Professional Documents

Culture Documents

Sep Mgse CM SCM 0031 Procedure For Valve Testing and Installation

Sep Mgse CM SCM 0031 Procedure For Valve Testing and Installation

Uploaded by

momin0 ratings0% found this document useful (0 votes)

6 views6 pagesOriginal Title

SEP-MGSE-CM-SCM-0031 PROCEDURE FOR VALVE TESTING AND INSTALLATION

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views6 pagesSep Mgse CM SCM 0031 Procedure For Valve Testing and Installation

Sep Mgse CM SCM 0031 Procedure For Valve Testing and Installation

Uploaded by

mominCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

co an

a Master Gas Systom Expansion — Phase

“ean,

[ComactNe: 6900035465 (k)

4

mee ‘SEPCO Electric Power Construction Corporation |

‘Dong Sho |Sabae Ams. te ‘i

Snr fora eer =

‘wleitsinateEetinee! [Silane [nett

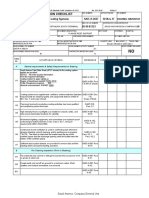

EPCO | __cocwenrwane |

Si

w

SEP.MGSE-CM-SCM-0031

FRED IB | proceouneronvaiverestne | REVNO °

Pace | 26

‘TABLE OF CONTENTS

1. Purpose 3

2 Seope 3

3. References sl

4. Work Procedure )

5. Storage and Preservation of Valves, 6

6. Installation of Valves 6

Inspection & Quality Records 6

8. Safety Precautions 6

‘SEPCO Electric Power Construction Corporation

SEPCO DOCUMENT NAME SEP-MGSE-CH.SCM-O031

LWW FR EB BB | Proceoure For vatve TESTING RevNo | 0

PURPOSE

To ensure that body and seat pressure testing of valves are performed safely,

efficiently and in accordance with good working practice as per Sepco / Saudi

ARAMCO job specifications and standards. This procedure is intended to provide

{guidance and to establish control for the preparation and execution of valve testing

and installation activities.

2. SCOPE

‘This procedure defines the requirements for the valve testing prior to installation

Jn Master Gas System Expansion Project

3. REFERENCES

Api s98 Valve Inspection and Testing

ASME B1634 Valves-Flanged, Threaded and Welding End

ASME B165 Pipe Flanges and Flange Fitting

SAES-A004 General Requirements for Pressure Test

SAES:A-007 Hydrostatic Testing Fluids and Lay-up Procedure

SAES-L-108 Selection of Valves

4, WORK PROCEDURE

4 Pressure Test Preparation

444. Ensure that all materials, relevant drawings, and procedure are available to

the personnel involved inthis activity. All personnel shall be aware ofthe

safety and loss prevention requirements prior to starting the work.

44.2 Pressure gages to be used shall have the required range and valid calibration,

‘as per SAES-A-004.

44.3. The test pumppressure hose, fittings, approved test manifold shall have

adequate capacity and certified for the specific pressure range for the

testing

4.14 Blind flanges ofthe correct rating and materials specification shall be

utlised for blarking of valves for test purpose.

4.15. The valves shall be visually examined for defects onthe valve body, ralse face

servation, boltholes, bonnet area and gland packing For lubricated surfaces,

thinner shall be used to clean seating surfaces, valve Interior, and flange face.

SSEPCO Electric Power Construction Sorporaton

SEPCO DOCUMENT NAME ‘SEP-MGSE-OMSCM-O031

WFREB RE | PRoceourerorvaiverestinc | REVNO °

"AND INSTALLATION PAGE | — def

4.2 Pressure Test Execution

4.2.1 Body (Shell) Test

42:1. The valve shall be adequately supported and stable enough forthe testing

activity, Thevalve shall be ina partially open position during water fling

It shall be filed until water flows out from the highest point.

42.12 Close the highest vent point when all trap air has been released,

42.13 Pressurize he system gradually as 25%, 75%, and 100% of the required

test pressure. Pressure shall be increased with at least 2 minutes hold at

teach step te permitinspection for leaks.

42.14 Close the isolation valve of the test manifold and disconnect the pressure

hose when the test pressure is achieved.

42.15 Observe the pressure gage reading.

85 minutes duration. Check for leaks.

‘it drops or ifit is maintained within

42.1.6 leaks occur, depressurize the system prior to repair or tightening

activity,

42.1.7 Aer the system has been checked and ifno leaks are found, ask the

approval from Aramco PID to verify If the test is cleared and if the

Adepressuriation can proceed.

42.18 Slowly depressurize the valve through vent and allow the pressure to be

at least § psi until it reaches zero which means that all water has

been removed.

42.2 SeatLeak Test

42.2.4. The valve siall be adequately supported and stable enough for the testing

Activity, The valve shal bein a fully closed position

422.2 Install blanking ange at one end of the valve. The other side shall not be

Dilinded.

42.23 Itshallbe filled until water flows out from the highest vent point.

42.24 Close the highest vent point when all rap alrhas been released.

42.2.8 Pressurizethe system gradually as 2596, 7596, and 100% of the required test

pressure. Pressure shall be increased with atleast 1 minute hold at each

‘sep to permit inspection fo leaks,

'SEPUU Elecine Power Construction Corporation:

[ SEPCO | _vocuentwaue | sevueeecusonsns

Wee PROCEDURE FOR VALVE TESTING. REV.NO- °

{AND INSTALLATION [pase | soe

4226 Check forleaks atthe seat

42.24 Close the isolation valve ofthe test manifold and disconnect the pressure

hhose when the test pressure is achieve.

4225 Observe the pressure gage reading iit drops or ift is maintained within

‘2 minutes duration. Check for leaks.

422.6 Ifleaks occur, depressurize the system prior to repair or tightening

activity,

42.2.7 After the system has been checked and ifn leaks are found, ask the

approval from Aramco PID to verify if the test is cleared and if the

depressurization can proceed,

42.28 Slowly depressurize the valve through vent and allow the pressure to be

at least § psi until it reaches zero which means that all water has been

removed

42.29 Remove the blanking Nange, clean and dry. Close the valve. Install

‘temporary protectors onthe valve flanges.

5, STORAGE AND PRESERVATION OF VALVES

5a

52

53

‘After test fluid has been drained and dried, machined surfaces of valves shall

bbe coated with alight film of high viscosity rust inhibiting ol. This oil

shall not runoff and will not become fluid at temperatures beloe 80 °C.

LUV resistant plastic covers shal be fitted for flanged valves with NPS2" and

smaller

Plywood covers shal be used for valve end flanges for other sizes. A cover

with thickness of at least 10 mm shall be used for used for valves up to NPS.

410" and 12 mm thickness for valves NPS 12" and larger. This cover shall be

attached by using a minimum of four bolts for NPS 10" size and eight bolts

for NPS 12" and larger. The diameter of bot shall not be less than % size of

the lange bolt hoe.

6. INSTALLATION OF VALVES

61

62.

Prior to installation of valves, Check the orientation of valve as per Isometric

‘and PAID drawings to make sure that flow direction is as per required.

Specifications for bolts, nuts, and gaskets shall be as per Bill of Materials of

Isometric Drawing or a specified by the manufacturer. Valve tags shall be

inspected to easly identify the valves

‘SEPCO Electric Power Construction Corporation

SEPCO DOCUMENT NAME EP MOSE-CM-Se¥.0091

LWW FR EB BB | PROCEDURE FOR VALVE TESTING. REV.NO- °

‘AND INSTALLATION os

‘G3 For manual operated valves, Check for damage and defects on the flange face

ofthe valve and the serration ofthe raise face. Also, check thatthe stem has is

‘in good condition and that fully open and fully closed operation can be done

with ease

{644 For instrument operated valves, inspec: for any damage on the instrument

and apply preservation by covering the electrical parts. Also, check for

damage and defects on the flange face ofthe valve and the serration of the

raise face,

65 During installation, The alignment ofthe alve must be observed such thatthe

boltcan pass thoroughiy between the bolt holes ofthe ange for pipingand the

flange ofthe valve.

6.6 The gasket must be checked for any defects and must be verified as never been.

used prior to installation. Implement proper bol torquing sequence and

procedure to ensure that the flange is tightened properly

7. INSPECTION & QUALITY RECORDS

‘+ All stages of work shall be inspected and documented in accordance with the

‘Approved Project Quality Control Inspection Plan are as follows:

1) SAICL-2041 - Storage and Preservation of Valves

2} SAIGI-2042 - Field Pressure Testing of Valves

3) SAIC-1-2043 - Valve Installation and Inspection

4) SAIC-A-2001 - In-line Testing of Valves

5) SATR-A-2001-V- Pressure Test Report (Valve Inspection and

Testing)

8. SAFETY PRECAUTIONS

* Safety officer will monitor all required safety precautions during testing

+ Proper barricade in the working area shall be done

+ All safety precautionary signboards must be visibly posted,

‘Ensure that only authorized personnel are working within the area

‘SEPCO Electric Power Construction Corporation

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Applicable Codes & Standards For Aramco Projects (Piping)Document107 pagesApplicable Codes & Standards For Aramco Projects (Piping)momin100% (9)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Hydrostatic Testing ProcedureDocument7 pagesHydrostatic Testing Proceduremomin100% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Non-Conformance Control ProcedureDocument12 pagesNon-Conformance Control Proceduremomin100% (1)

- IMS ManualDocument6 pagesIMS ManualmominNo ratings yet

- Management Review 2020Document2 pagesManagement Review 2020mominNo ratings yet

- Alf Piping 117 009Document6 pagesAlf Piping 117 009mominNo ratings yet

- Project Quality Plan (JFJS-788)Document18 pagesProject Quality Plan (JFJS-788)mominNo ratings yet

- Part.1 Issued For Construction (Fire Protection)Document322 pagesPart.1 Issued For Construction (Fire Protection)mominNo ratings yet

- Saic-H-2029Document12 pagesSaic-H-2029mominNo ratings yet

- Ba090205 001Document1 pageBa090205 001mominNo ratings yet

- Magnetic Particle Testing ProcedureDocument11 pagesMagnetic Particle Testing ProceduremominNo ratings yet

- Ba090211 005Document1 pageBa090211 005mominNo ratings yet

- 0001Document1 page0001mominNo ratings yet

- Saudi Aramco Inspection Checklist: Re-Instatement of Air Cooled Heat Exchanger SAIC-E-2008 15-Nov-17 MechDocument5 pagesSaudi Aramco Inspection Checklist: Re-Instatement of Air Cooled Heat Exchanger SAIC-E-2008 15-Nov-17 MechmominNo ratings yet

- Satr-H-2006 3.3Document3 pagesSatr-H-2006 3.3mominNo ratings yet

- Mgse T Sep Sa 0029Document1 pageMgse T Sep Sa 0029mominNo ratings yet

- Saic-H-2028Document11 pagesSaic-H-2028mominNo ratings yet

- Saic-H-2027Document3 pagesSaic-H-2027momin0% (1)

- Saic-H-2030Document9 pagesSaic-H-2030mominNo ratings yet

- Saudi Aramco Inspection Checklist: Storage Handling & Presevation of Heat Exchangers. SAIC-E-2003 15-Nov-17 MechDocument7 pagesSaudi Aramco Inspection Checklist: Storage Handling & Presevation of Heat Exchangers. SAIC-E-2003 15-Nov-17 MechmominNo ratings yet

- Saudi Aramco Inspection Checklist: Inspect Assembly of Air-Cooled Heat Exchanger ComponentsDocument12 pagesSaudi Aramco Inspection Checklist: Inspect Assembly of Air-Cooled Heat Exchanger ComponentsmominNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 15-Nov-17 MechDocument13 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 15-Nov-17 MechmominNo ratings yet

- Saudi Aramco Inspection Checklist: Nitrogen and Pearlite Application On BAHE Frame SAIC-E-2011 15-Nov-17 MechDocument1 pageSaudi Aramco Inspection Checklist: Nitrogen and Pearlite Application On BAHE Frame SAIC-E-2011 15-Nov-17 MechmominNo ratings yet

- Saudi Aramco Inspection Checklist: Internal Cleanliness Inspection of Heat Exchangers SAIC-E-2009 15-Nov-17 MechDocument3 pagesSaudi Aramco Inspection Checklist: Internal Cleanliness Inspection of Heat Exchangers SAIC-E-2009 15-Nov-17 MechmominNo ratings yet

- SATIP-S-060-08 Rev 8 Copper Piping FinalDocument2 pagesSATIP-S-060-08 Rev 8 Copper Piping FinalmominNo ratings yet

- SATIP-S-030-01, Rev 8 Storm Water Drainage System G FinalDocument3 pagesSATIP-S-030-01, Rev 8 Storm Water Drainage System G Finalmomin0% (1)

- Saudi Aramco Inspection Checklist: Review of SIS For Air Cooled Heat Exchanger SAIC-E-2004 15-Nov-17 MechDocument8 pagesSaudi Aramco Inspection Checklist: Review of SIS For Air Cooled Heat Exchanger SAIC-E-2004 15-Nov-17 MechmominNo ratings yet

- SATIP-S-060-02 Rev 8 Electric Drinking Water Coolers FinalDocument2 pagesSATIP-S-060-02 Rev 8 Electric Drinking Water Coolers FinalmominNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanmominNo ratings yet

- SATIP-S-060-04 REV 8 Plumbing Fixtures and Fittings FinalDocument2 pagesSATIP-S-060-04 REV 8 Plumbing Fixtures and Fittings FinalmominNo ratings yet