Professional Documents

Culture Documents

HGR3098 Engine 23aug

Uploaded by

Indo BemlOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HGR3098 Engine 23aug

Uploaded by

Indo BemlCopyright:

Available Formats

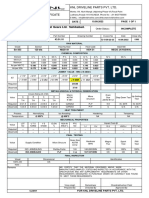

PT.

Tekenomiks Indonesia

Office : Jl. Jend Sudirman No. 58 RT 29 Balikpapan, 76114 Indonesia

WATCH

TECHNICAL ADVANCE FOR ECONOMIC GAIN

Wear Metal Report: 00908285

Client: PT. THRIVENI INDO MINING - SATUI

Attention: PT. THRIVENI INDO MINING - SATUI

Address

Machine: GRADER BEML BG825 ID No: HGR3098

Oil Name: SHELL RIMULA R3 MV 15W-40

Visc@40°C: 111 Visc@100°C: 14.6 TBN: 10.57

Compartm't: ENGINE S/N: -

Sample Date: - - - 24/07/2023 25/07/2023 12/08/2023

Received Date - - - 31/07/2023 31/07/2023 21/08/2023

Analysis Date: - - - 31/07/2023 31/07/2023 21/08/2023

Reported Date - - - 02/08/2023 01/08/2023 23/08/2023

Sample no: - - - 00904081 00903930 00908285

SMU:(hrs) - - - 50 107 334

Oil Hrs: - - - 50 107 334

Oil Changed: - - - No Yes Yes

Component Hours - - - - - -

Wear Metal Rate - - - 2.04 1.02 0.22

Wear Metals METHOD RESULT Caut High Comments on elevated results

lead (Pb)(mg/kg) ASTM D5185 n/a n/a n/a 10.9 17.0 10.9 48 80 Sampel pertama. SMU rendah. Cu dan

oksidasi di medium. fuel 1%. viskositas oli

iron (Fe)(mg/kg) ASTM D5185 n/a n/a n/a 8.3 10.0 10.7 57 95 rendah. terkait keausan Bearing Bushing

aluminium (Al)(mg/kg) ASTM D5185 n/a n/a n/a 1.0 1.0 1.5 28 46 Cooler. cek level dan kondisi oli. monitor

copper (Cu)(mg/kg) ASTM D5185 n/a n/a n/a 74.4 71.0 44.4 27 45 kondisi filter oli. cek drain plug dari debris.

cek engine noise. Cek fuel line kebocoran

chromium (Cr)(mg/kg) ASTM D5185 n/a n/a n/a 0.2 0.3 0.2 9 15 injector seals dan pump. cek timing injeksi.

tin (Sn)(mg/kg) ASTM D5185 n/a n/a n/a 5.8 9.1 6.6 9 15 cek kualitas fuel. Monitor kondisi operasi

nickel (Ni)(mg/kg) ASTM D5185 n/a n/a n/a

dan idling. Monitor engine temperatur.

1.2 0.4 0.3 9 15

Monitor sample selanjutnya. (arman)

Contaminants

silicon (Si)(mg/kg) ASTM D5185 n/a n/a n/a 34.9 37.3 14.1 24 40

sodium (Na)(mg/kg) ASTM D5185 n/a n/a n/a 4.3 4.3 2.7 60 100

Oil Additives

magnesium (Mg)(mg/kg) ASTM D5185 n/a n/a n/a 4 6 9 0 0

zinc (Zn)(mg/kg) ASTM D5185 n/a n/a n/a 958 1081 1084 0 0

molybdenum (Mo)(mg/kg) ASTM D5185 n/a n/a n/a 3 4 38 0 0

calcium (Ca)(mg/kg) ASTM D5185 n/a n/a n/a 2854 3401 3652 0 0 Approved by : Ita Saronika ( Manager Lab )

phosphorous (P)(mg/kg) ASTM D5185 n/a n/a n/a 826 940 962 0 0

boron (B)(mg/kg) ASTM D5185 n/a n/a n/a 18 17 356 0 0

Infra Red

TBN(mgKOH/g) ASTM D4739 n/a n/a n/a 9.16 8.97 7.89 -25% -50%

TAN(mgKOH/g) ASTM D974 n/a n/a n/a n/a n/a n/a 0 0

soot(Abs/cm) ASTM E2412 n/a n/a n/a 7 8 13 35 70

glycol(% vol) ASTM E2412 n/a n/a n/a 0 0 0 18 30

oxidation((x.100)abs/0.1mm) ASTM E2412 n/a n/a n/a 18 19 76 60 100

nitration((x.100)abs/0.1mm) ASTM E2412 n/a n/a n/a 7 7 7 60 100

sulphation((x.100)abs/0.1mm) ASTM E2412 n/a n/a n/a 3 0 16 60 100

Physical Tests Particle Cleanliness Analysis

water(ppm) ASTM D6304 n/a n/a n/a n/a n/a n/a 0 0 ISO 4406 - 04 | -

fuel dilution(% vol) In-house n/a n/a n/a 0.00 0.00 1.00 1 2 ISO 4406 - 06 | -

water(%) ASTM E2412 n/a n/a n/a 0.00 0.00 0.00 0 0 ISO 4406 - 14 | -

F.debris(mg Fe/L) ASTM D8120 n/a n/a n/a 4 3 3 12 20 Count 1ml | -

visc @ 100oC(mm2/s) ASTM D445 n/a n/a n/a 13.03 13.02 11.15 +-10 +-30

visc @ 40oC(mm2/s) ASTM D445 n/a n/a n/a 88.57 88.38 71.17 +-10 +-30

Iso Code (Part/mL)() ISO 4406 -/-/- -/-/- -/-/- -/-/- -/-/- -/-/- 0 0

Element Trends Graph

For enquiries: Tekenomiks Balikpapan, email : Labbpn@techenomics.com, phone : 0542-762226 fax : 0542 - 762256 mobile : 0542-764681

This wear analysis and oil condition report should be used in conjunction with normal maintenance and evaluated from sample to sample. Every care will be taken in processing samples but no express or implied guarantee is furnished in

regard to the continuing operation or condition of this machinery or any part thereof.

The Result of Analysis is only related to the sample analyzed.

You might also like

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3 out of 5 stars3/5 (4)

- HGR3100 Engine 23augDocument1 pageHGR3100 Engine 23augIndo BemlNo ratings yet

- TM GDR-413Document2 pagesTM GDR-413Ahmat RamadaniNo ratings yet

- DTHW 005Document1 pageDTHW 005Angga 99No ratings yet

- Batch 127232 Hexindo BalikpapanDocument2 pagesBatch 127232 Hexindo BalikpapanlilikNo ratings yet

- Batch 124232 Pt. Kerta Bumi Teknindo - PLTD TinaboganDocument5 pagesBatch 124232 Pt. Kerta Bumi Teknindo - PLTD Tinaboganamin ghozaliNo ratings yet

- DT1342 EngineDocument1 pageDT1342 EnginedayatNo ratings yet

- t345 Engine UpdateDocument1 paget345 Engine Updatearif adi saputraNo ratings yet

- HDTL 025Document1 pageHDTL 025Angga 99No ratings yet

- Mycom #1Document1 pageMycom #1Rifky Windya NNo ratings yet

- DT2872 Final Drive Center RHDocument1 pageDT2872 Final Drive Center RHdayatNo ratings yet

- Sterntube - Man. AstaDocument1 pageSterntube - Man. AstacahyoNo ratings yet

- Lube and Fuel Lab Consultant ReportDocument1 pageLube and Fuel Lab Consultant Reportabdul rahmatNo ratings yet

- Pdf24 MergedDocument9 pagesPdf24 MergedauliaadyaksaNo ratings yet

- DT2407 DifferentialDocument1 pageDT2407 DifferentialdayatNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- NKL-967 (0126 - Hpu-Mca) - Hydraulic - 2111 - Ob2324031 - BDocument2 pagesNKL-967 (0126 - Hpu-Mca) - Hydraulic - 2111 - Ob2324031 - BMUHAMMAD LUTHFINo ratings yet

- SKL-1155 (0132 - Hpu-Mca) - Hydraulic - 2111 - Ob2324030 - BDocument2 pagesSKL-1155 (0132 - Hpu-Mca) - Hydraulic - 2111 - Ob2324030 - BMUHAMMAD LUTHFINo ratings yet

- BT Oil Lab - Hpu - 09-10.06.2022Document1 pageBT Oil Lab - Hpu - 09-10.06.2022Faizhal ROGNo ratings yet

- PT Petrolab Services: Test DetailDocument1 pagePT Petrolab Services: Test DetailDiat NorNo ratings yet

- Lube and Fuel Lab Consultant ReportDocument1 pageLube and Fuel Lab Consultant Reportopen hartigNo ratings yet

- Lube and Fuel Laboratory Consultant ReportDocument1 pageLube and Fuel Laboratory Consultant Reportopen hartigNo ratings yet

- OJ10641 UO 23 QRDocument1 pageOJ10641 UO 23 QRSubastianNo ratings yet

- OJ10640 UO 23 QRDocument1 pageOJ10640 UO 23 QRSubastianNo ratings yet

- OJ10642 UO 23 QRDocument1 pageOJ10642 UO 23 QRSubastianNo ratings yet

- OJ10639 UO 23 QRDocument1 pageOJ10639 UO 23 QRSubastianNo ratings yet

- RD218 Gardan 3110 Ob2226657 NDocument1 pageRD218 Gardan 3110 Ob2226657 Nopen hartigNo ratings yet

- Oil Analysis Report: PT Petrolab ServicesDocument1 pageOil Analysis Report: PT Petrolab ServicesJon HermanNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAhmad HisyamNo ratings yet

- Oil Analysis Report: PT Petrolab ServicesDocument1 pageOil Analysis Report: PT Petrolab ServicesJon HermanNo ratings yet

- PT Petrolab Oil Analysis ReportDocument1 pagePT Petrolab Oil Analysis ReportJon HermanNo ratings yet

- Adt-03 Engine 3112 Ob1922568Document1 pageAdt-03 Engine 3112 Ob1922568abdul rahmatNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- PT Petrolab Services: Test DetailDocument2 pagesPT Petrolab Services: Test DetailDaniel Fr SinagaNo ratings yet

- Sample Oil April 2022 Manalagi AstaDocument9 pagesSample Oil April 2022 Manalagi Astacahyo putroNo ratings yet

- OJ10643 UO 23 QRDocument1 pageOJ10643 UO 23 QRSubastianNo ratings yet

- Lub Oil AnalysisDocument11 pagesLub Oil AnalysisMeghali BorleNo ratings yet

- RD 217 - Transmission - 3110 - Ob2226660 - CDocument2 pagesRD 217 - Transmission - 3110 - Ob2226660 - Copen hartigNo ratings yet

- PT Petrolab Services: Test DetailDocument2 pagesPT Petrolab Services: Test DetailDaniel Fr SinagaNo ratings yet

- RD218 - Left Final Drive - 3110 - Ob2226655 - CDocument2 pagesRD218 - Left Final Drive - 3110 - Ob2226655 - Copen hartigNo ratings yet

- INSPECTION TEST CERTIFICATE FOR FORGED STEEL GLOBE VALVESDocument1 pageINSPECTION TEST CERTIFICATE FOR FORGED STEEL GLOBE VALVESMohamed RaafatNo ratings yet

- Oil Analysis Report: PT Petrolab ServicesDocument1 pageOil Analysis Report: PT Petrolab ServicesJon HermanNo ratings yet

- PT Indonesia Power lube oil test reportsDocument9 pagesPT Indonesia Power lube oil test reportsarif ihwandaNo ratings yet

- Punjab Bevel Gears Ltd. Sahibabad.: KNL Driveline Parts Pvt. Ltd. Material Test CertificateDocument1 pagePunjab Bevel Gears Ltd. Sahibabad.: KNL Driveline Parts Pvt. Ltd. Material Test CertificateargmsfNo ratings yet

- Engine Experiment FormatDocument1 pageEngine Experiment FormatMD Ashfakul Karim KausikNo ratings yet

- Optigear 1100 RangeDocument3 pagesOptigear 1100 RangeResistenciaDisidenteNo ratings yet

- Infineum D3453Document2 pagesInfineum D3453Carlos Enrique Mora CortezNo ratings yet

- Reduction Gear En. C - 4154Document1 pageReduction Gear En. C - 4154Dimitrios MikrosNo ratings yet

- Enercare Lubricant Analysis: Rating Summary Table For British Osprey (9258882)Document11 pagesEnercare Lubricant Analysis: Rating Summary Table For British Osprey (9258882)Jagmohan SinghNo ratings yet

- 1.5MM 304Document1 page1.5MM 304pankaj kumarNo ratings yet

- Oil Analysis Report: Power Mech Projects LTD Site: 2x600 MW CEPL-Tuticorin-Tamil NaduDocument11 pagesOil Analysis Report: Power Mech Projects LTD Site: 2x600 MW CEPL-Tuticorin-Tamil Nadudevi JammanaNo ratings yet

- E-021 Auxiliary Engine Performance.04Document2 pagesE-021 Auxiliary Engine Performance.04Rizky Sapugungdo100% (1)

- MB Trucks Specifications For Engine Oils (Service Fill) V2022.1Document2 pagesMB Trucks Specifications For Engine Oils (Service Fill) V2022.1Olivier DupNo ratings yet

- SOS Sampling ReportDocument2 pagesSOS Sampling ReportAsaisan AsaisanNo ratings yet

- Sos Sampling ReportDocument2 pagesSos Sampling Reportomar solimanNo ratings yet

- Em'cy Gen-SetDocument59 pagesEm'cy Gen-SetGeorgiNo ratings yet

- 6.9 Quality - QFL 4 Series 900 Audit Checklist PKDDocument2 pages6.9 Quality - QFL 4 Series 900 Audit Checklist PKDNDRNo ratings yet

- Electrical Engineering CapsuleDocument209 pagesElectrical Engineering CapsuleAravindmadhav AravindmadhavNo ratings yet

- Sr. No Experiment List For Fluid Mechanics-Ii Lab Experiment NODocument19 pagesSr. No Experiment List For Fluid Mechanics-Ii Lab Experiment NOMohit JangraNo ratings yet

- ACS Periodic Table PDFDocument1 pageACS Periodic Table PDFRyan Christopher MartinezNo ratings yet

- Computation of Turbulent Jets in Annular Counter FlowDocument8 pagesComputation of Turbulent Jets in Annular Counter FlowKaffelNo ratings yet

- 13 - Landfill RemediationDocument7 pages13 - Landfill RemediationAteba MveNo ratings yet

- Specification For Construction, Testing & Commissioning of Ductile Iron Pipe SystemDocument46 pagesSpecification For Construction, Testing & Commissioning of Ductile Iron Pipe SystemAmro HarasisNo ratings yet

- SIS Book 577Document71 pagesSIS Book 577Hamza Alam100% (1)

- Reviews: 2D Materials For Quantum Information ScienceDocument16 pagesReviews: 2D Materials For Quantum Information ScienceRyanKenaleyNo ratings yet

- Designing Controls For The Process Industries 1st Seames Solution ManualDocument6 pagesDesigning Controls For The Process Industries 1st Seames Solution ManualElizabethVancejodf100% (42)

- Powhumus Msds - enDocument7 pagesPowhumus Msds - enJawwad KaleemNo ratings yet

- E10q4w3 Capslet 1Document7 pagesE10q4w3 Capslet 1MattNo ratings yet

- Annex 2 - Delivery Format - Task 2Document14 pagesAnnex 2 - Delivery Format - Task 2Sergio VargasNo ratings yet

- Single-Fired Ceramic Wall Tile Manufacture: by Dr. Agustin Escardino Benlloch (Spain)Document30 pagesSingle-Fired Ceramic Wall Tile Manufacture: by Dr. Agustin Escardino Benlloch (Spain)map vitcoNo ratings yet

- EOCQ - Ans - 17 2Document1 pageEOCQ - Ans - 17 2Куаныш ЖанадилNo ratings yet

- Chromium-Nickel Stainless SteelsDocument8 pagesChromium-Nickel Stainless SteelsRahul KhoslaNo ratings yet

- Materials and DesignDocument10 pagesMaterials and DesignFelipe De LimaNo ratings yet

- Cement Kiln RefractoryDocument166 pagesCement Kiln RefractorySyed Kazam RazaNo ratings yet

- Selective Desoldering Separation of Tin Lead Alloy For Dismantling of Electronic Components From Printed Circuit BoardsDocument6 pagesSelective Desoldering Separation of Tin Lead Alloy For Dismantling of Electronic Components From Printed Circuit BoardsSALAH NETNo ratings yet

- GLOSSARY: KEY TERMS ON POPULATION AND ENVIRONMENTDocument2 pagesGLOSSARY: KEY TERMS ON POPULATION AND ENVIRONMENTntbkgm0% (1)

- Supply, Installation & Commissioning of Effluent Treatment Plant (ETP) For Bang Jin Bangladesh-1Document24 pagesSupply, Installation & Commissioning of Effluent Treatment Plant (ETP) For Bang Jin Bangladesh-1Saif Ahmed Nabil100% (1)

- Modeling&Simulation of Multiple Effect Evaporator SystemDocument114 pagesModeling&Simulation of Multiple Effect Evaporator SystemJORGE CAICEDONo ratings yet

- 02 Magnetism AssignmentDocument27 pages02 Magnetism Assignmentatulpatil990% (1)

- Ecoprocesstm SBR Design NotesDocument3 pagesEcoprocesstm SBR Design NotesTrilok ChandraNo ratings yet

- T105 Engineering ThermodynamicsDocument14 pagesT105 Engineering ThermodynamicsLogesh WaranNo ratings yet

- Physics 12: JUNE 2000Document42 pagesPhysics 12: JUNE 2000Gkid GkidNo ratings yet

- Chem 1212 Exam KeyDocument6 pagesChem 1212 Exam KeyChris HeNo ratings yet

- Exam1 04Document7 pagesExam1 04Rodney SalazarNo ratings yet

- Photovoltaics Literature Survey (No. 100)Document4 pagesPhotovoltaics Literature Survey (No. 100)Lenin HuertaNo ratings yet

- ESP Guide: Working, Types, Parameters, Advantages & DisadvantagesDocument19 pagesESP Guide: Working, Types, Parameters, Advantages & DisadvantagesjomoltNo ratings yet

- 10 - Hydraulic Jump and Its Usefulness in The Design of Irrigation StructuresDocument11 pages10 - Hydraulic Jump and Its Usefulness in The Design of Irrigation StructuresSandeep sahNo ratings yet