Professional Documents

Culture Documents

20F1001 Flow Device Operating Parameters

Uploaded by

Diego SotoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

20F1001 Flow Device Operating Parameters

Uploaded by

Diego SotoCopyright:

Available Formats

1 RESPONSIBLE ORGANIZATION FLOW DEVICE 6 SPECIFICATION IDENTIF

2 Operating Parameters 7 Document no

3 8

4 9 Latest revision

5 10 Issue status

11 ADMINISTRATIVE IDENTIFICATIONS 4 SERVICE IDENTIFICATIONS Contin

12 Project number Sub project no 0 Inline hazardous area cl

13 4

14 Project 1 Inline area min ign temp

15 Enterprise 4 Remote hazardous area cl

16 Site 2 Remote area min ign temp

17 4

Area Cell Unit

18 3

19 4

20 SERVICE IDENTIFICATIONS 4 COMPONENT DESIGN CRITER

21 Tag no/Functional ident 4 Component type

22 Related equipment 5 Component style

23 4

24 Service 6 Output signal type

25 4 Characteristic curve

26 P&ID/Reference dwg number 7 Compensation style

27 Upstr line/nozzle number 4 Type of protection

28 8

29 Upstream line pipe spec 4 Criticality code

30 Upstr line nominal size Rating 9 Max EMI susceptibility

31 Upstr line conn type Style 5 Max temperature effect

32 0

Upstr line schedule no Wall thickness Min diameter ratio (d/D)

33 5

34 Upstr conn orientation 1 Max response time

35 Upstr line material type 5 Min required accuracy

36 Connection design code 2 Avail nom power supply

37 5

Dnstr line/nozzle number Min load capability

38 3

39 Downstream line pipe spec 5 Testing/Listing agency

Dnstr line nominal size Rating 4 Test requirements

Dnstr line conn type Style 5 Supply loss failure mode

5

Dnstr line schedule no Wall thickness Signal loss failure mode

5

Dnstr conn orientation 6

Dnstr line material type 5

Avail upstr straight lg Dnstr 7

69 PROCESS VARIABLES MATERIALlg FLOW CONDITIONS 5 101 PROCESS DESIGN C

8

70 5 102

71 Flow Case Identification Units 103 Minimum

Inlet 9

72 6 104

73 pressure

Outlet 105

0

74 pressure

Inlet 6 106

75 temperature 1 107

76 Inlet phase 108

type 6

77 Mass 109

2

78 fraction

Total mass 110

6

79 vaporrate

flow 111

Liquid mass 3

80 flow rate 6 112

81 Liquid 113

actual flow 4

82 Liquid 114

rate 6

83 standard

Liquid 115

5

84 flow rate

density 116

Liquid 6

85 6 117

specific

Liquid

86 6 118

gravity

viscosity

87 Absolute 7 119

88 vapor mass

Vapor 6 120

89 pressure

flow rate 8 121

Vapor

90 122

actual

Vapor flow

91 123

rate

standard

92 Vapor 124

93 flow rate

density 125

Vapor

94 specific 126

Vapor

95 gravity 127

molecular

Vapor

96 128

weight

viscosity

97 Inlet 129

98 compressibil 130

99 ityCALCULATED VARIABLES 131

Pressure

differential

95 127

96 128

97 129

98 130

99 131

Perm

pressure

Line fluid

drop

velocity

Line

Reynolds

Calculated

number

uncertainty

132 MATERIAL PROPERTIES 138 MATERIAL PROPERTIES Continu

133 Name 139 Abs critical pressure

134 140

Composition Critical temperature

135 141

136 Density at ref temp At 142 NFPA health hazard

137 Ratio sp heat capacity 143

Conductivity

Rev Date Revision Description By Appv1 Appv2 Appv3 REMARKS

Form: 20F1001 Rev 0 © 200

SPECIFICATION IDENTIFICATIONS

ument no

st revision Date

e status

ICE IDENTIFICATIONS Continued

Div/Zone Group

Temp ident number

Div/Zone Group

Temp ident number

OMPONENT DESIGN CRITERIA

Ref

Ref

Max

Ref

Number wires

PROCESS DESIGN CONDITIONS

Minimum Maximum Units

TERIAL PROPERTIES Continued

Flammability Reactivity

REMARKS

© 2001 ISA

You might also like

- Hoja de Datos (Flow Device)Document14 pagesHoja de Datos (Flow Device)Guillermo LariosNo ratings yet

- Hoja de Datos (Valve or Regulator Device)Document14 pagesHoja de Datos (Valve or Regulator Device)Guillermo LariosNo ratings yet

- 2 Rev. X Hoja 2 De: EPE-XXXX-HD-A-001Document1 page2 Rev. X Hoja 2 De: EPE-XXXX-HD-A-001Elizabeth RazoNo ratings yet

- Hoja de Datos (Analysis Device)Document15 pagesHoja de Datos (Analysis Device)Guillermo LariosNo ratings yet

- Hoja de Datos (Differential Pressure Device)Document14 pagesHoja de Datos (Differential Pressure Device)Guillermo LariosNo ratings yet

- Hoja de Datos (Level Device)Document14 pagesHoja de Datos (Level Device)Guillermo LariosNo ratings yet

- Analysis DeviceDocument1 pageAnalysis DeviceAntonio GallegosNo ratings yet

- EPE-XXXX-HD-A-001: DE Hoja 2 2 Rev. XDocument1 pageEPE-XXXX-HD-A-001: DE Hoja 2 2 Rev. XElizabeth RazoNo ratings yet

- EPE-XXXX-HD-A-001: 2 Hoja DE 2 Rev. XDocument1 pageEPE-XXXX-HD-A-001: 2 Hoja DE 2 Rev. XElizabeth RazoNo ratings yet

- Motorised Valve: Instrument Datasheet Tag NoDocument1 pageMotorised Valve: Instrument Datasheet Tag Nokrishna kumarNo ratings yet

- ThermocoupleDocument2 pagesThermocouplevivek mishraNo ratings yet

- Flow Transmitter Datasheet: TAG Number ServiceDocument1 pageFlow Transmitter Datasheet: TAG Number Servicejugal ranaNo ratings yet

- Delta P Level Transmitter TemplateDocument1 pageDelta P Level Transmitter TemplateUTKARSH GADVENo ratings yet

- Datasheet - Pressure TransmitterDocument1 pageDatasheet - Pressure Transmitterjugal ranaNo ratings yet

- Bimetallic Thermometer Template SmallDocument1 pageBimetallic Thermometer Template SmallEyuNo ratings yet

- 09 Weight-Or-Force-DeviceDocument1 page09 Weight-Or-Force-DeviceElizabeth RazoNo ratings yet

- Bimetal Thermometer Datasheet: TAG Number ServiceDocument1 pageBimetal Thermometer Datasheet: TAG Number ServicefernandopetitsterNo ratings yet

- SR - 2012-09 DP Pressure TransmitterDocument2 pagesSR - 2012-09 DP Pressure TransmitterHsein WangNo ratings yet

- Delta P Level Transmitter Datasheet: TAG Number ServiceDocument1 pageDelta P Level Transmitter Datasheet: TAG Number ServiceLucas RossiniNo ratings yet

- Transmisores de Presión y TemperaturaDocument6 pagesTransmisores de Presión y TemperaturaCh LoNo ratings yet

- Delta P Level Transmitter Template SmallDocument1 pageDelta P Level Transmitter Template SmallfernandopetitsterNo ratings yet

- Datasheet For RTD and ThermowellDocument1 pageDatasheet For RTD and ThermowellJeshinNo ratings yet

- Technical Specification - LT (DP Based)Document4 pagesTechnical Specification - LT (DP Based)ManodipPatilNo ratings yet

- 107 RotameterDocument1 page107 RotametervyasathNo ratings yet

- Pressure Transmitter Template SmallDocument1 pagePressure Transmitter Template SmallKamonpon PlungkratokNo ratings yet

- Actuated Block Valve: Instrument Datasheet Tag NoDocument1 pageActuated Block Valve: Instrument Datasheet Tag Nokrishna kumarNo ratings yet

- Pressure Switch Mechanical Template SmallDocument1 pagePressure Switch Mechanical Template Smallali AlinezhadNo ratings yet

- Pressure Transmitter Datasheet: TAG Number ServiceDocument1 pagePressure Transmitter Datasheet: TAG Number ServiceEyuNo ratings yet

- Coriolis Flowmeter Spec Form 20F2521Document1 pageCoriolis Flowmeter Spec Form 20F2521benditasea3352No ratings yet

- Delta P Level Transmitter TemplateDocument3 pagesDelta P Level Transmitter TemplateUTKARSH GADVENo ratings yet

- Pressure Transmitter Template SmallDocument2 pagesPressure Transmitter Template Smalldiksha surekaNo ratings yet

- SR - 2012-09 Flow IndicatorDocument2 pagesSR - 2012-09 Flow IndicatorHsein WangNo ratings yet

- Temperature GaugeDocument1 pageTemperature Gaugevivek mishraNo ratings yet

- DS ActuadElectDocument1 pageDS ActuadElectabelegpNo ratings yet

- ISA Format DatasheetsDocument10 pagesISA Format Datasheetsrpaliwal196767% (3)

- RTD Temperature Transmitter Datasheet: TAG Number ServiceDocument1 pageRTD Temperature Transmitter Datasheet: TAG Number ServiceMarcelNo ratings yet

- Pressure Gauge TemplateDocument1 pagePressure Gauge TemplateUTKARSH GADVENo ratings yet

- 312-Data Sheet For Pressure TransmitterDocument3 pages312-Data Sheet For Pressure TransmittervyasathNo ratings yet

- RTD Temperature Transmitter Template SmallDocument1 pageRTD Temperature Transmitter Template SmallMay Rodyn Cuba de la CruzNo ratings yet

- Pressure Switch Mechanical TemplateDocument3 pagesPressure Switch Mechanical TemplateUTKARSH GADVENo ratings yet

- RTD Temperature Transmitter Template SmallDocument1 pageRTD Temperature Transmitter Template SmallMohan BabuNo ratings yet

- RTD Temperature Transmitter Datasheet: TAG Number ServiceDocument1 pageRTD Temperature Transmitter Datasheet: TAG Number ServiceEyu100% (1)

- Pressure Switch Mechanical TemplateDocument1 pagePressure Switch Mechanical TemplateUTKARSH GADVENo ratings yet

- Pressure Transmitter Template MediumDocument3 pagesPressure Transmitter Template MediumMassaa ProNo ratings yet

- Temperature Transmitter Specification Sheet: Client Project Unit LocationDocument2 pagesTemperature Transmitter Specification Sheet: Client Project Unit LocationFranklin J Talero BNo ratings yet

- SPFM 001 PDFDocument1 pageSPFM 001 PDFOswaldo GuerraNo ratings yet

- Datasheet Vacuum Gauge: Project Project Number Purchase Order RequisitionDocument5 pagesDatasheet Vacuum Gauge: Project Project Number Purchase Order RequisitionManodipPatilNo ratings yet

- Temperature Client Transmitter Project Specification Sheet Unit LocationDocument2 pagesTemperature Client Transmitter Project Specification Sheet Unit LocationFranklin J Talero BNo ratings yet

- Pressure Transmitter Spec Form 403 - KWDocument1 pagePressure Transmitter Spec Form 403 - KWsurendharNo ratings yet

- PH - Orp - Sensor - Insertion AssemblyDocument1 pagePH - Orp - Sensor - Insertion AssemblyAntonio GallegosNo ratings yet

- Level TransmitterDocument1 pageLevel Transmittervivek mishraNo ratings yet

- 16 Humidity-Dewpoint-Transmitter-SwitchesDocument1 page16 Humidity-Dewpoint-Transmitter-SwitchesElizabeth RazoNo ratings yet

- DS FlowSonarDocument1 pageDS FlowSonarabelegpNo ratings yet

- Humidity Dewpoint TransmitterDocument1 pageHumidity Dewpoint TransmitterAntonio GallegosNo ratings yet

- Data Sheet For Pressure TransmitterDocument2 pagesData Sheet For Pressure TransmitterDavinder Singh BhattiNo ratings yet

- TT 453Document3 pagesTT 453Manuel Rodriguez CNo ratings yet

- 85000PT629Document1 page85000PT629LibyanManNo ratings yet

- Conemeter DatasheetDocument2 pagesConemeter DatasheetShakeel AhmedNo ratings yet

- Macolla 11, Fase I: Vialidad de Acceso, Plataforma Y Definición de Equipos Mayores de La Macolla 11 en El Centro Operativo Petromonagas (Copem)Document2 pagesMacolla 11, Fase I: Vialidad de Acceso, Plataforma Y Definición de Equipos Mayores de La Macolla 11 en El Centro Operativo Petromonagas (Copem)vacarrizaNo ratings yet

- x3301 and x3302 Exida International Sil 2019Document2 pagesx3301 and x3302 Exida International Sil 2019Asad NaeemNo ratings yet

- 90 1203 Eqp3750 Addressable Smoke Heat Ash ModuleDocument2 pages90 1203 Eqp3750 Addressable Smoke Heat Ash ModulesebasfranNo ratings yet

- Instruction Manual: LINC86 Series Electric Chemical Metering Pump Plunger Type Bellows TypeDocument26 pagesInstruction Manual: LINC86 Series Electric Chemical Metering Pump Plunger Type Bellows TypeVinicio VillarruelNo ratings yet

- Certificado Sil II Mezaclas ExplosivasDocument2 pagesCertificado Sil II Mezaclas ExplosivasCARLOS JAVIER LUNA MARTÍNEZNo ratings yet

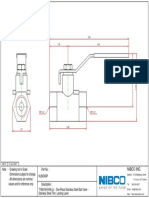

- EB15902062Document1 pageEB15902062Diego SotoNo ratings yet

- Nl943k6p Nibco 2dsalesdrawing 07-13-2020Document1 pageNl943k6p Nibco 2dsalesdrawing 07-13-2020Diego SotoNo ratings yet

- Isa-Tr20 00 01-2001Document1 pageIsa-Tr20 00 01-2001makkee81997No ratings yet

- 20Z2011 Pick ListDocument17 pages20Z2011 Pick ListDiego SotoNo ratings yet

- 20Z2012 Pick ListDocument18 pages20Z2012 Pick ListDiego SotoNo ratings yet

- Vernier Act11 VaporpressureDocument12 pagesVernier Act11 Vaporpressurezorroben1953No ratings yet

- Vapor PressureDocument33 pagesVapor PressureSara FatimaNo ratings yet

- Raoult'S Law: Engr - Arshad IqbalDocument9 pagesRaoult'S Law: Engr - Arshad IqbalfarazcoolNo ratings yet

- CHEM 111.1 Exercise 4Document13 pagesCHEM 111.1 Exercise 4paradoxcomplex100% (1)

- Astm D323-15a PVRDocument11 pagesAstm D323-15a PVRAngel MurilloNo ratings yet

- Rotronic Humidity Handbook - UnlockedDocument99 pagesRotronic Humidity Handbook - Unlockedrom009No ratings yet

- CHEG 201 Chemical Process Calculation Homework #3Document11 pagesCHEG 201 Chemical Process Calculation Homework #3AASHISH CHAULAGAINNo ratings yet

- CHE 304 Optional Homework Due Toluene HyDocument9 pagesCHE 304 Optional Homework Due Toluene Hyqurat ul ainNo ratings yet

- 4200:225 Equilibrium Thermodynamics Spring 2013: Homework #9Document2 pages4200:225 Equilibrium Thermodynamics Spring 2013: Homework #9Henry NgoNo ratings yet

- CHAPTER 5 - STATES OF MATTER (S) Edit20152016Document12 pagesCHAPTER 5 - STATES OF MATTER (S) Edit20152016PAKK20622P Syarifah Nor Izzah binti Syed Abd HamidNo ratings yet

- Relative Lowering of Vapour Pressure - 1524262518Document4 pagesRelative Lowering of Vapour Pressure - 1524262518PavitraNo ratings yet

- Mechanics of FluidsDocument64 pagesMechanics of FluidsShiva U100% (2)

- ASTM E96 Standard Test Methods For Water Vapor Transmission of MaterialsDocument2 pagesASTM E96 Standard Test Methods For Water Vapor Transmission of MaterialsAmanda Ariesta ApriliaNo ratings yet

- Theory of Solutions: Basics Section - 1Document34 pagesTheory of Solutions: Basics Section - 1Siddharth DhurandharNo ratings yet

- Liquid Solutions: Physical Chemistry by Prince SirDocument14 pagesLiquid Solutions: Physical Chemistry by Prince SirSunnyNo ratings yet

- Physical Science Week 5 - 6Document14 pagesPhysical Science Week 5 - 6Aleli Joy Profugo Dalisay100% (1)

- International Physics OlympiadsDocument468 pagesInternational Physics OlympiadsJurandi Leão100% (1)

- Quiz PHASE EQUILIBRIA (Set 2)Document4 pagesQuiz PHASE EQUILIBRIA (Set 2)Supia NazmaNo ratings yet

- Chapter 5Document36 pagesChapter 5Lucy BrownNo ratings yet

- SH 5107 Gases, Vapour & Aerosols 2021 Version 1Document131 pagesSH 5107 Gases, Vapour & Aerosols 2021 Version 1Shuyuan LuNo ratings yet

- TORING LC Exer4 7LDocument19 pagesTORING LC Exer4 7LLanoline ToringNo ratings yet

- Chemsep HelpDocument59 pagesChemsep Helpmacleod230286No ratings yet

- Distillation Processes: June 2014Document29 pagesDistillation Processes: June 2014Najmi NasirNo ratings yet

- Kinetic Particle Theory: Answers To Textbook ExercisesDocument3 pagesKinetic Particle Theory: Answers To Textbook ExercisesariiNo ratings yet

- Liquid Solution (13th)Document19 pagesLiquid Solution (13th)Raju SinghNo ratings yet

- Chap 3 Properties of Pure Substances.Document37 pagesChap 3 Properties of Pure Substances.William SalazarNo ratings yet

- Lab Report (RVP)Document9 pagesLab Report (RVP)nisasoberi100% (1)

- Handbook of Property Estimation Methods For Chemicals: Environmental and Health SciencesDocument491 pagesHandbook of Property Estimation Methods For Chemicals: Environmental and Health SciencesSolhaNo ratings yet

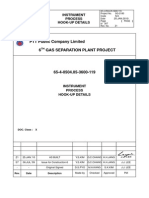

- Instrument Process Hook-Up DetailsDocument301 pagesInstrument Process Hook-Up DetailsNikki Roberts100% (6)

- Chapter 1Document11 pagesChapter 1adlaborce7_821112170No ratings yet