Professional Documents

Culture Documents

Matrix Trend CM DZR-218

Uploaded by

Ahmat RamadaniCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Matrix Trend CM DZR-218

Uploaded by

Ahmat RamadaniCopyright:

Available Formats

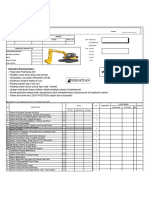

UNIT PERFORMANCE MATRIX TREND DASHBOARD

DZR-218 -> CAT D6R2 XL PLUG FILTER

TREND PLUG LAST CEK TREND FILTER LAST CEK

Date 1-Sep-23 14-Sep-23 19-Sep-23 29-Sep-23 8-Nov-23 16-Nov-23

HM 4527 7475 4803 4980 5090 5204

ENGINE C C C C C C AAAAA 29-Sep-23

Oil Changed? CO YES YES YES YES NO YES

Cr meningkat terkait keausan Fuel detected 2% oil viscosity Si di atas normal Keausan normal Fuel detected 1% oil viscosity Keausan elemen logam normal. Keausan elemen logam normal.

Piston rings Bearing. Fuel 2%. below standard. Pb Cr Oxidation at level 1% fuel dan oxidation cukup below standard. Cr at high level. Si Fuel 2%. viskositas oli rendah. Fuel 2%. viskositas oli rendah.

viskositas oli rendah. oksidasi high level. wear of rod and main tinggi Viskositas rendah dari and Oxidation at medium level. oksidasi tinggi. Cek fuel line oksidasi dan Si tinggi. Si terkait

naik tinggi. Cek engine noise. Cek bearings turbocharger bearings standard Check overheating wear ofcylinder liners and piston kebocoran injector seals dan kontaminasi debu. Cek level oli

fuel line kebocoran injector seals camshaft bushings piston rings. check filter cut dan monitor debris rings dirt entry. Check oil pressure pump. cek timing injeksi. Monitor Cek air induction system Cek

dan pump. cek timing injeksi. cek Check oil pressure and unusual Check Leaking seals injector atau and unusual noise. Inspect air kondisi operasi dan idling.lakukan breather dan sumber kontaminasi.

kualitas fuel. Monitor kondisi noise. Check turbocharger bearing barrel injector Leaking seals fuel induction system from leaking. pemeriksaan. (arman) Cek fuel line kebocoran injector

operasi dan idling. Monitor engine condition. Inspect air induction line unit injector tip Cracked fuel Check fuel line leaking injector seals dan pump. cek timing

temperatur. Lakukan pemeriksaan. system from leaking. Check fuel supply manifold Leaking seal fuel seals and pump. check injection injeksi. Monitor kondisi operasi

(arman) line leaking injector seals and transfer pump. Monitor operational timing. check fuel quality. Monitor dan idling.lakukan pemeriksaan

pump. check injection timing. unit (nugroho) operating conditions. cut open dan perbaikan. (catur)

check fuel quality. Monitor filter and inspect for large

operating conditions. cut open particles. (Febri)

filter and inspect for large

particles. (Febri)

Wear Metal CONTAMINANT Soot, Oxi, Visc & TBN

14.0 14.0 2.5 25.0 200.0

13.1 188.0 180.0

12.0 23.0

12.0 12.0

2.0 2.0 2.0 2.0 2.0 20.0 160.0

10.0 10.1

Water - Fuel %

10.0 10.0 10.0 140.0

8.5 1.5 124.0

Oxidation

8.9 8.0 15.0 15.0 120.0

8.0 113.0 106.0

7.3 6.9 100.0

6.8 6.0 6.3 11.2 90.0

5.7 1.0 1.0 1.0 10.0 10.3 10.0 80.0

6.0 4.8 9.6 9.2 9.0 8.9

5.2 4.0 8.0 7.6 7.9 7.7 8.3 60.0

3.7 3.6 59.0 7.2 7.0

4.0 4.0 4.0 3.0 0.5 5.0 40.0

3.7 3.8 3.4 2.0 2.2 2.3

3.0 2.8 20.0

2.0 2.5 2.4 2.2 2.0 2.0

2.0 2.0 1.7 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0

1.4 1.5 0.0 0.0

0.7

0.6 0.4 0.4 0.6 0.4 1-Sep-23 14-Sep-23 19-Sep-23 29-Sep-23 8-Nov-23 16-Nov-23

0.0 0.3

0.2

0.1 0.1 0.1 1-Sep-23 14-Sep-23 19-Sep-23 29-Sep-23 8-Nov-23 16-Nov-23

1-Sep-23 14-Sep-23 19-Sep-23 29-Sep-23 8-Nov-23 16-Nov-23

PQ Fe Cr Al Cu Pb Si Na Water Fuel TBN Soot V100 Oxi

Date 6-Feb-23 8-Jul-23 3-Aug-23 1-Sep-23 19-Sep-23 29-Sep-23

HM 2021 3587 4025 45 4803 4980

TRANSMISSION A A A A A A AB 29-Sep-23

Oil Changed? CO YES NO YES NO NO YES

Oil viscosity Wear and Parameter hasil analisa berada Parameter hasil analisa berada Parameter hasil analisa berada Parameter hasil analisa berada Oil viscosity Wear and

contamination within acceptable pada batasan normal. Lanjutkan pada batasan normal. Lanjutkan pada batasan normal. Lanjutkan pada batasan normal lanjutkan contamination within acceptable

levels. Continue with regular resample sesuai dengan jadwal resample sesuai dengan jadwal resample sesuai dengan jadwal resample sesuai dengan jadwal levels. Continue with regular

maintenance. yang ada. (catur) yang ada.(nugroho) yang ada. (arman) yang ada. (nugroho) maintenance. (Febri)

Wear Metal Ferrous Metal CONTAMINANT

14.0 18 9.0

13.2

16 16.0 8.0 7.8

12.0

14 7.0

10.0 6.6

12 6.0

8.0 10 10.5 5.0 5.2

4.8

4.5

6.0 8 4.0

7.0 3.5

6 5.8 3.0

4.0 5.2

4.6 2.3 2.2

4 2.0

2.5 2.7 3.0 2.9 3.0 3.0 1.6 1.5

2.0 1.8 1.7 1.9

1.6

1.4 1.5 1.5

1.3 2 2.0 2.0 1.0 0.9

0.7 0.8 1.1

0.8 0.7

0.6 0.4 0.5

0.0 0.1 0.1 0.1 0 YES NO YES NO NO YES 0.0

6-Feb-23 8-Jul-23 3-Aug-23 1-Sep-23 19-Sep-23 29-Sep-23 6-Feb-23 8-Jul-23 3-Aug-23 1-Sep-23 19-Sep-23 29-Sep-23 6-Feb-23 8-Jul-23 3-Aug-23 1-Sep-23 19-Sep-23 29-Sep-23

Cr Al Cu Pb CO PQ Fe Si Na

Date 14-Nov-22 6-Feb-23 25-Feb-23 31-Jul-23 10-Aug-23 29-Sep-23

HM 992 2021 2046 4025 4146 4980

FINAL DRIVE LH A B A C A C BBABB 29-Sep-23

Oil Changed? CO UNSURE YES NO YES NO YES

Oil viscosity Wear elements and Fe and PQ increase. Si at medium Oil viscosity Wear and Fe dan ferrous debris Al serta Si Parameter hasil analisa berada Fe Al Cr Si at high level. PQ

Contaminant within acceptable level. Cr at high level. indicate dirt contamination within acceptable tinggi Indikasi debu masuk Wear pada batasan normal lanjutkan increase. indicate dirt entry wear

levels. Continue with regular entry. wear of Gears Bearings levels. Continue with regular Gears Roller bearings Splines resample sesuai dengan jadwal of Gears Bearings Splines

maintenance Splines housing Shafts check oil maintenance Shafts Housing. Sample oli gelap yang ada. housing Shafts check oil level

level inspect oil leak & unusual Check oil level inspect oil leak & inspect oil leak & unusual noise

noise check the source of dirt unusual noise check sumber check the source of dirt entry

entry inspect for damage or kontaminan masuk inspect inspect for damage or excessive

excessive wear on seals/ O ring. kondisi keausan seals/ O ring. wear on seals/ O ring. Check the

Check the magnetic plug for Check magnetic plug dan debris. magnetic plug for debris. Take an

debris.( Lakukan perbaikan. (nugroho) necessary action.(Febri)

Wear Metal Ferrous Metal CONTAMINANT

35.0 250 140.0

32.8 228.0

30.0 120.0 122.3

28.3 200

25.0 100.0 103.8

161.5

20.0 150 146.4 80.0

15.0 100 60.0

97.0

10.0 40.0 40.5

7.2 50 57.4 29.8

5.0 5.5

5.0 5.6 34.0 20.0

3.9 3.2 3.4

3.2 29.2 24.0 13.7 13.4

1.6 2.7 2.6 18.0 19.3

1.5

0.0 0.8

0.1 0.3

0.1 0.5 0.9 0.9

0.2 0.8

0.5 0 UNSURE YES NO 8.1

8.0 YES NO YES 0.0 1.5 1.2 1.1 2.0 1.2 2.5

14-Nov-22 6-Feb-23 25-Feb-23 31-Jul-23 10-Aug-23 29-Sep-23 14-Nov-22 6-Feb-23 25-Feb-23 31-Jul-23 10-Aug-23 29-Sep-23 14-Nov-22 6-Feb-23 25-Feb-23 31-Jul-23 10-Aug-23 29-Sep-23

Cr Al Cu Pb CO PQ Fe Si Na

You might also like

- Matrix CM DZR-215Document2 pagesMatrix CM DZR-215Ahmat RamadaniNo ratings yet

- Matrix Trend CM DZR-215Document1 pageMatrix Trend CM DZR-215Ahmat RamadaniNo ratings yet

- Exc102-13 CMDocument5 pagesExc102-13 CMAhmat RamadaniNo ratings yet

- Matrix Trend CM EXC103-1Document2 pagesMatrix Trend CM EXC103-1Ahmat RamadaniNo ratings yet

- Matrix CM EXC102-22Document5 pagesMatrix CM EXC102-22Ahmat RamadaniNo ratings yet

- Matrix Trend Health GDR-410Document1 pageMatrix Trend Health GDR-410Ahmat RamadaniNo ratings yet

- Weber 4 Barrel Carburetor (PDFDrive)Document41 pagesWeber 4 Barrel Carburetor (PDFDrive)Matheus BorelliNo ratings yet

- 50 Point Service CheckDocument1 page50 Point Service CheckToddNo ratings yet

- Pre-Purchase Vehicle InspectionDocument1 pagePre-Purchase Vehicle InspectionToddNo ratings yet

- Periodic Preservice Inspection Sheet Kom PDFDocument2 pagesPeriodic Preservice Inspection Sheet Kom PDFEko FebriyantoNo ratings yet

- Jadwal Weekly MaintanaceDocument8 pagesJadwal Weekly Maintanaceardy ansyahNo ratings yet

- 10 - Emission Control SystemDocument4 pages10 - Emission Control Systemzaq94No ratings yet

- 1gr FeDocument36 pages1gr FeAlejandro SmilovicNo ratings yet

- Unit Engine Model Serial No. Code No. Model: Beri Tanda " V " Jika Kondisi Baik Dan " X " Jika Kondisi Tidak BaikDocument15 pagesUnit Engine Model Serial No. Code No. Model: Beri Tanda " V " Jika Kondisi Baik Dan " X " Jika Kondisi Tidak BaikkkmechNo ratings yet

- Caterpillar D8R 250 Hrs Service No Unit: Date: HM: ShiftDocument8 pagesCaterpillar D8R 250 Hrs Service No Unit: Date: HM: ShiftTLK ChannelNo ratings yet

- Engine Lubrication & Cooling Systems: ZD TD27TiDocument34 pagesEngine Lubrication & Cooling Systems: ZD TD27TiRifki AwaludinNo ratings yet

- Engine Lubrication & Cooling Systems: ZD TD27TiDocument34 pagesEngine Lubrication & Cooling Systems: ZD TD27TiLudo PiętakNo ratings yet

- Qa2 Quality Sheet Engine Page 1Document2 pagesQa2 Quality Sheet Engine Page 1Nadhira SalsabilaNo ratings yet

- CompactorDocument8 pagesCompactorkkmech100% (1)

- HISTORE SYSTEM PmsDocument29 pagesHISTORE SYSTEM PmsAzka AlfariziNo ratings yet

- 04 1957 BU-Engine Fuel & ExhaustDocument60 pages04 1957 BU-Engine Fuel & ExhaustSheriff ServiceNo ratings yet

- CCR Logsheet BbciDocument1 pageCCR Logsheet BbciherwinNo ratings yet

- Caterpillar: Cat - D6RDocument8 pagesCaterpillar: Cat - D6Rkkmech100% (1)

- Fortnightly - Checklist - Kobelco CranesDocument3 pagesFortnightly - Checklist - Kobelco Cranesdevansh ranaNo ratings yet

- Cashman EM Solutions Brochure 3 16Document2 pagesCashman EM Solutions Brochure 3 16jov100% (1)

- Periodical Service Scania P380: Maintenance SheetDocument2 pagesPeriodical Service Scania P380: Maintenance SheetWanda Panggih KurniawanNo ratings yet

- Mercedes PM Check ListsDocument6 pagesMercedes PM Check Listsalexberhane3No ratings yet

- HGDocument6 pagesHGlaxman JoshiNo ratings yet

- Moduspec ChecklistDocument64 pagesModuspec Checklistbehnam197100% (8)

- Manuals 7 3L Power Stroke ManualDocument78 pagesManuals 7 3L Power Stroke ManualuriealNo ratings yet

- LYC 60294 9 2 Overhaul 76series1975 1996 PDFDocument230 pagesLYC 60294 9 2 Overhaul 76series1975 1996 PDFDAVID WRIGHT100% (2)

- Section 2.16 - Life Saving Appliances Maintenance. Maintenance Code N - 1 Month Components Working DescriptionDocument10 pagesSection 2.16 - Life Saving Appliances Maintenance. Maintenance Code N - 1 Month Components Working DescriptionRochmat AdityaNo ratings yet

- Parts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 021032-0010-E1Document13 pagesParts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 021032-0010-E1Jose AltamiranoNo ratings yet

- Maintenance Check Sheet - DISCOVERY 3 4 ARMOURED DIESEL MODELS - MilesDocument2 pagesMaintenance Check Sheet - DISCOVERY 3 4 ARMOURED DIESEL MODELS - MilesCristiano DellazariNo ratings yet

- 4 - 3D Ah-5vcmDocument1 page4 - 3D Ah-5vcmMamiherintsoa Issaia RanaivoarimananaNo ratings yet

- 2009manual ST-2TDocument12 pages2009manual ST-2TJean Michel BattailNo ratings yet

- Cummins Statistical Analysis of Used Oil Lead in HHP EnginesDocument10 pagesCummins Statistical Analysis of Used Oil Lead in HHP EnginesRushikesh SawantNo ratings yet

- Mantenimiento Compresor BlackmerDocument10 pagesMantenimiento Compresor BlackmerMarco NoccettiNo ratings yet

- Frm-plt-015 Periodical Service GraderDocument3 pagesFrm-plt-015 Periodical Service GraderAbi Yusuf CahyadiNo ratings yet

- RTX Piston Running GuideDocument32 pagesRTX Piston Running GuideDaniel TsvetilovNo ratings yet

- AppendixI N2 Transport TrailerDocument9 pagesAppendixI N2 Transport TrailerMohammed H. Al AyatNo ratings yet

- Full Diesel SistemDocument41 pagesFull Diesel SistemMynor WittNo ratings yet

- Fuel System: Section 3B - CarburetorDocument31 pagesFuel System: Section 3B - CarburetorpedroNo ratings yet

- Inspection Sheet UNTUK DozerDocument12 pagesInspection Sheet UNTUK DozerkkmechNo ratings yet

- 182 Special Features TN.3819A - CB22Document28 pages182 Special Features TN.3819A - CB22Matija GužvinecNo ratings yet

- E-021 Auxiliary Engine Performance.04Document2 pagesE-021 Auxiliary Engine Performance.04Rizky Sapugungdo100% (1)

- Water Pump 250 Hrs Service No Unit: Date: HM: ShiftDocument8 pagesWater Pump 250 Hrs Service No Unit: Date: HM: ShiftTLK ChannelNo ratings yet

- Form Inspection Sheet - GraderDocument1 pageForm Inspection Sheet - Graderkamalakannan.muthukumaranNo ratings yet

- Preventive KompresorDocument13 pagesPreventive KompresorSatria PradanaNo ratings yet

- ZG Engine 9 - 1Document48 pagesZG Engine 9 - 1Ignacio MuguiroNo ratings yet

- Ezg - 9a Motor PDFDocument48 pagesEzg - 9a Motor PDFIgnacio MuguiroNo ratings yet

- M9136WSDocument2 pagesM9136WScurlyjockeyNo ratings yet

- Periodical Service KOMATSU D155-6: Maintenance SheetDocument2 pagesPeriodical Service KOMATSU D155-6: Maintenance SheetAndaru GunawanNo ratings yet

- Varco TDS-4S & TDS-4H Top Drive Pocket GuideDocument21 pagesVarco TDS-4S & TDS-4H Top Drive Pocket GuideMuhammad SaiedNo ratings yet

- 1gr-Fe MTDocument226 pages1gr-Fe MTPedro ValerioNo ratings yet

- Pa-18 Pa-18a Inspection Reportv1999Document4 pagesPa-18 Pa-18a Inspection Reportv1999Jessey StonerNo ratings yet

- WheelHorse Model 603 Service ManualDocument8 pagesWheelHorse Model 603 Service ManualKevins Small Engine and Tractor ServiceNo ratings yet

- LV Mitsubishi TritonDocument6 pagesLV Mitsubishi TritonAdie PranataNo ratings yet

- 4.volvo Weekly MaintainanceDocument12 pages4.volvo Weekly MaintainanceAnbarasanNo ratings yet

- Daily Breakdown Monitoring - DMPDocument1 pageDaily Breakdown Monitoring - DMPAhmat RamadaniNo ratings yet

- Daily Breakdown Monitoring & Backlog - Site AA - 21 Maret 2024 - 10.33 WITADocument2 pagesDaily Breakdown Monitoring & Backlog - Site AA - 21 Maret 2024 - 10.33 WITAAhmat RamadaniNo ratings yet

- Lampiran PAP Template Monthly MaretDocument2 pagesLampiran PAP Template Monthly MaretAhmat RamadaniNo ratings yet

- Daily Breakdown Monitoring - SMN 21 MARET 2024Document1 pageDaily Breakdown Monitoring - SMN 21 MARET 2024Ahmat RamadaniNo ratings yet

- PS-11 Fju EngineDocument1 pagePS-11 Fju EngineAhmat RamadaniNo ratings yet

- Mtarix PAP ADT-01Document5 pagesMtarix PAP ADT-01Ahmat RamadaniNo ratings yet

- Mtarix PAP ADT-01Document5 pagesMtarix PAP ADT-01Ahmat RamadaniNo ratings yet

- PS-11 Fju EngineDocument1 pagePS-11 Fju EngineAhmat RamadaniNo ratings yet

- PS-11 Fju EngineDocument1 pagePS-11 Fju EngineAhmat RamadaniNo ratings yet

- G22-01 MHS EngineDocument1 pageG22-01 MHS EngineAhmat RamadaniNo ratings yet

- R-11 MHS EngineDocument1 pageR-11 MHS EngineAhmat RamadaniNo ratings yet

- Akm-01 - Slk-Akm - Differential FrontDocument1 pageAkm-01 - Slk-Akm - Differential FrontAhmat RamadaniNo ratings yet

- Adt-403 Slk-Akm Brake CoolingDocument1 pageAdt-403 Slk-Akm Brake CoolingAhmat RamadaniNo ratings yet

- Adt-403 Slk-Akm TransmissionDocument1 pageAdt-403 Slk-Akm TransmissionAhmat RamadaniNo ratings yet

- Exc101-6 Slk-Akm Final Drive LHDocument1 pageExc101-6 Slk-Akm Final Drive LHAhmat RamadaniNo ratings yet

- Akm-01 - Slk-Akm - Final Drive Front LHDocument1 pageAkm-01 - Slk-Akm - Final Drive Front LHAhmat RamadaniNo ratings yet

- Akm-01 - Slk-Akm - Final Drive Front RHDocument1 pageAkm-01 - Slk-Akm - Final Drive Front RHAhmat RamadaniNo ratings yet

- Exc103-49 - Slk-Akm - Final Drive LHDocument1 pageExc103-49 - Slk-Akm - Final Drive LHAhmat RamadaniNo ratings yet

- Exc101-6 Slk-Akm Final Drive RHDocument1 pageExc101-6 Slk-Akm Final Drive RHAhmat RamadaniNo ratings yet

- MML-07 - Slk-Akm - Final Drive LHDocument1 pageMML-07 - Slk-Akm - Final Drive LHAhmat RamadaniNo ratings yet

- Exc101-7 Slk-Akm Final Drive RHDocument1 pageExc101-7 Slk-Akm Final Drive RHAhmat RamadaniNo ratings yet

- R-40 Slk-Akm EngineDocument1 pageR-40 Slk-Akm EngineAhmat RamadaniNo ratings yet

- Adt-408 - Slk-Akm - Brake CoolingDocument1 pageAdt-408 - Slk-Akm - Brake CoolingAhmat RamadaniNo ratings yet

- MML-07 Slk-Akm HydraulicDocument1 pageMML-07 Slk-Akm HydraulicAhmat RamadaniNo ratings yet

- Exc101-7 - Slk-Akm - Final Drive LHDocument1 pageExc101-7 - Slk-Akm - Final Drive LHAhmat RamadaniNo ratings yet

- MML-07 - Slk-Akm - Final Drive RHDocument1 pageMML-07 - Slk-Akm - Final Drive RHAhmat RamadaniNo ratings yet

- Utilities User Guide: Caefatigue Software (CF)Document38 pagesUtilities User Guide: Caefatigue Software (CF)Oliver RailaNo ratings yet

- Service Bulletin: SubjectDocument6 pagesService Bulletin: SubjectWaitylla DiasNo ratings yet

- Psychology of Color2Document33 pagesPsychology of Color2abdikani abdilaahiNo ratings yet

- Two Day Workshop On: Embedded Systems Design Using ARDUINO BoardsDocument2 pagesTwo Day Workshop On: Embedded Systems Design Using ARDUINO BoardsBritto Ebrington AjayNo ratings yet

- Super Capacitor - Seminar Report, PPT, PDF For ECE StudentsDocument3 pagesSuper Capacitor - Seminar Report, PPT, PDF For ECE StudentsvvkrkzNo ratings yet

- Marketing Manager: at Aztec GroupDocument2 pagesMarketing Manager: at Aztec GroupAgnish GhatakNo ratings yet

- Selling NDocument33 pagesSelling NADITYA VARPENo ratings yet

- Account Statement From 3 Jan 2021 To 3 Jul 2021: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalanceDocument8 pagesAccount Statement From 3 Jan 2021 To 3 Jul 2021: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalanceSanatan ThakurNo ratings yet

- SBxx-1SP-US-40-IA-xx-16 Instruct ManDocument224 pagesSBxx-1SP-US-40-IA-xx-16 Instruct ManSmellyDog360No ratings yet

- Comprehensive Comparison of 99 Efficient Totem-Pole PFC With Fixed PWM or Variable TCM Switching FrequencyDocument8 pagesComprehensive Comparison of 99 Efficient Totem-Pole PFC With Fixed PWM or Variable TCM Switching FrequencyMuhammad Arsalan FarooqNo ratings yet

- MS Disc Brake CaliperDocument2 pagesMS Disc Brake Caliperghgh140No ratings yet

- Computer Vision - Ipynb - ColaboratoryDocument17 pagesComputer Vision - Ipynb - Colaboratoryzb laiNo ratings yet

- Terminal Parking Spaces + 30% Open Space As Required by National Building CodeDocument3 pagesTerminal Parking Spaces + 30% Open Space As Required by National Building CodeDyra Angelique CamposanoNo ratings yet

- Board of Intermediate & Secondary Education, SargodhaDocument1 pageBoard of Intermediate & Secondary Education, SargodhaEic SNo ratings yet

- Chapter 2 PurposiveDocument3 pagesChapter 2 PurposiveVenus BarnuevoNo ratings yet

- Ocr GttsDocument49 pagesOcr GttsKshitij NishantNo ratings yet

- EE314 Lab 1 FinalDocument19 pagesEE314 Lab 1 FinalCarlos BabuNo ratings yet

- Tech M Service LetterDocument1 pageTech M Service LetterRahul upadhyayNo ratings yet

- 1 Correlation Between Na2SiO3 NaOH Ratio ADocument6 pages1 Correlation Between Na2SiO3 NaOH Ratio AedwardcolmeNo ratings yet

- Unit 8. New Ways To Learn: Part I. PhoneticsDocument14 pagesUnit 8. New Ways To Learn: Part I. PhoneticsPhạm Gia LợiNo ratings yet

- Fujifilm GFX100S Medium Format Camera SpecificationsDocument5 pagesFujifilm GFX100S Medium Format Camera SpecificationsNikonRumorsNo ratings yet

- BTech CS 4th Year SyllabusDocument19 pagesBTech CS 4th Year SyllabusRahul Kumar SInhaNo ratings yet

- ITC LAB 4 - FlowchartsDocument7 pagesITC LAB 4 - FlowchartspathwayNo ratings yet

- TM AHU 60R410A Onoff T SA NA 171205Document67 pagesTM AHU 60R410A Onoff T SA NA 171205Sam RVNo ratings yet

- Fs Project ReportDocument50 pagesFs Project Reportfizzy thingsNo ratings yet

- Desktop F0ecjd0 20230613 0007Document8 pagesDesktop F0ecjd0 20230613 0007Mican HoriaNo ratings yet

- تقارير مختبر محركات احتراق داخليDocument19 pagesتقارير مختبر محركات احتراق داخليwesamNo ratings yet

- ProjectDocument14 pagesProjectNavneet singh50% (2)

- Tuguegarao Certificate of Non-Availability of Stocks: Product Code Product Description UOM PriceDocument7 pagesTuguegarao Certificate of Non-Availability of Stocks: Product Code Product Description UOM PriceNenbon NatividadNo ratings yet

- Medical Sensors MarketDocument2 pagesMedical Sensors MarketHarshada DoiphodeNo ratings yet