Professional Documents

Culture Documents

HGR3100 Engine 23aug

Uploaded by

Indo BemlOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HGR3100 Engine 23aug

Uploaded by

Indo BemlCopyright:

Available Formats

PT.

Tekenomiks Indonesia

Office : Jl. Jend Sudirman No. 58 RT 29 Balikpapan, 76114 Indonesia

PROBLEM

TECHNICAL ADVANCE FOR ECONOMIC GAIN

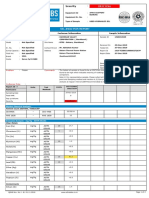

Wear Metal Report: 00908245

Client: PT. THRIVENI INDO MINING - SATUI

Attention: PT. THRIVENI INDO MINING - SATUI

Address

Machine: GRADER BEML BG825 ID No: HGR3100

Oil Name: SHELL RIMULA R3 MV 15W-40

Visc@40°C: 111 Visc@100°C: 14.6 TBN: 10.57

Compartm't: ENGINE S/N: -

Sample Date: - - - - 23/07/2023 11/08/2023

Received Date - - - - 31/07/2023 21/08/2023

Analysis Date: - - - - 31/07/2023 21/08/2023

Reported Date - - - - 02/08/2023 23/08/2023

Sample no: - - - - 00904082 00908245

SMU:(hrs) - - - - 50 231

Oil Hrs: - - - - 50 231

Oil Changed: - - - - No Yes

Component Hours - - - - - -

Wear Metal Rate - - - - 1.60 0.66

Wear Metals METHOD RESULT Caut High Comments on elevated results

lead (Pb)(mg/kg) ASTM D5185 n/a n/a n/a n/a 10.1 23.8 48 80 Viskositas oli rendah dibawah standar dan

Fuel 1% terdeteksi. Oksidasi medium. Cu

iron (Fe)(mg/kg) ASTM D5185 n/a n/a n/a n/a 10.1 20.6 57 95 tinggi dan Sn Si kemungkinan dari bearing

aluminium (Al)(mg/kg) ASTM D5185 n/a n/a n/a n/a 1.0 1.4 28 46 bushing thrust washer oil cooler seals

copper (Cu)(mg/kg) ASTM D5185 n/a n/a n/a n/a 52.7 92.4 27 45 gasket material. Oli sudah diganti. Unit

masih break in period. Monitor filter cut. Cek

chromium (Cr)(mg/kg) ASTM D5185 n/a n/a n/a n/a 0.3 0.4 9 15 performa pressure. Cek cooling system Cek

tin (Sn)(mg/kg) ASTM D5185 n/a n/a n/a n/a 4.8 12.8 9 15 fuel system malfunction. Resample oli untuk

nickel (Ni)(mg/kg) ASTM D5185 n/a n/a n/a n/a

monitor sample berikutnya. by(Supian)

1.2 0.5 9 15

Contaminants

silicon (Si)(mg/kg) ASTM D5185 n/a n/a n/a n/a 32.8 33.8 24 40

sodium (Na)(mg/kg) ASTM D5185 n/a n/a n/a n/a 4.0 3.3 60 100

Oil Additives

magnesium (Mg)(mg/kg) ASTM D5185 n/a n/a n/a n/a 4 8 0 0

zinc (Zn)(mg/kg) ASTM D5185 n/a n/a n/a n/a 845 1067 0 0

molybdenum (Mo)(mg/kg) ASTM D5185 n/a n/a n/a n/a 15 26 0 0

calcium (Ca)(mg/kg) ASTM D5185 n/a n/a n/a n/a 2887 3414 0 0

phosphorous (P)(mg/kg) ASTM D5185 n/a n/a n/a n/a 733 960 0 0

Approved by : Ita Saronika ( Manager Lab )

boron (B)(mg/kg) ASTM D5185 n/a n/a n/a n/a 7 110 0 0

Infra Red

TBN(mgKOH/g) ASTM D4739 n/a n/a n/a n/a 9.12 7.90 -25% -50%

TAN(mgKOH/g) ASTM D974 n/a n/a n/a n/a n/a n/a 0 0

soot(Abs/cm) ASTM E2412 n/a n/a n/a n/a 2 8 35 70

glycol(% vol) ASTM E2412 n/a n/a n/a n/a 0 0 18 30

oxidation((x.100)abs/0.1mm) ASTM E2412 n/a n/a n/a n/a 21 75 60 100

nitration((x.100)abs/0.1mm) ASTM E2412 n/a n/a n/a n/a 7 10 60 100

sulphation((x.100)abs/0.1mm) ASTM E2412 n/a n/a n/a n/a 3 14 60 100

Physical Tests Particle Cleanliness Analysis

water(ppm) ASTM D6304 n/a n/a n/a n/a n/a n/a 0 0 ISO 4406 - 04 | -

fuel dilution(% vol) In-house n/a n/a n/a n/a 0.00 1.00 1 2 ISO 4406 - 06 | -

water(%) ASTM E2412 n/a n/a n/a n/a 0.00 0.00 0 0 ISO 4406 - 14 | -

F.debris(mg Fe/L) ASTM D8120 n/a n/a n/a n/a 2 5 12 20 Count 1ml | -

visc @ 100oC(mm2/s) ASTM D445 n/a n/a n/a n/a 12.91 11.34 +-10 +-30

visc @ 40oC(mm2/s) ASTM D445 n/a n/a n/a n/a 87.66 73.01 +-10 +-30

Iso Code (Part/mL)() ISO 4406 -/-/- -/-/- -/-/- -/-/- -/-/- -/-/- 0 0

Element Trends Graph

For enquiries: Tekenomiks Balikpapan, email : Labbpn@techenomics.com, phone : 0542-762226 fax : 0542 - 762256 mobile : 0542-764681

This wear analysis and oil condition report should be used in conjunction with normal maintenance and evaluated from sample to sample. Every care will be taken in processing samples but no express or implied guarantee is furnished in

regard to the continuing operation or condition of this machinery or any part thereof.

The Result of Analysis is only related to the sample analyzed.

You might also like

- Essential Rubber Formulary: Formulas for PractitionersFrom EverandEssential Rubber Formulary: Formulas for PractitionersRating: 3 out of 5 stars3/5 (1)

- HGR3098 Engine 23augDocument1 pageHGR3098 Engine 23augIndo BemlNo ratings yet

- Batch 127232 Hexindo BalikpapanDocument2 pagesBatch 127232 Hexindo BalikpapanlilikNo ratings yet

- TM GDR-413Document2 pagesTM GDR-413Ahmat RamadaniNo ratings yet

- DTHW 005Document1 pageDTHW 005Angga 99No ratings yet

- Batch 124232 Pt. Kerta Bumi Teknindo - PLTD TinaboganDocument5 pagesBatch 124232 Pt. Kerta Bumi Teknindo - PLTD Tinaboganamin ghozaliNo ratings yet

- DT1342 EngineDocument1 pageDT1342 EnginedayatNo ratings yet

- Sterntube - Man. AstaDocument1 pageSterntube - Man. AstacahyoNo ratings yet

- DT2872 Final Drive Center RHDocument1 pageDT2872 Final Drive Center RHdayatNo ratings yet

- NKL-967 (0126 - Hpu-Mca) - Hydraulic - 2111 - Ob2324031 - BDocument2 pagesNKL-967 (0126 - Hpu-Mca) - Hydraulic - 2111 - Ob2324031 - BMUHAMMAD LUTHFINo ratings yet

- Mycom #1Document1 pageMycom #1Rifky Windya NNo ratings yet

- DT2407 DifferentialDocument1 pageDT2407 DifferentialdayatNo ratings yet

- SKL-1155 (0132 - Hpu-Mca) - Hydraulic - 2111 - Ob2324030 - BDocument2 pagesSKL-1155 (0132 - Hpu-Mca) - Hydraulic - 2111 - Ob2324030 - BMUHAMMAD LUTHFINo ratings yet

- OJ10641 UO 23 QRDocument1 pageOJ10641 UO 23 QRSubastianNo ratings yet

- t345 Engine UpdateDocument1 paget345 Engine Updatearif adi saputraNo ratings yet

- Oil Analysis Report: PT Petrolab ServicesDocument1 pageOil Analysis Report: PT Petrolab ServicesJon HermanNo ratings yet

- OJ10640 UO 23 QRDocument1 pageOJ10640 UO 23 QRSubastianNo ratings yet

- OJ10642 UO 23 QRDocument1 pageOJ10642 UO 23 QRSubastianNo ratings yet

- Oil Analysis Report: PT Petrolab ServicesDocument1 pageOil Analysis Report: PT Petrolab ServicesJon HermanNo ratings yet

- Adt-03 Engine 1001 Ob2000450Document1 pageAdt-03 Engine 1001 Ob2000450abdul rahmatNo ratings yet

- DT1650 - Front Differential - 2023-09-21 - P23021361Document1 pageDT1650 - Front Differential - 2023-09-21 - P23021361herdazu13No ratings yet

- HDTL 025Document1 pageHDTL 025Angga 99No ratings yet

- Pdf24 MergedDocument9 pagesPdf24 MergedauliaadyaksaNo ratings yet

- Oil Analysis Report: PT Petrolab ServicesDocument1 pageOil Analysis Report: PT Petrolab ServicesJon HermanNo ratings yet

- BD 108 - Engine - 3110 - Ob2226659 - BDocument1 pageBD 108 - Engine - 3110 - Ob2226659 - Bopen hartigNo ratings yet

- OJ10639 UO 23 QRDocument1 pageOJ10639 UO 23 QRSubastianNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- OJ10643 UO 23 QRDocument1 pageOJ10643 UO 23 QRSubastianNo ratings yet

- RD218 Gardan 3110 Ob2226657 NDocument1 pageRD218 Gardan 3110 Ob2226657 Nopen hartigNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- RD218 - Left Final Drive - 3110 - Ob2226655 - CDocument2 pagesRD218 - Left Final Drive - 3110 - Ob2226655 - Copen hartigNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- Oil Analysis Report: PT Petrolab ServicesDocument1 pageOil Analysis Report: PT Petrolab ServicesJon HermanNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- RD 217 - Transmission - 3110 - Ob2226660 - CDocument2 pagesRD 217 - Transmission - 3110 - Ob2226660 - Copen hartigNo ratings yet

- PT Petrolab Services: Test DetailDocument2 pagesPT Petrolab Services: Test DetailDaniel Fr SinagaNo ratings yet

- PT Petrolab Services: Test DetailDocument2 pagesPT Petrolab Services: Test DetailDaniel Fr SinagaNo ratings yet

- Adt-03 Engine 3112 Ob1922568Document1 pageAdt-03 Engine 3112 Ob1922568abdul rahmatNo ratings yet

- BT Oil Lab - Hpu - 09-10.06.2022Document1 pageBT Oil Lab - Hpu - 09-10.06.2022Faizhal ROGNo ratings yet

- RD 215 - Engine - 3110 - Ob2226661 - NDocument1 pageRD 215 - Engine - 3110 - Ob2226661 - Nopen hartigNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsDimasNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAhmad HisyamNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsdnoaisapsNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsNanang PrasetyaNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- Zdocs - Hu 773007136-ADocument1 pageZdocs - Hu 773007136-AMohamed RaafatNo ratings yet

- Jenis Minyak Nomor: 133/LUBE OIL/KIMIA/VII/2020Document9 pagesJenis Minyak Nomor: 133/LUBE OIL/KIMIA/VII/2020arif ihwandaNo ratings yet

- 6:: Ff-Hna$Ufa (Ra:::: TLW - Psbol .Co"Id LnilDocument1 page6:: Ff-Hna$Ufa (Ra:::: TLW - Psbol .Co"Id Lnilkingpin182No ratings yet

- Infineum D3453Document2 pagesInfineum D3453Carlos Enrique Mora CortezNo ratings yet

- Sample Oil April 2022 Manalagi AstaDocument9 pagesSample Oil April 2022 Manalagi Astacahyo putroNo ratings yet

- Harry 11 Me PortDocument1 pageHarry 11 Me PortDaniel Fr SinagaNo ratings yet

- Aph#a Support BearingDocument4 pagesAph#a Support BearingAbhishek KumarNo ratings yet

- Microsoft PowerPoint - Hi-Water Content On Lube Oil FGC EMCLDocument18 pagesMicrosoft PowerPoint - Hi-Water Content On Lube Oil FGC EMCLnjajaljehNo ratings yet

- 350 Acetic AcidDocument1 page350 Acetic Acidinderverma1975No ratings yet

- الجهات الخارجية تقرير فحص خزانات البنزين الاسبوعيDocument2 pagesالجهات الخارجية تقرير فحص خزانات البنزين الاسبوعيDORA REFINERYNo ratings yet

- PT Petrolab Services: Test DetailDocument1 pagePT Petrolab Services: Test DetailDiat NorNo ratings yet

- Specifications Unit Limits Method ) : Annex V Fuel SpecificationsDocument3 pagesSpecifications Unit Limits Method ) : Annex V Fuel Specificationsbasharat121No ratings yet

- Lube Oil Analysis ReportDocument11 pagesLube Oil Analysis ReportPhilic RohitNo ratings yet

- 1.5MM 304Document1 page1.5MM 304pankaj kumarNo ratings yet

- Harry 11 Me STBDocument1 pageHarry 11 Me STBDaniel Fr SinagaNo ratings yet

- To Analyze A Sample of Brass QualitativelyDocument16 pagesTo Analyze A Sample of Brass QualitativelyAditya saxena100% (1)

- Corrosion - WikipediaDocument16 pagesCorrosion - WikipediaAVINASHRAJNo ratings yet

- Corrosion: of Dental MaterialsDocument19 pagesCorrosion: of Dental MaterialsDRPRIYA007No ratings yet

- Knack Manhole Cover Grey Cast IronDocument100 pagesKnack Manhole Cover Grey Cast Irongolf2010No ratings yet

- Adichanallur: A Prehistoric Mining Site: BS, S S, DV R, BR R, S B, S RDocument26 pagesAdichanallur: A Prehistoric Mining Site: BS, S S, DV R, BR R, S B, S RThirumalai SundaramNo ratings yet

- ASTM A-788 - Standard Specification For Steel Forgings, General RequirementsDocument11 pagesASTM A-788 - Standard Specification For Steel Forgings, General RequirementsadrianosoNo ratings yet

- Refresher Day 20Document3 pagesRefresher Day 20Jevan A. CalaqueNo ratings yet

- Unit 4Document24 pagesUnit 4Itachi UchihaNo ratings yet

- Mineralogy 06 01 PDFDocument28 pagesMineralogy 06 01 PDFAhmedElmoghanyNo ratings yet

- Science - Form 4 - Chapter 5Document12 pagesScience - Form 4 - Chapter 5Marcia PattersonNo ratings yet

- Standard Test Method For Loss of Mass in A Reducing Gas Atmosphere For Cobalt, Copper, Tungsten, and Iron Powders (Hydrogen Loss)Document3 pagesStandard Test Method For Loss of Mass in A Reducing Gas Atmosphere For Cobalt, Copper, Tungsten, and Iron Powders (Hydrogen Loss)viverefeliceNo ratings yet

- Causes of Deterioration of Reinforced ConcreteDocument40 pagesCauses of Deterioration of Reinforced Concretesahel khaanNo ratings yet

- 8265 13604 1 SMDocument20 pages8265 13604 1 SMRensy Tuto HalimakingNo ratings yet

- Design Guide Galvanized Steel StructuresDocument28 pagesDesign Guide Galvanized Steel StructuresHung Mai VanNo ratings yet

- Nickel and Cobalt Mining in PhilippinesDocument2 pagesNickel and Cobalt Mining in PhilippinesJunel AlapaNo ratings yet

- #The Exudation Test For "Bleeding" in Bituminous RoofingDocument3 pages#The Exudation Test For "Bleeding" in Bituminous RoofingMa JamieNo ratings yet

- Master Question Bank: Inorganic ChemistryDocument29 pagesMaster Question Bank: Inorganic ChemistryPRIYANSHNo ratings yet

- Lime Systems - Brochure PDFDocument32 pagesLime Systems - Brochure PDFRomeu Branco Simões0% (1)

- Cambridge O Level: CHEMISTRY 5070/21Document20 pagesCambridge O Level: CHEMISTRY 5070/21Viswesh VenugopalNo ratings yet

- Chem ColoursDocument1 pageChem ColoursNur Amalina Izzati ZakieNo ratings yet

- The Hardness of Metals A Visual Representation of The Mohs ScaleDocument1 pageThe Hardness of Metals A Visual Representation of The Mohs ScaleElioNo ratings yet

- Lesson Plan For Minerals and Energy Resources Part 1 RevisedDocument8 pagesLesson Plan For Minerals and Energy Resources Part 1 Revisedapi-27927708067% (9)

- Moskalyk, Alfantazi - 2003 - Review of Copper Pyrometallurgical Practice Today and Tomorrow - Minerals EngineeringDocument27 pagesMoskalyk, Alfantazi - 2003 - Review of Copper Pyrometallurgical Practice Today and Tomorrow - Minerals EngineeringÁlvaro JaraNo ratings yet

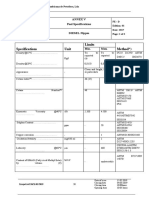

- Posmac: Posco Magnesium Aluminium Alloy Coating ProductDocument48 pagesPosmac: Posco Magnesium Aluminium Alloy Coating ProductCatherine DussnNo ratings yet

- Sheet MetalDocument41 pagesSheet MetalMa. Bianca Isabelle S. GoNo ratings yet

- Astm B115Document9 pagesAstm B115claudio547550% (2)

- Metallurgy of GoldDocument7 pagesMetallurgy of Goldvenkat_786100% (1)

- Epithermal Au-Ag Deposit Types - ImplicationsDocument16 pagesEpithermal Au-Ag Deposit Types - ImplicationsJhon Oliver TrebejoNo ratings yet

- Africa's Strategic Minerals in WWIIDocument29 pagesAfrica's Strategic Minerals in WWIITarredPigeonNo ratings yet

- GLASSDocument5 pagesGLASSPamela SidicNo ratings yet