Professional Documents

Culture Documents

Matrix Trend CM DZR-215

Uploaded by

Ahmat RamadaniOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Matrix Trend CM DZR-215

Uploaded by

Ahmat RamadaniCopyright:

Available Formats

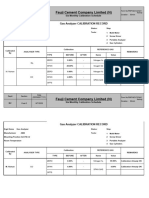

UNIT PERFORMANCE MATRIX TREND DASHBOARD

DZR-215 -> CAT D6R2 XL PLUG FILTER

TREND PLUG LAST CEK TREND FILTER LAST CEK

Date 7-Aug-23 19-Aug-23 1-Sep-23 21-Sep-23 18-Oct-23 9-Dec-23

HM 4571 4799 5073 5262 5728 6432

ENGINE A A C A C C AA 10-Oct-23

Oil Changed? CO YES NO YES NO NO NO

Oil viscosity Wear and Parameter hasil analisa berada Pb Cr dab Si diatas level normal. Parameter hasil analisa berada Viskositas oli rendah Fuel dilution Keausan elemen logam normal.

contamination within acceptable pada batasan normal. Lanjutkan Indikasi dari Main bearing Cyl liner pada batasan normal. Lanjutkan 1%. Oxidation dilevel medium. Fuel 3%. viskositas oli rendah.

levels. Continue with regular resample sesuai dengan jadwal Ring piston dan Debu. Cek level oli resample sesuai dengan jadwal Wear element normal.Cek level oli oksidasi naik tinggi. Cek fuel line

maintenance. (Febri) yang ada. (catur) Cek kebocoran seal atau gasket. yang ada. (catur) Cek kebocoran Cek filter cut dan kebocoran injector seals dan

Cek filter cut dan monitor debris. debris. Cek kebocoran fuel system pump. cek timing injeksi. Monitor

Cek air induction system Cek dan injector. cek kualitas fuel. Cek kondisi operasi. Monitor engine

breather Cek kontaminasi Ce temperature. monitor kondisi temperatur. Lakukan pemeriksaan.

temperature operation Cek noise operasi dan monitor interval (arman)

dan peforma engine. Monitor dan penggantian oli. Lanjutkan

resample (catur) resample. (catur)

Wear Metal CONTAMINANT Soot, Oxi, Visc & TBN

20.0 14.0 3.5 35.0 250.0

18.0 18.2 18.6 12.8

17.1 12.0 3.0 3.0 30.0 30.0

16.0 209.0 200.0

14.9 10.0 2.5

Water - Fuel %

14.0 25.0 24.0

8.9

Oxidation

12.0 12.6 8.0 2.0 20.0 20.0 150.0

6.8

10.0 6.0 5.8 1.5 15.0 16.0

5.3 5.1 14.0

13.1 13.0 13.0 100.0

8.0 8.4 4.6 4.6 4.4 12.7

7.7 4.0 3.9 1.0 1.0 10.0 11.0

7.0 8.9 9.0 8.9 67.0

6.0 6.0 3.1 2.7 8.4 7.9 50.0

4.9 5.0 5.0 5.0 2.0 0.5 6.9

6.6

4.0 4.6 4.4 5.0

4.0

3.9 3.8 3.6 22.0 19.0 3.0

3.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0 6.0 9.0

2.0 1.9 2.2 2.0 1.9 1.8

1.6 0.0 0.0

1.2 1.4 1.5

1.0

0.0 0.1 0.6 0.4 0.1 7-Aug-23 19-Aug-23 1-Sep-23 21-Sep-23 18-Oct-23 9-Dec-23 7-Aug-23 19-Aug-23 1-Sep-23 21-Sep-23 18-Oct-23 9-Dec-23

7-Aug-23 19-Aug-23 1-Sep-23 21-Sep-23 18-Oct-23 9-Dec-23

PQ Fe Cr Al Cu Pb Si Na Water Fuel TBN Soot V100 Oxi

Date 1-May-23 6-Jun-23 20-Jun-23 7-Aug-23 1-Sep-23 21-Sep-23

HM 3506 3814 4011 4571 5073 5262

TRANSMISSION A A A A C A

Oil Changed? CO NO NO YES NO YES NO

Oil viscosity Wear elements and Parameter hasil analisa berada Parameter hasil analisa berada Oil viscosity Wear and Vissual oli gelap. Pb Al dan Si Parameter hasil analisa berada

Contaminant within acceptable pada batasan normal. Lanjutkan pada batasan normal. Lanjutkan contamination within acceptable kelevel medium. Indikasi dari Disc pada batasan normal. Lanjutkan

levels. Continue with regular resample sesuai dengan jadwal resample sesuai dengan jadwal levels. Continue with regular clutc Coller leaching Bearing dan resample sesuai dengan jadwal

maintenance. yang ada. (arman) yang ada. (arman) maintenance. (Febri) Debu. Cek kondisi oli Cek yang ada. (catur)

kebocoran seal atau gasket cek

filter cut Cek magnetik drain plug

dan debris. Cek breather dan

sumber kontaminasi. Cek

abnormal noise dan performa

shifting Lakukan pemeriksaan dan

resample (catur)

Wear Metal Ferrous Metal CONTAMINANT

12.0 25 25.0

10.0 21.6

9.9 20 20.0

19.3

8.6 18.0

8.0

15 15.0

6.0 13.1 13.1

5.9

4.9 10 10.8 10.0

4.0 4.4 8.4

3.7 7.0 6.4

6.0 5.9 6.6

2.6 2.3 5 5.0 5.0 4.7 4.7

2.0 2.2

2.1 4.4 4.4

1.8 1.7 3.0 3.0 3.4 3.7

1.2 1.2

1.1 2.7

0.4 1.6

0.0 0.1 0.2 0.1 0.1 0 NO NO YES NO YES NO 0.0

1-May-23 6-Jun-23 20-Jun-23 7-Aug-23 1-Sep-23 21-Sep-23 1-May-23 6-Jun-23 20-Jun-23 7-Aug-23 1-Sep-23 21-Sep-23 1-May-23 6-Jun-23 20-Jun-23 7-Aug-23 1-Sep-23 21-Sep-23

Cr Al Cu Pb CO PQ Fe Si Na

Date - 15-Sep-22 11-Mar-23 20-Jun-23 1-Sep-23 14-Sep-23

HM 1019 2981 4011 5073 5237

FINAL DRIVE LH A C C C B B 14-Sep-23

Oil Changed? CO UNSURE YES YES YES NO

Wear elements and Contamination Viscosity lower contaminant Viskositas oli @ 40oC 58% Oli gelap. Fe Al Si berada dilevel Al naik di medium. Si meningkat.

within acceptable levels. Continue normal Fe increase Check oil dibawah standard. Keausan tinggi. terkait keausan Gear terkait keausan bushing/bearing

with regular maintenance. level. Check overall leakage. elemen logam dalam batasan Bearing Shaft Housing. Cek level atau dirt. Cek level dan kondisi oli.

Check operating temperature. normal. Monitor level dan kondisi dan kondisi oli. Monitor cek kondisi gasket/seals & inspek

Check possibility oil mix/ transfer. oli. Monitor dari kebocoran dan kebocoran. cek suara tidak kebocoran. Monitor noise dan

Check oil grade being used.oil kontaminasi. cek spesifikasi oli. normal. cek magnetic plug dan debris. cek sumber

already change. (nugroho) Monitor sample berikutnya. (arman) debris. Cek kontaminan. Lakukan dirt/kontaminan. Lakukan

pemeriksaan dan perbaikan. (catur) pemeriksaan. (arman)

Wear Metal Ferrous Metal CONTAMINANT

25.0 300 90.0

83.7

80.0

21.3 250

20.0 239.0 70.0

200 60.0

15.0 176.4

167.4 50.0

11.9 12.5 150 43.7

40.0 39.1

10.0

100 30.0

72.6 24.3

5.0 5.6 70.2 20.0

3.9 50 56.0 46.4

3.3

3.0 3.4 40.0 41.0 10.0

2.3 25.0 8.0

0.7 1.3 0.7 0.6 3.6 4.5 3.8 4.3

0.0 0.0 0.1 0.1 0.1 0.1 0.1

0.0 0 0.0 UNSURE YES YES YES NO 0.0 0.0 1.3

- 15-Sep-22 11-Mar-23 20-Jun-23 1-Sep-23 14-Sep-23 - 15-Sep-22 11-Mar-23 20-Jun-23 1-Sep-23 14-Sep-23 - 15-Sep-22 11-Mar-23 20-Jun-23 1-Sep-23 14-Sep-23

Cr Al Cu Pb CO PQ Fe Si Na

You might also like

- Matrix CM DZR-215Document2 pagesMatrix CM DZR-215Ahmat RamadaniNo ratings yet

- Matrix Trend CM DZR-218Document1 pageMatrix Trend CM DZR-218Ahmat RamadaniNo ratings yet

- Matrix CM EXC102-22Document5 pagesMatrix CM EXC102-22Ahmat RamadaniNo ratings yet

- Matrix Trend CM EXC103-1Document2 pagesMatrix Trend CM EXC103-1Ahmat RamadaniNo ratings yet

- Exc102-13 CMDocument5 pagesExc102-13 CMAhmat RamadaniNo ratings yet

- Matrix Trend Health GDR-410Document1 pageMatrix Trend Health GDR-410Ahmat RamadaniNo ratings yet

- Engine Lubrication & Cooling Systems: ZD TD27TiDocument34 pagesEngine Lubrication & Cooling Systems: ZD TD27TiRifki AwaludinNo ratings yet

- Engine Lubrication & Cooling Systems: ZD TD27TiDocument34 pagesEngine Lubrication & Cooling Systems: ZD TD27TiLudo PiętakNo ratings yet

- Weber 4 Barrel Carburetor (PDFDrive)Document41 pagesWeber 4 Barrel Carburetor (PDFDrive)Matheus BorelliNo ratings yet

- Periodic Preservice Inspection Sheet Kom PDFDocument2 pagesPeriodic Preservice Inspection Sheet Kom PDFEko FebriyantoNo ratings yet

- Preventive KompresorDocument13 pagesPreventive KompresorSatria PradanaNo ratings yet

- DSH2018 11 10Document2 pagesDSH2018 11 10gustavo joel fierro mendozaNo ratings yet

- Fuel System: Section 3B - CarburetorDocument31 pagesFuel System: Section 3B - CarburetorpedroNo ratings yet

- B5 Lubrication System: To IndexDocument9 pagesB5 Lubrication System: To Indexwei fooNo ratings yet

- LV Mitsubishi TritonDocument6 pagesLV Mitsubishi TritonAdie PranataNo ratings yet

- Cat Spin 2021 WebDocument60 pagesCat Spin 2021 WebTanel LaanemägiNo ratings yet

- HISTORE SYSTEM PmsDocument29 pagesHISTORE SYSTEM PmsAzka AlfariziNo ratings yet

- CompactorDocument8 pagesCompactorkkmech100% (1)

- Mtarix PAP ADT-01Document5 pagesMtarix PAP ADT-01Ahmat RamadaniNo ratings yet

- Training Preparation For M-Step 1: Preparation at Class Room Preparation at Practice RoomDocument1 pageTraining Preparation For M-Step 1: Preparation at Class Room Preparation at Practice RoomtusamsiNo ratings yet

- SAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018)Document2 pagesSAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018)nadeem shaikhNo ratings yet

- Cam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetDocument2 pagesCam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetJHONATAN RODRIGUEZ VENTONo ratings yet

- A2 Maintenance: To IndexDocument5 pagesA2 Maintenance: To IndexKwun Hok ChongNo ratings yet

- 00 - General, Technical DataDocument5 pages00 - General, Technical Dataakmal150% (1)

- Pa-18 Pa-18a Inspection Reportv1999Document4 pagesPa-18 Pa-18a Inspection Reportv1999Jessey StonerNo ratings yet

- (From CAT Maintenance Guide) (From CAT Maintenance Guide) : No Information: To Be CompletedDocument1 page(From CAT Maintenance Guide) (From CAT Maintenance Guide) : No Information: To Be CompletedVicNo ratings yet

- Test Certificate: Customer Saleh Zaid Ai Quralshi&Parteners TradDocument5 pagesTest Certificate: Customer Saleh Zaid Ai Quralshi&Parteners Tradalkaf08No ratings yet

- 50 Point Service CheckDocument1 page50 Point Service CheckToddNo ratings yet

- 10 - Emission Control SystemDocument4 pages10 - Emission Control Systemzaq94No ratings yet

- Of-MF 08B - Preventive Maintenance ChecklistDocument3 pagesOf-MF 08B - Preventive Maintenance ChecklistJBMMPL - QUALITYNo ratings yet

- Cubuilt Cepl VC 02 MsaDocument1 pageCubuilt Cepl VC 02 MsaCu Built Engineers Pvt. Ltd.No ratings yet

- Compressor Data Sheet Rev3 - Updated by EFXDocument9 pagesCompressor Data Sheet Rev3 - Updated by EFXmanuNo ratings yet

- M9136WSDocument2 pagesM9136WScurlyjockeyNo ratings yet

- KubotaDocument34 pagesKubotaBondan Ari Rahmawan80% (5)

- Jadwal Weekly MaintanaceDocument8 pagesJadwal Weekly Maintanaceardy ansyahNo ratings yet

- Sop & Diagram Penyulang Maret 2016 NatarDocument35 pagesSop & Diagram Penyulang Maret 2016 NatarJARINGAN UP3 TANJUNG KARANGNo ratings yet

- 04 1957 BU-Engine Fuel & ExhaustDocument60 pages04 1957 BU-Engine Fuel & ExhaustSheriff ServiceNo ratings yet

- CCR Logsheet BbciDocument1 pageCCR Logsheet BbciherwinNo ratings yet

- Coal L2 Analyzer Calibration 1200010871Document2 pagesCoal L2 Analyzer Calibration 1200010871Don't MindNo ratings yet

- Assy Oil Level Gauge P/No.: 5511692860 Oil Dipstick P/No.: 5501660444 Bracket Oil P/No.:5511692862Document1 pageAssy Oil Level Gauge P/No.: 5511692860 Oil Dipstick P/No.: 5501660444 Bracket Oil P/No.:5511692862Naswadi NawiNo ratings yet

- 123K020217E1Document27 pages123K020217E1Guillermo VossNo ratings yet

- RT-123 - A3 Appendix 3 (Issue 3) (Flex 82) Nov 2016Document7 pagesRT-123 - A3 Appendix 3 (Issue 3) (Flex 82) Nov 2016ajeshkrishnanNo ratings yet

- ETHIO Infra Engineering Private Limited Company: Summary of Test ResultsDocument1 pageETHIO Infra Engineering Private Limited Company: Summary of Test ResultsSolomon MehariNo ratings yet

- Form Inspection Sheet - GraderDocument1 pageForm Inspection Sheet - Graderkamalakannan.muthukumaranNo ratings yet

- Pre-Purchase Vehicle InspectionDocument1 pagePre-Purchase Vehicle InspectionToddNo ratings yet

- Group 40 M191en 05 2015 PDFDocument38 pagesGroup 40 M191en 05 2015 PDFDavid SolisNo ratings yet

- Inspection and Preventive Maintenance: ServicereportDocument2 pagesInspection and Preventive Maintenance: ServicereportMoz KamalNo ratings yet

- Job Schedule Sheet: Machine Component Job Description Planned by Wo NoDocument8 pagesJob Schedule Sheet: Machine Component Job Description Planned by Wo NoYudha RafiNo ratings yet

- Form PS ForkliftDocument7 pagesForm PS Forkliftzaid chidmahNo ratings yet

- Form 65-09 STK - A4Document1 pageForm 65-09 STK - A4Khalid bin WalidNo ratings yet

- LQC STDDocument2 pagesLQC STDAstronNo ratings yet

- ENGINE LRUs STATUS REPORTDocument5 pagesENGINE LRUs STATUS REPORTImran SalehNo ratings yet

- Checklist Ps Cmt96 & Cmt106Document1 pageChecklist Ps Cmt96 & Cmt106mhmmdrhmn76No ratings yet

- Pump Life Cycle Cost 4 Inventory Cost ReductionDocument24 pagesPump Life Cycle Cost 4 Inventory Cost ReductionRafael OrjuelaNo ratings yet

- Service Manual Nissan Engine Model PDocument10 pagesService Manual Nissan Engine Model Pmichel100% (54)

- Periodical Maintenance: I. Alat Dan BahanDocument2 pagesPeriodical Maintenance: I. Alat Dan BahanAFIRESNo ratings yet

- 1gr FeDocument36 pages1gr FeAlejandro SmilovicNo ratings yet

- API 682 Accumulator Data SheetDocument1 pageAPI 682 Accumulator Data SheetBhyrappaNo ratings yet

- Italjet Dragster 125 180 Workshop ManualDocument130 pagesItaljet Dragster 125 180 Workshop Manualmrsc4ry67% (3)

- Daily Breakdown Monitoring & Backlog - Site AA - 21 Maret 2024 - 10.33 WITADocument2 pagesDaily Breakdown Monitoring & Backlog - Site AA - 21 Maret 2024 - 10.33 WITAAhmat RamadaniNo ratings yet

- Daily Breakdown Monitoring - SMN 21 MARET 2024Document1 pageDaily Breakdown Monitoring - SMN 21 MARET 2024Ahmat RamadaniNo ratings yet

- Lampiran PAP Template Monthly MaretDocument2 pagesLampiran PAP Template Monthly MaretAhmat RamadaniNo ratings yet

- Mtarix PAP ADT-01Document5 pagesMtarix PAP ADT-01Ahmat RamadaniNo ratings yet

- Akm-01 - Slk-Akm - Final Drive Front LHDocument1 pageAkm-01 - Slk-Akm - Final Drive Front LHAhmat RamadaniNo ratings yet

- Daily Breakdown Monitoring - DMPDocument1 pageDaily Breakdown Monitoring - DMPAhmat RamadaniNo ratings yet

- PS-11 Fju EngineDocument1 pagePS-11 Fju EngineAhmat RamadaniNo ratings yet

- G22-01 MHS EngineDocument1 pageG22-01 MHS EngineAhmat RamadaniNo ratings yet

- MML-07 - Slk-Akm - Final Drive RHDocument1 pageMML-07 - Slk-Akm - Final Drive RHAhmat RamadaniNo ratings yet

- Exc101-6 Slk-Akm Final Drive LHDocument1 pageExc101-6 Slk-Akm Final Drive LHAhmat RamadaniNo ratings yet

- Akm-01 - Slk-Akm - Differential FrontDocument1 pageAkm-01 - Slk-Akm - Differential FrontAhmat RamadaniNo ratings yet

- R-11 MHS EngineDocument1 pageR-11 MHS EngineAhmat RamadaniNo ratings yet

- Exc103-49 - Slk-Akm - Final Drive LHDocument1 pageExc103-49 - Slk-Akm - Final Drive LHAhmat RamadaniNo ratings yet

- Exc101-6 Slk-Akm Final Drive RHDocument1 pageExc101-6 Slk-Akm Final Drive RHAhmat RamadaniNo ratings yet

- Adt-403 Slk-Akm Brake CoolingDocument1 pageAdt-403 Slk-Akm Brake CoolingAhmat RamadaniNo ratings yet

- Adt-403 Slk-Akm TransmissionDocument1 pageAdt-403 Slk-Akm TransmissionAhmat RamadaniNo ratings yet

- MML-07 - Slk-Akm - Final Drive LHDocument1 pageMML-07 - Slk-Akm - Final Drive LHAhmat RamadaniNo ratings yet

- Exc101-7 Slk-Akm Final Drive RHDocument1 pageExc101-7 Slk-Akm Final Drive RHAhmat RamadaniNo ratings yet

- Akm-01 - Slk-Akm - Final Drive Front RHDocument1 pageAkm-01 - Slk-Akm - Final Drive Front RHAhmat RamadaniNo ratings yet

- R-40 Slk-Akm EngineDocument1 pageR-40 Slk-Akm EngineAhmat RamadaniNo ratings yet

- Adt-408 - Slk-Akm - Brake CoolingDocument1 pageAdt-408 - Slk-Akm - Brake CoolingAhmat RamadaniNo ratings yet

- Exc101-7 - Slk-Akm - Final Drive LHDocument1 pageExc101-7 - Slk-Akm - Final Drive LHAhmat RamadaniNo ratings yet

- MML-07 Slk-Akm HydraulicDocument1 pageMML-07 Slk-Akm HydraulicAhmat RamadaniNo ratings yet

- Calculations and Designs of Lighting Scheme PDFDocument12 pagesCalculations and Designs of Lighting Scheme PDFAzmeraw Zedebre WorkNo ratings yet

- Bioentry P2: Compact Ip Fingerprint DeviceDocument2 pagesBioentry P2: Compact Ip Fingerprint DevicenokphyNo ratings yet

- Bangladesh RailwayDocument67 pagesBangladesh RailwaytakoNo ratings yet

- MATH 10 Reports 2ndquarterDocument4 pagesMATH 10 Reports 2ndquarterSheila Mauricio GarciaNo ratings yet

- 4817 14807 1 PB PDFDocument142 pages4817 14807 1 PB PDFAaron BalbuenaNo ratings yet

- Tenths and Hundredths: Mathematics CurriculumDocument4 pagesTenths and Hundredths: Mathematics Curriculumnew vivyNo ratings yet

- Using A System Cost Analysis ToDocument11 pagesUsing A System Cost Analysis Tosaa6383No ratings yet

- Freebitco inDocument8 pagesFreebitco inGayan SankalpaNo ratings yet

- Dte - Rolling Contact BearingsDocument32 pagesDte - Rolling Contact Bearingspotnuru Jaivanth100% (1)

- Sgs56m32eu 80Document4 pagesSgs56m32eu 80Ola CukierdaNo ratings yet

- OAF Session Basics1Document18 pagesOAF Session Basics1Sulochana RonankiNo ratings yet

- Grade 8 (Common Monomial Factoring-2nd Week) EditedDocument17 pagesGrade 8 (Common Monomial Factoring-2nd Week) EditedEmyren Apuya100% (1)

- Machine&cutting 2Document35 pagesMachine&cutting 2solomon guadeNo ratings yet

- TriDAR White PaperDocument8 pagesTriDAR White PaperCharis SurosoNo ratings yet

- Lesson Plan in Math 2 (UDL Strategy)Document10 pagesLesson Plan in Math 2 (UDL Strategy)Karla De Guzman Hornilla100% (21)

- CLINITEK Atlas Software V7.50 Update KitDocument3 pagesCLINITEK Atlas Software V7.50 Update KitAlvaro Restrepo GarciaNo ratings yet

- Using PivotTDocument36 pagesUsing PivotTZara RamisNo ratings yet

- Grip Flow Metal Stampings Design GuideDocument19 pagesGrip Flow Metal Stampings Design GuidejdcarvajalNo ratings yet

- Belt Conveyor - Pull Rope Switch HEN PDFDocument4 pagesBelt Conveyor - Pull Rope Switch HEN PDFOussema ElloumiNo ratings yet

- Lecture 3-4 - Geometry of A Vertical Aerial PhotographDocument35 pagesLecture 3-4 - Geometry of A Vertical Aerial PhotographFaisel mohammedNo ratings yet

- Simplex Method FlowchartDocument2 pagesSimplex Method FlowchartRezaNo ratings yet

- Tool Code List SchlumbergerDocument16 pagesTool Code List SchlumbergerRaulHerrera100% (1)

- Thin-Walled Structures: Zhiyuan Fang, Krishanu Roy, Boshan Chen, Chiu-Wing Sham, Iman Hajirasouliha, James B.P. LimDocument19 pagesThin-Walled Structures: Zhiyuan Fang, Krishanu Roy, Boshan Chen, Chiu-Wing Sham, Iman Hajirasouliha, James B.P. LimganeshNo ratings yet

- Pasquali - Treatment of NMSC PDFDocument109 pagesPasquali - Treatment of NMSC PDFIvanus NicoletaNo ratings yet

- Anaphy Lab Notes Specimen SlidesDocument5 pagesAnaphy Lab Notes Specimen SlidesAvi HylixNo ratings yet

- 1Document19 pages1Ahammad KabeerNo ratings yet

- DS-2CC102/112/192P (N) - IR3 Color IR Camera: SpecificationsDocument1 pageDS-2CC102/112/192P (N) - IR3 Color IR Camera: SpecificationsRicardo LescanoNo ratings yet

- MATHDocument4 pagesMATHCisco MontalvoNo ratings yet

- 18.1 Pressure CIE IGCSE Physics Ext Theory MsDocument5 pages18.1 Pressure CIE IGCSE Physics Ext Theory Msyousef.abdelazim11No ratings yet