Professional Documents

Culture Documents

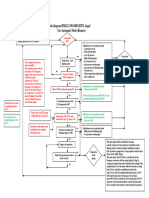

Test and troubleshoot alarm functions on maintenance procedures

Uploaded by

Robert IvancicOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Test and troubleshoot alarm functions on maintenance procedures

Uploaded by

Robert IvancicCopyright:

Available Formats

MAINTENANCE, PROCEDURESM

4.1 ALARM TEST

A test can be performed by activating an alarm

functioon. However

certain alarm functions can tested by simple means

to be disconnected prior to testing. but have

By testing one of the alarm loops the logical functione

simultaneously. ons is tested

If alarm functions is to be disconnected in the

make sure POWER is switched OFF. control unit

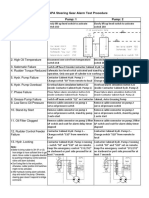

Guide for how to test alarm functions (a and b alternative actions)

Alerm symbol Alarm function Sensor Actions alternatives

3. Stop oil feed pump

Low oil flow FS 4

b. Change V1 position by

air pressure reducing

. Stop oil feed pump

PS4 Low oil flow PS4

ghood olb . Change V1 position by reducing

air pressure

Remove the level indicator from the

54 High intermediate tank level LS 4 tank. Lift the float of the high level

switch through the opening

Vibration

Emergency stop XS12

x$ Tap on the vibration switch

Press Emergency stop pushbotton

Faulty switch Bridge terminal X7:4 and XC

FS

pnin

Initiate a sludge discharge

Preheater fault 1. Start the heater

2. Disconnect cable to X9:3

bile gniv0 a. Remove sensor from pipe and

High or low oil put into

temperatureibiiu TT1wo

hot/cool liquid

b yrivang b.

Change alarm limit parameters

Bmet (P5 max temp/P6 min temp) in

Communication error relation to actual temperaturee

Processor faut

Remove fuse F2

Remove fuse F2

Programming mode too long Alarm A2 -6

Leave the mode selector switch in

Power failure position P20 for 30

minutes

Excessive deviation Switch

operationpower off-on when EPC is in

swre sensor

signals between temper

TT1 and TT2 TT1 TT2

Remove one sensor

89 Extua alarm

off or be

heated up from pipe tocool

30'CActivate

/86°F)appropriate

(temp a

sensor

Disconnect cable X7:1

20

You might also like

- Alarm and Fault FindingDocument36 pagesAlarm and Fault Findingmilad100% (2)

- Electrical Panel SOPDocument10 pagesElectrical Panel SOPRiyaZ55100% (1)

- Pilot NotesDocument12 pagesPilot NotesFabian FuchsNo ratings yet

- Field Repair/Service Blanketrol Iii, Model 233 Operation and Technical ManualDocument9 pagesField Repair/Service Blanketrol Iii, Model 233 Operation and Technical ManualRogerio SilvaNo ratings yet

- MSFS Hawker Hunter Pilot's Notes for Cockpit and Pre-Start ChecksDocument11 pagesMSFS Hawker Hunter Pilot's Notes for Cockpit and Pre-Start Checksrodolfoaznar100% (1)

- Chiller Operation ManualDocument14 pagesChiller Operation Manualeburbano12No ratings yet

- SPX - 2 - 3 - 4 - 5 - Operating Manual PDFDocument89 pagesSPX - 2 - 3 - 4 - 5 - Operating Manual PDFYaseen JamilNo ratings yet

- VAILLANT Combi Compact and Thermocompact Logical Fault FindingDocument16 pagesVAILLANT Combi Compact and Thermocompact Logical Fault Findingacw285100% (1)

- spx2280 2281Document56 pagesspx2280 2281TÌNH LÊNo ratings yet

- 820 NOVA: Multifunctional Gas ControlDocument8 pages820 NOVA: Multifunctional Gas ControlJose Luis Jimenez InfanteNo ratings yet

- B25D B30D MKIII Automatic GreasingDocument43 pagesB25D B30D MKIII Automatic GreasingMIANo ratings yet

- Manual Chillers20 NewDocument14 pagesManual Chillers20 NewMinh NguyễnNo ratings yet

- Servo Emergency System: Product Leaflet VentilationDocument1 pageServo Emergency System: Product Leaflet VentilationKusri YantoNo ratings yet

- Troubleshooting alarms and signalsDocument3 pagesTroubleshooting alarms and signalsCidi ComNo ratings yet

- Water Level Limiter 933 (Instruction of Use)Document2 pagesWater Level Limiter 933 (Instruction of Use)Miraz RahmanNo ratings yet

- GT shutdown sequence overviewDocument1 pageGT shutdown sequence overviewsmart_eng2009100% (1)

- FlowCon FN Actuator Installation GuideDocument4 pagesFlowCon FN Actuator Installation GuideGabriel Arriagada UsachNo ratings yet

- Operating Instructions Operating Instructions: Nano-L SMJ Nano-L SMJ R-16, R-CAN R-16, R-CANDocument20 pagesOperating Instructions Operating Instructions: Nano-L SMJ Nano-L SMJ R-16, R-CAN R-16, R-CANpopo20084455No ratings yet

- FG - Operation Manual Controller R515 - Installation - UNDocument9 pagesFG - Operation Manual Controller R515 - Installation - UNŞaban YıldırımNo ratings yet

- Of 914Document29 pagesOf 914christianvilcaNo ratings yet

- 9500 Faults 1Document1 page9500 Faults 1José Luis SassoNo ratings yet

- GD10manual PDFDocument102 pagesGD10manual PDFben ali abderrazakNo ratings yet

- Block diagram Automatic Remote Mode _BHELDocument1 pageBlock diagram Automatic Remote Mode _BHELMELCO JITPLNo ratings yet

- Maxxforce DT IPR TSDocument6 pagesMaxxforce DT IPR TSحسين عبدالهاديNo ratings yet

- On Load Tap Changing Transformers - Voltage Regulation ControlDocument53 pagesOn Load Tap Changing Transformers - Voltage Regulation ControlmoosuhaibNo ratings yet

- 3.3. Fault Codes: Error Code Origin State of The Centrifuge User's Action 01Document3 pages3.3. Fault Codes: Error Code Origin State of The Centrifuge User's Action 01Ruben DuranNo ratings yet

- Emergency Release Coupling: For Marine Loading ArmDocument11 pagesEmergency Release Coupling: For Marine Loading ArmShamsul Azhar SulaimanNo ratings yet

- Brivis DRC Inverter ControllerDocument35 pagesBrivis DRC Inverter ControllerNeamat AliNo ratings yet

- 62te GDDocument4 pages62te GDluiz fernando leal verneNo ratings yet

- IPG9INSTRUCDocument1 pageIPG9INSTRUCpatgarettNo ratings yet

- Solo Sovereign Panel ManualDocument9 pagesSolo Sovereign Panel ManualLuke WilsonNo ratings yet

- Trouble Shooting of PumpsDocument14 pagesTrouble Shooting of PumpsHukam ChandNo ratings yet

- Alarm and Alert CodesDocument4 pagesAlarm and Alert Codesramadan aliNo ratings yet

- Service Tips: Efl Dometic@Document23 pagesService Tips: Efl Dometic@ugas666999No ratings yet

- Telehandler 3Document50 pagesTelehandler 3GERSON DAVID RODRIGUEZ TORRESNo ratings yet

- M2100Document6 pagesM2100kylegazeNo ratings yet

- Fault, Protection and Failure Indications in PSE Soft StarterDocument5 pagesFault, Protection and Failure Indications in PSE Soft StartermichaelNo ratings yet

- Inamcon42i Part2Document184 pagesInamcon42i Part2ROENZARONo ratings yet

- Acceptance: External Alarm Validation and RectificationDocument3 pagesAcceptance: External Alarm Validation and RectificationimamNo ratings yet

- Container Refrigeration Operation and Service Manual Alarm Code GuideDocument9 pagesContainer Refrigeration Operation and Service Manual Alarm Code GuideMiguel CamposNo ratings yet

- Single Phase MotorsDocument4 pagesSingle Phase MotorsAmit DebnathNo ratings yet

- FlowCon FN02 InstructionDocument8 pagesFlowCon FN02 Instructionfmelman 04No ratings yet

- Itp Precedure SiemensDocument2 pagesItp Precedure SiemensRizki Jak ManiaNo ratings yet

- Revision of Chapter 16 - Trouble Shooting of LHB Manual (Electrical)Document22 pagesRevision of Chapter 16 - Trouble Shooting of LHB Manual (Electrical)Ahmed HossainNo ratings yet

- Allison Fire Pump Mode Io4096enDocument2 pagesAllison Fire Pump Mode Io4096enfernandoNo ratings yet

- 10K Ships - Steering Gear Alarm Test ProcedureDocument3 pages10K Ships - Steering Gear Alarm Test ProcedureDhammika AbeysinghaNo ratings yet

- Emergency Check List Technam p2008jcDocument4 pagesEmergency Check List Technam p2008jcGourav DasNo ratings yet

- Aritco 7000 Part1Document15 pagesAritco 7000 Part1Rodel SimonNo ratings yet

- Installation & Servicing InstructionsDocument44 pagesInstallation & Servicing InstructionsRob MaxoreNo ratings yet

- FPS Smart SCADA MANUAL With Exor HmiDocument117 pagesFPS Smart SCADA MANUAL With Exor HmiSHAILESH PATELNo ratings yet

- Test Unit For Burnerlogix y Controls 57yb4 5000Document4 pagesTest Unit For Burnerlogix y Controls 57yb4 5000edgarNo ratings yet

- 902 SMPS: Electronic Controllers For Refrigeration UnitsDocument16 pages902 SMPS: Electronic Controllers For Refrigeration UnitsCaZias EoiNo ratings yet

- Operation Taiyo Draft R2Document32 pagesOperation Taiyo Draft R2Saivul ChazisNo ratings yet

- Manual de Servicio Nevera Gobernadora OcoaDocument2 pagesManual de Servicio Nevera Gobernadora OcoaEdison EspinalNo ratings yet

- Block diagram Local Mode HMQ-F_250-2000 5800029_BHELDocument1 pageBlock diagram Local Mode HMQ-F_250-2000 5800029_BHELMELCO JITPLNo ratings yet

- 3 Operation InstructionDocument22 pages3 Operation Instructioncengiz kutukcuNo ratings yet

- MM 14 CcsDocument13 pagesMM 14 CcsGaspar GarciaNo ratings yet

- I3rc Insights Pvt. Ltd. India - Company Credentials PDFDocument28 pagesI3rc Insights Pvt. Ltd. India - Company Credentials PDFManoj Kumar JhaNo ratings yet

- Database AwsDocument15 pagesDatabase AwsHareesha N GNo ratings yet

- German Companies in RwandaDocument6 pagesGerman Companies in RwandaTabitha KaraniNo ratings yet

- Timetable 1Document1 pageTimetable 1sunilbijlaniNo ratings yet

- R4850G2 Rectifier Data Sheet 05Document2 pagesR4850G2 Rectifier Data Sheet 05PP CharlyNo ratings yet

- Jurnal Mira FixDocument16 pagesJurnal Mira Fixarisanto micoNo ratings yet

- S7 - Q2 - Answer KeyDocument11 pagesS7 - Q2 - Answer KeyRaniel LacuarinNo ratings yet

- The Secret Science of Shaktipat - Guide To Initiation 13 September 2020Document77 pagesThe Secret Science of Shaktipat - Guide To Initiation 13 September 2020Patrick JenksNo ratings yet

- Mens Care Active Concepts PDFDocument19 pagesMens Care Active Concepts PDFFredy MendocillaNo ratings yet

- OlayDocument36 pagesOlayrachit.chaudharyNo ratings yet

- Labconco-3905503 Rev e Purifier Hepa Filtered and Class I Filtered Enclosures User ManualDocument77 pagesLabconco-3905503 Rev e Purifier Hepa Filtered and Class I Filtered Enclosures User ManualCalixto GrajalesNo ratings yet

- Sharp Sharp Cash Register Xe A207 Users Manual 284068Document1 pageSharp Sharp Cash Register Xe A207 Users Manual 284068Zeila CordeiroNo ratings yet

- OYO Case Study SolutionDocument4 pagesOYO Case Study SolutionVIKASH GARGNo ratings yet

- Managerial Economics L4 Consumer BehaviourDocument50 pagesManagerial Economics L4 Consumer BehaviourRifat al haque DhruboNo ratings yet

- Omega: Mahdi Alinaghian, Nadia ShokouhiDocument15 pagesOmega: Mahdi Alinaghian, Nadia ShokouhiMohcine ES-SADQINo ratings yet

- GCS Activity 2003Document33 pagesGCS Activity 2003donnottryNo ratings yet

- The Dogon Tribe of The Sirius MysteryDocument5 pagesThe Dogon Tribe of The Sirius MysteryLaron Clark100% (1)

- Electric Charges and Fields Bank of Board QuestionsDocument11 pagesElectric Charges and Fields Bank of Board QuestionsNishy GeorgeNo ratings yet

- Master in Public Management: Application PacketDocument6 pagesMaster in Public Management: Application PacketMark GironNo ratings yet

- A Detailed Lesson Plan in (Teaching Science)Document8 pagesA Detailed Lesson Plan in (Teaching Science)Evan Jane Jumamil67% (3)

- S-H Polarimeter Polartronic-532 Eng - 062015 PDFDocument2 pagesS-H Polarimeter Polartronic-532 Eng - 062015 PDFSuresh KumarNo ratings yet

- SAQ Ans 6Document3 pagesSAQ Ans 6harshanauocNo ratings yet

- Cultures of Learning: Language Classrooms in China: Martin Cortazzi Lixian JinDocument54 pagesCultures of Learning: Language Classrooms in China: Martin Cortazzi Lixian JinyhoulhandhariNo ratings yet

- Project management software enables collaborationDocument4 pagesProject management software enables collaborationNoman AliNo ratings yet

- Gigabyte 8simlh - Rev 3.02Document32 pagesGigabyte 8simlh - Rev 3.02Denis MartinsNo ratings yet

- IM PS Fashion-Business-Digital-Communication-And-Media 3Y Course Pathway MI 04Document7 pagesIM PS Fashion-Business-Digital-Communication-And-Media 3Y Course Pathway MI 04oliwia bujalskaNo ratings yet

- Nord Stage Factory Patches v3 v4 v5Document18 pagesNord Stage Factory Patches v3 v4 v5Danilo Giuliani DobermannNo ratings yet

- Islamic Center Design With Islamic ArchiDocument11 pagesIslamic Center Design With Islamic ArchiMuhammad Sufiyan SharafudeenNo ratings yet

- Ffective Riting Kills: Training & Discussion OnDocument37 pagesFfective Riting Kills: Training & Discussion OnKasi ReddyNo ratings yet

- 1 Catalyst FundamentalsDocument17 pages1 Catalyst FundamentalsSam AnuNo ratings yet