezNo ratings yet

- Example Dissertation Cover PageDocument5 pagesExample Dissertation Cover PageCanIPaySomeoneToWriteMyPaperMobile100% (1)

- Checklist For Welding and NDE SectionDocument2 pagesChecklist For Welding and NDE SectionMuhammadShabbirNo ratings yet

- Lesson PlanDocument1 pageLesson Planapi-551142254No ratings yet

- Introduction To The Philosophy of Social ResearchDocument240 pagesIntroduction To The Philosophy of Social ResearchRob Londs100% (1)

- Monthly Magzine JAN 2023Document165 pagesMonthly Magzine JAN 2023charan100% (1)

- SSRN Id4067211Document53 pagesSSRN Id4067211mnpxzdsqs8No ratings yet

- Soil Stabilization Using Bottom Ash and Areca Fiber: Experimental Investigations and Reliability AnalysisDocument11 pagesSoil Stabilization Using Bottom Ash and Areca Fiber: Experimental Investigations and Reliability AnalysisHugo Dario Machaca CondoriNo ratings yet

- ASTM E1845 - Standard Practice For Calculating Pavement Macrotexture Mean Profile Depth PDFDocument4 pagesASTM E1845 - Standard Practice For Calculating Pavement Macrotexture Mean Profile Depth PDFrendy100% (1)

- N164.UCPE12B LANmark - OF - UC - 12x - Singlemode - 9 - 125 - OS2 - PE - BlackDocument2 pagesN164.UCPE12B LANmark - OF - UC - 12x - Singlemode - 9 - 125 - OS2 - PE - BlackRaniaTortueNo ratings yet

- Syllabus of NCERT Booster Test Series - CoE NEET-2024 - 071157Document1 pageSyllabus of NCERT Booster Test Series - CoE NEET-2024 - 071157bishnuprasadmohapatra01No ratings yet

- Anthropology: Cultural Anthropology Biological AnthropologyDocument3 pagesAnthropology: Cultural Anthropology Biological AnthropologyHannah Althea Hijan JocsonNo ratings yet

- Roots of EquationsDocument31 pagesRoots of EquationsGzim RamadaniNo ratings yet

- 41303110on Network Theory PDFDocument15 pages41303110on Network Theory PDFArnawan AriefNo ratings yet

- Water Budget Equation Exercise Problems SolvedDocument10 pagesWater Budget Equation Exercise Problems SolvedSheeraz AhmedNo ratings yet

- SchimmentiDevelopmentalrootsofdissociationpre PrintDocument42 pagesSchimmentiDevelopmentalrootsofdissociationpre PrintZeynep ÖzmeydanNo ratings yet

- Non Industrial Applications of RobotsDocument3 pagesNon Industrial Applications of RobotsDhalal AsmiNo ratings yet

- LPS Training - 2015 Update FINALDocument65 pagesLPS Training - 2015 Update FINALAsriSaffuan86% (7)

- The Impact of Communication On OrganisatDocument12 pagesThe Impact of Communication On Organisatewrerwrew100% (1)

- Measurement Accuracy and Six Sigma Green Belt ExamDocument12 pagesMeasurement Accuracy and Six Sigma Green Belt ExamKumaran VelNo ratings yet

- Thermal Expansion of Iridium at High TemperaturesDocument5 pagesThermal Expansion of Iridium at High TemperaturesAntonio CamaranoNo ratings yet

- Medical Assistant Essay ExamplesDocument2 pagesMedical Assistant Essay ExamplesbhhrxpaegNo ratings yet

- Agilent Cary 8454 UV-Visible Spectroscopy System: Installation GuideDocument104 pagesAgilent Cary 8454 UV-Visible Spectroscopy System: Installation Guidehugo martinezNo ratings yet

- Fs1 Complete Learning Episodes 1Document126 pagesFs1 Complete Learning Episodes 1REDELYN M. CANCINONo ratings yet