Professional Documents

Culture Documents

Amuria Fam

Uploaded by

Okello StevenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Amuria Fam

Uploaded by

Okello StevenCopyright:

Available Formats

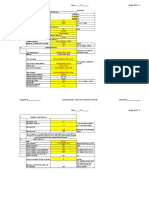

CENTRAL MATERIALS LABORATORY

CLIENT : M/S AMURIA FARMERS & TRANSPORTERS LTD

PROJECT : CONSTRUCTION OF DR. APORU OKOL MEMORIAL SEED SECONDARY SCHOOL

DATE : 6 SEPTEMBER 2023

TEST RESULTS FOR STEEL BAR SAMPLES FOR REINFORCEMENT OF CONCRETE

(Tested in accordance with the requirements in US EAS 412-2:2019 and in accordance with the test method

in ASTM E 8M-16a “Tension Testing of Metallic Materials [Metric]” and ASTM: E 290 - 14 “Bend Testing of

Materials for Ductility” respectively)

A. Sample Description

i. Manufacturer / Exporter; Tembo Steels (U) LTD and Great Steel Limited (GRS-TMT)

ii. 1No. 6mm Plane steel bar and 1No. each of 12mm and 16mm diameter steel bars for Tembo and GRS

B. Physical and Mechanical Properties – Using a CTR – E – SERIES - 1000 Universal Testing Machine

No. Identification/ Type Size Mass/ Yield Tensile Ratio Elongation Bend Test

Trademark Metre Strength Strength A5

(mm) (kg/m) (MPa), Re (MPa), Rm (Rm/Re) (%)

1. Plane/ Round Plane 6 0.182 599 640 1.07 16.5 No Visible Cracks

bar

2. GRS TMT Ribbed 12 0.857 393 553 1.41 32.5 No Visible Cracks

500BCWR

3. TEMBO TMT Ribbed 16 1.551 538 655 1.22 18.0 No Visible Cracks

B500CWR

Specifications;

420 540 1.25 16

US EAS 412-1:2019 for Plane bars

Minimum Maximum Minimum Minimum

grade (B420DWP) *See No sign of visible

Specifications; Legend fracture or cracks

500 1.15 14

US EAS 412-2:2019 for Ribbed bars --

Minimum Minimum Minimum

grade B500CWR

Condition of testing: As delivered by the client, and at Ambient temperatures

Acronyms; US – Uganda Standard, EAS – East Africa Standard, ASTM – American Society for Testing and Materials

Re - Yield strength, Rm - Tensile strength, mm – Millimetres, A5 - Percentage elongation after fracture

Legend * The permissible deviation for mass per meter is as follows;

6mm = 0.222 ± 6.0% (0.209 – 0.235) Plane bar

12mm = 0.888 ± 5.0% (0.834 – 0.941) Ribbed bar

16mm = 1.58 ± 5.0% (1.501 – 1.659) Ribbed bar

……………………………………..

CHIEF MATERIALS ENGINEER

You might also like

- HASODocument1 pageHASOOkello StevenNo ratings yet

- Bars, Rods & RebarsDocument9 pagesBars, Rods & RebarskxalxoNo ratings yet

- Asme BDocument5 pagesAsme Bwlm1967No ratings yet

- mechanical-metigurical-dimensionalDocument4 pagesmechanical-metigurical-dimensionalPaviter SinghNo ratings yet

- AlMg 4.5Mn Product-SheetDocument1 pageAlMg 4.5Mn Product-SheetLuca MemoliNo ratings yet

- ASNZS 3679 - 2 400 (L15) Welded Beam and Columns Datasheet Apr 2020Document2 pagesASNZS 3679 - 2 400 (L15) Welded Beam and Columns Datasheet Apr 2020aries andhikaNo ratings yet

- Technical Specification for Medium Voltage AAA Covered Conductor & AccessoriesDocument36 pagesTechnical Specification for Medium Voltage AAA Covered Conductor & AccessoriesCabcon India100% (1)

- Updated - Type Test Schedule - Ams 5719 - 16-12-2023 - SignedDocument13 pagesUpdated - Type Test Schedule - Ams 5719 - 16-12-2023 - SignedGyanendraNo ratings yet

- 65X M L - 211224 - 180120 - Converted - by - AbcdpdfDocument1 page65X M L - 211224 - 180120 - Converted - by - AbcdpdfVidhyarthi Photocopy KhargoneNo ratings yet

- Welder Job Clearance Card for Ali QurbanDocument43 pagesWelder Job Clearance Card for Ali QurbanDhanush NairNo ratings yet

- Plain Mild Steel BarsDocument1 pagePlain Mild Steel BarsPrabhakar KattulaNo ratings yet

- Pet Non-Woven Geo Textile Data SheetDocument2 pagesPet Non-Woven Geo Textile Data SheetAnonymous MAQrYFQDzVNo ratings yet

- 7451 (1-15) Rebar - Tensile-Grade 105 and 55Document15 pages7451 (1-15) Rebar - Tensile-Grade 105 and 55MOHAMEDNo ratings yet

- Comment - Draft - Comp Girder-26.34-R6Document61 pagesComment - Draft - Comp Girder-26.34-R6Nilay GandhiNo ratings yet

- Refillable Seamless Steel Cylinder For Compressed Gases PER ISO 11114-1Document1 pageRefillable Seamless Steel Cylinder For Compressed Gases PER ISO 11114-1bkprodhNo ratings yet

- Specification For Pressure Vessel Plates, Carbon Steel, For Moderate-And Lower - Temperature ServiceDocument6 pagesSpecification For Pressure Vessel Plates, Carbon Steel, For Moderate-And Lower - Temperature ServiceLuthfi ArdiansyahNo ratings yet

- Designation A516 A516M 10 PDFDocument4 pagesDesignation A516 A516M 10 PDFSiddharth GuptaNo ratings yet

- Pressure Vessel Plates, Carbon Steel, For Moderate-And Lower-Temperature ServiceDocument4 pagesPressure Vessel Plates, Carbon Steel, For Moderate-And Lower-Temperature ServicemarykongNo ratings yet

- Mechanical Properties of High Strength Steel BarDocument4 pagesMechanical Properties of High Strength Steel Barsitaramap10 sathupallyNo ratings yet

- Bidim Technical Datasheet NZ 04 16Document3 pagesBidim Technical Datasheet NZ 04 16Jay SantosNo ratings yet

- GLOBAL BUSBAR INSULATORSDocument16 pagesGLOBAL BUSBAR INSULATORSKatty CachagoNo ratings yet

- Procedure Qualification Record (PQR) Khewari Development ProjectDocument2 pagesProcedure Qualification Record (PQR) Khewari Development Projectsar sarNo ratings yet

- US 160NW: Property Test Method English MetricDocument1 pageUS 160NW: Property Test Method English MetricChrislet VaelNo ratings yet

- Product Certification FabCo 811N1 Lot 01873Document1 pageProduct Certification FabCo 811N1 Lot 01873Sleyda MunozNo ratings yet

- Pressure Vessel Plates, Carbon Steel, For Moderate-And Lower-Temperature ServiceDocument4 pagesPressure Vessel Plates, Carbon Steel, For Moderate-And Lower-Temperature Servicemohamed senoussiNo ratings yet

- 3173 SIS Non VW-1Document2 pages3173 SIS Non VW-1Anh TrầnsvbkNo ratings yet

- A325MDocument8 pagesA325MmsbarretosNo ratings yet

- Kaiser Aluminum 7075 Rod and BarDocument2 pagesKaiser Aluminum 7075 Rod and BarH VNo ratings yet

- Series Asme Safety Valve: DescriptionDocument1 pageSeries Asme Safety Valve: DescriptionADAN CESSANo ratings yet

- Property Test Method English Metric: US Fabrics, Inc. - 3904 Virginia Avenue - Cincinnati, OH 45227Document1 pageProperty Test Method English Metric: US Fabrics, Inc. - 3904 Virginia Avenue - Cincinnati, OH 45227Chrislet VaelNo ratings yet

- Catálogo de Válvulas de Segurança ApolloDocument1 pageCatálogo de Válvulas de Segurança Apolloarhon berdichNo ratings yet

- Lee Metal Wire Mafia CertDocument1 pageLee Metal Wire Mafia CertGeorge KanellakisNo ratings yet

- Ii-E (E: G NoanDocument16 pagesIi-E (E: G NoanCnel RyanNo ratings yet

- Conarc85 EngDocument2 pagesConarc85 EngRaviTeja Bhamidi100% (1)

- Engineering Material Specification: Controlled Document at Page 1 of 7Document7 pagesEngineering Material Specification: Controlled Document at Page 1 of 7Reginaldo SantosNo ratings yet

- ME 205 - 432 - Assignment 1Document9 pagesME 205 - 432 - Assignment 1جعفر السلطانNo ratings yet

- Usa Mechanical1046-01Document5 pagesUsa Mechanical1046-01Rick HenbidNo ratings yet

- Astm A325m - 14Document4 pagesAstm A325m - 14thomasalbatros137No ratings yet

- Ampcoloy 972: Technical Data SheetDocument1 pageAmpcoloy 972: Technical Data SheetmazaherramazaniNo ratings yet

- Form Wps JBL09-2011Document2 pagesForm Wps JBL09-2011fawad aliNo ratings yet

- List of Test (Updated November 2015)Document10 pagesList of Test (Updated November 2015)kmiqdNo ratings yet

- Gate Valve Specification Manuf'S Offer: Signature & Seal of ManufacturerDocument1 pageGate Valve Specification Manuf'S Offer: Signature & Seal of ManufacturerDIPANKAR LALANo ratings yet

- Physical Properties of SteelDocument1 pagePhysical Properties of SteelBigfoot2018No ratings yet

- Tin Mill Products, Black Plate Electrolytic Chromium-Coated, Single and Double ReducedDocument8 pagesTin Mill Products, Black Plate Electrolytic Chromium-Coated, Single and Double ReducedsamehNo ratings yet

- Ficha Técnica - FRAYÖL GEAR S 2 EP - 680Document2 pagesFicha Técnica - FRAYÖL GEAR S 2 EP - 680Julio Oliveira Goncalves JuniorNo ratings yet

- Rites LTD Stainless Steel Sheet / Plate: Inspection & Test PlanDocument3 pagesRites LTD Stainless Steel Sheet / Plate: Inspection & Test Plansrisabarinath sugumarNo ratings yet

- Corodur SP 108: Flux Cored Wires For Thermal Spray ApplicationDocument1 pageCorodur SP 108: Flux Cored Wires For Thermal Spray ApplicationJosua Cavin WijayaNo ratings yet

- Ficha Tecnica Castrol Optigear BM RangeDocument3 pagesFicha Tecnica Castrol Optigear BM RangeVictor Manuel Gonzalez PerezNo ratings yet

- D 1 1Document956 pagesD 1 1karthi82887No ratings yet

- Astm A 516 UltimoDocument4 pagesAstm A 516 UltimoElkin Mauricio Paba LascarroNo ratings yet

- Weld Repair Procedure For The Rear Axle A-Frame and Rear Axle Housing On 785, 789, and 793 OHTDocument18 pagesWeld Repair Procedure For The Rear Axle A-Frame and Rear Axle Housing On 785, 789, and 793 OHTcarlosNo ratings yet

- Tensar - BX161060 MPDSDocument1 pageTensar - BX161060 MPDSkapoor234No ratings yet

- Astm A-572Document5 pagesAstm A-572Wanderley CardosoNo ratings yet

- BOPP Films Polypropylene DatasheetDocument1 pageBOPP Films Polypropylene DatasheetPiyush A JoshiNo ratings yet

- R03RRDocument1 pageR03RRPiyush A JoshiNo ratings yet

- ASTM-A563-A563M-21Document7 pagesASTM-A563-A563M-21zhang binNo ratings yet

- Mirafi RS580i: Roadway Design and Performance Properties Guidance Document / Test Method Unit Design / Calibration ValueDocument2 pagesMirafi RS580i: Roadway Design and Performance Properties Guidance Document / Test Method Unit Design / Calibration ValueLuis Angel Criollo DivertidoNo ratings yet

- WPS Format SampleDocument12 pagesWPS Format SampleminiraqibNo ratings yet

- Cube MouldDocument3 pagesCube MouldOkello StevenNo ratings yet

- 12mmTMX-UNBS. March23Document3 pages12mmTMX-UNBS. March23Okello StevenNo ratings yet

- Gomoyi Solomon 1Document1 pageGomoyi Solomon 1Okello StevenNo ratings yet

- 12mmTMX-UNBS. March23Document3 pages12mmTMX-UNBS. March23Okello StevenNo ratings yet

- Grading Soil 1Document1 pageGrading Soil 1Okello StevenNo ratings yet

- Filter Snd.Document8 pagesFilter Snd.Okello StevenNo ratings yet

- Electronic Balance 5 KGDocument3 pagesElectronic Balance 5 KGOkello StevenNo ratings yet

- Slump Test ApparatusDocument7 pagesSlump Test ApparatusOkello StevenNo ratings yet

- 16mm TMX-UNBS. March23Document3 pages16mm TMX-UNBS. March23Okello StevenNo ratings yet

- Sub-Regions in Uganda: West Nile Acholi KaramojaDocument1 pageSub-Regions in Uganda: West Nile Acholi KaramojaOkello StevenNo ratings yet

- AGG5Document1 pageAGG5Okello StevenNo ratings yet

- Ministry of Works and Transport-01220745 - 20220929051602Document1 pageMinistry of Works and Transport-01220745 - 20220929051602Okello StevenNo ratings yet

- Classification ResultsDocument1 pageClassification ResultsOkello StevenNo ratings yet

- Draft East African Standard: DEAS 412-2:2018-Steel For The Reinforcement of Concrete - Part 2: Ribbed BarsDocument18 pagesDraft East African Standard: DEAS 412-2:2018-Steel For The Reinforcement of Concrete - Part 2: Ribbed BarsOkello StevenNo ratings yet

- University of Oklahoma Graduate CollegeDocument323 pagesUniversity of Oklahoma Graduate CollegeOkello StevenNo ratings yet

- Determining The Longitudinal Profile Roughness of Traveled Surfaces Using Automated ProfilersDocument8 pagesDetermining The Longitudinal Profile Roughness of Traveled Surfaces Using Automated ProfilersOkello StevenNo ratings yet

- Tensile test report for residential apartments steelDocument1 pageTensile test report for residential apartments steelOkello StevenNo ratings yet

- AUEJ Volume 15 Issue 55 Pages 573-583Document11 pagesAUEJ Volume 15 Issue 55 Pages 573-583Okello StevenNo ratings yet

- Koboko Bpit-1Document1 pageKoboko Bpit-1Okello StevenNo ratings yet

- Advert Lab Tech TESDocument2 pagesAdvert Lab Tech TESOkello StevenNo ratings yet

- ConcreteDocument2 pagesConcreteOkello StevenNo ratings yet

- Trial - 1 - A1westDocument3 pagesTrial - 1 - A1westOkello StevenNo ratings yet

- Handbook On Biscuit of LamedaDocument13 pagesHandbook On Biscuit of LamedaMike TorenoNo ratings yet

- Precast Concrete Pipe Test CertificatesDocument2 pagesPrecast Concrete Pipe Test CertificatesOkello StevenNo ratings yet

- CUBESDocument2 pagesCUBESOkello StevenNo ratings yet

- MoWT MTR LAB'S STOCK TAKE FEB 2022Document3 pagesMoWT MTR LAB'S STOCK TAKE FEB 2022Okello StevenNo ratings yet

- CubesDocument1 pageCubesOkello StevenNo ratings yet

- KupdfDocument16 pagesKupdfOkello StevenNo ratings yet

- JointDocument1 pageJointOkello StevenNo ratings yet

- CamScanner 08-26-2022 18.55Document3 pagesCamScanner 08-26-2022 18.55Okello StevenNo ratings yet

- 05 12 00 Structural SteelDocument10 pages05 12 00 Structural SteelIsidro P. BuquironNo ratings yet

- Transparent ConcreteDocument26 pagesTransparent Concretekapil more67% (3)

- Domestic water pump head calculations for 300-bed hospitalDocument14 pagesDomestic water pump head calculations for 300-bed hospitalmirza057No ratings yet

- Vikodeck Shield 2020Document2 pagesVikodeck Shield 2020AminNo ratings yet

- Civil SpecsDocument136 pagesCivil Specsshravan.office11No ratings yet

- NH 3Document2 pagesNH 3Daniel Puello RodeloNo ratings yet

- Corrosion Prevention Pt2Document33 pagesCorrosion Prevention Pt2allanNo ratings yet

- A Comparative Evaluation of Cement and Lime Modification of LateriteDocument11 pagesA Comparative Evaluation of Cement and Lime Modification of Lateriteherve JordanNo ratings yet

- Cutting Speeds and Feeds GuideDocument4 pagesCutting Speeds and Feeds GuideAnonymous dh6DITNo ratings yet

- Element - 111 - 579-Bill of Quantity For Constructing Main House of MosqueDocument8 pagesElement - 111 - 579-Bill of Quantity For Constructing Main House of MosqueKapros Junior AphrodiceNo ratings yet

- "Strength and Analysis of Basalt Fibre in Concrete": Project Seminar OnDocument29 pages"Strength and Analysis of Basalt Fibre in Concrete": Project Seminar OnArsam Haq100% (1)

- I S 617 - 1994Document15 pagesI S 617 - 1994Muthusamy ArumugamNo ratings yet

- Zemichael Berhe MehariDocument99 pagesZemichael Berhe Meharidhanesh kumarNo ratings yet

- Architectural Concrete Part 1Document80 pagesArchitectural Concrete Part 1Samuel FuentesNo ratings yet

- RVR-Building Tech. 3 - Steel Construction - Ppt. PresentationDocument47 pagesRVR-Building Tech. 3 - Steel Construction - Ppt. Presentationtoyi kamiNo ratings yet

- Summary RebarsDocument6 pagesSummary RebarsEmmerson NavarroNo ratings yet

- Cast Iron Price Calculator - Gray Iron, Ductile IronDocument4 pagesCast Iron Price Calculator - Gray Iron, Ductile IronKrishna Mohan T.RNo ratings yet

- GSTN Numbers and Contact Details of 52 Manufacturers and TradersDocument38 pagesGSTN Numbers and Contact Details of 52 Manufacturers and TradersHarpreet SinghNo ratings yet

- Nzcs tr32Document145 pagesNzcs tr32Jianhua WuNo ratings yet

- Roofing Manual 06 PDFDocument76 pagesRoofing Manual 06 PDFmutton moonswami100% (2)

- 4-07-RWX4 Cladding SystemDocument18 pages4-07-RWX4 Cladding SystempaolocparreraNo ratings yet

- 10201Document5 pages10201Christian Rey LumantaoNo ratings yet

- Rate AnalysisDocument60 pagesRate AnalysisLuojisi CilNo ratings yet

- Imperial Era Mansion Plumbing SpecsDocument29 pagesImperial Era Mansion Plumbing SpecsLorena TanNo ratings yet

- Hoja de Datos - 116-4FCDocument2 pagesHoja de Datos - 116-4FCHenry Garavito RamirezNo ratings yet

- Al Zamil Water TanksDocument12 pagesAl Zamil Water TanksNathan Patterson100% (1)

- High-Strength Low-Alloy Structural Steel: Standard Specification ForDocument3 pagesHigh-Strength Low-Alloy Structural Steel: Standard Specification ForJaleel ClaasenNo ratings yet

- Lincore 65-O: Typical Applications Key FeaturesDocument2 pagesLincore 65-O: Typical Applications Key FeaturesDaniel Lvqve GarciaNo ratings yet

- Plumbing Practical Handouts PDFDocument288 pagesPlumbing Practical Handouts PDFfaye yanzonNo ratings yet

- U.S. NRC Guide on ASME Code Case Acceptability for Nuclear Power Plant ComponentsDocument59 pagesU.S. NRC Guide on ASME Code Case Acceptability for Nuclear Power Plant ComponentsSivadol VongmongkolNo ratings yet