Professional Documents

Culture Documents

Saic-H-2030

Saic-H-2030

Uploaded by

mominOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saic-H-2030

Saic-H-2030

Uploaded by

mominCopyright:

Available Formats

SAUDI ARAMCO ID/PIEU - 30-Nov-2017- REV. 2017.09.00 (Standards Cutoff - September 30, 2017) Rev. 2017.09.

00 30-Sep-17

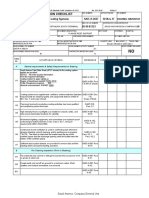

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

In-Process Insp - Intermediate or Top Coat Application SAIC-H-2030 30-Nov-17 COAT-1402515937

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

UPGRADE FIRE WATER SYSTEM AT RASTANURA SOUTH TERMINAL BI-10-01333 SAUDI ARCHIRODON COMPANY LTD

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

PIPE SUPPORT

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

054-M-XA-864806-003-00

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

08/01/2022 09:30 AM 08/01/2022 09:30 AM SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SATIP-100-01 3.4

SAUDI ARAMCO INSPECTION LEVEL

S

CONTRACTOR INSPECTION LEVEL

H

NO

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A General requirements & Safety Requirements for Painting

Saudi Aramco Paint Data Sheet for the coating system (APCS) applied is

provided.

NOTES: Fill in the required information for

Coating System: 19C (TOP COAT )HEMPEL HEMPADUR SMULTI SAES-H-101V &

STRENGHT GF 35870

A1 Wet film thickness/Coat :875 µm / Reqd. DFT:750µm SAES-H-001 Para

Recoat interval (Min / Max):10 Hrs /75 Days.at Steel Temp10 ºC 4 & APCS Sheets

04 Hrs/ 15Days e at Steel Temp 30 ºC

01 Hrs /5 Days at Steel Temp 50 ºC

Intermediate or top coat paint material for each coating system is supplied

by same Manufacturer (Different brands may be used if approved by SAES-H-001,

A2

CSD). Para. 9.2.4

Note: Thinner used is supplied or approved by the paint manufacturer.

For Multi-coat applications, primer, intermediate coat, and topcoats shall SAES-H-001,

A3

be of contrasting colors. Para. 9.3.1

Personnel involved in protective coating activities has been qualified and SAEP-316,

A4

certified to perfom their task. Para. 5.1

Necessary safety requirements are provided such as:

SAES-H-001 Para

High intensity flood or spotlights are installed in vessels, tanks, and other

6.5.3

A5 poorly illuminated locations for visibility.

Para 8.1.5

Continuous forced ventilation is operated throughout the paint application

Para 5.2

and curing period while coating inside Tanks & Vessels.

B Weather Conditions for Painting

Paint shall not be applied during adverse weather conditions such as, but

not restricted to following:

1) Wind is strong enough to blow sand, salt spray or other

foreign matter onto the surface being painted. SAES-H-001 Para

B1

2) Wind is 6.1.1

strong enough to cause dry spay or otherwise seriously

disturb the spray pattern when application is by spray gun.

3) Rain

Paint shall not be applied if one or more of the following conditions exist

(unless paint is specifically formulated for averted condition):

a) Substrate temperature is less than 10°C of the temperature

limit given in the applicable Saudi Aramco Data Sheet SAES-H-001 Para

B2

b) Substrate temperature is more than the temperature limit 6.1.1

given in the applicable Saudi Aramco Data Sheet.

c) Substrate temperature is less than 3°C above the dew point.

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Nov-2017- REV. 2017.09.00 (Standards Cutoff - September 30, 2017) Rev. 2017.09.00 30-Sep-17

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

In-Process Insp - Intermediate or Top Coat Application SAIC-H-2030 30-Nov-17 COAT-1402515937

PROJECT TITLE WBS / BI / JO NUMBER

UPGRADE FIRE WATER SYSTEM AT RASTANURA SOUTH TERMINAL BI-10-01333 SAUDI ARCHIRODON COMPANY LTD

ITEM RE-INSP

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A

No. DATE

C Requirements for surface preparation

C1 Primed or initially coated surfaces require to be solvent or detergent SAES-H-001 Para

cleaned due to presence of oil or grease. 6.4.1

Primed or initially coated surfaces that have exceeded the recoat interval SAES-H-001 Para

C2 are cleaned & roughened prior to application of intermediate or top coat. 9.3.4

Inspect surfaces to preclude foreign matter. (Data Sheet)

Surfaces primed with inorganic zinc primer are free from zinc oxide SAES-H-001,

C3

formation prior to application of epoxy top coat. Para. 9.3.3

Any oxide formation shall be removed by high pressure cleaning using

sweet water (with maximum chloride contents of 50 PPM and maximum SAES-H-001,

C4

TDS of 500 PPM), or by sweet water hosing followed by scrubbing with Para. 9.3.3

stiff brushes to remove zinc salts.

The water washed surfaces are dried thoroughly prior to applying the SAES-H-001,

C5

topcoat. Para. 9.3.3

When inorganic zinc primer is used stripe coating is applied after the SAES-H-001,

C6

prime coat on all weld lines, edges, bolts, nuts and rivets using a brush. Para. 9.3.3

A mist-coat thinned 10 to 20% is applied to the inorganic zinc primer to SAES-H-001,

C7

avoid pinholes and bubbles occurring in the intermediate coat of epoxy. Para. 9.3.3

D Paint Preparation

Paints has not exceeded the shelf life as stamped/labeled in the SAES-H-001 Para

D1

containers. 11.6

SAES-H-001

D2 Paint cans showing leakage, gelled paints or skinning are rejected.

Para6.2.4 & 9.2

If sludge is formed at the bottom of the paint container and cannot be SAES-H-001

D3

dispersed by mixing , the paint shall be rejected. Para6.2.4 & 9.2

Partial mixing and use of two-component and multi-component coatings is SAES-H-001 Para

D4

prohibited. 9.2.5

Paints are thoroughly mixed until it is homogeneous. Power stirrer is SAES-H-001 Para

D5

used for mixing 2-Pack paints and all paint quantities over 5 liters. 9.2.3

Thinner type (Stock No) and quantity to be added (Percentage)

SAES-H-001 Para

D6 shall be as given in the Saudi Aramco Data Sheet, SAES-H101V.

9.2.3

Thinner is added only when the paint is fully homogeneous mixed.

E Spray Application of Paint

Primed or initially coated surfaces were inspected and released for Quality Plan &

E1

intermediate or top coating by verifying completion of SAIC-H-2028. SATIP-H-100-01

A 360° spray gun nozzle with proper tip size is used to coat the interior of SAES-H-001,

E2

nozzles and traps inside tanks and vessels. Para. 9.4.4

SAES-H-101V,

Coating nozzle tip size and fluid pressure are verified to be as specified in

E3 Paint

Saudi Aramco Paint Data sheets SAES-H-101V .

Data Sheets

Compressed air supply for conventional spray application is not

contaminated with oil, moisture or other contaminants. SAES-H-001 Para

E4 (NOTE: This is determined by performing a blotter test at start and 6.5.1

mid- point of 8-hour shift.)

Paints to be sprayed are filtered through a 30 to 60-mesh screen prior to SAES-H-001,

E5

use. Para 9.3.7

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Nov-2017- REV. 2017.09.00 (Standards Cutoff - September 30, 2017) Rev. 2017.09.00 30-Sep-17

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

In-Process Insp - Intermediate or Top Coat Application SAIC-H-2030 30-Nov-17 COAT-1402515937

PROJECT TITLE WBS / BI / JO NUMBER

UPGRADE FIRE WATER SYSTEM AT RASTANURA SOUTH TERMINAL BI-10-01333 SAUDI ARCHIRODON COMPANY LTD

Paints shall be continuously agitated with a low-speed stirrer during SAES-H-001,

E6

application. Para 9.3.7

Proper spraying techniques and control of spray pattern are

demonstrated during paint application as follows:

A) Spray Gun is held perpendicular to surface at a distance that will

ensure that a wet layer of paint is deposited on the surface.

SAEP-316

B) Trigger of the gun is released at the end of each stroke.

Para.

C) Paint is applied in a uniform layer with over lapping at the edges of the

E7 4.4.4 (J) &

spray pattern.

As Referenced

Note 1: Spray application techniques per SSPC-PA 1 Par 7.3.4

(SSPC)

Note 2: Inspectors shall identify poor technique that results in any of

the unacceptable application defects (runs, sags, drips, etc)

Note 3: Corrective action shall be accepted when applications can

be performed without defects in accordance with Data sheets.

F Brush/Roller Application

Brush/roller are used when allowed by the paint manufacturer or as SAES-H-101V,

F1

indicated in the paint manufacturer's data sheet in Item A1. Paint Data Sheet

SAES-H-001 Para

F2 The maximum brush size if used for painting is125 mm.

9.3.6

G Final Wet Coat Inspection

The number of coat applied conforms to the number of coat listed in the

APCS-sheets of SAES-H-101 SAES-H-101V,

G1

See Attachment 1 Paint Data Sheet

Wet coating shall be free of application related defects such as runs, sags, SAES-H-001,

G2

drips or foreign matter. Para 9.3.5 b

Coating wet film thickness meets the requirement of Saudi Aramco Paint SAES-H-101V,

G3

data sheet SAES-H-101V and as listed in Item A1. Paint Data Sheet

REMARKS:

ATTACHMENTS:

1. REQUIREMENTS OF SAUDI ARAMCO APPROVED PROPTECTIVE COATING SYSTEMS

REFERENCE DOCUMENTS:

1. SAES-H-102: Safety requirements for Coating Applications (24 October 2012)

2. SAES-H-101V, Approved Saudi Aramco Data Sheets – Paints and Coatings, ( 9 October 2012 )

3. SAEP-316, Performance Qualification of Coating Personnel (31 July 2016)

4. SAES-H-001, Coating Selection and Application Requirements for Industrial Plants and Equipment (5 April 2016)

5. Steel Structures Painting Council, SSPC-PA 1, June 1996

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: HARSHAD PATIL Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

ZEESHAN Mr. SHANMUGAM GURUSWAMY

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date: MOHAMMED YASER KHAN Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Nov-2017- REV. 2017.09.00 (Standards Cutoff - September 30, 2017) Rev. 2017.09.00 30-Sep-17

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

In-Process Insp - Intermediate or Top Coat Application SAIC-H-2030 30-Nov-17 COAT-

REQUIREMENTS- SAUDI ARAMCO APPROVED PROTECTIVE COATING SYSTEMS

Each Specific Requirements for Coating

S.R. No APCS

Coating No. of Coats Coat DFT Application

Type/Service (Total DFT) Micrometer #1 #2

Epoxy, Inorg Zinc Primer

Atmospheric Service 3 Coats Min Prime-65-100 Solvent Based Zinc Water Based Zinc

1 APCS-1A

(275-400) Top- 150 Max Primer - RH > 50% Primer - RH < 50%

Epoxy, Epoxy Primer Atmospheric

Service 3 Coats Min Prime-50-100

2 APCS-1B

(275-400) Top-150 Max

Epoxy, Zinc rich Epx Primer

Atmospheric Service 3 Coats Min Prime-40-75

3 APCS-1C

(250-375) Top-150 Max

Epoxy/ Polyurethane, Inorg Zinc Prime-65-100

Primer Atmospheric Service 3 Coats Min Solvent Based Zinc Water Based Zinc

4 APCS-1D Int-100-150

(190-315) Primer - RH > 50% Primer - RH < 50%

Top-25-65

Epoxy/ Polyurethane, Epoxy Primer Prime-50-100

Atmospheric Service 3 Coats Min

5 APCS-1E Int-100-150

(175-315)

Top-25-65

Epoxy/ Polyurethane, Zinc rich Prime-40-75

Epoxy Primer Atmospheric Service 3 Coats Min

6 APCS-1F Int-125-175

(190-315)

Top-25-65

Phenolic Epoxy Immersion Service Succeeding coats shall Coating thickness

(Self-Priming). 3 Coats Min

7 APCS-2A 125 each coat be of contrasting within 2 m of anode

(275-375) colors. 30% greater

Epoxy Coating Potable Water Succeeding coats shall Coating thickness

Immersion Service (Self-Priming). 3 Coats Min

8 APCS-2B 125 each coat be of contrasting within 2 m of anode

(275-375) colors. 30% greater

Epoxy Coating Immersion Service, Prime @ Succeeding coats shall Coating thickness

up to 120°C. 3 Coats Min

9 APCS-2C SAES-H-101V be of contrasting within 2 m of anode

(275-375)

Top-125 Max colors. 30% greater

Epoxy - Interior of Steel Aviation The total system thickness shall be applied in

Fuel Storage Tank /Piping. 2 Coats Min 2 Coats Min a minimum of two coats of contrasting colors.

10 APCS-2D

(200-250) (200-250)

Solvent Free Phenolic Epoxy Succeeding coats shall Coating thickness

General Immersion Service Min 1 Coat be of contrasting within 2 m of anode

11 APCS-2E

(Self-Priming). (500-600) colors. 30% greater

Glass Flake Polyester General The total system thickness is applied in a

Immersion Service Max 2 Coat single coat or two coats wet on wet. Use

12 APCS-2F

(600-1000) contrasting colors if the second coat is to be

applied within the allowed re-coating

Glass Flake Vinyl Ester Heavy-Duty Coating

intervals.thickness

Also Stripe coat sharp corners

Immersion Service Max 2 Coat within 2 m of anode

13 APCS-2G

(600-1000) 30% greater

100% Solid, Glass Flake Epoxy Coating thickness

Immersion Service up to 105C. One Coat within 2 m of anode

14 APCS-2H

(30-40 mils) 30% greater

Ceramic/Inorganic Filled Epoxy- Coating thickness

Phenolic/Novolac Coating - One Coat within 2 m of anode

15 APCS-2I

Immersion Service up to 150C (20-40 mils) 30% greater

Coal Tar Epoxy Immersion Service Succeeding coats shall coating concrete,

and buried (steel and concrete) Min Two Coats

16 APCS-3 300 max /Coat be of contrasting thickness-not less

(400-600) colors. than 720 microns

Saudi Aramco: Company General Use

Aluminum - Pigmented Alkyd Prime-50/coat,

Coating 3 Coats Min (min prime 75)

17 APCS-4

Atmospheric (115-118) Top-40

Max/coat

Heat Radiant Insulating Coating

System Total System

18 APCS-5A

300 – 500

Hot Insulating Coating System - Depend on Design

carbon steel and stainless steel 500 Micron

19 APCS-5B Req & Substrate

service reduces 40°F

temperature

Alkyd Enamel Coating System. Prime-50/coat,

3 Coats Min (min prime 75)

20 APCS-6

(125-200) Top-50Max/

Rust Convertor

coat

Rust Conversion Primer/Alkyd one coat min Aluminum alkyds Alkyd enamels

Topcoat System (SAES-H- 37-75 micrometers 50-100 above

21 APCS-7 3 Coats Min

101V) above thickness of thickness of rust

Top-One or rust converter converter

Chlorinated Rubber Coating System more coat

2 Coats Min Prime-50-75

22 APCS-9

(100-175) Top-50-100

Bituminous Paint Moderate Thickness per

Buried: 750 min

Temperature, Buried or Immersion coat and No. of

23 APCS-10 Immersed:

Service coats. @ SAES-

1150 min

H-101V

High Temp System Atmospheric Solvent Based Zinc Water Based Zinc

Service 150°C-400°C (with Two coats Prime-25-65 Primer - RH > 50% Primer - RH < 50%

24 APCS-11A

Inorganic Zinc Primer). (40-105) Top-15-40

Very High Temp System

Atmospheric Service 400-540°C. Two coats Prime-15-40

25 APCS-11B System 2: Hot

(30-80)1:

System Top-15-40

Steel

Ambient Steel

Air-Drying, single component, high Application Protective Coating for Pitting Corrosion and

Application

heat external coating for bare and (300-500F) Stress Corrosion Cracking bare and

26 APCS-11C Two Coat:

insulated carbon steel & austenitic Three Coat: 5-6 insulated Austenitic 300 Series Stainless

5-6 mils/Coat

stainless mils/Coat Steel

Total DFT: 10-12

Total DFT: 15- Nonskid aggregate added into the next to last

Prime-50-100

Nonskid Epoxy Coating System for mils

3 Coats Min

27 APCS-12 18 mils

Top-150 topcoat while it is still wet. A final topcoat

Floors and Decks (275-400) shall be applied over the aggregate sealing it

Max/coat

Relative humidity >50% during application

inorganic Zinc Primer, Solvent- One Coat and curing.

28 APCS-17A

Based. (65-100)

Relative humidity <50% during application

One Coat and curing.

29 APCS-17B inorganic Zinc Primer, Water-Based.

(65-100)

Splash Zone Compound, Hand One Coat

30 APCS-19A

Applied Grade (2500 Min)

Splash Zone Compound, Spray One Coat

31 APCS-19B

Applied Grade (2500 Min)

Maintenance

New Construction: Coating

Glass Flake Reinforced Polyester/

Two coats @ 750 Existing

32 APCS-19C Epoxy Systems for Offshore

per coat -total of Structures: One

Structural Steel at Splash Zone.

1500

2 layers of glass Coat @ 750 –

cloth with a 3:1 1000 microns Entrapped air, entrapped sand or other

Fiberglass Reinforced Coatings, foreign matter, wrinkles, sags and dry spots

33 APCS-20A ratio of resin:

Hand Lay-Up. in the coating shall be removed and the

reinforcement by

weight affected area repaired.

Glass Flake/Chopped Fiberglass Entrapped air, entrapped sand or other

34 APCS-20B Reinforced Coatings (Spray foreign matter, wrinkles, sags and dry spots

Applied) in the coating shall be removed and the

affected area repaired.

Epoxy Coating for Application onto Two coats

35 APCS-22A 200 Max /Coat

Damp Steel Surfaces (300-400)

Saudi Aramco: Company General Use

Atmospheric

Epoxy Coating for Application onto 350-400

36 APCS-22B One Coat

Damp Steel Surfaces Splash Zn

400-575

Thickness per

High Temperature Mastic Paint for

coat and No. of Total system

37 APCS-23 Buried or Immersion Service (Self-

coats. @ SAES- 500

Priming)

H-101V

Two or more coats 150-200 Each

38 APCS-26 Epoxy Mastic Coating (Self-Priming)

(300-400) Coat

Use when added gloss color retention, and

Epoxy Mastic/Polyurethane Coating Two coats Prim- 250-300 abrasion resistance are required.

39 APCS-26T

System (290-360) Top-40-60

Solvent Free Two-component Ultra The total dry film Use contrasting

One or Two thickness shall be colors if the second

40 APCS-27 Hybrid Epoxy Coating Immersion

(600-1000) applied in a single coat coat is to be applied

Service up to 150ºC.

or two coats (wet on within the allowed re-

wet). coating intervals.

Saudi Aramco: Company General Use

R NUMBER

OAT-

ements for Coating

lication

#2

Water Based Zinc

Primer - RH < 50%

Water Based Zinc

Primer - RH < 50%

Coating thickness

within 2 m of anode

30% greater

Coating thickness

within 2 m of anode

30% greater

Coating thickness

within 2 m of anode

30% greater

kness shall be applied in

ats of contrasting colors.

Coating thickness

within 2 m of anode

30% greater

kness is applied in a

ats wet on wet. Use

he second coat is to be

owed re-coating

coat sharp corners

coating concrete,

thickness-not less

than 720 microns

Saudi Aramco: Company General Use

Alkyd enamels

50-100 above

thickness of rust

converter

Water Based Zinc

Primer - RH < 50%

or Pitting Corrosion and

n Cracking bare and

c 300 Series Stainless

Steel

dded into the next to last

wet. A final topcoat

the aggregate sealing it

0% during application

0% during application

pped sand or other

es, sags and dry spots

e removed and the

d.

pped sand or other

es, sags and dry spots

e removed and the

d.

Saudi Aramco: Company General Use

oss color retention, and

ance are required.

Use contrasting

colors if the second

coat is to be applied

within the allowed re-

coating intervals.

Saudi Aramco: Company General Use

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Applicable Codes & Standards For Aramco Projects (Piping)Document107 pagesApplicable Codes & Standards For Aramco Projects (Piping)momin100% (9)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Saudi Aramco Inspection Checklist: Storage Handling & Presevation of Heat Exchangers. SAIC-E-2003 15-Nov-17 MechDocument7 pagesSaudi Aramco Inspection Checklist: Storage Handling & Presevation of Heat Exchangers. SAIC-E-2003 15-Nov-17 MechmominNo ratings yet

- Saudi Aramco Inspection Checklist: Review of SIS For Air Cooled Heat Exchanger SAIC-E-2004 15-Nov-17 MechDocument8 pagesSaudi Aramco Inspection Checklist: Review of SIS For Air Cooled Heat Exchanger SAIC-E-2004 15-Nov-17 MechmominNo ratings yet

- Non-Conformance Control ProcedureDocument12 pagesNon-Conformance Control Proceduremomin100% (1)

- Saudi Aramco Inspection Checklist: Nitrogen and Pearlite Application On BAHE Frame SAIC-E-2011 15-Nov-17 MechDocument1 pageSaudi Aramco Inspection Checklist: Nitrogen and Pearlite Application On BAHE Frame SAIC-E-2011 15-Nov-17 MechmominNo ratings yet

- Saudi Aramco Inspection Checklist: Internal Cleanliness Inspection of Heat Exchangers SAIC-E-2009 15-Nov-17 MechDocument3 pagesSaudi Aramco Inspection Checklist: Internal Cleanliness Inspection of Heat Exchangers SAIC-E-2009 15-Nov-17 MechmominNo ratings yet

- Hydrostatic Testing ProcedureDocument7 pagesHydrostatic Testing Proceduremomin100% (2)

- Project Quality Plan (JFJS-788)Document18 pagesProject Quality Plan (JFJS-788)mominNo ratings yet

- SATIP-S-060-04 REV 8 Plumbing Fixtures and Fittings FinalDocument2 pagesSATIP-S-060-04 REV 8 Plumbing Fixtures and Fittings FinalmominNo ratings yet

- IMS ManualDocument6 pagesIMS ManualmominNo ratings yet

- Management Review 2020Document2 pagesManagement Review 2020mominNo ratings yet

- Alf Piping 117 009Document6 pagesAlf Piping 117 009mominNo ratings yet

- Part.1 Issued For Construction (Fire Protection)Document322 pagesPart.1 Issued For Construction (Fire Protection)mominNo ratings yet

- Saic-H-2027Document3 pagesSaic-H-2027momin0% (1)

- Ba090205 001Document1 pageBa090205 001mominNo ratings yet

- Magnetic Particle Testing ProcedureDocument11 pagesMagnetic Particle Testing ProceduremominNo ratings yet

- Ba090211 005Document1 pageBa090211 005mominNo ratings yet

- 0001Document1 page0001mominNo ratings yet

- Saudi Aramco Inspection Checklist: Re-Instatement of Air Cooled Heat Exchanger SAIC-E-2008 15-Nov-17 MechDocument5 pagesSaudi Aramco Inspection Checklist: Re-Instatement of Air Cooled Heat Exchanger SAIC-E-2008 15-Nov-17 MechmominNo ratings yet

- Saic-H-2029Document12 pagesSaic-H-2029mominNo ratings yet

- Sep Mgse CM SCM 0031 Procedure For Valve Testing and InstallationDocument6 pagesSep Mgse CM SCM 0031 Procedure For Valve Testing and InstallationmominNo ratings yet

- Mgse T Sep Sa 0029Document1 pageMgse T Sep Sa 0029mominNo ratings yet

- Saic-H-2028Document11 pagesSaic-H-2028mominNo ratings yet

- Satr-H-2006 3.3Document3 pagesSatr-H-2006 3.3mominNo ratings yet

- Saudi Aramco Inspection Checklist: Inspect Assembly of Air-Cooled Heat Exchanger ComponentsDocument12 pagesSaudi Aramco Inspection Checklist: Inspect Assembly of Air-Cooled Heat Exchanger ComponentsmominNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 15-Nov-17 MechDocument13 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 15-Nov-17 MechmominNo ratings yet

- SATIP-S-060-08 Rev 8 Copper Piping FinalDocument2 pagesSATIP-S-060-08 Rev 8 Copper Piping FinalmominNo ratings yet

- SATIP-S-030-01, Rev 8 Storm Water Drainage System G FinalDocument3 pagesSATIP-S-030-01, Rev 8 Storm Water Drainage System G Finalmomin0% (1)

- SATIP-S-060-02 Rev 8 Electric Drinking Water Coolers FinalDocument2 pagesSATIP-S-060-02 Rev 8 Electric Drinking Water Coolers FinalmominNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanmominNo ratings yet