Professional Documents

Culture Documents

DT2872 Final Drive Center RH

Uploaded by

dayatCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DT2872 Final Drive Center RH

Uploaded by

dayatCopyright:

Available Formats

PT.

Tekenomiks Indonesia

Office : Jl. Jend Sudirman No. 58 RT 29 Balikpapan, 76114 Indonesia

PROBLEM

TECHNICAL ADVANCE FOR ECONOMIC GAIN

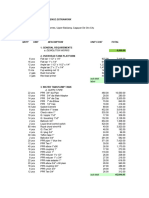

Wear Metal Report: 00932862

Client: PT. DARMA HENWA ASAM-ASAM

Attention: PT. DARMA HENWA ASAM-ASAM

Address ASAM-ASAM

Machine: SANY SKT 80S ID No: DT2872

Oil Name: SHELL SPIRAX S2 A 85W-140

Visc@40°C: 358 Visc@100°C: 25.6 TBN: 0

Compartm't: FINAL DRIVE RH CENTER S/N: -

Sample Date: 07/07/2023 28/07/2023 14/08/2023 16/09/2023 17/10/2023 08/12/2023

Received Date 10/07/2023 31/07/2023 21/08/2023 20/09/2023 27/10/2023 18/12/2023

Analysis Date: 11/07/2023 01/08/2023 22/08/2023 21/09/2023 27/10/2023 18/12/2023

Reported Date 13/07/2023 04/08/2023 24/08/2023 22/09/2023 01/11/2023 19/12/2023

Sample no: 00900295 00904470 00908499 00914902 00921906 00932862

SMU:(hrs) 503 750 1013 1498 1983 2484

Oil Hrs: 368 615 263 485 485 978

Oil Changed: No Yes Yes Yes Yes No

Component Hours - - - - - -

Wear Metal Rate 0.31 0.50 1.51 0.56 0.42 0.43

Wear Metals METHOD RESULT Caut High Comments on elevated results

lead (Pb)(mg/kg) ASTM D5185 0.0 2.4 7.0 6.1 2.0 2.5 9 15 Oli gelap. PQ naik tinggi. terkait keausan

Gear Bearing Shaft Housing. Cek level dan

iron (Fe)(mg/kg) ASTM D5185 109.8 249.6 302.6 187.2 157.4 373.4 450 750 kondisi oli. Monitor kebocoran. cek suara

aluminium (Al)(mg/kg) ASTM D5185 0.6 1.0 1.1 0.6 0.1 0.8 12 20 tidak normal. cek magnetic plug dan debris.

copper (Cu)(mg/kg) ASTM D5185 0.7 49.5 74.3 69.1 41.9 37.6 135 225 Lakukan pemeriksaan. (arman)

chromium (Cr)(mg/kg) ASTM D5185 1.3 1.4 2.0 0.9 0.3 1.7 12 20

tin (Sn)(mg/kg) ASTM D5185 0.1 2.6 7.1 5.2 0.1 1.2 9 15

nickel (Ni)(mg/kg) ASTM D5185 0.2 1.9 1.9 0.8 0.1 2.6 9 15

Contaminants

silicon (Si)(mg/kg) ASTM D5185 3.8 20.3 20.4 8.9 4.5 3.8 60 100

sodium (Na)(mg/kg) ASTM D5185 10.5 7.9 6.5 2.4 0.8 2.5 36 60

Oil Additives

magnesium (Mg)(mg/kg) ASTM D5185 0 1 1 1 0 0 0 0

zinc (Zn)(mg/kg) ASTM D5185 4 12 18 11 3 2 0 0

molybdenum (Mo)(mg/kg) ASTM D5185 0 0 0 0 0 0 0 0

calcium (Ca)(mg/kg) ASTM D5185 4 13 13 6 1 5 0 0

phosphorous (P)(mg/kg) ASTM D5185 323 233 251 214 229 251 0 0

boron (B)(mg/kg) ASTM D5185 19 5 15 11 0 0 0 0

Infra Red

TBN(mgKOH/g) ASTM D4739 n/a n/a n/a n/a n/a n/a -0% -0%

TAN(mgKOH/g) ASTM D974 n/a n/a n/a n/a n/a n/a 0 0 Approved by : Ita Saronika ( Manager Lab )

soot(Abs/cm) ASTM E2412 n/a n/a n/a n/a n/a n/a 0 0

glycol(% vol) ASTM E2412 n/a n/a n/a n/a n/a n/a 0 0

oxidation((x.100)abs/0.1mm) ASTM E2412 n/a n/a n/a n/a n/a n/a 0 0

nitration((x.100)abs/0.1mm) ASTM E2412 n/a n/a n/a n/a n/a n/a 0 0

sulphation((x.100)abs/0.1mm) ASTM E2412 n/a n/a n/a n/a n/a n/a 0 0

Physical Tests Particle Cleanliness Analysis

water(ppm) ASTM D6304 n/a n/a n/a n/a n/a n/a 0 0 ISO 4406 - 04 | -

fuel dilution(% vol) In-house n/a n/a n/a n/a n/a n/a 0 0 ISO 4406 - 06 | -

water(%) ASTM E2412 0.00 0.00 0.00 0.00 0.00 0.00 0 0 ISO 4406 - 14 | -

F.debris(mg Fe/L) ASTM D8120 162 145 261 300 330 922 300 500 Count 1ml | -

visc @ 100oC(mm2/s) ASTM D445 n/a n/a n/a n/a n/a n/a +-0 0

visc @ 40oC(mm2/s) ASTM D445 316.4 339.8 305.1 320.1 338.7 350.5 +-10 +-30

Iso Code (Part/mL)() ISO 4406 -/-/- -/-/- -/-/- -/-/- -/-/- -/-/- 0 0

Element Trends Graph

For enquiries: Tekenomiks Balikpapan, email : Labbpn@techenomics.com, phone : 0542-762226 fax : 0542 - 762256 mobile : 0542-764681

This wear analysis and oil condition report should be used in conjunction with normal maintenance and evaluated from sample to sample. Every care will be taken in processing samples but no express or implied guarantee is furnished in

regard to the continuing operation or condition of this machinery or any part thereof.

The Result of Analysis is only related to the sample analyzed.

You might also like

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- DT2407 DifferentialDocument1 pageDT2407 DifferentialdayatNo ratings yet

- DT1342 EngineDocument1 pageDT1342 EnginedayatNo ratings yet

- Batch 124232 Pt. Kerta Bumi Teknindo - PLTD TinaboganDocument5 pagesBatch 124232 Pt. Kerta Bumi Teknindo - PLTD Tinaboganamin ghozaliNo ratings yet

- t345 Engine UpdateDocument1 paget345 Engine Updatearif adi saputraNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- HDTL 025Document1 pageHDTL 025Angga 99No ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- Lube and Fuel Lab Consultant ReportDocument1 pageLube and Fuel Lab Consultant Reportabdul rahmatNo ratings yet

- HGR3100 Engine 23augDocument1 pageHGR3100 Engine 23augIndo BemlNo ratings yet

- NKL-967 (0126 - Hpu-Mca) - Hydraulic - 2111 - Ob2324031 - BDocument2 pagesNKL-967 (0126 - Hpu-Mca) - Hydraulic - 2111 - Ob2324031 - BMUHAMMAD LUTHFINo ratings yet

- Mycom #1Document1 pageMycom #1Rifky Windya NNo ratings yet

- SKL-1155 (0132 - Hpu-Mca) - Hydraulic - 2111 - Ob2324030 - BDocument2 pagesSKL-1155 (0132 - Hpu-Mca) - Hydraulic - 2111 - Ob2324030 - BMUHAMMAD LUTHFINo ratings yet

- HGR3098 Engine 23augDocument1 pageHGR3098 Engine 23augIndo BemlNo ratings yet

- RD218 Gardan 3110 Ob2226657 NDocument1 pageRD218 Gardan 3110 Ob2226657 Nopen hartigNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAhmad HisyamNo ratings yet

- Sterntube - Man. AstaDocument1 pageSterntube - Man. AstacahyoNo ratings yet

- PT Petrolab Services: Test DetailDocument2 pagesPT Petrolab Services: Test DetailDaniel Fr SinagaNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- RD218 - Left Final Drive - 3110 - Ob2226655 - CDocument2 pagesRD218 - Left Final Drive - 3110 - Ob2226655 - Copen hartigNo ratings yet

- RD 217 - Transmission - 3110 - Ob2226660 - CDocument2 pagesRD 217 - Transmission - 3110 - Ob2226660 - Copen hartigNo ratings yet

- Oil Analysis Report: PT Petrolab ServicesDocument1 pageOil Analysis Report: PT Petrolab ServicesJon HermanNo ratings yet

- Lube and Fuel Lab Consultant ReportDocument1 pageLube and Fuel Lab Consultant Reportopen hartigNo ratings yet

- PT Petrolab Services: Test DetailDocument2 pagesPT Petrolab Services: Test DetailDaniel Fr SinagaNo ratings yet

- TM GDR-413Document2 pagesTM GDR-413Ahmat RamadaniNo ratings yet

- Pdf24 MergedDocument9 pagesPdf24 MergedauliaadyaksaNo ratings yet

- Lube and Fuel Laboratory Consultant ReportDocument1 pageLube and Fuel Laboratory Consultant Reportopen hartigNo ratings yet

- PT Petrolab Oil Analysis ReportDocument1 pagePT Petrolab Oil Analysis ReportJon HermanNo ratings yet

- OJ10643 UO 23 QRDocument1 pageOJ10643 UO 23 QRSubastianNo ratings yet

- Adt-03 Engine 3112 Ob1922568Document1 pageAdt-03 Engine 3112 Ob1922568abdul rahmatNo ratings yet

- Oil Analysis Report: PT Petrolab ServicesDocument1 pageOil Analysis Report: PT Petrolab ServicesJon HermanNo ratings yet

- PT Petrolab Services: Test DetailDocument1 pagePT Petrolab Services: Test DetailDiat NorNo ratings yet

- OJ10642 UO 23 QRDocument1 pageOJ10642 UO 23 QRSubastianNo ratings yet

- OJ10641 UO 23 QRDocument1 pageOJ10641 UO 23 QRSubastianNo ratings yet

- Oil Analysis Report: PT Petrolab ServicesDocument1 pageOil Analysis Report: PT Petrolab ServicesJon HermanNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsNanang PrasetyaNo ratings yet

- OJ10640 UO 23 QRDocument1 pageOJ10640 UO 23 QRSubastianNo ratings yet

- OJ10639 UO 23 QRDocument1 pageOJ10639 UO 23 QRSubastianNo ratings yet

- Harry 11 Me PortDocument1 pageHarry 11 Me PortDaniel Fr SinagaNo ratings yet

- Brockville Lubricant Certificate of AnalysisDocument2 pagesBrockville Lubricant Certificate of Analysisfabian de jesus alvarez restrepoNo ratings yet

- BECOSA Preslia GT 46 (9-23)Document4 pagesBECOSA Preslia GT 46 (9-23)jose manuelNo ratings yet

- API Test Data For Distribution 1 1Document6 pagesAPI Test Data For Distribution 1 1Avyan KelanNo ratings yet

- Dewpoint Copper DPC-0521-DDocument4 pagesDewpoint Copper DPC-0521-DTengku MunzirNo ratings yet

- Microsoft PowerPoint - Hi-Water Content On Lube Oil FGC EMCLDocument18 pagesMicrosoft PowerPoint - Hi-Water Content On Lube Oil FGC EMCLnjajaljehNo ratings yet

- Lube and Fuel Lab Consultant ReportDocument1 pageLube and Fuel Lab Consultant ReportDaniel Fr SinagaNo ratings yet

- Cement Mill Test - Fairborn Cement Company Type-IA - Jan2022Document2 pagesCement Mill Test - Fairborn Cement Company Type-IA - Jan2022mohamed ElsayedNo ratings yet

- FOB Extra Duty Gear Oil TDSW 815913 - 815914Document3 pagesFOB Extra Duty Gear Oil TDSW 815913 - 815914Elwin arifinNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsDimasNo ratings yet

- Characteristics Units Result Test Method: Southern Pars 1 CondensateDocument14 pagesCharacteristics Units Result Test Method: Southern Pars 1 CondensatemohammadhadiNo ratings yet

- Product Data Sheet OK Autrod 12.51: G 'Gas-Shielded Metal-Arc Welding'Document2 pagesProduct Data Sheet OK Autrod 12.51: G 'Gas-Shielded Metal-Arc Welding'Filipe CordeiroNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsdnoaisapsNo ratings yet

- Product Data Sheet OK Autrod 12.64: G 'Gas-Shielded Metal-Arc Welding'Document2 pagesProduct Data Sheet OK Autrod 12.64: G 'Gas-Shielded Metal-Arc Welding'Cem DufourNo ratings yet

- Zinc Ribbon AnodeDocument1 pageZinc Ribbon AnodeABIJITH R NATHNo ratings yet

- Condensate Specs and TBP 1Document1 pageCondensate Specs and TBP 1asad razaNo ratings yet

- 211 JS ProcessDocument1 page211 JS ProcessPRITESHNo ratings yet

- Test Certificate: (, Phone: 26751763 MillDocument1 pageTest Certificate: (, Phone: 26751763 MillQc QatarNo ratings yet

- Techalloy 625: Conformances Key FeaturesDocument2 pagesTechalloy 625: Conformances Key FeaturesJulian AdaraqueNo ratings yet

- AUTROD 316LSiDocument2 pagesAUTROD 316LSijoao guilhermeNo ratings yet

- DT2872 Final Drive Center RHDocument1 pageDT2872 Final Drive Center RHdayatNo ratings yet

- DT2407 Final Drive LHDocument1 pageDT2407 Final Drive LHdayatNo ratings yet

- Omm Ex-9200 PDFDocument31 pagesOmm Ex-9200 PDFdayatNo ratings yet

- Ex2500-5 Maintenance (Ttla0449)Document140 pagesEx2500-5 Maintenance (Ttla0449)Khairuddin KhairuddinNo ratings yet

- 4ch1 2cr Que 20230614Document24 pages4ch1 2cr Que 20230614Ahmed Mahmoud100% (1)

- Sinter Plant Presentation Dec18Document18 pagesSinter Plant Presentation Dec18Shashi Kant TiwariNo ratings yet

- Remediation Lesson in SMAW NC IIDocument49 pagesRemediation Lesson in SMAW NC IIemmabentonioNo ratings yet

- Chemistry Titration Questions Worked SolutionsDocument4 pagesChemistry Titration Questions Worked SolutionshdawgNo ratings yet

- Carbon Fiber's Strengths for ConstructionDocument11 pagesCarbon Fiber's Strengths for ConstructionAdarsh SooryaNo ratings yet

- Structural Beam Drawing Notes and ScheduleDocument1 pageStructural Beam Drawing Notes and ScheduleDHIRAJNo ratings yet

- Act - Red Mud PolymerDocument39 pagesAct - Red Mud PolymerNaGamani KanDanNo ratings yet

- SS 608-2015+A1-2017 - PreviewDocument10 pagesSS 608-2015+A1-2017 - PreviewchrajeshNo ratings yet

- Ambra-Akcela Oil Specs PDFDocument1 pageAmbra-Akcela Oil Specs PDFJUNA RUSANDI S100% (1)

- 3.welding ProcessDocument45 pages3.welding ProcessaleventNo ratings yet

- Chemistry Model Exam For G 8Document11 pagesChemistry Model Exam For G 8Kedir MohammedNo ratings yet

- Altered Art Circus - Techniques For Journals, Paper Dolls, Art Cards, and AssemblagesDocument129 pagesAltered Art Circus - Techniques For Journals, Paper Dolls, Art Cards, and AssemblagesHoàng Anh Phương100% (2)

- Foundation Drawing PDFDocument1 pageFoundation Drawing PDFParvez KhanNo ratings yet

- Chemistry of Newer MaterialsDocument30 pagesChemistry of Newer MaterialsDr. Dhondiba Vishwanath100% (1)

- Limit TestDocument34 pagesLimit TestAbhinav kumarNo ratings yet

- Mobilgrease MPDocument2 pagesMobilgrease MPjerrypoaNo ratings yet

- Using the Right Fire ExtinguisherDocument8 pagesUsing the Right Fire ExtinguisherAjit BhosaleNo ratings yet

- Concrete Construction Article PDF - Using The New ACI 301Document3 pagesConcrete Construction Article PDF - Using The New ACI 301NoNa MohammedNo ratings yet

- CC203 Concrete Lab Slump TestDocument4 pagesCC203 Concrete Lab Slump TestLee Thiam Chai Lee0% (1)

- Fused Deposition Modeling (FDM)Document10 pagesFused Deposition Modeling (FDM)siddharthsainiNo ratings yet

- Tata Steel - MRVCDocument16 pagesTata Steel - MRVCRahul NirbaanNo ratings yet

- Raghu Engineering College: AutonomousDocument12 pagesRaghu Engineering College: Autonomousganesh chowdaryNo ratings yet

- Tanggol Duplex Extrawork 01Document3 pagesTanggol Duplex Extrawork 01Ar Mj GandarosaNo ratings yet

- Technicals of 316/lDocument2 pagesTechnicals of 316/lASHISH DOSHINo ratings yet

- Code A: Comment Resolution Sheet (CRS) Owners: EPCM ConsultantDocument6 pagesCode A: Comment Resolution Sheet (CRS) Owners: EPCM Consultantsumit kumarNo ratings yet

- LAB REPORT #4 COURSE SUMMARYDocument5 pagesLAB REPORT #4 COURSE SUMMARYGodwayneNo ratings yet

- Arsenic + AntimonyDocument3 pagesArsenic + AntimonyTyroneNo ratings yet

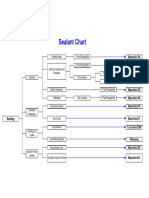

- Sealant Chart: Best Sealants for Waterproofing, Traffic Areas & MoreDocument1 pageSealant Chart: Best Sealants for Waterproofing, Traffic Areas & MoreDoby YuniardiNo ratings yet

- Lead Acid Battery: Department of Electrical & Electronics EngineeringDocument13 pagesLead Acid Battery: Department of Electrical & Electronics EngineeringHoneylyn IgnacioNo ratings yet

- Engineering Data Pack for D, P, & T Series PumpsDocument14 pagesEngineering Data Pack for D, P, & T Series PumpsAlvaro Jose DíazNo ratings yet