Professional Documents

Culture Documents

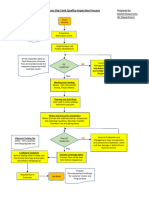

Flow Chart of Receiving Operation Process

Uploaded by

Khawarizmi SuraniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flow Chart of Receiving Operation Process

Uploaded by

Khawarizmi SuraniCopyright:

Available Formats

Document Number

XIN XIN ENGINEERING QC - 001

SDN BHD Effective Date 16/05/23

Page Number 1

Document Name : Quality and Process Control

Flow Chart of

Receiving Operation Procedure

Start

Receiving Invoice / DO / COA

and Issue to QC Receiving

No Urgent Yes

Release?

Perform QC No

Receive Final Approved

Drawing from Inspection like

Dimension Check, Repair, Reweld or by QC

Engineering Head?

Head Pressure Test, Modify the FAILED

Welding & REJECTED ITEM

Workmanship and

Visual Check Yes

Mark and Indicate

All the "Urgent Release" on

inspection data the Inspection

recorded inside Report and the

the Inspection Any Urgent Item.

Report for PASS Defect?

and FAIL results

No Yes Collect sample for

Inspection

Product Marking and Labelling Indicate

Details: "FAILED/REJECTED"

1) Identification Code status on the Item

- Name of Item short form using Paint Spray,

Any No

- Contractor Incharge Paint Marker and

- Sample Number Sticker Defect?

- Inspection Date (Month and Year)

ex: LATT A0001 0523

Yes

Issue Rejected Item to Hold and Indicate

Indicate QC PASSED/QC TESTED Supplier and raise VCAR "FAILED/REJECTED

status on the Item using Paint Spray, (Vendor Corrective Action status on Item

Paint Marker and Sticker Requisition

Prepare Retain Quality Record

Documentation/Certificate

for customer review and

filing purpose

End

Acknowledged By Approved By Checked By Prepared By

Mr Lim Mohd Khawarizmi

You might also like

- Work Inspection Process FlowchartDocument16 pagesWork Inspection Process Flowchartdavethiyagu100% (4)

- Risk Assessment Internal Quality AuditDocument2 pagesRisk Assessment Internal Quality AuditSheila Marie Gil-VersozaNo ratings yet

- QAD Procedure - Control of Inspection, Measuring & Test Equipment P2Document1 pageQAD Procedure - Control of Inspection, Measuring & Test Equipment P2sumanNo ratings yet

- Top Management Audit Questions for ISO 9001Document1 pageTop Management Audit Questions for ISO 9001dnmuleNo ratings yet

- Final Inspection Report SummaryDocument2 pagesFinal Inspection Report SummarySK Mishra100% (1)

- Competence MatrixDocument4 pagesCompetence MatrixvkeertiNo ratings yet

- QMS Risk & Opportunity RegisterDocument4 pagesQMS Risk & Opportunity Registernaveen yadavNo ratings yet

- Cis-Sp-18-Customer Complaints HandlingDocument5 pagesCis-Sp-18-Customer Complaints HandlingVaibhav Gadhawe100% (1)

- ORA-LAB.4.3 Document Control and Management (v02)Document9 pagesORA-LAB.4.3 Document Control and Management (v02)rajesh sharmaNo ratings yet

- Quality Manual - VVRDocument67 pagesQuality Manual - VVRRajamani100% (2)

- Change Control Alaxan FR Capsule 2020Document6 pagesChange Control Alaxan FR Capsule 2020Rio FebriansyahNo ratings yet

- Calibration Process Audit ExampleDocument1 pageCalibration Process Audit ExampleMuhammad Alief OthmanNo ratings yet

- NCR Flow ChartDocument1 pageNCR Flow ChartPramod AthiyarathuNo ratings yet

- 9001 Audit Checklist-Monitoring Measurement and ImprovDocument7 pages9001 Audit Checklist-Monitoring Measurement and ImprovAmer RahmahNo ratings yet

- Environmental Management System: Standard Operating ProcedureDocument4 pagesEnvironmental Management System: Standard Operating ProcedureMohammed AffrozeNo ratings yet

- Chopra Industries (P) Ltd.-Unit-Iv: Quality Management System ProcedureDocument5 pagesChopra Industries (P) Ltd.-Unit-Iv: Quality Management System ProcedureShankar ChowdhuryNo ratings yet

- Sample Updated IQA Check Sheet.Document16 pagesSample Updated IQA Check Sheet.ashwaniNo ratings yet

- Identification of Aspects & ImpactsDocument15 pagesIdentification of Aspects & Impactsvindice flameNo ratings yet

- TD-HSE-FORM-003 Supplier Evaluation FormDocument4 pagesTD-HSE-FORM-003 Supplier Evaluation FormDamalie100% (1)

- ETS QMS documentation standardizationDocument3 pagesETS QMS documentation standardizationfnaik100% (2)

- Process Control ProcedureDocument12 pagesProcess Control ProcedureGrazel MDNo ratings yet

- Internal Quality Audit ProcessDocument4 pagesInternal Quality Audit ProcessJennylyn Favila MagdadaroNo ratings yet

- Merchandising Department Quality Objectives for 2009Document3 pagesMerchandising Department Quality Objectives for 2009huysymNo ratings yet

- Supplier Audits and SurveysDocument13 pagesSupplier Audits and SurveysBighneswar PatraNo ratings yet

- Precast PCFQA AuditDocument14 pagesPrecast PCFQA AuditNguyễn Thanh Cường100% (2)

- Control of Noncomformitiy and Corrective Action PDFDocument7 pagesControl of Noncomformitiy and Corrective Action PDFNixNo ratings yet

- Annex A Nonconformity ReportsDocument8 pagesAnnex A Nonconformity ReportsGodwin A.udo-akanNo ratings yet

- 8.7 Control of Nonconforming Process Outputs, Products, and ServiceDocument2 pages8.7 Control of Nonconforming Process Outputs, Products, and ServiceNavnath TamhaneNo ratings yet

- PQP Rev. 6 Holy Mosque Extension of King Abdullah ProjectDocument136 pagesPQP Rev. 6 Holy Mosque Extension of King Abdullah ProjectVacume Emucav100% (3)

- UNIDO's Step-by-Step GMP Roadmap for Developing CountriesDocument24 pagesUNIDO's Step-by-Step GMP Roadmap for Developing Countriesiabureid7460No ratings yet

- QAD Procedure - Corrective Action P2Document1 pageQAD Procedure - Corrective Action P2sumanNo ratings yet

- Iqa Audit Checklist Form 4 EempsdDocument22 pagesIqa Audit Checklist Form 4 EempsdRonald PreNo ratings yet

- Tcsi Quality Plan: One Ayala Avenue Project Makati City, Metro ManilaDocument20 pagesTcsi Quality Plan: One Ayala Avenue Project Makati City, Metro ManilaEugene Santiago PadillaNo ratings yet

- Quality Management ProgramDocument31 pagesQuality Management ProgramBibo RamirezNo ratings yet

- Change Request Flow ChartDocument1 pageChange Request Flow ChartRabab BINo ratings yet

- Turtle Diagram & Its Usage in ISO 9001Document4 pagesTurtle Diagram & Its Usage in ISO 9001Gopalakrishnan100% (1)

- Change Control Management SOP PDFDocument7 pagesChange Control Management SOP PDFPrashansa ShresthaNo ratings yet

- Quality Manual: ISO/TS 16949:2009 Quality Management SystemDocument47 pagesQuality Manual: ISO/TS 16949:2009 Quality Management Systemluismi081300No ratings yet

- Non Conformance ReportDocument1 pageNon Conformance ReportchandraNo ratings yet

- Inspection ProcedureDocument1 pageInspection ProcedureManu SharmaNo ratings yet

- Risk-Opportunities Identification-Evalaution Sheet CED2Document3 pagesRisk-Opportunities Identification-Evalaution Sheet CED2Seph PasagNo ratings yet

- Esic Case StudyDocument8 pagesEsic Case StudyNishant BaroliaNo ratings yet

- IMS-P-10 Communication, Consulation & ParticipationDocument6 pagesIMS-P-10 Communication, Consulation & Participationjogender kumarNo ratings yet

- Controlled Documents' Masterlist of EPSA CentralDocument85 pagesControlled Documents' Masterlist of EPSA CentralGetahunNo ratings yet

- Quality Evaluation, Problem and Follow Up Results Pdca FormatDocument1 pageQuality Evaluation, Problem and Follow Up Results Pdca FormatPk Nimiwal100% (1)

- ISO/TS 16949:2009 Checklist - QWBT Issue: Ref. Question CommentsDocument40 pagesISO/TS 16949:2009 Checklist - QWBT Issue: Ref. Question CommentsleadyourlifeNo ratings yet

- Risk Assessment Registry SAMPLEDocument2 pagesRisk Assessment Registry SAMPLERTL JRNo ratings yet

- Procedures Manual 8-31-07Document36 pagesProcedures Manual 8-31-07vabimhahNo ratings yet

- Quality Manual RS QMS 002Document11 pagesQuality Manual RS QMS 002WayneNo ratings yet

- Change Log TemplateDocument3 pagesChange Log TemplatedrustagiNo ratings yet

- Customer Feedback FormDocument2 pagesCustomer Feedback FormSelamat Ndt50% (2)

- Check List - Product Realisation ProcessDocument4 pagesCheck List - Product Realisation ProcessDisha ShahNo ratings yet

- Internal Audit - KRA and KPIDocument2 pagesInternal Audit - KRA and KPIMaria Rona SilvestreNo ratings yet

- Can You Provide Some Examples of Quality Objectives For An Organization?Document1 pageCan You Provide Some Examples of Quality Objectives For An Organization?balusandeep20No ratings yet

- Environmental Audit Report For Z TanneryDocument56 pagesEnvironmental Audit Report For Z Tanneryhami2pkNo ratings yet

- Construction Non-Compliance Notice in AfghanistanDocument1 pageConstruction Non-Compliance Notice in AfghanistanRohullah AkhtarNo ratings yet

- TTC Audit Committee Report No.: Information ItemDocument16 pagesTTC Audit Committee Report No.: Information Itemrakeshsharmaji1972No ratings yet

- Quality Risk Management Plan SummaryDocument9 pagesQuality Risk Management Plan Summarysakib445No ratings yet

- S.O 729 and S.O.730 Dated 21-08-1995-SDocument48 pagesS.O 729 and S.O.730 Dated 21-08-1995-SParmod SiwachNo ratings yet

- Process Tank Flow ChartDocument1 pageProcess Tank Flow ChartKhawarizmi SuraniNo ratings yet

- Salerio SlidesCarnivalDocument39 pagesSalerio SlidesCarnivalGihan VialinNo ratings yet

- Age Of Empires III guide with keys, screenshots & downloadDocument2 pagesAge Of Empires III guide with keys, screenshots & downloadRamon_sjcNo ratings yet

- EAC (External Alarm Cable) + FSEE Rev.3 (Security Belt)Document27 pagesEAC (External Alarm Cable) + FSEE Rev.3 (Security Belt)Reffangga Ajib YPNo ratings yet

- R8124B MJTW01Document150 pagesR8124B MJTW01Rinda_RaynaNo ratings yet

- #5 - Volcanoes Lab Activity-F23 VersionDocument18 pages#5 - Volcanoes Lab Activity-F23 Versionmwaimoffat100% (1)

- Calculus ReflectionDocument2 pagesCalculus Reflectionapi-341195901No ratings yet

- SpaceClaim DocumentationDocument1,291 pagesSpaceClaim DocumentationV CafNo ratings yet

- Before Ulte - Vilmut - BKSDocument171 pagesBefore Ulte - Vilmut - BKSWahyoe AryaNo ratings yet

- Erc Qualification Standards: Position SG Education Experience Training Eligibiliy Additional Requirements Accountant IIIDocument9 pagesErc Qualification Standards: Position SG Education Experience Training Eligibiliy Additional Requirements Accountant IIIArafat BauntoNo ratings yet

- India Edition OM Best Practice Guidelines 1Document132 pagesIndia Edition OM Best Practice Guidelines 1Abhishek P100% (3)

- JQ1-24F Ds 61B03 en jq-469944Document7 pagesJQ1-24F Ds 61B03 en jq-469944NobodyNo ratings yet

- Shruti Assignment 2Document25 pagesShruti Assignment 2Shruti SuryawanshiNo ratings yet

- B.E. EeeDocument92 pagesB.E. Eeessathishkumar88No ratings yet

- MySQL SQL Injection Cheat SheetDocument3 pagesMySQL SQL Injection Cheat SheetAbhijit ChatterjeeNo ratings yet

- Ral Stainer: The RAL Automated Staining SystemDocument49 pagesRal Stainer: The RAL Automated Staining SystemShoaib AhmedNo ratings yet

- Pointers: M. Usman GhousDocument34 pagesPointers: M. Usman GhousMalik Farrukh RabahNo ratings yet

- Unit 11Document3 pagesUnit 11Yevhenii TkachenkoNo ratings yet

- Guideline-For-Regular (Summer) Exam 2021 B. PharmacyDocument1 pageGuideline-For-Regular (Summer) Exam 2021 B. PharmacyBHRUJ PATELNo ratings yet

- EPFO - Collect Online Claim ReceiptDocument2 pagesEPFO - Collect Online Claim ReceiptAJAY KUMAR26100% (1)

- Stolyarov Mathematical EconomicsDocument35 pagesStolyarov Mathematical EconomicslordkesNo ratings yet

- Gundarks Fantastic Technology Personal Gear WEG40158 PDFDocument114 pagesGundarks Fantastic Technology Personal Gear WEG40158 PDFPed_exing100% (3)

- Turbo Code Encoder Structure and PerformanceDocument6 pagesTurbo Code Encoder Structure and PerformancematildaNo ratings yet

- RKB00001 PSRPT 2019-02-22 17.08.54 PDFDocument12 pagesRKB00001 PSRPT 2019-02-22 17.08.54 PDFyori cristiyaNo ratings yet

- Ergonomic Design For People at Work PDFDocument2 pagesErgonomic Design For People at Work PDFMarkNo ratings yet

- Eh600 A Series 2Document92 pagesEh600 A Series 2Nguyễn Đình Bảo KhangNo ratings yet

- Microprocessor Lecture Notes 1 10Document202 pagesMicroprocessor Lecture Notes 1 10Ambarish SinghNo ratings yet

- Crash 2023 10 18 - 23.04.30 ClientDocument8 pagesCrash 2023 10 18 - 23.04.30 Clientfish96716No ratings yet

- Development and Control of Virtual Plants in A Co Simulation Environment 1Document35 pagesDevelopment and Control of Virtual Plants in A Co Simulation Environment 1Laura Maria RodriguezNo ratings yet

- Fox ESS K Series Datasheet 3.22Document2 pagesFox ESS K Series Datasheet 3.22iandcNo ratings yet

- Get Modern Deploy and Maintain Guidance With Windows11Document28 pagesGet Modern Deploy and Maintain Guidance With Windows11bberry100% (1)