Professional Documents

Culture Documents

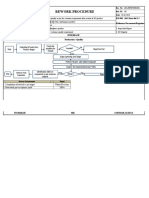

Process Tank Flow Chart

Uploaded by

Khawarizmi SuraniCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Tank Flow Chart

Uploaded by

Khawarizmi SuraniCopyright:

Available Formats

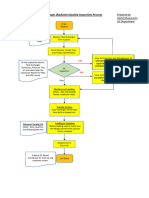

Flow Chart of Process Dip Tank Quality Inspection Process Prepared by

Mohd Khawarizmi

QC Department

Order

Receive

Receive Final

Drawing from Production

Engineering Head (Fabrication Start)

Code Number and

Project Identification

All the inspection data ex:

Tank Dimension, Pressure

Test all recorded inside the Fail Issue to Production and

QC

Inspection Report for PASS Management if any leaking and

Inspection

and FAIL results any defect found. Repair, rework

and modify according to the actual

design and specification.

Pass

Marking and Labelling

Details : (QC Checked/QC

Tested, Project Name).

Cleaning and Acid Wash

Acid used to clean welding

mark and rusty part.

Motor and Acessories Installation

Motor (Full set with shaft and stirrer. Accessories

like Jacketing Insulation, Pipe Cap, Impeller,

Overflow Tray and Spring Hose.

Shipment Packing List Final QC Fail Issue to Production and

Detail : Item, Quantity Inspection Management if got wrong motor

and Shipping Date line and accessories installation. Same

as if any damage or defect found.

Pass Need to rework.

Loading to Container

Before loading need to make sure Transfer to Storage Space

the correct tank type and project Process Tank will be kept

according to Shipping List. here before shipped out.

Prepare

Documentation/Certificate

Shipped Out to

Job Done for customer review and

Customer

filing purpose

You might also like

- Heat Exchanger (Radiator) Flow ChartDocument1 pageHeat Exchanger (Radiator) Flow ChartKhawarizmi SuraniNo ratings yet

- Bottom Thermal Insulation (Washing Tank) Flow ChartDocument1 pageBottom Thermal Insulation (Washing Tank) Flow ChartKhawarizmi SuraniNo ratings yet

- Flow Chart of Receiving Operation ProcessDocument1 pageFlow Chart of Receiving Operation ProcessKhawarizmi SuraniNo ratings yet

- Buffco Eng AS9100 Quality Manual 2-28-06Document26 pagesBuffco Eng AS9100 Quality Manual 2-28-06savlafNo ratings yet

- CDP RDC Ar Mal Qac 0001Document5 pagesCDP RDC Ar Mal Qac 0001ElvinNo ratings yet

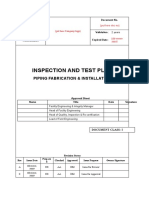

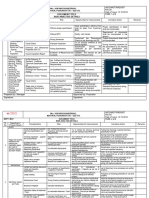

- Inspection and Test Plan 2 PDF FreeDocument3 pagesInspection and Test Plan 2 PDF FreeaefNo ratings yet

- PEIPL-SOP-01 For Incoming Material Insp.Document1 pagePEIPL-SOP-01 For Incoming Material Insp.Balkishan DyavanapellyNo ratings yet

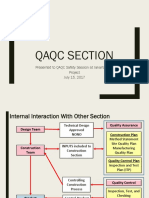

- QAQC Section PresentationDocument17 pagesQAQC Section PresentationWildan Al BaihaqiNo ratings yet

- VERVE RESIDENCES PLUMBING INSPECTION TEST PLANDocument3 pagesVERVE RESIDENCES PLUMBING INSPECTION TEST PLANEdNo ratings yet

- Aqp Flow FmeaDocument2 pagesAqp Flow FmeaqmsnorthNo ratings yet

- Design-Qualification-Protocol-cum-Report-for-Lifting-Positioning-DeviceDocument12 pagesDesign-Qualification-Protocol-cum-Report-for-Lifting-Positioning-Devicesantosh yadavNo ratings yet

- Ray Itp For PaitingDocument18 pagesRay Itp For PaitingVinayaga MoorthiNo ratings yet

- Itp Electrical CheweeDocument2 pagesItp Electrical CheweeRonnel Dean LimNo ratings yet

- Copia de Process SignoffDocument1 pageCopia de Process SignoffpaoaleNo ratings yet

- Itp PipingDocument15 pagesItp PipingEkhy Transmisi100% (1)

- Customer Process Design FlowchartDocument1 pageCustomer Process Design FlowchartBharath100% (1)

- Itp FormatDocument8 pagesItp FormatAhmed KassemNo ratings yet

- Mannan Shahid Forgings Presentation OverviewDocument29 pagesMannan Shahid Forgings Presentation OverviewbhimraNo ratings yet

- In Process Inspection Stage Flow Chart: Spacechem EnterprisesDocument6 pagesIn Process Inspection Stage Flow Chart: Spacechem EnterprisesSourav SharmaNo ratings yet

- Qality Assurance Inspection and Test Plan: Piping Fabrication & InstallationDocument16 pagesQality Assurance Inspection and Test Plan: Piping Fabrication & Installationmanoj thakkarNo ratings yet

- QCR W 2036Document1 pageQCR W 2036Madhan KannanNo ratings yet

- Pumps ItpDocument3 pagesPumps Itpkokod9757No ratings yet

- QAD Procedure - Control of Non-Conforming Products P2Document2 pagesQAD Procedure - Control of Non-Conforming Products P2sumanNo ratings yet

- Work Flow DCMTestingDocument6 pagesWork Flow DCMTestingapi-3738458No ratings yet

- 1.mechanical - Electrical Completion Inspection Checklist - E20812Document3 pages1.mechanical - Electrical Completion Inspection Checklist - E20812Lulu ChaniagoNo ratings yet

- Installation of Static EquipmentsDocument5 pagesInstallation of Static Equipmentsmansih457No ratings yet

- As-QMS-014 in Process InspectionDocument8 pagesAs-QMS-014 in Process Inspectiondehamanez100% (1)

- QSP Qad 08Document2 pagesQSP Qad 08prabha_1No ratings yet

- Cathodic Protection ItpDocument9 pagesCathodic Protection ItpHarmalNo ratings yet

- Reference Format No.: SOP/QA/001-F01-00Document4 pagesReference Format No.: SOP/QA/001-F01-00Rahul67% (3)

- AUH QA&QC MS 01 Receiving InspectionDocument5 pagesAUH QA&QC MS 01 Receiving Inspectionsaifullah629No ratings yet

- 43 WTCA QC Manual AC10 Add On COMPLETED EXAMPLEDocument6 pages43 WTCA QC Manual AC10 Add On COMPLETED EXAMPLEAhmed GomaaNo ratings yet

- ITP - Blockwork R0 - HKHDocument2 pagesITP - Blockwork R0 - HKHabdou89% (9)

- Rework Process FlowDocument6 pagesRework Process FlowIsaac Samuel100% (1)

- INSPECTION AND TEST PLAN - Driven of Pre Cast Concrete Piles PDFDocument3 pagesINSPECTION AND TEST PLAN - Driven of Pre Cast Concrete Piles PDFmustafaNo ratings yet

- Ezhomz - Handover ProcessDocument1 pageEzhomz - Handover ProcessVishal GoyalNo ratings yet

- ET - CONCRTE GENERIC ITP - 001 - Rev0 (Prelim) 1Document2 pagesET - CONCRTE GENERIC ITP - 001 - Rev0 (Prelim) 1Sagar Aliasjackey100% (1)

- Template For Performace Qualification Protocol - Pharmaceutical GuidanceDocument4 pagesTemplate For Performace Qualification Protocol - Pharmaceutical GuidanceMIRZA AFAQ ALINo ratings yet

- Ayc Inspection Checklist: Linolium Sheet Pre - Installation Inspection Industrial Support Facilities BuildingDocument6 pagesAyc Inspection Checklist: Linolium Sheet Pre - Installation Inspection Industrial Support Facilities Buildingmoytabura96No ratings yet

- Design - Activities - 03081018 R2 PDFDocument15 pagesDesign - Activities - 03081018 R2 PDFSubhashNo ratings yet

- Shic A 0009Document1 pageShic A 000901095902062ahmedNo ratings yet

- BoeingdistribqmDocument19 pagesBoeingdistribqmVarun ZotaNo ratings yet

- IQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFDocument15 pagesIQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFAli MajeedNo ratings yet

- Missouri DOT Standard Inspection and Testing Plan Sections 200-300Document32 pagesMissouri DOT Standard Inspection and Testing Plan Sections 200-300mohamedamine.zemouriNo ratings yet

- ITPDocument32 pagesITPBenjamin ChavezNo ratings yet

- Field Quality Plan (FQP)Document2 pagesField Quality Plan (FQP)Ranjit Singh100% (3)

- Inspection and Test Plan for Fuel Oil Piping SystemDocument2 pagesInspection and Test Plan for Fuel Oil Piping Systemachusanachu100% (1)

- Tins-Gen-Itp-M-001 To 005-r00 - Mechanical Works (Logo 2)Document4 pagesTins-Gen-Itp-M-001 To 005-r00 - Mechanical Works (Logo 2)achusanachuNo ratings yet

- Development Time LineDocument1 pageDevelopment Time LineMohitrajranikashyapNo ratings yet

- SAIC-RT-2001 Revw of RT ProcedureDocument1 pageSAIC-RT-2001 Revw of RT ProcedureKirubhakarPooranamNo ratings yet

- Process Flow ChartDocument1 pageProcess Flow ChartUsama ShameerNo ratings yet

- New Installations ATA and Activity Quality Check SOP V 4.2Document22 pagesNew Installations ATA and Activity Quality Check SOP V 4.2Malik Rizwan AhmedNo ratings yet

- Inspection and Test Plan for Piping Fabrication and InstallationDocument16 pagesInspection and Test Plan for Piping Fabrication and InstallationEyoh EffiongNo ratings yet

- Curriculum Vitae of G.Ramesh in Construction FieldDocument5 pagesCurriculum Vitae of G.Ramesh in Construction FieldAmul PontingNo ratings yet

- 17 - Risk Analysis Rev-1Document5 pages17 - Risk Analysis Rev-1vinuNo ratings yet

- Make It! The Engineering Manufacturing Solution: Engineering the Manufacturing SolutionFrom EverandMake It! The Engineering Manufacturing Solution: Engineering the Manufacturing SolutionNo ratings yet

- Workshop 4 Inventory Management at PhilipsDocument5 pagesWorkshop 4 Inventory Management at PhilipsAlexanderNo ratings yet

- Final Project Sal PDFDocument75 pagesFinal Project Sal PDFSoni JigeshNo ratings yet

- DELIVERY Transfer of Risk and Transfer of TitleDocument2 pagesDELIVERY Transfer of Risk and Transfer of TitleLesterNo ratings yet

- Tacloban Master Training Schedule (Jan-June 2010)Document2 pagesTacloban Master Training Schedule (Jan-June 2010)Michael Dodger SanchezNo ratings yet

- Optimize Supply Chains with Bonded WarehousingDocument8 pagesOptimize Supply Chains with Bonded WarehousingJohannesRöderNo ratings yet

- Periodic inventory method accounting entriesDocument9 pagesPeriodic inventory method accounting entriesnicole bancoroNo ratings yet

- PWC Revenue From Contracts With CustomersDocument16 pagesPWC Revenue From Contracts With CustomersJobelyn CasimNo ratings yet

- MTM Application Form-BlankDocument6 pagesMTM Application Form-BlankIlie SarbuNo ratings yet

- What Is SAP Extended Warehouse ManagementDocument7 pagesWhat Is SAP Extended Warehouse ManagementShyamNo ratings yet

- S393 SPM Lopl Opr MS 2301 - 0Document134 pagesS393 SPM Lopl Opr MS 2301 - 0Barm FuttNo ratings yet

- Commercial Invoice: AWB No: 9620218322 Invoice Date: 2021-10-16 Invoice No: 28293641-28193400 H22A IBDocument3 pagesCommercial Invoice: AWB No: 9620218322 Invoice Date: 2021-10-16 Invoice No: 28293641-28193400 H22A IBGorgaNo ratings yet

- Law on Transportation and Public UtilitiesDocument49 pagesLaw on Transportation and Public UtilitiesJana marieNo ratings yet

- Philippine Charter Vs Unknown Owner of VesselDocument12 pagesPhilippine Charter Vs Unknown Owner of VesselZjai SimsNo ratings yet

- Psguide 2015Document83 pagesPsguide 2015laacostam93No ratings yet

- Tcodes SapDocument42 pagesTcodes SapRui AlmeidaNo ratings yet

- Manitou TMM (EN)Document16 pagesManitou TMM (EN)ManitouNo ratings yet

- Logistics & Supply Chain Management - EltahhanDocument62 pagesLogistics & Supply Chain Management - EltahhanAdnanNo ratings yet

- Train SymbolsDocument20 pagesTrain SymbolsDavid LashNo ratings yet

- Presentation To TBSB - 30 June 2015 PDFDocument13 pagesPresentation To TBSB - 30 June 2015 PDFMuzhaffar AzizNo ratings yet

- Transpo Case DigestsDocument19 pagesTranspo Case Digests'Elainne EncilaNo ratings yet

- Public Act No. 521 Carriage of Goods by Sea ActDocument7 pagesPublic Act No. 521 Carriage of Goods by Sea ActIah LincoNo ratings yet

- DHL StrategyDocument7 pagesDHL StrategyMoumita Dutta100% (1)

- WarehousingDocument4 pagesWarehousingMarcus Hah Kooi YewNo ratings yet

- Torres Madrid vs. FEBDocument4 pagesTorres Madrid vs. FEBJustin Luis JalandoniNo ratings yet

- Projectplan Design LNG NetworksDocument59 pagesProjectplan Design LNG Networkswaking_daysNo ratings yet

- 2015 Kyokushin Price ListDocument51 pages2015 Kyokushin Price ListArtur RodasNo ratings yet

- Financial Accounting and Reporting: INVENTORIES (Part 1Document9 pagesFinancial Accounting and Reporting: INVENTORIES (Part 1DyenNo ratings yet

- Deck Stowage and Securing of PipesDocument5 pagesDeck Stowage and Securing of PipesLucero LunaNo ratings yet

- Good and Bad DocumentsDocument4 pagesGood and Bad Documentsapi-4387598700% (1)

- Fentek CatalogueDocument95 pagesFentek Cataloguejbloggs2007No ratings yet