Professional Documents

Culture Documents

MERICON™ I, II, III - Caustic Treatments - Merichem - I

Uploaded by

Othman Mat YamanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MERICON™ I, II, III - Caustic Treatments - Merichem - I

Uploaded by

Othman Mat YamanCopyright:

Available Formats

Request Technical Support » 24/7 Logistics Support: +1 (713) 409-3182 Search site...

' REQUEST A QUOTE

SpentCausticTreatmentSystemEmployingWetAirOxidation

Contaminants We Treat Technologies, Chemicals & Catalysts

(

( Our Services Industries We Serve

(

( About Us (

( (

( (

( Resources (

( Contact Us (

(

Home

Off-Gas

Treatment Solutions for MERICON I, II, III ™ AcidOils

Processing Spent Caustics Applications Nitrogen

ScrubbingPhase $ Refinery Spent Caustics

MERICON™ I, II, III | Treatment Solutions Separation Neutralization

Processwatel

Oxidation $ Ethylene Spent Caustics

Developed by Merichem , MERICON I, II and III are on-site treatment

® ™

$ Other Spent Caustic Streams

technologies used in the processing of spent caustics for BOD/COD reduction,

AlkalineSolution

odor control and/or pH adjustment.

OxidationAir

These solutions employ either oxidation or acidification—along with the option FreshCaustic

of final neutralization—to yield a neutral brine effluent stream acceptable for Chemical Oxidation

disposal to wastewater treating facilities, evaporation ponds or waterways.

Advantages

MPSteam

MERICON™ I Advantages NeutralizedBrine

Best for destroying phenolics and

SpentCaustic

Best for sulfidic spent caustics treatment with less demanding lowering COD for smaller streams

COD specs in spent caustics

SulfuricAcid

Oxidizes

LEGEND: sulfides to sulfate and thiosulfate; oxidizes mercaptides to Uses hydrogen peroxide and an

Steam,Off-Gas,Nitrogen,Air,Water

disulfide oils iron catalyst

Caustic

Reduces chemical

SulfuricAcid oxygen demand (COD) by 75% Can be added to MERICON I, II ™

LowBrine

pressure and temperature operation allows the use of stainless and III as needed to meet

AcidOils

steel, reducing capital expenses product specs

Uses plant air—no dedicated air compressors required—reducing

operating expenses

MERICON™ II Advantages

Effective in treating all mixed refinery and ethylene caustics, including We offer multiple

naphthenic and phenolic caustics, to low COD specifications solutions for handling

Oxidizes spent caustics at high pressures (30-100 barg) and

temperatures (200° – 300° C) to reduce COD by 98+%.

spent caustic:

Oxidizes all sulfides and thiosulfates to sulfates; destroys phenolics,

REGEN® | Spent

naphthenics and mercaptides depending on oxidation temperature.

Caustic Regeneration

Effective in treating sulfidic caustics at low pressures and temperatures,

and in treating mixed refinery caustics, including naphthenic caustics at Regeneration and reuse of caustic

higher pressures and temperatures solution during the mercaptan

Non-catalyst process extraction process.

Minimum contaminates in the final brine

About REGEN »

MERICON™ III Advantages

Spent Caustic Management

Best for treating sulfidic and naphthenic spent caustics

Removes spent caustic products safely

Acidifies all spent caustics at low pressures and temperatures, releasing and reliably from your facility for

most high COD impurities from caustic; reduces COD by 90-95% beneficial reuse.

Allows recapture of organic compounds (naphthenates and phenolics)

if advantageous About Spent Caustic Management »

Flexible operation managing varying compositions and quantities of

spent caustic in a timely and responsible manner

Proven technology for removal of naphthenates in caustic streams

How It Works

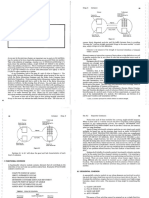

MERICON I, II and III use on-site neutralization and/or oxidation on sulfidic and organic

™

spent caustics to produce a neutral brine effluent stream. Afterwards, the stream can

be routed to wastewater treating facilities, evaporation ponds or waterways. If

technology is not your solution for spent caustic regeneration or neutralization,

Merichem also offers spent caustic management services that allow you to ship your

®

caustic as non-hazardous waste.

SpentCausticTreatmentSystemEmployingWetAirOxidation

Off-Gas

AcidOils

Nitrogen

ScrubbingPhase

Separation Neutralization

Processwatel

Oxidation

AlkalineSolution

OxidationAir

FreshCaustic

MPSteam

NeutralizedBrine

SpentCaustic

SulfuricAcid

LEGEND:

Steam,Off-Gas,Nitrogen,Air,Water

Caustic

SulfuricAcid

Brine

AcidOils

'

MERICON™ I MERICON™ II MERICON™ III

History of Innovation

For nearly 75 years, Merichem has provided proven spent

®

caustic services and processing technologies to oil and gas

industry leaders. Our reputation for innovation, expertise

and dedication to customer service continue to

be unsurpassed.

Extensive Capabilities

To every challenge, we bring a comprehensive suite of

capabilities to help our customers address their treatment

issues. Whether it’s licensing technology, guidance, design,

engineering, fabrication, testing or implementation,

Merichem can apply the right resources, when and where

®

they’re needed.

Proven Flexibility, Global Reach

All over the world, Merichem has helped customers address some of their most

®

challenging treating problems with extensive capabilities and a flexible array of

supply-chain options.

We have licensed more than 35 MERICON units worldwide ™

MERICON™

We Evaluate. We Solve. We Prove.

MERICON : Extracting Value ™

Choosing the Optimal Treatment

from Caustic Treating Streams Technology for Effluent Caustics

MERICON™ | Spent Caustic MERICON™ | Spent Caustic

VIEW MORE % VIEW MORE %

Is MERICON ™

I, II, or III the

right solution for you?

At Merichem®, we are here to help you solve your

contaminant challenges, with comprehensive

end-to-end solutions.

Contact Our Experts »

About Merichem® Quick Links Upcoming Events / Recent News

& Resources Time to Process

Merichem specializes in proven solutions for sulfur

®

& Contaminants We Treat

removal, caustic treating and spent caustic treatment

& Spent Caustic Handling

technologies. Merichem also provides spent caustic

®

handling services as an alternative to technology solutions. & Environmental Stewardship

Serving customers worldwide, our deep expertise and

& Request Technical Support

comprehensive capabilities encompass design and Cleaning sulphur from renewable

engineering, fabrication, research and testing, logistics, & 24/7 Logistics Support diesel production

implementation and technical support.

& Request a Quote

Follow us on Social Media: ! " # & Contact Us

& Employee Resources

SPECIAL FOCUS: REFINING

TECHNOLOGY

Phone Number: +1-713-428-5000 Address: Merichem Company 601 Sawyer Street, Suite 205, Houston, TX 77007, USA

Copyright © 2023 All Rights Reserved Terms of Use & Global Data Privacy | Sitemap

You might also like

- MERICON™ I, II, III - Caustic Treatments - Merichem - IIDocument1 pageMERICON™ I, II, III - Caustic Treatments - Merichem - IIOthman Mat YamanNo ratings yet

- Sustainable Development Standards JAN2023Document97 pagesSustainable Development Standards JAN2023lirepi8208No ratings yet

- Hyundai2.0L 5 of 5 (5 Files Merged)Document5 pagesHyundai2.0L 5 of 5 (5 Files Merged)Nicolás García AlbaNo ratings yet

- Honda Civic 2001 A 2006 - Iluminação Externa - Diagrama ElétricoDocument3 pagesHonda Civic 2001 A 2006 - Iluminação Externa - Diagrama ElétricoWiterMarcos0% (1)

- 1994 Toyota Corolla 1994 Toyota CorollaDocument1 page1994 Toyota Corolla 1994 Toyota CorollaAngie CamargoNo ratings yet

- Shipmaster Business Self-ExaminerDocument308 pagesShipmaster Business Self-ExaminerŘhýđm Šâűřābh100% (1)

- Pharmacologic Approaches To Glycemic Treatment Standards of Medical Care in Diabetes-2018 Diabetes CareDocument1 pagePharmacologic Approaches To Glycemic Treatment Standards of Medical Care in Diabetes-2018 Diabetes CareRathchapon BuranasawadNo ratings yet

- 2003 Mitsubishi Montero Sport LS 2003 Mitsubishi Montero Sport LSDocument1 page2003 Mitsubishi Montero Sport LS 2003 Mitsubishi Montero Sport LSNicole Rodriguez De JesusNo ratings yet

- Fiber Materials and SolutionsDocument2 pagesFiber Materials and SolutionsKatNo ratings yet

- JNTUK I B.Tech I Semester Exam Timetable Feb 2023Document1 pageJNTUK I B.Tech I Semester Exam Timetable Feb 2023satish kolluruNo ratings yet

- TEIL PPT May2019Document42 pagesTEIL PPT May2019Ankush GiriNo ratings yet

- Toyota Corolla 94Document1 pageToyota Corolla 94Angie CamargoNo ratings yet

- Dodge Journey 3.6L 2010 - Controle Do Motor - Diagrama ElétricoDocument6 pagesDodge Journey 3.6L 2010 - Controle Do Motor - Diagrama ElétricoAndré Sartori100% (1)

- Developing the Best Process for MMADocument11 pagesDeveloping the Best Process for MMAManojNo ratings yet

- 2004 Volkswagen Jetta GL 2004 Volkswagen Jetta GLDocument1 page2004 Volkswagen Jetta GL 2004 Volkswagen Jetta GLMiguel BsNo ratings yet

- Arvind Sir Tutorials - Maths Formula Book 22 April 2018Document8 pagesArvind Sir Tutorials - Maths Formula Book 22 April 2018Kumar ArvindNo ratings yet

- 2013 Mercedes-Benz Sprinter 2500 2013 Mercedes-Benz Sprinter 2500Document1 page2013 Mercedes-Benz Sprinter 2500 2013 Mercedes-Benz Sprinter 2500Ezequiel ZetaNo ratings yet

- 1.3.1) Concept of ScreeningDocument2 pages1.3.1) Concept of ScreeningMadiha ZaimuriNo ratings yet

- Cohesion: Element Means An Instruction, A Group of Instructions, A Data Definition or A CallDocument11 pagesCohesion: Element Means An Instruction, A Group of Instructions, A Data Definition or A CallcarlosNo ratings yet

- Cohesion: Element Means An Instruction, A Group of Instructions, A Data Definition or A CallDocument11 pagesCohesion: Element Means An Instruction, A Group of Instructions, A Data Definition or A CallcarlosNo ratings yet

- Cohesion: Element Means An Instruction, A Group of Instructions, A Data Definition or A CallDocument11 pagesCohesion: Element Means An Instruction, A Group of Instructions, A Data Definition or A CallcarlosNo ratings yet

- 09 Project Risk Register For Oct-2022Document2 pages09 Project Risk Register For Oct-2022Rajesh KrishnanNo ratings yet

- Risk Register for 400kV OHL and Substation Modification ProjectDocument2 pagesRisk Register for 400kV OHL and Substation Modification ProjectRajesh Krishnan100% (1)

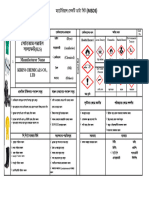

- (MSDS) : (SLS) Manufacturer NameDocument1 page(MSDS) : (SLS) Manufacturer NamemoniruzzamanbuetNo ratings yet

- SUNDARBAN COURIER SERVICE (PVT.) LTD. COMPANY ORGANOGRAMDocument1 pageSUNDARBAN COURIER SERVICE (PVT.) LTD. COMPANY ORGANOGRAMMd. TaSlIM100% (1)

- Cement Plants Located in ChadDocument4 pagesCement Plants Located in ChadOsama EhtawishNo ratings yet

- Gassing of Insulating Liquid Under Electric Stress AND - I. Ionization IDocument6 pagesGassing of Insulating Liquid Under Electric Stress AND - I. Ionization IShyam K PatelNo ratings yet

- Formulae, Equations and Amounts of Substance 1 QPDocument14 pagesFormulae, Equations and Amounts of Substance 1 QPMuhammad Sameer AmirNo ratings yet

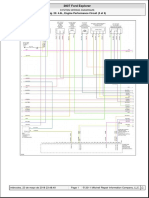

- 2007 Ford Explorer 2007 Ford ExplorerDocument1 page2007 Ford Explorer 2007 Ford ExploreromyNo ratings yet

- Analyses by Segment: 3.1 Operating SegmentsDocument4 pagesAnalyses by Segment: 3.1 Operating SegmentscamilaNo ratings yet

- Annual Report of IOCL 188Document1 pageAnnual Report of IOCL 188Nikunj ParmarNo ratings yet

- How To Analyze CaseDocument8 pagesHow To Analyze CaseArpita GuptaNo ratings yet

- 2007 Ford Explorer 2007 Ford ExplorerDocument1 page2007 Ford Explorer 2007 Ford Exploreromy100% (1)

- Pe PDFDocument2 pagesPe PDFPiyush kumarNo ratings yet

- Process Technology For recoveredCarbonBlack - enDocument4 pagesProcess Technology For recoveredCarbonBlack - enVivek MoreNo ratings yet

- Dissolved SolidsDocument2 pagesDissolved SolidsOkaibe RhintaroNo ratings yet

- 2013 Mercedes-Benz Sprinter 2500 2013 Mercedes-Benz Sprinter 2500Document1 page2013 Mercedes-Benz Sprinter 2500 2013 Mercedes-Benz Sprinter 2500Ezequiel ZetaNo ratings yet

- ECO ListDocument10 pagesECO Listxohaibali0% (1)

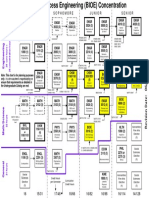

- 11 BT R20-July-2023Document1 page11 BT R20-July-2023PRUDHIVI KOLLATINo ratings yet

- BIOE 2015 FlowsheetDocument1 pageBIOE 2015 FlowsheetAmit SharmaNo ratings yet

- EPD ReferenciaDocument14 pagesEPD ReferenciaElla EnveNo ratings yet

- Jawaharlal Nehru Technological University KakinadaDocument3 pagesJawaharlal Nehru Technological University KakinadabhanuNo ratings yet

- Mauro Mancini: Academic YearDocument3 pagesMauro Mancini: Academic Yearnz jumaNo ratings yet

- Laurel Glass CatalogueDocument42 pagesLaurel Glass Catalogueecjvi1No ratings yet

- A Nálisis Del M Odo y E Fecto de La F AllaDocument43 pagesA Nálisis Del M Odo y E Fecto de La F AllaAlfredoNo ratings yet

- A FINAL Apples Version 3 2022 23 DECEMBER 2022Document21 pagesA FINAL Apples Version 3 2022 23 DECEMBER 2022CharlotteNo ratings yet

- Process Description Fact Uc - Fertliser PlantsDocument13 pagesProcess Description Fact Uc - Fertliser PlantsShivahari GopalakrishnanNo ratings yet

- 3799 (1)Document1 page3799 (1)ian dubeNo ratings yet

- Solution TBMT 19Document12 pagesSolution TBMT 19Md. Maminul IslamNo ratings yet

- 2007 Ford Explorer 2007 Ford ExplorerDocument1 page2007 Ford Explorer 2007 Ford ExploreromyNo ratings yet

- Technostream PDFDocument15 pagesTechnostream PDFraulkmainaNo ratings yet

- 2007 Ford Explorer 2007 Ford ExplorerDocument1 page2007 Ford Explorer 2007 Ford Exploreromy100% (1)

- ANEVAZO Plant Layout GuideDocument1 pageANEVAZO Plant Layout GuideAlyssa Sarah ArenasNo ratings yet

- 2012 Nissan Frontier S 2012 Nissan Frontier S: System Wiring Diagrams System Wiring DiagramsDocument1 page2012 Nissan Frontier S 2012 Nissan Frontier S: System Wiring Diagrams System Wiring DiagramsSergio HernandezNo ratings yet

- 2004 Jeep Grand Cherokee Laredo 2004 Jeep Grand Cherokee LaredoDocument1 page2004 Jeep Grand Cherokee Laredo 2004 Jeep Grand Cherokee LaredoRonfermNo ratings yet

- Rev 00 enDocument25 pagesRev 00 ennebodepa lyftNo ratings yet

- Dodge RAM 6.7L 2010 - Módulo de Controle Da Carroceria No Compartimento Do Motor - Diagrama Elétrico PDFDocument2 pagesDodge RAM 6.7L 2010 - Módulo de Controle Da Carroceria No Compartimento Do Motor - Diagrama Elétrico PDFAnonymous TMFgAgR09tNo ratings yet

- ETIP Bioenergy - 2020!11!11 - P. Corvo - Bringing Commercial Cellulosic Ethanol Production To The MarketDocument23 pagesETIP Bioenergy - 2020!11!11 - P. Corvo - Bringing Commercial Cellulosic Ethanol Production To The MarkethzulqadadarNo ratings yet

- Vacancy For Branch ChangeDocument1 pageVacancy For Branch Changejohnwicker129No ratings yet

- Control Valve Actuators and Positioners - Spirax SarcoDocument25 pagesControl Valve Actuators and Positioners - Spirax SarcoOthman Mat YamanNo ratings yet

- Chemical BondDocument1 pageChemical BondOthman Mat YamanNo ratings yet

- MPC TXCDocument153 pagesMPC TXCsandy2911No ratings yet

- Understanding Process Control for Oil & Gas WebinarDocument5 pagesUnderstanding Process Control for Oil & Gas WebinarOthman Mat YamanNo ratings yet

- Flashing & CavitationDocument8 pagesFlashing & CavitationOthman Mat YamanNo ratings yet

- Car Honda Interest RateDocument2 pagesCar Honda Interest RateOthman Mat YamanNo ratings yet

- Motor Load and Efficiency PDFDocument16 pagesMotor Load and Efficiency PDFwfjerrNo ratings yet

- Air Receivers Tech TipDocument3 pagesAir Receivers Tech TipOthman Mat YamanNo ratings yet

- PSV Releiving TempDocument3 pagesPSV Releiving TempOthman Mat YamanNo ratings yet

- PCV sizing discussion from LinkedDocument1 pagePCV sizing discussion from LinkedOthman Mat YamanNo ratings yet

- Thermal Liquid Expansion PDFDocument14 pagesThermal Liquid Expansion PDFOthman Mat Yaman100% (1)

- Boilers: 9-1. Minimum Maintenance Activities For BoilersDocument12 pagesBoilers: 9-1. Minimum Maintenance Activities For BoilersLacshay ShekharNo ratings yet

- What You Should Know About Liquid Thermal - ExpansionDocument4 pagesWhat You Should Know About Liquid Thermal - ExpansionOthman Mat YamanNo ratings yet

- Mis11e ch03Document42 pagesMis11e ch03Vasudha RaoNo ratings yet

- 2017 Normal EnglishDocument854 pages2017 Normal EnglishÂnuda M ĞalappaththiNo ratings yet

- Japanese Occupation Court Ruling ValidityDocument2 pagesJapanese Occupation Court Ruling ValidityGlen VillanuevaNo ratings yet

- Curriculum Vitae (Download)Document4 pagesCurriculum Vitae (Download)Hilary RivasNo ratings yet

- Corporate Finance I - Lecture 7bDocument20 pagesCorporate Finance I - Lecture 7bSandra BempongNo ratings yet

- InvisiblePPC University L2-3 Create Your OfferDocument9 pagesInvisiblePPC University L2-3 Create Your OfferFran EtsyNo ratings yet

- My Rpms Angelina S. SantosDocument109 pagesMy Rpms Angelina S. SantosAngelina SantosNo ratings yet

- MSC Logic Self Study 2019 CompleteDocument88 pagesMSC Logic Self Study 2019 CompleteAlyssa RenataNo ratings yet

- Tall Buildings Case Studies of John Hancock Centre and Sears TowerDocument75 pagesTall Buildings Case Studies of John Hancock Centre and Sears TowerShanikAromgottilNo ratings yet

- Timor-1 CFSPP Project Supporting Dokumen: Doc No.: 003.SD/ENC-UBE/TIMOR1/III/2021 Ref No. 0Document2 pagesTimor-1 CFSPP Project Supporting Dokumen: Doc No.: 003.SD/ENC-UBE/TIMOR1/III/2021 Ref No. 0Hendra AwanNo ratings yet

- Air Asia Final ProjectDocument59 pagesAir Asia Final Projectmanaswini sharma B.G.No ratings yet

- DLP Reading Comprehension 15th SeptemberDocument3 pagesDLP Reading Comprehension 15th SeptemberHanaa ElmostaeenNo ratings yet

- Tesei - 'The Romans Will Win'Document29 pagesTesei - 'The Romans Will Win'sokhratNo ratings yet

- Scratch 2Document45 pagesScratch 2Mihai Alexandru Tuțu0% (1)

- Best Sellers - Books & AudiobooksDocument7 pagesBest Sellers - Books & AudiobooksRykan KolbyNo ratings yet

- Nature The Gentlest MotherDocument4 pagesNature The Gentlest MotherMeeta Sharma100% (2)

- Nick & Sammy - Baby You Love Me (Bass Tab)Document6 pagesNick & Sammy - Baby You Love Me (Bass Tab)Martin MalenfantNo ratings yet

- English For Business: Level 1Document24 pagesEnglish For Business: Level 1anonymous9196806No ratings yet

- C01 Globalisation: The Global Village?Document21 pagesC01 Globalisation: The Global Village?Mat RoyNo ratings yet

- Wound Healing PhasesDocument27 pagesWound Healing PhasesAnil BasnetNo ratings yet

- Describing LearnersDocument29 pagesDescribing LearnersSongül Kafa67% (3)

- Azure FaDocument4 pagesAzure Faanurag pattanayakNo ratings yet

- Well Construction Journal - May/June 2014Document28 pagesWell Construction Journal - May/June 2014Venture PublishingNo ratings yet

- Land Titling and Transfer Legal Services in Trece Martirez and DasmarinasDocument1 pageLand Titling and Transfer Legal Services in Trece Martirez and DasmarinasMark RyeNo ratings yet

- Ameama Zubair 70080433 Poem: Goe, and Catche A Falling Star: Poem: The Sunne RisingDocument2 pagesAmeama Zubair 70080433 Poem: Goe, and Catche A Falling Star: Poem: The Sunne RisingAsma KhanNo ratings yet

- Neil Mcdonald - The King's Indian Attack Move by Move PDFDocument353 pagesNeil Mcdonald - The King's Indian Attack Move by Move PDFantonius-raducu91% (43)

- PRACTICE TEST 1 2021-2022: = còi cọcDocument8 pagesPRACTICE TEST 1 2021-2022: = còi cọcMinh ThùyNo ratings yet

- Rfc3435 Dial Plan Digit MapsDocument211 pagesRfc3435 Dial Plan Digit MapsSrinivas VenumuddalaNo ratings yet

- EDP 3 Product DevelopmentDocument15 pagesEDP 3 Product DevelopmentatulkirarNo ratings yet

- Telecom Business Information System AbstractDocument5 pagesTelecom Business Information System AbstractTelika RamuNo ratings yet