Professional Documents

Culture Documents

Preparecarbonatefree 10 Nao HSolution

Uploaded by

Ayesha AzizOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Preparecarbonatefree 10 Nao HSolution

Uploaded by

Ayesha AzizCopyright:

Available Formats

192 ANALYTICAL EDITION Vol. 5 , No.

purity of the plasticizer was determined by refractive index nation of plasticizer content of organic cellulosic plastics,

measurements, as well as by saponification values if the was found satisfactory for practical purposes.

plasticizer belonged to the ester type.

LITERATURE

CITED

SUMMARY

(1) Bradley, IND. ENO.CHEM.,Anal. Ed., 3, 306 (1931).

A rapid method for the separation of plasticizers from or- (2) Gardner, “Physical and Chemical Examination of Paints,

ganic cellulosic plastics, described in this article, has been Varnishes, and Lacquer,” 5th ed., pp. 491-550, 818-28, 850,

Institute of Paint and Varnish Research, Washington, 1930.

shown to be to cellulose, cellulose, (3) Hickman and Sanford, J. Phys. Chem., 34, 637 (1980).

and cellulose acetate plastics.

Its accuracy, when- applied quantitatively to the determi- RECEIYBD

December 19, 1932.

Preparation of Sodium Hydroxide Solutions of

Low Carbonate Content by Centrifugation

NELSONALLEN AND GEORGEW. Low, JR.

Frick Chemical Laboratory, Princeton University, Princeton, N. J.

H AVING had occasion to prepare sodium hydroxide

solutions of low carbonate content, the use of a centri-

fugein connection with the oily alkali method (6) sug-

gested itself. This method has long been used for preparing

4.2 as determined by methyl orange indicator and a buffer

solution. The natural offset between the two end points

for pure water was found to be 0.140 ml. and this correction

was applied. Some typical data are given in Table I.

sodium hydroxide solutions and possesses the advantages of

simplicity and freedom from the introduction of contaminating DISCUSSION

OF RESULTS

ions. On the other hand it has the disadvantages of extreme

slowness and incomplete removal of carbonate. Clark (1) Nan and Chao (2) secured an average value of 0.15 per cent

speeded up the process by filtering the alkali through paper, for the hydrochloric acid used for the carbonate in their

and Kolthoff (4) filtered it through a Jena sintered-glass solutions, whereas the above data show a n average of 0.12

crucible. Han and Chao (g), who have recently made a per cent for the centrifuged alkali. This clearly indicates

comprehensive study of all methods of preparing alkali free that centrifugation gives a lower content of carbonate in the

from carbonate, clarified the solution by heating in a water alkali with a very much smaller expenditure of time and

bath (6) and followed this by filtration through glass. Ap- labor. Then, too, no elaborate heating or filtering devices

parently no one has made use of the centrifuge for the clari- are needed.

fication. Forty milliliters of a 0.1124 N sodium hydroxide solution

prepared by diluting the centrifuged alkali with carbon di-

EXPERIMENTAL oxide-free water required an average of 0.190 ml. of 0.0998 N

Samples of the oily alkali were prepared by dissolving 50 hydrochloric acid to go from the phenolphthalein end point

grams of pellet sodium hydroxide in 50 ml. of carbon dioxide- to pH 4.2. This value less 0.140 ml. (the natural offset)

free water. After cooling, each lot was transferred to a Pyrex equals 0.050 ml., which corresponds to the carbonate content.

centrifuge tube, made from a 125-ml. Erlenmeyer flask by Solutions prepared in this manner are perfectly satisfactory

rounding out the base and blowing out an opening to fit a No. for all ordinary titrations.

2 rubber stopper. The neck of the flask was drawn off and

a tube 5 cm. long and 0.8 cm. inside diameter sealed on. MODIFIEDTITRATION

HEAD

Centrifuging for 30 minutes a t 2200 to 2300 r. p. m. gave ab- In connection with the above work the titration head

solutely clear solutions with the undissolved carbonate and recommended by Hillebrand and Lundell (3) has been modi-

alkali tightly packed in the bottom. fied by leading the carbon dioxide-free air stream through a

tube passing through the cap by a ring seal and extending

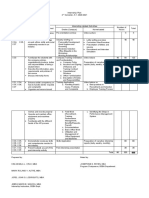

I. CARBONATE

TABLE CONTENT

OF ALKALI

down about 8 cm. below the top of the head. This change

TOTAL VOL. ACID VOL.HCl FOR PERCENTHCI

SAMPLE AS 0.0998 N HC1 cos - - FOR cos-- insures that the titration flask will be completely swept out

M1. M1. by the air stream. The head was made of very heavy Pyrex

tubing and of a size to fit over a 250-ml. Erlenmeyer flask.

1

2

BEFORE CENTRIFUQINQ

273.36

270.67

2.40

2.42

0.88

0.88

. Such a titration head makes a very rugged and useful piece

3

4

306.66

276.24

2.48

2.26

0.81

0.82

of equipment,

AFTBR CENTRIFUQINQ

1 271.28 0.314 0.12

LITERATURE

CITED

278.37 0.284 0.10 (1) Clark, “Determination of Hydrogen Ions,” Williams and Wilkins,

2 309.36 0.610 0.16

3 276.33 0.280 0.10 1928.

4 330.64 0.450 0.14 (2) Han and Chao, IND. ENQ.CHEM.,Anal. Ed., 4, 229 (1932).

Av. 0.12 (3) Hillebrand and Lundell, “Applied Inorganic Analysis,” p. 141,

Wiley, 1929.

Samples of alkali were analyzed for carbonate before and (4) Kolthoff and Furman, “Volumetric Analysis,” Vol. 11, Wiley,

after centrifuging by titration in the absence of carbon di- 1929.

(5) Pregl, 2. anal. Chem., 67, 23-7 (1925).

oxide with standard hydrochloric acid. On reaching a (6) Sbrensen, Biochem. Z . , 21, 186 (1909).

phenolphthalein end point the titration was continued with

0.0998 N hydrochloric acid, from a microburet, to a pH of RECEIYED

January 31, 1933.

You might also like

- CRYSTALLIZER DESIGN (Rev02)Document33 pagesCRYSTALLIZER DESIGN (Rev02)Shai Sta CatalinaNo ratings yet

- Experiment 2 Preparation of Some Cobalt ComplexesDocument9 pagesExperiment 2 Preparation of Some Cobalt ComplexesTonderai MupetiNo ratings yet

- Comprehensive Handbook on HydrosilylationFrom EverandComprehensive Handbook on HydrosilylationB. MarciniecNo ratings yet

- (Nikolaj Wolfson, Alexander Lerner, Leonid Roshal (B-Ok - CC)Document589 pages(Nikolaj Wolfson, Alexander Lerner, Leonid Roshal (B-Ok - CC)Andi sutandi100% (1)

- Article PDFDocument4 pagesArticle PDFAdriana Flores DepazNo ratings yet

- Nature: A New Synthesis of Lead AzideDocument1 pageNature: A New Synthesis of Lead AzideRobson Fernandes de FariasNo ratings yet

- Carbon-13 Fractionation Between Aragonite and Calcite: NOTE!3Document6 pagesCarbon-13 Fractionation Between Aragonite and Calcite: NOTE!3Estefany AcostaNo ratings yet

- 3025 51Document8 pages3025 51rambinodNo ratings yet

- The Electrochemical Oxidation of Ammonia 12 26 16Document12 pagesThe Electrochemical Oxidation of Ammonia 12 26 16bailgail76No ratings yet

- The Density of Aqueous Hydrogen Peroxide Solutions PDFDocument4 pagesThe Density of Aqueous Hydrogen Peroxide Solutions PDFVictor VazquezNo ratings yet

- Fichero para Tratamiento de Aguas Por CNTDocument6 pagesFichero para Tratamiento de Aguas Por CNTLuis M. de LunaNo ratings yet

- This Study Resource Was: Experiment 3Document6 pagesThis Study Resource Was: Experiment 3U2103536 STUDENTNo ratings yet

- Vol. A. W. Lawengayer,: Boron. Preparation Properties of Pure Crystalline BoronDocument8 pagesVol. A. W. Lawengayer,: Boron. Preparation Properties of Pure Crystalline Boronaxes1234No ratings yet

- Preparation of Baso Nanoparticles With Self-Dispersing PropertiesDocument6 pagesPreparation of Baso Nanoparticles With Self-Dispersing PropertiesngoanvnNo ratings yet

- 1955 The System Ba (NO3) 2-KNO3Document3 pages1955 The System Ba (NO3) 2-KNO3Adrian CaraballoNo ratings yet

- Laboratory Manual For Engineering Chemistry Practical: First / Second Semester B.EDocument50 pagesLaboratory Manual For Engineering Chemistry Practical: First / Second Semester B.EDaizy GillNo ratings yet

- 1 s2.0 0013468673800313 MainDocument7 pages1 s2.0 0013468673800313 MainbrianNo ratings yet

- 3112 Metals by Cold-Vapor Atomic Absorption Spectrometry (2009) (Editorial Revisions, 2011)Document2 pages3112 Metals by Cold-Vapor Atomic Absorption Spectrometry (2009) (Editorial Revisions, 2011)TaniaCarpioNo ratings yet

- The Case Study of Isothermal Adsorption of Phenol, O-Cresol On Natural Charcoal's and ApplicationsDocument16 pagesThe Case Study of Isothermal Adsorption of Phenol, O-Cresol On Natural Charcoal's and ApplicationsIJRASETPublicationsNo ratings yet

- Ion ExchangeDocument3 pagesIon ExchangeelftahtasakalNo ratings yet

- Global Warming Carbon Dioxide Sequestration in CoaDocument9 pagesGlobal Warming Carbon Dioxide Sequestration in Coasameer bakshiNo ratings yet

- Elsevier Science Publishers B.V., Amsterdam - Printed in The NetherlandsDocument6 pagesElsevier Science Publishers B.V., Amsterdam - Printed in The NetherlandsRENATO JAIR COSTA MINGANo ratings yet

- The Parable of The PipelineDocument4 pagesThe Parable of The PipelineRudraNo ratings yet

- Salting-Out of Acetone From Water Basis of A New Solvent Extraction SystemDocument7 pagesSalting-Out of Acetone From Water Basis of A New Solvent Extraction SystemAl-Kawthari As-Sunni100% (1)

- A New Method For Preparing Hydrophobic Nano-Copper PowdersDocument5 pagesA New Method For Preparing Hydrophobic Nano-Copper PowdersbacNo ratings yet

- 10.1515 htmp.2009.28.3.141Document6 pages10.1515 htmp.2009.28.3.141Oualid HamdaouiعععNo ratings yet

- CHEM181 Experiment8 DetermiantionofDissolvedOxygenDocument7 pagesCHEM181 Experiment8 DetermiantionofDissolvedOxygenNeckle JadeNo ratings yet

- Ac 2020 SuppDocument5 pagesAc 2020 SuppTanganedzani MashigashigaNo ratings yet

- Asish Anatase Tio2Document11 pagesAsish Anatase Tio2Jhasaketan NayakNo ratings yet

- Functionalization-Mediated Physicochemical Properties of inDocument6 pagesFunctionalization-Mediated Physicochemical Properties of inNguyen Cong TuNo ratings yet

- Ravi MtechDocument28 pagesRavi MtechSAURABH KUMAR PANDEY Research Scholar, Chemical Engg. & Technology , IIT(BHU)No ratings yet

- 3112 Metals by Cold-Vapor Atomic Absorption Spectrometry (2009) (Editorial Revisions, 2011)Document2 pages3112 Metals by Cold-Vapor Atomic Absorption Spectrometry (2009) (Editorial Revisions, 2011)seninhentayNo ratings yet

- Zhang 2014Document5 pagesZhang 2014oviabeautyNo ratings yet

- Oxalic Acid Via Nitric Acid Oxidation of Hardwood Red OakDocument11 pagesOxalic Acid Via Nitric Acid Oxidation of Hardwood Red Oaknurlayli amanahNo ratings yet

- Ammonia Removal From Aquaculture Water by Means of Fluidised Technology (NG Et Al. 1996)Document8 pagesAmmonia Removal From Aquaculture Water by Means of Fluidised Technology (NG Et Al. 1996)Sumoharjo La MpagaNo ratings yet

- Visveswaraya Technological University Dayananda Sagar College of Engineering Department of Chemical EngineeringDocument29 pagesVisveswaraya Technological University Dayananda Sagar College of Engineering Department of Chemical EngineeringKumarShiveshNo ratings yet

- 29 IntJSciResSciEngTech 54 2018 43Document6 pages29 IntJSciResSciEngTech 54 2018 43Seni Ramadhanti SNo ratings yet

- FL53098 Chemical Analysis Brass Lesson PlanDocument6 pagesFL53098 Chemical Analysis Brass Lesson Planmbbk5783No ratings yet

- SN - 118 - 2013 - TKN Determination in Water and Waste Water Using Potentiometric TitrationDocument1 pageSN - 118 - 2013 - TKN Determination in Water and Waste Water Using Potentiometric TitrationSara ÖZGENNo ratings yet

- Larson 1953Document3 pagesLarson 1953Kaouther JouiniNo ratings yet

- Diatomite As High Performance and Environmental Friendly Catalysts For Phenol Hydroxylation With H ODocument4 pagesDiatomite As High Performance and Environmental Friendly Catalysts For Phenol Hydroxylation With H ONguyễn DungNo ratings yet

- Benedetti Pichler1939Document6 pagesBenedetti Pichler1939Gillary Peña MuñozNo ratings yet

- Huizenga 1950Document7 pagesHuizenga 1950brouuorbNo ratings yet

- Nanocrystallinae Hap From Egg ShellDocument4 pagesNanocrystallinae Hap From Egg Shellcollin samuelNo ratings yet

- US4119502Document5 pagesUS4119502sheenat100No ratings yet

- Applied Surface ScienceDocument5 pagesApplied Surface ScienceGTheresiaNo ratings yet

- 20 Synthesis of NC From BagasseDocument4 pages20 Synthesis of NC From BagasseVịt Siêu Ngu DốtNo ratings yet

- CEST2017 Paper KopsidasDocument8 pagesCEST2017 Paper KopsidasAnonymous zyIfM5SNo ratings yet

- 3112 Metals by Cold-Vapor Atomic Absorption Spectrometry : 1.00 MG Hg. G/L by Appropriate DilutionDocument2 pages3112 Metals by Cold-Vapor Atomic Absorption Spectrometry : 1.00 MG Hg. G/L by Appropriate Dilutionpollux23No ratings yet

- 06-Et-Nguyen Van Dat (45-49) 006Document5 pages06-Et-Nguyen Van Dat (45-49) 006Nguyen NgocChanNo ratings yet

- Dissolved OxygenDocument24 pagesDissolved OxygenBoj VillanuevaNo ratings yet

- OrgochemsampleworkDocument10 pagesOrgochemsampleworkMakcaNo ratings yet

- Use of A BOD Oxygen Probe For Estimating Primary ProductivityDocument4 pagesUse of A BOD Oxygen Probe For Estimating Primary Productivityerina aurelliaaNo ratings yet

- Wang 2021 J. Phys. Conf. Ser. 2021 012087Document6 pagesWang 2021 J. Phys. Conf. Ser. 2021 012087vikash chourasiaNo ratings yet

- Is 3025 34 1988Document19 pagesIs 3025 34 1988Gayathri AsNo ratings yet

- Annexure II Journal CuO Nanofluid For FPHP PDFDocument5 pagesAnnexure II Journal CuO Nanofluid For FPHP PDFAmuthan ValenTino SaravananNo ratings yet

- US3029298Document2 pagesUS3029298Muhammad Akbar FahleviNo ratings yet

- Spectroscopy Formal Lab ReportDocument5 pagesSpectroscopy Formal Lab Reportapi-640968436No ratings yet

- Ion-Exchange Resin CapacityDocument6 pagesIon-Exchange Resin CapacityShreyash UtekarNo ratings yet

- University of Mines and Technology (Umat)Document16 pagesUniversity of Mines and Technology (Umat)Chris HarmsworthNo ratings yet

- Carbon Nanomaterials for Advanced Energy Systems: Advances in Materials Synthesis and Device ApplicationsFrom EverandCarbon Nanomaterials for Advanced Energy Systems: Advances in Materials Synthesis and Device ApplicationsWen LuNo ratings yet

- 8355-Article Text PDF-17116-2-10-20160325Document6 pages8355-Article Text PDF-17116-2-10-20160325Ayesha AzizNo ratings yet

- Crystals 08 00470Document9 pagesCrystals 08 00470Ayesha AzizNo ratings yet

- Boron-Chemistry ChapterDocument30 pagesBoron-Chemistry ChapterAyesha AzizNo ratings yet

- Amberlite IRA 96 LDocument2 pagesAmberlite IRA 96 LLoera AntonioNo ratings yet

- ASSIST - Precipitation Reaction (Sodium Hydroxide and Barium Nitrate) - 2019-03-05Document4 pagesASSIST - Precipitation Reaction (Sodium Hydroxide and Barium Nitrate) - 2019-03-05Vy VyNo ratings yet

- 049I PraxisDocument4 pages049I PraxisAyesha AzizNo ratings yet

- Boron Determination-A Review of Analytical MethodsDocument21 pagesBoron Determination-A Review of Analytical MethodsNeidys Sanchez HernandezNo ratings yet

- Compact Water Treatment 200 m3Document3 pagesCompact Water Treatment 200 m3civil eng915No ratings yet

- Laboratory Manual For Microbiology Fundamentals A Clinical Approach 4Th Edition Susan Finazzo Full ChapterDocument51 pagesLaboratory Manual For Microbiology Fundamentals A Clinical Approach 4Th Edition Susan Finazzo Full Chapterlinda.ferguson121100% (8)

- First Quarter Examination For AP 10Document4 pagesFirst Quarter Examination For AP 10Reynan Orillos HorohoroNo ratings yet

- ISO 9001 - 14001 - 2015 enDocument2 pagesISO 9001 - 14001 - 2015 enVĂN THÀNH TRƯƠNGNo ratings yet

- ProposalDocument3 pagesProposalAbdullahAlmasNo ratings yet

- SCRAPBOOKDocument19 pagesSCRAPBOOKJulius Michael GuintoNo ratings yet

- Animal Death Unknown 2010Document57 pagesAnimal Death Unknown 2010Vincent J. CataldiNo ratings yet

- Initial Data Base FormatDocument7 pagesInitial Data Base FormatrhamhonaNo ratings yet

- Year Test - Ii: (Batch - A)Document11 pagesYear Test - Ii: (Batch - A)sachin sakuNo ratings yet

- Calinescu2017 PDFDocument38 pagesCalinescu2017 PDFElizabeth UrrutiaNo ratings yet

- Cognitive Behavioral Therapy - 7 Ways To Freedom From Anxiety, Depression, and Intrusive Thoughts (Happiness Is A Trainable, Attainable Skill! Book 1)Document105 pagesCognitive Behavioral Therapy - 7 Ways To Freedom From Anxiety, Depression, and Intrusive Thoughts (Happiness Is A Trainable, Attainable Skill! Book 1)SOUFIANE RACHID100% (8)

- ES 92.05 D1 Fire ProofingDocument18 pagesES 92.05 D1 Fire ProofingKanjana LeardrakNo ratings yet

- Internship-Plan BSBA FInalDocument2 pagesInternship-Plan BSBA FInalMark Altre100% (1)

- To: Head of Sea Training Department PT Gemilang Bina Lintas Tirta Ship ManagementDocument1 pageTo: Head of Sea Training Department PT Gemilang Bina Lintas Tirta Ship ManagementtarNo ratings yet

- 3RD Summative Exam in Science 6Document6 pages3RD Summative Exam in Science 6Maricris Palermo SancioNo ratings yet

- 2 TABLE 1.1. Key Events in The Development of Cell and Tissue CultureDocument1 page2 TABLE 1.1. Key Events in The Development of Cell and Tissue CultureCatalina ColoradoNo ratings yet

- BSNL KERALA Executives and Non Executives Health Insurance Policy 2021-22Document3 pagesBSNL KERALA Executives and Non Executives Health Insurance Policy 2021-22Vikramjeet MannNo ratings yet

- Benefits of Playing Badminton (An Essay)Document2 pagesBenefits of Playing Badminton (An Essay)Haryoung Sta CruzNo ratings yet

- Carac Biogas FlamelessDocument7 pagesCarac Biogas FlamelessTaine EstevesNo ratings yet

- Service ProgramDocument47 pagesService ProgramHuseyn aliyevNo ratings yet

- Hydraulic Seat Puller KitDocument2 pagesHydraulic Seat Puller KitPurwanto ritzaNo ratings yet

- Gastrointestinal Tract PDFDocument3 pagesGastrointestinal Tract PDFAlexandra Suan CatambingNo ratings yet

- Awsum BrandingDocument18 pagesAwsum Brandingdharam123_904062105No ratings yet

- Chapter 10 Fitness Training PrinciplesDocument80 pagesChapter 10 Fitness Training Principlesapi-115744109No ratings yet

- Retention and Relapse in OrthodonticsDocument48 pagesRetention and Relapse in OrthodonticsSurabhi roy33% (3)

- UntitledDocument41 pagesUntitledDion AdalaNo ratings yet

- Immulite Homocysteine 2000Document30 pagesImmulite Homocysteine 2000Symbolin MusenkoNo ratings yet

- PSV Sizing For Two Phase FlowDocument28 pagesPSV Sizing For Two Phase FlowSyed Haideri100% (1)

- Oil Palm Fractions Derivatives Web PDFDocument6 pagesOil Palm Fractions Derivatives Web PDFIan RidzuanNo ratings yet