Professional Documents

Culture Documents

IS 919 (Part 1) - 1993

IS 919 (Part 1) - 1993

Uploaded by

Avishek GuptaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IS 919 (Part 1) - 1993

IS 919 (Part 1) - 1993

Uploaded by

Avishek GuptaCopyright:

Available Formats

| -ueveioa ep ose ‘essepRUeIBIOL martvolr even. ‘sep sours | By i xxi | & ‘eevee sic sows iti rolucl eounoe: | a 7 : oN geome | srounder spens nn ions eau, voweny | wontea | cote [une { { Sadi} 30 (Continued from second cover ) In the adopted standard certain terminology and conventions are not identical with those used in the Indian Standard, attention is especially drawn to the following: in Standards, the current e) Comma (,) has been used as.a decimal marker while in In practice is to use point (.) as the decimal marker. b) Wherever the words ‘Intornational Standarcs’ appear, referring to this standard, they shall be read as ‘Indian Standard’. In the adopted standard reference appears to certain international standards for which Indian Standard also exist. The corresponding Indian Standards which are to be substituted in their place are listed below along with their degree of equivalence for the editions indicate International. Corresponding Indian Standard Degree of ‘Standord Equivetence ISO 286-2: 1988 IS. 919 ( Fart 2) : 1993 ISO system of limits and Identical fits : Part 2. Tables of standard tolerance grades nd limit deviations for holes end. shaits (first revision ) 180 8015:1986 —1S_ 12160: 1987 Technical drawings — etentical Fundamental toleranoing principles The concerned technical committee has reviewed the provision of ISO 1 and 1SO/R 1938 referred in this adopted standard and has decided that they are acceptable for use in conjunction with this standard Bureau of Indian Standards BIS is a statutory institution established under the Bureau of Indian Standards Act, 1986 to promote harmonious development of the activities of standardization, marking and quality certification of goods and attending to connected matters in the country. Copyright BIS has the copyright of all its publications. No part of these publications may be reproduced in any form without the prior permission in writing of BIS. This does not preclude the free use, in the course of implementing the standard, of necessary details, such as. symbols and sizes, type or grade designations. Enquiries relating to copyright be addressed to the Director (Publication), BIS, Review of Indian Standards Amendments are issued to standards as the need arises on the basis of comments, Standards are also reviewed periodically; a standard along with amendments is reaffirmed when such review indicates that no changes are needed; if the review indicates that changes are nceded, it is taken up for revision, Users of Indian Standards should ascertain that they are in possession of the latest amendments or edition by referring (o the Iatest issue of ‘BIS Handbook’ and ‘Standards Monthly Additions’, ‘This Indian Standard has been developed from Doe: Nu. LMO 1 (0039). Amendments Issued Since Publication Amend No. Date of issue “Text Affected BUREAU OF INDIAN STANDARDS Headquanters: Manak Bhavan, 9 Bahadur Shah Zafar Marg, New Delhi 110002 ‘Telegrams: Manaksanstha ‘Telephones: 323 01 31, 323 33 75,323 94.02 (Common to all offices) Regional Offices: Telephone Central: Manak Bhavan, 9 Bahadur Shah Zafar Marg 323 76 17, 323 38.41 NEW DELHI 110002 Eastern: 1/14 CLT. Scheme VIEM, V.LP. Road, Manikiola 337 84 99, 337 8561 CALCUTTA 700054 337 86 26, 337 91.20 Northern : SCO 335-336, Sector 34-A, CHANDIGARH 160022 6038.43 60 2025 Southern: C.-T. Campus, IV Cross Road, CHENNAL 600113 235 02.16, 235 04.42 235 15 19, 235 2315 Western; Manakalaya, E9 MIDC, Marol, Andheri (East) 832 92 95, 832 78 58 MUMBAI 400093 832 78 91, 832 78 92 Branches : AHMADABAD. BANGALORE, BHOPAL. BHUBANESHWAR. COIMBATORE. FARIDABAD. GHAZIABAD. GUWAHATI. HYDERABAD. JAIPUR. KANPUR. LUCKNOW. NAGPUR, PATNA. PUNE. THIRUVANANTHAPURAM. Prise at Dee Kay Primes, New Delhi, fad

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5808)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Is 1367-Part Xii - 1981Document4 pagesIs 1367-Part Xii - 1981Avishek GuptaNo ratings yet

- Is 1879-1987-Spec - For Malleable Ci Pipe FitingsDocument35 pagesIs 1879-1987-Spec - For Malleable Ci Pipe FitingsAvishek GuptaNo ratings yet

- Is 1367-Part 14-1984Document12 pagesIs 1367-Part 14-1984Avishek GuptaNo ratings yet

- Is 1367-Part 19-1997Document23 pagesIs 1367-Part 19-1997Avishek GuptaNo ratings yet

- Berger Zinc Chromate Primer Pds - 9113Document2 pagesBerger Zinc Chromate Primer Pds - 9113Avishek GuptaNo ratings yet

- Contractual - Overall Schedule - PEMEX - 88 Weeks - ATM Heaters - R8Document5 pagesContractual - Overall Schedule - PEMEX - 88 Weeks - ATM Heaters - R8Avishek GuptaNo ratings yet

- Is 12427 - 2001-Fasteners For Transmission TowersDocument7 pagesIs 12427 - 2001-Fasteners For Transmission TowersAvishek GuptaNo ratings yet

- Contractual - Overall Schedule - PEMEX - 17months - CDU Heaters - R9Document5 pagesContractual - Overall Schedule - PEMEX - 17months - CDU Heaters - R9Avishek GuptaNo ratings yet

- Is 1367-Part 18-1996Document7 pagesIs 1367-Part 18-1996Avishek GuptaNo ratings yet

- Berger Lumeros HR 123 Heat Resisting AluminiumDocument2 pagesBerger Lumeros HR 123 Heat Resisting AluminiumAvishek GuptaNo ratings yet

- Contractual - Overall Schedule - PEMEX - 88 Weeks - CDU Heaters - R8Document5 pagesContractual - Overall Schedule - PEMEX - 88 Weeks - CDU Heaters - R8Avishek GuptaNo ratings yet

- Ce ScanDocument1 pageCe ScanAvishek GuptaNo ratings yet

- SOR Closer - 917Document1 pageSOR Closer - 917Avishek GuptaNo ratings yet

- BR Rozc Primer Is 2074Document1 pageBR Rozc Primer Is 2074Avishek GuptaNo ratings yet

- 00 IndexDocument4 pages00 IndexAvishek GuptaNo ratings yet

- Deoxaluminite Primer, 155-00: Johnson Manufacturing Company Safety Data SheetDocument4 pagesDeoxaluminite Primer, 155-00: Johnson Manufacturing Company Safety Data SheetAvishek GuptaNo ratings yet

- Dop Ce RGG - SignedDocument1 pageDop Ce RGG - SignedAvishek GuptaNo ratings yet

- Berger Synthetic Enamel PaintDocument2 pagesBerger Synthetic Enamel PaintAvishek GuptaNo ratings yet

- Imir Civ 01Document3 pagesImir Civ 01Avishek GuptaNo ratings yet

- File TopDocument1 pageFile TopAvishek GuptaNo ratings yet

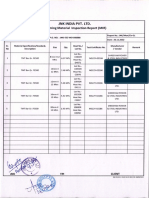

- JNK India Pvt. LTD.: Radiographic Examination ReportDocument337 pagesJNK India Pvt. LTD.: Radiographic Examination ReportAvishek GuptaNo ratings yet

- JNKI-SOP-011-Holing ProcedureDocument2 pagesJNKI-SOP-011-Holing ProcedureAvishek GuptaNo ratings yet

- Flame StraighteningDocument3 pagesFlame StraighteningAvishek Gupta100% (1)

- Jig Validation ProcedureDocument2 pagesJig Validation ProcedureAvishek Gupta100% (1)

- JNKI SOP 010 Visual Examination ProcedureDocument17 pagesJNKI SOP 010 Visual Examination ProcedureAvishek GuptaNo ratings yet

- JNKI-SOP-004-Welder Continuity Procedure - RevisionDocument3 pagesJNKI-SOP-004-Welder Continuity Procedure - RevisionAvishek GuptaNo ratings yet

- RT TrackingDocument6 pagesRT TrackingAvishek GuptaNo ratings yet

- RT HandoverDocument26 pagesRT HandoverAvishek GuptaNo ratings yet

- Rad LHSDocument4 pagesRad LHSAvishek GuptaNo ratings yet

- JNK India Pvt. LTD.: Positive Material Identification ReportDocument84 pagesJNK India Pvt. LTD.: Positive Material Identification ReportAvishek GuptaNo ratings yet