Professional Documents

Culture Documents

JNKI-SOP-004-Welder Continuity Procedure - Revision

Uploaded by

Avishek GuptaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JNKI-SOP-004-Welder Continuity Procedure - Revision

Uploaded by

Avishek GuptaCopyright:

Available Formats

Doc No.

: JNKI/SOP/004

SOP for Welder

Date: 18.11.2022

Continuity Revision: 00

Introduction:

This procedure defines the requirement and process to re-certify welders in required procedure and

position as per ISO requirements, to ensure that the welds produced by the welders are of high

quality and free from defects.

Responsibility

Responsible Welding Co-ordinator will be responsible for the maintaining the record, of each

welder and conducting the required test for checking working quality of any given welder. He will

also be responsible for indicating the NDT co-ordinator and Execution engineer regarding the end of

serviceability period for a welder and required test to be conducted.

NDT Co-ordinator will be responsible for conducting and evaluation all the required NDTs for the

revalidation of welder for continuity and prolonging the service time.

Execution Engineer will be responsible for making sure all welders are proper certification to

conduct and perform the required welding.

Period of Validity

1. Initial Qualification

The welder’s qualification begins from the date of welding the test Piece(s), provided that

the required testing has been carried out and the test results obtained were acceptable. The

certificate needs to be confirmed every 6 months otherwise the certificate(s) become(s)

invalid.

The validity of the certificate will be extended as specified ISO 9606-1 Para 9.3.a, same will

be stated in the certificate at the time of issue.

2. Confirmation of validity

The qualifications of a welder for a process shall be confirmed every 6 Months by the person

responsible for welding activities or examiner/examining body. This is confirming that the

welder has worked within the range of qualification and extends the validity of the

qualification for further 6 Months period.

3. Revalidation of welder qualification

Revalidation will be carried out by an examiner/examining body.

The skill if the welder shall be periodically tested, the welder shall retest every 3 years.

Avishek Gupta Rakesh Singh Shashikant Kumar

Deputy Welding Co-ordinator Responsible Welding Co- Factory Production Control

ordinator Manager

Doc No.: JNKI/SOP/004

SOP for Welder

Date: 18.11.2022

Continuity Revision: 00

Records

1. Welder Continuity record will be maintained by the RWC and circulated to all concerned

parties.

2. Re-validation / prolongation will be marked and maintained in the Welder Qualification

Certificate & Welder Card, with endorsement. Same will be available with welder and RWC.

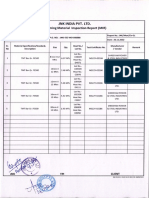

SAMPLE FORMAT FOR WELDER CONTIUITY RECORD

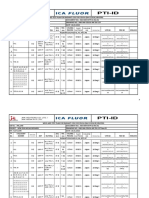

Sr. Welde Welder Date of WPS Position Revalidat NDT Revalida NDT Serviceabilit

Qualification ed On

No. r No. Qualified In Report No ted on Report y

Name No

SAMPLE WELDER QUALIFICATION TEST CERTIFICATE (WITH REVALIDATION)

Avishek Gupta Rakesh Singh Shashikant Kumar

Deputy Welding Co-ordinator Responsible Welding Co- Factory Production Control

ordinator Manager

Doc No.: JNKI/SOP/004

SOP for Welder

Date: 18.11.2022

Continuity Revision: 00

Avishek Gupta Rakesh Singh Shashikant Kumar

Deputy Welding Co-ordinator Responsible Welding Co- Factory Production Control

ordinator Manager

You might also like

- Preparation and Control of WeldingDocument3 pagesPreparation and Control of Weldingbalakumar rajaramNo ratings yet

- A-Qac-Pro-730-38928 Rev ADocument10 pagesA-Qac-Pro-730-38928 Rev ARamzi ZoghlamiNo ratings yet

- 12-Sec 7 - WeldingDocument5 pages12-Sec 7 - WeldingMo ZeroNo ratings yet

- ENV-SPV-DR-B-003 Fabrication Procedure-Rev - ADocument11 pagesENV-SPV-DR-B-003 Fabrication Procedure-Rev - AyoeyNo ratings yet

- Saep 323 PDFDocument8 pagesSaep 323 PDFthanga balanNo ratings yet

- QA/QC Procedure for FabricationDocument7 pagesQA/QC Procedure for FabricationRajesh K Pillai100% (6)

- Document Purpose & Personnel ResponsibilityDocument3 pagesDocument Purpose & Personnel ResponsibilityIlkin hasanovNo ratings yet

- Saep 323Document8 pagesSaep 323paul cafeNo ratings yet

- Saep 324Document8 pagesSaep 324brecht1980100% (3)

- Procedure for Welder QualificationDocument1 pageProcedure for Welder QualificationSatish KeskarNo ratings yet

- ISO 3834 - Checklist-2Document6 pagesISO 3834 - Checklist-2Abhishek Anand83% (6)

- KON 8.2 QA PRO 0020 C1 Welding Control ProcedureDocument15 pagesKON 8.2 QA PRO 0020 C1 Welding Control ProcedureAlizamin Salmanov100% (1)

- Saep 323Document8 pagesSaep 323brecht1980100% (1)

- Welding Control ProcedureDocument4 pagesWelding Control Procedurevenkatesh100% (2)

- MDOT Pile Welding QCPDocument8 pagesMDOT Pile Welding QCPvelmurug_balaNo ratings yet

- Welder and Wps Qualification Control ProcedureDocument24 pagesWelder and Wps Qualification Control ProcedurejhuliocessarsNo ratings yet

- A-Qac-Pro-730-38926-A Welding Machine Calibration ProcedureDocument25 pagesA-Qac-Pro-730-38926-A Welding Machine Calibration ProcedureRamzi Zoghlami100% (1)

- WI02-QCD-03 Procedure For Vessel Inspection - 01jul20Document10 pagesWI02-QCD-03 Procedure For Vessel Inspection - 01jul20Phu PhuocNo ratings yet

- Abj 89 103778 Ba 6070 00024 0000 01Document16 pagesAbj 89 103778 Ba 6070 00024 0000 01Nithin GNo ratings yet

- Welding Procedure DocumentDocument7 pagesWelding Procedure DocumentikponmwonsaNo ratings yet

- NDT General Requirements 115679505Document8 pagesNDT General Requirements 115679505FerdyCodetzNo ratings yet

- Section 7 - Examination and Inspection ProgramDocument4 pagesSection 7 - Examination and Inspection ProgramYasser Hammad MohamedNo ratings yet

- Welding Control Manual SectionDocument6 pagesWelding Control Manual SectionALNo ratings yet

- PO/Contract Number: 25875-000-POA-PS02-00001 Supplier/Contractor Name: Document Title: Material Traceability and Identification ProcedureDocument11 pagesPO/Contract Number: 25875-000-POA-PS02-00001 Supplier/Contractor Name: Document Title: Material Traceability and Identification ProcedureKarthikNo ratings yet

- Saep 323Document12 pagesSaep 323rafatNo ratings yet

- Fe-Gen-St-Xxxxx-Welder Qualification and Control Procedure-R1Document10 pagesFe-Gen-St-Xxxxx-Welder Qualification and Control Procedure-R1Parag WadekarNo ratings yet

- Alm-Ims-Prc-Si-013 Welding Inspection FDocument11 pagesAlm-Ims-Prc-Si-013 Welding Inspection F123netflix542No ratings yet

- SOP-SRC-QC-02 - Calibration of Equipments and Measuring InstrumentsDocument5 pagesSOP-SRC-QC-02 - Calibration of Equipments and Measuring InstrumentsDHANEESH VELLILAPULLINo ratings yet

- SAIC-W-2009 Revw-Control of Weld Consum - On PlotDocument1 pageSAIC-W-2009 Revw-Control of Weld Consum - On PlotAnonymous S9qBDVkyNo ratings yet

- To, Tata Projects Limited, Mumbai Walchandnagar Industries LTD, WalchandnagarDocument1 pageTo, Tata Projects Limited, Mumbai Walchandnagar Industries LTD, WalchandnagarVitthal DeokateNo ratings yet

- Sop 7.003aDocument8 pagesSop 7.003aKalpana BansalNo ratings yet

- SAIC W 2009 Revw Control of Weld Consum (EE) RLC FFDocument1 pageSAIC W 2009 Revw Control of Weld Consum (EE) RLC FFAnonymous S9qBDVkyNo ratings yet

- CERTIFICATION PROCEDURESDocument8 pagesCERTIFICATION PROCEDURESAlizamin SalmanovNo ratings yet

- 25875-000-V1A-PS02-00004 - Rev.003-With ApprovalDocument11 pages25875-000-V1A-PS02-00004 - Rev.003-With ApprovalKarthikNo ratings yet

- 1a. Crawler CraneDocument2 pages1a. Crawler CraneSHARAFUDHEEN TKNo ratings yet

- Qatar Engineering & Construction Company WLL (Qcon)Document12 pagesQatar Engineering & Construction Company WLL (Qcon)Dan DumbravescuNo ratings yet

- HelmetDocument2 pagesHelmetSHARAFUDHEEN TKNo ratings yet

- CSWIP-WI-6-92 14th Edition April 2017Document17 pagesCSWIP-WI-6-92 14th Edition April 2017mullanjiNo ratings yet

- Weld Procedure Specification - PR - 0XXDocument7 pagesWeld Procedure Specification - PR - 0XXRAMAKRISHNANo ratings yet

- Mobile CraneDocument2 pagesMobile CraneSHARAFUDHEEN TKNo ratings yet

- Welding Personnel ResponsibilityDocument2 pagesWelding Personnel ResponsibilityIlkin hasanovNo ratings yet

- IQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFDocument15 pagesIQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFAli MajeedNo ratings yet

- Welding Process Control - PR - 0XXDocument21 pagesWelding Process Control - PR - 0XXRAMAKRISHNA100% (2)

- Weld Joint Repaire Procedure - 08.04.14Document6 pagesWeld Joint Repaire Procedure - 08.04.14Raj AryanNo ratings yet

- 07423.cos - Qua.std - Inspection and Tests For Package SuppliesDocument6 pages07423.cos - Qua.std - Inspection and Tests For Package SuppliesMatteoNo ratings yet

- METHOD STATEMENT For Roll-Up Doors InstallationDocument16 pagesMETHOD STATEMENT For Roll-Up Doors Installationmoytabura96100% (2)

- In House Welding Inspector ONGCDocument1 pageIn House Welding Inspector ONGCGaurang PandyaNo ratings yet

- 20SP-010-BA-6180-00006 - 01E - IFR - Method Statement For Inverter Installation - Code-3Document21 pages20SP-010-BA-6180-00006 - 01E - IFR - Method Statement For Inverter Installation - Code-3lintangNo ratings yet

- WI05-QCD-03 Procedure For Water Tank Inspection - 31jul20Document11 pagesWI05-QCD-03 Procedure For Water Tank Inspection - 31jul20Phu PhuocNo ratings yet

- Saep 324Document13 pagesSaep 324Hansel Francis100% (4)

- Saif Ullah Updated AramcoDocument4 pagesSaif Ullah Updated AramcoHaleem Ur Rashid BangashNo ratings yet

- Quality Control Manual of PT Sarku Enjinering Utama (ASME JR)Document110 pagesQuality Control Manual of PT Sarku Enjinering Utama (ASME JR)herlan100% (1)

- Validation Commissioning DocumentsDocument4 pagesValidation Commissioning DocumentsPrashansa ShresthaNo ratings yet

- Inspection of Fixed Steel Offshore Structures During Fabrication and Installation - GuidelinesDocument9 pagesInspection of Fixed Steel Offshore Structures During Fabrication and Installation - GuidelinesShanmugam SailappanNo ratings yet

- Welding Consumable Receiving LogDocument11 pagesWelding Consumable Receiving LogKandula Raju100% (1)

- B-Qac-Pro-210-391xx QCP Welding ControlDocument22 pagesB-Qac-Pro-210-391xx QCP Welding ControlZaidiNo ratings yet

- 测深仪型式认可证书(EP系列)Document4 pages测深仪型式认可证书(EP系列)Zafar YabNo ratings yet

- Saep 324Document4 pagesSaep 324Dhaval PatelNo ratings yet

- Ensuring Quality to Gain Access to Global Markets: A Reform ToolkitFrom EverandEnsuring Quality to Gain Access to Global Markets: A Reform ToolkitNo ratings yet

- BGAS-CSWIP Welding and Coating Inspection: Certification, Process, Exam Preparation and Q&AFrom EverandBGAS-CSWIP Welding and Coating Inspection: Certification, Process, Exam Preparation and Q&ANo ratings yet

- Overall Schedule for PEMEX PROJECT - 04 Nos. Crude HeatersDocument5 pagesOverall Schedule for PEMEX PROJECT - 04 Nos. Crude HeatersAvishek GuptaNo ratings yet

- SOR Closer - 917Document1 pageSOR Closer - 917Avishek GuptaNo ratings yet

- 00 IndexDocument4 pages00 IndexAvishek GuptaNo ratings yet

- Dop Ce RGG - SignedDocument1 pageDop Ce RGG - SignedAvishek GuptaNo ratings yet

- Deoxaluminite Primer, 155-00: Johnson Manufacturing Company Safety Data SheetDocument4 pagesDeoxaluminite Primer, 155-00: Johnson Manufacturing Company Safety Data SheetAvishek GuptaNo ratings yet

- Contractual - Overall Schedule - PEMEX - 88 Weeks - ATM Heaters - R8Document5 pagesContractual - Overall Schedule - PEMEX - 88 Weeks - ATM Heaters - R8Avishek GuptaNo ratings yet

- Contractual - Overall Schedule - PEMEX - 17months - CDU Heaters - R9Document5 pagesContractual - Overall Schedule - PEMEX - 17months - CDU Heaters - R9Avishek GuptaNo ratings yet

- Lumeros 123 HR Aluminium heat resistant coatingDocument2 pagesLumeros 123 HR Aluminium heat resistant coatingAvishek GuptaNo ratings yet

- Ce ScanDocument1 pageCe ScanAvishek GuptaNo ratings yet

- Imir Civ 01Document3 pagesImir Civ 01Avishek GuptaNo ratings yet

- File TopDocument1 pageFile TopAvishek GuptaNo ratings yet

- JNK India Pvt. LTD.: Radiographic Examination ReportDocument337 pagesJNK India Pvt. LTD.: Radiographic Examination ReportAvishek GuptaNo ratings yet

- BR Rozc Primer Is 2074Document1 pageBR Rozc Primer Is 2074Avishek GuptaNo ratings yet

- SOP for Holing Fabrication WorksDocument2 pagesSOP for Holing Fabrication WorksAvishek GuptaNo ratings yet

- JNK SOP for Weld Visual InspectionDocument17 pagesJNK SOP for Weld Visual InspectionAvishek GuptaNo ratings yet

- Jig Validation ProcedureDocument2 pagesJig Validation ProcedureAvishek GuptaNo ratings yet

- RT HandoverDocument26 pagesRT HandoverAvishek GuptaNo ratings yet

- Rad LHSDocument4 pagesRad LHSAvishek GuptaNo ratings yet

- WELD AND TEST PLAN FOR RADIANT COILDocument2 pagesWELD AND TEST PLAN FOR RADIANT COILAvishek GuptaNo ratings yet

- RT TrackingDocument6 pagesRT TrackingAvishek GuptaNo ratings yet

- Procedure for Flame Straightening Structural SteelDocument3 pagesProcedure for Flame Straightening Structural SteelAvishek Gupta100% (1)

- JNK India Pvt. LTD.: Positive Material Identification ReportDocument84 pagesJNK India Pvt. LTD.: Positive Material Identification ReportAvishek GuptaNo ratings yet

- 18.WTP Atm1a 2 & 3Document2 pages18.WTP Atm1a 2 & 3Avishek GuptaNo ratings yet

- Weld and Test Plan for Crossover CoilDocument1 pageWeld and Test Plan for Crossover CoilAvishek GuptaNo ratings yet

- Radiant Coil Pass 2Document1 pageRadiant Coil Pass 2Avishek GuptaNo ratings yet

- 01a.cdu1a WTP-RCDocument2 pages01a.cdu1a WTP-RCAvishek GuptaNo ratings yet

- 26.WPS Log CoilDocument1 page26.WPS Log CoilAvishek GuptaNo ratings yet

- 18.WTP Atm1a 2 & 3Document2 pages18.WTP Atm1a 2 & 3Avishek GuptaNo ratings yet

- Radiant Coil Pass 3Document1 pageRadiant Coil Pass 3Avishek GuptaNo ratings yet

- 0010 SAP TM Syllabus UCPL TechnologiesDocument7 pages0010 SAP TM Syllabus UCPL TechnologiesUCPL TrainingNo ratings yet

- Market Analysis of Footwear Industry in India With Ref To LakhaniDocument74 pagesMarket Analysis of Footwear Industry in India With Ref To LakhaniVinod Upadhyay100% (7)

- SCM-Module 3B-PPT-01Document47 pagesSCM-Module 3B-PPT-01arkmaniNo ratings yet

- Part 1: EBBL's Managerial Structure: Chief Executive Officer (CEO)Document4 pagesPart 1: EBBL's Managerial Structure: Chief Executive Officer (CEO)Ahnaf Chowdhury NiloyNo ratings yet

- Black Money in IndiaDocument19 pagesBlack Money in Indiadeysi rojasNo ratings yet

- Reviewer Chapter 1 - Book 1 - Comprehensive ExamDocument5 pagesReviewer Chapter 1 - Book 1 - Comprehensive ExamKrizel Dixie ParraNo ratings yet

- Examination Session 2019-20: Exam Form # Verification #Document2 pagesExamination Session 2019-20: Exam Form # Verification #arjun guptaNo ratings yet

- Plastics Recycling Business PlanDocument30 pagesPlastics Recycling Business PlanDawit TesfaNo ratings yet

- Process ValidationDocument883 pagesProcess Validationjaime manciaNo ratings yet

- Lecture One: The Pay Model: Course Name: Compensation ManagementDocument25 pagesLecture One: The Pay Model: Course Name: Compensation ManagementInzamamul HaqueNo ratings yet

- Corporation, Annum That Was Expressly Stipulated in The Sales Invoices. The Court Held ThatDocument10 pagesCorporation, Annum That Was Expressly Stipulated in The Sales Invoices. The Court Held ThatCamille DuterteNo ratings yet

- Dynamics of Regulator Functionality: An Assessment of The Legal and Institutional Frameworks of The Nigeria Securities and Exchange CommissionDocument21 pagesDynamics of Regulator Functionality: An Assessment of The Legal and Institutional Frameworks of The Nigeria Securities and Exchange CommissionGabriel AdenyumaNo ratings yet

- Chapter 24 Measuring The Cost of LivingDocument20 pagesChapter 24 Measuring The Cost of LivingNusaiba Binte MamunNo ratings yet

- Basic Econometrics Gujarati 2008Document946 pagesBasic Econometrics Gujarati 2008api-239303870100% (11)

- Sumedh GangulyDocument12 pagesSumedh GangulyArnab TalukdarNo ratings yet

- Name Current Employer Email Mobile Current Location Current Annual Salary (Rs. in Lacs)Document3 pagesName Current Employer Email Mobile Current Location Current Annual Salary (Rs. in Lacs)nani0% (1)

- CA3 Pankaj ACC215Document10 pagesCA3 Pankaj ACC215Pankaj MahantaNo ratings yet

- Cafc - QCP General Civil WorksDocument26 pagesCafc - QCP General Civil WorksAimar SmartNo ratings yet

- FINANCIAL SYSTEMS AND MARKETS CHAPTER 1Document67 pagesFINANCIAL SYSTEMS AND MARKETS CHAPTER 1Gabrielle Anne MagsanocNo ratings yet

- List of Nodal OfficersDocument52 pagesList of Nodal OfficersSunny SinghNo ratings yet

- CPA CV Seeking Accounting PositionDocument2 pagesCPA CV Seeking Accounting Positionsamy njorogeNo ratings yet

- Application DocsDocument54 pagesApplication Docsthe next miamiNo ratings yet

- Form GST ADT - 01Document2 pagesForm GST ADT - 01Shekhar UrlagondaNo ratings yet

- B2B MARKETING (Business Marketing)Document6 pagesB2B MARKETING (Business Marketing)lynette_rodrigues88No ratings yet

- Current Asset Management Chapter SummaryDocument14 pagesCurrent Asset Management Chapter SummaryLokamNo ratings yet

- Pilatus PC-12 Assembly Line: Industrialization, Manufacturing and Process ImprovementDocument8 pagesPilatus PC-12 Assembly Line: Industrialization, Manufacturing and Process ImprovementTGTrindadeNo ratings yet

- Hilton CH 5 Select SolutionsDocument42 pagesHilton CH 5 Select Solutionsangganteng13No ratings yet

- Shopzilla Clone 07 July 2009Document4 pagesShopzilla Clone 07 July 2009Suvrajit BanerjeeNo ratings yet

- Identify Functional RequirementsDocument3 pagesIdentify Functional RequirementsEugene LingNo ratings yet

- Study Guide-FRM24Document30 pagesStudy Guide-FRM24motiquotes4No ratings yet