Professional Documents

Culture Documents

Lube and Fuel Lab Consultant Report

Uploaded by

abdul rahmatOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lube and Fuel Lab Consultant Report

Uploaded by

abdul rahmatCopyright:

Available Formats

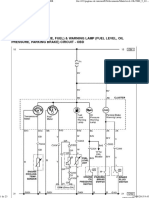

Lube and Fuel Laboratory Consultant

PT PETROLAB SERVICES

Jl. Jend Sudirman No. 874 Komp. UT Stalkuda Balikpapan 76114

Telp 0542-762873 fax. 0542-765019; petrolab@cbn.net.id; www.petrolab.co.id No. 00450/BPN/01/20

Company Name : PT. SEFAS PELINDOTAMA Unit Model : A40E Oil Matrix : RIMULA R4 X 15W40

To Customer : PT. EQUALINDO Unit Number : ADT-03 Serial Number : -

Address : Component : ENGINE Make/Brand : -

Location : Component Matrix : EG HDT Sample From :

Test Detail Overall Analysis Result:

Lab Number OB1922568 OB2000450

Sampling Date 2019-12-28 2020-01-08

Received Date 2019-12-31 2020-01-10

Report Date 2020-01-04 2020-01-16

Hours on Oil 260 350

Hours on Unit 27678 27801

SHELL RIMULA SHELL RIMULA Attention

Oil Type

R4 X R4 X

Oil Change No No

STATUS NORMAL ATTENTION Attention Urgent

Physical Test Unit Method Test Value Min | Max Min | Max

Visc@40C (*) cSt ASTM D7279 98.1 | 119.9 87.2 | 130.8

Visc@100C (*) cSt ASTM D7279 13.26 13.12 / BL 13.23 | 16.17 11.76 | 17.64

Visccosity Index - ASTM D2270-10e1

TBN mg KOH/g ASTM D2896-15 9.58 9.41 5.78 3.17

TAN mg KOH/g ASTM D974-14e2

Metal Additive Warning Limit

Magnesium (Mg) ppm ASTM D5185-13e1 8 8

Calcium (Ca) ppm ASTM D5185-13e1 3457 3533

Zinc (Zn) ppm ASTM D5185-13e1 1207 1251

Contaminant

Natrium (Na) ppm ASTM D5185-13e1 1 4 35 50

Silicon (Si) ppm ASTM D5185-13e1 8 8 30 45

Fuel Dilution *) %v ASTM E2412-10 0 0 2 3

Water Content *) %v ASTM E2412-10 0 0 0.1 0.2

G L Y C O L *) %v ASTM E2412-10 0 0 2 3

Wear Metal

Iron (Fe) ppm ASTM D5185-13e1 13 12 100 150

Copper (Cu) ppm ASTM D5185-13e1 <1 1 30 40

Alumunium (Al) ppm ASTM D5185-13e1 3 3 20 30

Chromium (Cr) ppm ASTM D5185-13e1 1 1 10 15

Nickel (Ni) ppm ASTM D5185-13e1 <1 1 10 15

Tin (Sn) ppm ASTM D5185-13e1 1 <1 10 20

Lead (Pb) ppm ASTM D5185-13e1 2 1 35 50

PQ Index *) - PQ Analyzer 21 31

FTIR Warning Limit

Soot Abs/01mm ASTM E2412-10 0.08 0.17 0.7 1

Oxidation Abs/01mm ASTM E2412-10 0.11 0.08 0.3 0.5

Nitration Abs/01mm ASTM E2412-10 0.05 0.02 0.3 0.5

Sulfation Abs/01mm ASTM E2412-10 0.06 < 0.02 0.3 0.5

Source of Abnormality

HASIL ANALISA ATTENTION. Nilai viskositas pelumas turun tetapi masih dalam batas toleransi.

Action to be Taken

Perhatikan kontaminan pada saat handling (pengisian) pelumas. Periksa penyebab tingginya laju penurunan nilai viskositas. Periksa kemungkinan terjadi overload.

Perhatikan kebersihan tool sampling dan cara pengambilan sampel. Lanjutkan sampling pada jadwal service berikutnya.

Note:

- hasil uji pada report ini adalah sesuai dengan sample yang diterima

- laporan hasil uji tidak boleh digandakan sebagian atau seluruhnya tanpa persetujuan tertulis dari laboratorium

You might also like

- Adt-03 Engine 3112 Ob1922568Document1 pageAdt-03 Engine 3112 Ob1922568abdul rahmatNo ratings yet

- SKL-1155 (0132 - Hpu-Mca) - Hydraulic - 2111 - Ob2324030 - BDocument2 pagesSKL-1155 (0132 - Hpu-Mca) - Hydraulic - 2111 - Ob2324030 - BMUHAMMAD LUTHFINo ratings yet

- Lube and Fuel Lab Consultant ReportDocument1 pageLube and Fuel Lab Consultant Reportopen hartigNo ratings yet

- Lube and Fuel Laboratory Consultant ReportDocument1 pageLube and Fuel Laboratory Consultant Reportopen hartigNo ratings yet

- RD218 Gardan 3110 Ob2226657 NDocument1 pageRD218 Gardan 3110 Ob2226657 Nopen hartigNo ratings yet

- Oil Analysis Report: PT Petrolab ServicesDocument1 pageOil Analysis Report: PT Petrolab ServicesJon HermanNo ratings yet

- RD218 - Left Final Drive - 3110 - Ob2226655 - CDocument2 pagesRD218 - Left Final Drive - 3110 - Ob2226655 - Copen hartigNo ratings yet

- NKL-967 (0126 - Hpu-Mca) - Hydraulic - 2111 - Ob2324031 - BDocument2 pagesNKL-967 (0126 - Hpu-Mca) - Hydraulic - 2111 - Ob2324031 - BMUHAMMAD LUTHFINo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- PT Petrolab Oil Analysis ReportDocument1 pagePT Petrolab Oil Analysis ReportJon HermanNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- Oil Analysis Report: PT Petrolab ServicesDocument1 pageOil Analysis Report: PT Petrolab ServicesJon HermanNo ratings yet

- Oil Analysis Report: PT Petrolab ServicesDocument1 pageOil Analysis Report: PT Petrolab ServicesJon HermanNo ratings yet

- RD 217 - Transmission - 3110 - Ob2226660 - CDocument2 pagesRD 217 - Transmission - 3110 - Ob2226660 - Copen hartigNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsDimasNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsNanang PrasetyaNo ratings yet

- Harry 11 Me PortDocument1 pageHarry 11 Me PortDaniel Fr SinagaNo ratings yet

- Lube and Fuel Lab Consultant ReportDocument1 pageLube and Fuel Lab Consultant ReportDaniel Fr SinagaNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- Mycom #1Document1 pageMycom #1Rifky Windya NNo ratings yet

- OJ10641 UO 23 QRDocument1 pageOJ10641 UO 23 QRSubastianNo ratings yet

- OJ10643 UO 23 QRDocument1 pageOJ10643 UO 23 QRSubastianNo ratings yet

- PT Petrolab Services: Test DetailDocument2 pagesPT Petrolab Services: Test DetailDaniel Fr SinagaNo ratings yet

- OJ10640 UO 23 QRDocument1 pageOJ10640 UO 23 QRSubastianNo ratings yet

- OJ10642 UO 23 QRDocument1 pageOJ10642 UO 23 QRSubastianNo ratings yet

- Sterntube - Man. AstaDocument1 pageSterntube - Man. AstacahyoNo ratings yet

- PT Petrolab Services: Test DetailDocument1 pagePT Petrolab Services: Test DetailDiat NorNo ratings yet

- PT Petrolab Services: Test DetailDocument2 pagesPT Petrolab Services: Test DetailDaniel Fr SinagaNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAhmad HisyamNo ratings yet

- OJ10639 UO 23 QRDocument1 pageOJ10639 UO 23 QRSubastianNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsdnoaisapsNo ratings yet

- Pdf24 MergedDocument9 pagesPdf24 MergedauliaadyaksaNo ratings yet

- Microsoft PowerPoint - Hi-Water Content On Lube Oil FGC EMCLDocument18 pagesMicrosoft PowerPoint - Hi-Water Content On Lube Oil FGC EMCLnjajaljehNo ratings yet

- DT1342 EngineDocument1 pageDT1342 EnginedayatNo ratings yet

- Batch 124232 Pt. Kerta Bumi Teknindo - PLTD TinaboganDocument5 pagesBatch 124232 Pt. Kerta Bumi Teknindo - PLTD Tinaboganamin ghozaliNo ratings yet

- Standard Spec FAME-EBTKE+PETDocument1 pageStandard Spec FAME-EBTKE+PETMuhamad Firmansyah Hermana PutraNo ratings yet

- 6:: Ff-Hna$Ufa (Ra:::: TLW - Psbol .Co"Id LnilDocument1 page6:: Ff-Hna$Ufa (Ra:::: TLW - Psbol .Co"Id Lnilkingpin182No ratings yet

- 15W40 Mega 2 20190316Document1 page15W40 Mega 2 20190316Khaerul Ade WiyatnoNo ratings yet

- DT2872 Final Drive Center RHDocument1 pageDT2872 Final Drive Center RHdayatNo ratings yet

- Infineum D3453Document2 pagesInfineum D3453Carlos Enrique Mora CortezNo ratings yet

- Translik HD Sae 30 Mega 2 20190316Document1 pageTranslik HD Sae 30 Mega 2 20190316Khaerul Ade WiyatnoNo ratings yet

- DT2407 DifferentialDocument1 pageDT2407 DifferentialdayatNo ratings yet

- Characteristics Units Result Test Method: Southern Pars 1 CondensateDocument14 pagesCharacteristics Units Result Test Method: Southern Pars 1 CondensatemohammadhadiNo ratings yet

- HGR3098 Engine 23augDocument1 pageHGR3098 Engine 23augIndo BemlNo ratings yet

- Infineum D3398Document1 pageInfineum D3398Carlos Enrique Mora Cortez100% (1)

- Lube and Fuel Laboratory Consultant Petrolab ServicesDocument1 pageLube and Fuel Laboratory Consultant Petrolab Serviceskingpin182No ratings yet

- Komatsu PC 400Document1 pageKomatsu PC 400kingpin182No ratings yet

- Property Unit Test Method Specificatio N: Table 4.4 - Alkylate Product Specification - LPG (Butanes) (Note 1, 2)Document1 pageProperty Unit Test Method Specificatio N: Table 4.4 - Alkylate Product Specification - LPG (Butanes) (Note 1, 2)Nguyễn Hồng SơnNo ratings yet

- BECOSA Preslia GT 46 (9-23)Document4 pagesBECOSA Preslia GT 46 (9-23)jose manuelNo ratings yet

- HGR3100 Engine 23augDocument1 pageHGR3100 Engine 23augIndo BemlNo ratings yet

- API Test Data For Distribution 1 1Document6 pagesAPI Test Data For Distribution 1 1Avyan KelanNo ratings yet

- Comparison oil testDocument2 pagesComparison oil testdede azandriNo ratings yet

- Supreme Roa02Document1 pageSupreme Roa02MUDI SOBARHADINo ratings yet

- Special steels A320 L7 - L7M American standards ASTMDocument1 pageSpecial steels A320 L7 - L7M American standards ASTMNarimane BentyNo ratings yet

- t345 Engine UpdateDocument1 paget345 Engine Updatearif adi saputraNo ratings yet

- Infineum D3451Document2 pagesInfineum D3451Carlos Enrique Mora CortezNo ratings yet

- Premium: SAE 20W-50 Motor OilDocument2 pagesPremium: SAE 20W-50 Motor OilengerbethNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Properties of Bituminous Binder Modified With Waste Polyethylene TerephthalateDocument12 pagesProperties of Bituminous Binder Modified With Waste Polyethylene Terephthalatezeidan111No ratings yet

- 1 Design Engineering Drawings For The EasyDry M500 JD Version PDFDocument169 pages1 Design Engineering Drawings For The EasyDry M500 JD Version PDFSelim Lukman100% (1)

- Root of Women’s Oppression According to Psychoanalytic FeminismDocument8 pagesRoot of Women’s Oppression According to Psychoanalytic FeminismPrincess Janine SyNo ratings yet

- GRADE 5 Answer Sheet q1 Module 9&10Document6 pagesGRADE 5 Answer Sheet q1 Module 9&10Jina Mellino OrbitaNo ratings yet

- Assessment in The Affective DomainDocument13 pagesAssessment in The Affective DomainLeslie MarciaNo ratings yet

- Statin RisksDocument2 pagesStatin RisksYazen JoudehNo ratings yet

- Perlos HistoryDocument21 pagesPerlos HistoryRiyali TardyNo ratings yet

- Laurie BakerDocument12 pagesLaurie BakerchaplinNo ratings yet

- Pharmacoepidemiology and Environmental HealthDocument3 pagesPharmacoepidemiology and Environmental HealthAashish BhattaraiNo ratings yet

- Goat anatomy and physiology guideDocument8 pagesGoat anatomy and physiology guideLochi GmNo ratings yet

- Fish Processing CGDocument41 pagesFish Processing CGmelisasumbilon100% (1)

- Dokumen - Tips Daewoo Service Manual Instrument Cluster Matiz-2023Document23 pagesDokumen - Tips Daewoo Service Manual Instrument Cluster Matiz-2023urexalg AlgériaNo ratings yet

- Aprinnova Simply Solid One Page SummaryDocument2 pagesAprinnova Simply Solid One Page SummaryPatrick FlowerdayNo ratings yet

- SGS-GIS-RFC - Combined Version-A4 - v8 - Mar 16 2018Document3 pagesSGS-GIS-RFC - Combined Version-A4 - v8 - Mar 16 2018Refresh CornerNo ratings yet

- Condensate Drain Calculation - Lab AHU PDFDocument1 pageCondensate Drain Calculation - Lab AHU PDFAltaf KhanNo ratings yet

- PS - 2K - PC210-10M0 - BY - FATI - Copy (1) (2) (Read-Only)Document19 pagesPS - 2K - PC210-10M0 - BY - FATI - Copy (1) (2) (Read-Only)Fatra JuliandNo ratings yet

- Gesell's Maturational TheoryDocument4 pagesGesell's Maturational TheorysanghuNo ratings yet

- Observation of Unknown SpectrumDocument3 pagesObservation of Unknown SpectrumOmar HusseinNo ratings yet

- Klee N Rite 50100Document24 pagesKlee N Rite 50100Nestor Marquez-DiazNo ratings yet

- Method Statement - 23apr18Document5 pagesMethod Statement - 23apr18hinitahNo ratings yet

- M&e Electrical AccessoriresDocument11 pagesM&e Electrical Accessorirespetroyston909937100% (5)

- Introduction To CommerceDocument30 pagesIntroduction To Commerceapi-24690719591% (11)

- PDFDocument478 pagesPDFPriyaranjan PradhanNo ratings yet

- The Giant First YearDocument1,234 pagesThe Giant First YearEthan DyerNo ratings yet

- Naemi Root Crop Rat Killer ResearchDocument3 pagesNaemi Root Crop Rat Killer ResearchJerome BumagatNo ratings yet

- Comparative Study of Soaps of Hul P Amp G Godrej Nirma and Johnson Amp Johnson 130410234307 Phpapp01 PDFDocument71 pagesComparative Study of Soaps of Hul P Amp G Godrej Nirma and Johnson Amp Johnson 130410234307 Phpapp01 PDFdheeraj agarwalNo ratings yet

- HE - Food and Beverages CGDocument14 pagesHE - Food and Beverages CGJohn Leonard88% (8)

- PFC Katalog PPDocument128 pagesPFC Katalog PPbmsinghNo ratings yet

- X PPT CH 12 ElectricityDocument12 pagesX PPT CH 12 ElectricityAakriti100% (1)

- Dating Questions and AnswersDocument13 pagesDating Questions and AnswersFelicia Babrant98% (49)