Professional Documents

Culture Documents

Hazop Sil Lopa LNG Reloading Station1

Hazop Sil Lopa LNG Reloading Station1

Uploaded by

Nikhil Nixon0 ratings0% found this document useful (0 votes)

16 views2 pagesKlaipėdos Nafta, Lithuania's state-owned petroleum terminal operator, appointed a consortium to carry out construction of an LNG Reloading Station in Klaipėda, Lithuania from 2016-2017. PSC provided risk evaluation services including HAZOP and SIL workshops to identify hazards and safety instrumented functions, LOPA of critical functions, and updates after design changes. PSC also prepared a Safety Requirements Specification in line with international standards.

Original Description:

Original Title

Hazop Sil Lopa Lng Reloading Station1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentKlaipėdos Nafta, Lithuania's state-owned petroleum terminal operator, appointed a consortium to carry out construction of an LNG Reloading Station in Klaipėda, Lithuania from 2016-2017. PSC provided risk evaluation services including HAZOP and SIL workshops to identify hazards and safety instrumented functions, LOPA of critical functions, and updates after design changes. PSC also prepared a Safety Requirements Specification in line with international standards.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views2 pagesHazop Sil Lopa LNG Reloading Station1

Hazop Sil Lopa LNG Reloading Station1

Uploaded by

Nikhil NixonKlaipėdos Nafta, Lithuania's state-owned petroleum terminal operator, appointed a consortium to carry out construction of an LNG Reloading Station in Klaipėda, Lithuania from 2016-2017. PSC provided risk evaluation services including HAZOP and SIL workshops to identify hazards and safety instrumented functions, LOPA of critical functions, and updates after design changes. PSC also prepared a Safety Requirements Specification in line with international standards.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

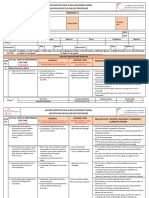

HAZOP / SIL / LOPA FOR

LNG LOADING STATION

PROJECT Klaipėdos Nafta, Lithuania

OWNER:

TIMEFRAME: 2016 – 2017

KEY Klaipėdos Nafta (KN), Lithuania’s state-owned

PROJECT petroleum product terminal operator appointed

DATA: PPS-CF Consortium in 2015 to carry out EPC

construction of an LNG Reloading Station in

Klaipėda, Lithuania.

The Reloading Station will be used for storage

of LNG in vacuum insulated tanks, filling of LNG

to road tankers, filling of LNG to ships as fuel

(bunkering) and evaporation of LNG to provide

natural gas to local gas consumers. LNG is supplied

to the station from an LNG carrier.

The facility comprises mainly:

• Five 1000 m³ vacuum insulated tanks

• Unloading / bunkering facility at existing jetty

• Two truck loading bays for filling of LNG-

trucks

SCOPE OF The EPC Consortium engaged PSC to provide risk

SERVICES: evaluation services, including:

• HAZOP Workshop at Owner’s premises

• SIL-Analysis / Workshop using calibrated Risk

Graph Method

• LOPA of critical SIF functions

• HAZOP and SIL update after design changes

• Preparation of Safety Requirements

Specification

All services were carried out in accordance with

PSC’s FSM-Plan as per DIN EN 61511 and CFSE-

certified.

PSC has provided ongoing risk management

consulting services to Klaipėdos Nafta LNG

projects since 2013.

PipeSystemConsult GmbH Phone: +49 (0)89 326 021 36

Adelheidstrasse 12 Fax: +49 (0)89 374 135 23

80798 Munich, Germany Email: info@pipesyscon.com

EXTENDED DESCRIPTION

The following gives a detailed description of PSC‘s services.

a) HAZOP / SIL Workshop

The HAZOP/SIL Workshop took place over 4 days at Owners

office adjacent to the new site. PSC provided HAZOP Chairman

and Scribe. 25 persons participated, including representatives

of Contractor and Owner. In total 267 entries were made in the

HAZOP Record Sheets for 10 nodes, from which 19 deviations

were identified to have a residual risk in ALARP region. There

were 86 HAZOP recommendations.

The SIL Workshop took place directly following the HAZOP.

PSC pre-populated the SIL-worksheets in order to streamline

the Workshop. Of 41 potential SIFs, 7 functions did not require

a SIL rating, 25 resulted in SIL 1, four SIL 2, and five SIL 3

functions.

b) LOPA

Five SIFs identified to have SIL-3 were further evaluated using

LOPA methodology as per IEC 61511-3, Annex F. Additional

ILP’s, as well as non-ESD control and monitoring functions were

considered. Finally the PFD was re-calculated, confirming that

a less stringent SIL-rating was permissible for the individual

elements of these loops.

c) HAZOP / SIL Update

Approximately one year after completion of the original

HAZOP / SIL analysis, Contractor requested a re-validation

exercise considering changes that had been incorporated

during the further detailed design. PSC identified and evaluated

138 changes for impact on HAZOP/SIL Analysis, resulting in 125

changed or new HAZOP causes, with corresponding updates

to HAZOP conclusions and recommendations. For the SIL

report, the revalidation resulted in two additional SIFs, as well

as complete revision of all evaluation sheets (including revised

tag numbers, updated HAZOP references and more detailed

definition of the SIF action).

d) Preparation of Safety Requirements Specification

PSC prepared the SRS in line with IEC61511 guidelines,

including an individual SRS-Sheet for each SIF, as well as relevant

data such as: proof test requirements, final element response

times, mission time/life cycle requirements, MTTR, MTTFS,

HFT, RRF. The SRS was aligned with the SIL-Validation report

which was carried out by a separate Consultant.

PipeSystemConsult GmbH Phone: +49 (0)89 326 021 36

Adelheidstrasse 12 Fax: +49 (0)89 374 135 23

80798 Munich, Germany Email: info@pipesyscon.com

You might also like

- K S Zamreen 00761734 Tciq ProjectDocument19 pagesK S Zamreen 00761734 Tciq ProjectNikhil Nixon100% (2)

- Nixon Nikhil 00761635 Tciq ProjectDocument17 pagesNixon Nikhil 00761635 Tciq ProjectNikhil Nixon100% (4)

- Solar Project Example - FINAL - FINALDocument19 pagesSolar Project Example - FINAL - FINALYassine Iferden TorssanovskiNo ratings yet

- Nikhil PS - 00579704Document28 pagesNikhil PS - 00579704Nikhil Nixon60% (5)

- Menon P Ravikeerthi 00761732 Tciq ProjectDocument19 pagesMenon P Ravikeerthi 00761732 Tciq ProjectNikhil Nixon100% (7)

- Design Selection of LNG ProjectDocument17 pagesDesign Selection of LNG Projectkselvan_1100% (2)

- Power Zone Company ProfileDocument31 pagesPower Zone Company ProfileDanish HamidNo ratings yet

- China LNG TerminalDocument37 pagesChina LNG Terminalamirlng100% (1)

- Natural Gas Explained - LNGDocument24 pagesNatural Gas Explained - LNGMELVIN MAGBANUANo ratings yet

- Curriculum Vitae Engr. TGC MSC, BSC, Tuv Fs Eng. Personal StatementDocument9 pagesCurriculum Vitae Engr. TGC MSC, BSC, Tuv Fs Eng. Personal StatementPratiek PatreNo ratings yet

- SPE-188704-MS Coral South FLNG Technology From Screening To Real ApplicationDocument11 pagesSPE-188704-MS Coral South FLNG Technology From Screening To Real ApplicationLawrence MbahNo ratings yet

- October 1, 2012 - December 14 2012: Andrew - Jones@netl - Doe.govDocument15 pagesOctober 1, 2012 - December 14 2012: Andrew - Jones@netl - Doe.govnarasimhamurthy414No ratings yet

- Summary 1Document8 pagesSummary 1Shabbir ShabbsNo ratings yet

- PDF Refrigeration Compressor Driver SelectionDocument27 pagesPDF Refrigeration Compressor Driver SelectionDjamel EeddinNo ratings yet

- Project ReportDocument59 pagesProject Reportsunaina100% (1)

- Overview of An Integrated Research Facility For Advancing Hydrogen InfrastructureDocument22 pagesOverview of An Integrated Research Facility For Advancing Hydrogen InfrastructureDiego CamachoNo ratings yet

- Novanam 11271 CAPDocument2 pagesNovanam 11271 CAPAndres FalmacelNo ratings yet

- Fiwa Informs 2013Document16 pagesFiwa Informs 2013Hhaabbde SybaritzNo ratings yet

- Case Study-Quick Production FacilitiesDocument10 pagesCase Study-Quick Production FacilitiesAlvaro Andres Blanco Gomez100% (1)

- LPG Train 4 - Zcina Hassi Messaoud: ProjetDocument5 pagesLPG Train 4 - Zcina Hassi Messaoud: ProjetMEZOUED ALINo ratings yet

- Capacity Assessment Sheet - ICAS CAS - Com Kit - 2010-12-09Document12 pagesCapacity Assessment Sheet - ICAS CAS - Com Kit - 2010-12-09Luis SousaNo ratings yet

- Refrigeration Compressor Driver SelectionDocument27 pagesRefrigeration Compressor Driver SelectionsppramNo ratings yet

- From Pore To Pipeline: Integrating Exploration and Production TechnologiesDocument1 pageFrom Pore To Pipeline: Integrating Exploration and Production TechnologiesPOWER.REGNo ratings yet

- Api 610Document36 pagesApi 610espluisjavierNo ratings yet

- 2.0 Project Description and Scope of Assessment 2.1 The ProponentDocument59 pages2.0 Project Description and Scope of Assessment 2.1 The ProponentvikramNo ratings yet

- LNG Project Reference Snohvit Success StoryDocument8 pagesLNG Project Reference Snohvit Success StoryKong LingweiNo ratings yet

- FLNG Training Module 1.1 Introduction To FLNG Rev 1Document34 pagesFLNG Training Module 1.1 Introduction To FLNG Rev 1Jay Kanes100% (3)

- Mubasher Javaid - OriginalDocument6 pagesMubasher Javaid - OriginalMuhammad ShehzadNo ratings yet

- CV - Nainish Sahare Oil and GasDocument5 pagesCV - Nainish Sahare Oil and GasNitai DuraisamiNo ratings yet

- ET 37-58 LPG QRA FERA Safety Layout Study ProposalDocument12 pagesET 37-58 LPG QRA FERA Safety Layout Study ProposalHafiz Akhtar100% (1)

- LNG Filling StationDocument42 pagesLNG Filling Stationian84No ratings yet

- Schlumberger and Qlogic: Alliance BriefDocument3 pagesSchlumberger and Qlogic: Alliance BriefHspetrocrusosNo ratings yet

- News and Information: Your Partner For Advanced SolutionsDocument4 pagesNews and Information: Your Partner For Advanced SolutionsJuan David Muriel CastilloNo ratings yet

- HC Compliance Status Dec 20Document93 pagesHC Compliance Status Dec 20Hrushikesh ReddyNo ratings yet

- Enppi Profile SummaryDocument38 pagesEnppi Profile SummarySijo XaviarNo ratings yet

- Successful Commissioning and Flawless Project Startup With Zero LTI, in Specified Time and BudgetDocument7 pagesSuccessful Commissioning and Flawless Project Startup With Zero LTI, in Specified Time and BudgetChandraSekaranBmNo ratings yet

- PROCESS ENGINEER CV (06 Years Experience) .Document3 pagesPROCESS ENGINEER CV (06 Years Experience) .Shoaib JadoonNo ratings yet

- Ali Huzafa Sayyar - OriginalDocument3 pagesAli Huzafa Sayyar - OriginalMuhammad ShehzadNo ratings yet

- Qatar Liquified Gas Company Limited (II) : QG2, The Designs and Technologies For A 7.8 MTPA TrainDocument16 pagesQatar Liquified Gas Company Limited (II) : QG2, The Designs and Technologies For A 7.8 MTPA TrainweldsvNo ratings yet

- LNG Small Terminal ViabilityDocument2 pagesLNG Small Terminal ViabilityRicardo BecNo ratings yet

- Value Engineering & Sustainable Development of LNG Receiving Terminal in The LNG Supply Chain ManagementDocument4 pagesValue Engineering & Sustainable Development of LNG Receiving Terminal in The LNG Supply Chain Managementsamriddh25No ratings yet

- CCCDocument65 pagesCCCtechnicaNo ratings yet

- Instr 4 Vincent TirillyDocument12 pagesInstr 4 Vincent Tirillyأصلان أصلانNo ratings yet

- RPPP Project PresentationDocument12 pagesRPPP Project PresentationveenaNo ratings yet

- 175 LNG19 04april2019 Morilhat Eric PaperDocument7 pages175 LNG19 04april2019 Morilhat Eric Paperivg8562No ratings yet

- Commissioning and Start-Up of QAFCO 5 and 6: Ali Abdi JamaDocument14 pagesCommissioning and Start-Up of QAFCO 5 and 6: Ali Abdi JamaGrootNo ratings yet

- Rsq-0560 Vms 6.1 ReleaseDocument4 pagesRsq-0560 Vms 6.1 ReleaseIgor PetrovNo ratings yet

- Crude Oil ProductionDocument7 pagesCrude Oil Productionumer shafiqueNo ratings yet

- Gas Network (Region) : 08 (A B F G I L M P) (Film-Bap-G)Document5 pagesGas Network (Region) : 08 (A B F G I L M P) (Film-Bap-G)Mudassar Akhtar0% (1)

- LNG 3.4.e Floating LNG Production19 19967Document12 pagesLNG 3.4.e Floating LNG Production19 19967Richard HollidayNo ratings yet

- 32 Talisman Malaysia Assets Maintenance Program SCE ExaminationDocument2 pages32 Talisman Malaysia Assets Maintenance Program SCE ExaminationMuhammad Fahmmi Bin MahmudNo ratings yet

- 6th Annual LNG Tech Global Summit 2001 - SOFREGAZ PresentationDocument36 pages6th Annual LNG Tech Global Summit 2001 - SOFREGAZ Presentationyan energiaNo ratings yet

- Capacity and Technology For The Snohvit LNG PlantDocument7 pagesCapacity and Technology For The Snohvit LNG PlantwebwormcptNo ratings yet

- 16 Gas Lift OptimizationDocument3 pages16 Gas Lift OptimizationAhmed FahmyNo ratings yet

- Fpso Revamp For A Marginal Field Ea-SpeDocument34 pagesFpso Revamp For A Marginal Field Ea-Spe고병석No ratings yet

- Hanas - LNG - March 2011 - WebDocument4 pagesHanas - LNG - March 2011 - WebamirlngNo ratings yet

- Innovations in LNG TechnologyDocument15 pagesInnovations in LNG TechnologyCraigUnderwoodNo ratings yet

- Paper Seapac2017doc 110 HinkleyDocument8 pagesPaper Seapac2017doc 110 HinkleyNarayanan RajagopalNo ratings yet

- Design and Construction of LNG RegasificDocument12 pagesDesign and Construction of LNG RegasificOusseini SidibeNo ratings yet

- NPL-NG-P140001-BM-752 Pipe Material Class Summary - Rev 2.0Document38 pagesNPL-NG-P140001-BM-752 Pipe Material Class Summary - Rev 2.0Kehinde AdebayoNo ratings yet

- Geotechnical Investigation SpecificationDocument39 pagesGeotechnical Investigation Specificationelnaqa176No ratings yet

- Energy and EnvironmentFrom EverandEnergy and EnvironmentMichel AndréNo ratings yet

- Proceedings of the 6th International Workshop on Hydro Scheduling in Competitive Electricity MarketsFrom EverandProceedings of the 6th International Workshop on Hydro Scheduling in Competitive Electricity MarketsArild HelsethNo ratings yet

- Summary Review on the Application of Computational Fluid Dynamics in Nuclear Power Plant DesignFrom EverandSummary Review on the Application of Computational Fluid Dynamics in Nuclear Power Plant DesignNo ratings yet

- Ar009Document16 pagesAr009IrenataNo ratings yet

- Chai Pe Charcha - 2Document2 pagesChai Pe Charcha - 2AKshayNo ratings yet

- Improve Storytelling HBRDocument1 pageImprove Storytelling HBRsultanNo ratings yet

- Managing Different Stages of CRM: Dr. Savita SharmaDocument28 pagesManaging Different Stages of CRM: Dr. Savita SharmaShaurya VirmaniNo ratings yet

- Scroll Down To Complete All Parts of This Task.: Situation ResponseDocument15 pagesScroll Down To Complete All Parts of This Task.: Situation ResponseDaljeet SinghNo ratings yet

- Capacity Planning - NASDocument37 pagesCapacity Planning - NASDanielNo ratings yet

- PartnershipDocument2 pagesPartnershipAndrea BreisNo ratings yet

- TQMDocument9 pagesTQMhimanityagi28No ratings yet

- QWP SL Rfo 1 05 Annex 1 Capa Plan 2016Document3 pagesQWP SL Rfo 1 05 Annex 1 Capa Plan 2016brocs relucioNo ratings yet

- West Bengal E-DistrictDocument2 pagesWest Bengal E-DistrictPRADIP BISWASNo ratings yet

- Brand Called You - Tom PetersDocument5 pagesBrand Called You - Tom Petersprofthadaskew4433No ratings yet

- JSP For OHTL No. 13 Pilot Wire Paying Out For ConductorsDocument10 pagesJSP For OHTL No. 13 Pilot Wire Paying Out For ConductorsJaafar LagayanNo ratings yet

- SII-Service Lift and Climb Assistance (6-Monthly and Yearly)Document6 pagesSII-Service Lift and Climb Assistance (6-Monthly and Yearly)Washington JuniorNo ratings yet

- Arjay Alllanigui - Working Team, Swot Analysis and BudgetingDocument6 pagesArjay Alllanigui - Working Team, Swot Analysis and BudgetingArjay AllaniguiNo ratings yet

- Outsourcing and In-House Facilities Management Practices Advantages and DisadvantagesDocument7 pagesOutsourcing and In-House Facilities Management Practices Advantages and DisadvantagesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- YUM FSA FSSC 22000 Comparison DocumentDocument7 pagesYUM FSA FSSC 22000 Comparison DocumentJessi Z. MarañonNo ratings yet

- Ahsan and Jawad PFM Assignment No1Document6 pagesAhsan and Jawad PFM Assignment No1janay martinNo ratings yet

- Rolex Brand AuditDocument21 pagesRolex Brand AuditShazbah ShafiNo ratings yet

- EntrepDocument6 pagesEntrepShannelle AndressNo ratings yet

- MAC 2 - Strategic Cost Management Set of ProblemsDocument10 pagesMAC 2 - Strategic Cost Management Set of ProblemsC/PVT DAET, SHAINA JOYNo ratings yet

- Kenaikan Tarif Dasar Listrik Dan Respon Kebijakan Untuk Meminimisasi Dampak Negatif Terhadap Perekonomian IndonesiaDocument14 pagesKenaikan Tarif Dasar Listrik Dan Respon Kebijakan Untuk Meminimisasi Dampak Negatif Terhadap Perekonomian IndonesiaElan Juliana RahmahNo ratings yet

- Road Marking Materials Ð Physical Properties: British Standard Bs en 1871:2000Document43 pagesRoad Marking Materials Ð Physical Properties: British Standard Bs en 1871:2000Sameh Ahmed100% (3)

- DMAIC Defect AnalysisDocument9 pagesDMAIC Defect AnalysisVenkatramani GireesanNo ratings yet

- MAC (Misdirected Directive Case Analysis)Document3 pagesMAC (Misdirected Directive Case Analysis)Prasad GowdNo ratings yet

- Marketing Case StudyDocument4 pagesMarketing Case StudyAbdul RafayNo ratings yet

- PAPER: Financial Accounting (FA) : Certified College of Accountancy's Mock ExamDocument8 pagesPAPER: Financial Accounting (FA) : Certified College of Accountancy's Mock ExamJack PayneNo ratings yet

- NSE List of Expelled Brokers 19 Oct 2021Document7 pagesNSE List of Expelled Brokers 19 Oct 2021Moneylife FoundationNo ratings yet

- Managing Major Accident Hazards Through Sce Management ProcessDocument4 pagesManaging Major Accident Hazards Through Sce Management ProcessLi QiNo ratings yet

- 1.electrolux VBI Master GuidelineDocument160 pages1.electrolux VBI Master GuidelinekakolakoNo ratings yet