Professional Documents

Culture Documents

M Bac 000000 GH00 Mem 000046

Uploaded by

manuel agostinhoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

M Bac 000000 GH00 Mem 000046

Uploaded by

manuel agostinhoCopyright:

Available Formats

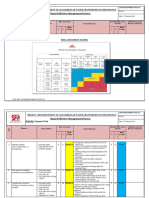

PROJECT HS&E BULLETIN

Riyadh Metro Project

No. 042

Document No. M-BAC-000000-GH00-MEM-000046 11 January 2015

Hazards with Manual Handling of Heavy Objects

On a non-BACS project a group of seven workers were involved in offloading chemical drums (200

Kg) from a truck. The workers were not provided suitable mechanical lifting equipment for the

task. The supervising foreman instructed the employees to manually handle the drums from the

truck to the ground. Four workers were handling the last drum and about to place it on the

ground. One of the workers did not remove his fingers in time and they were squashed under the

base rim of the drum.

Direct and Indirect Causes:

No lifting equipment provided

Unsafe work procedure set up by the Foreman

Fear of reporting the unsafe practice and resulting consequences by the

workers

Lack of communication between workers while handling the drum

Poor manual handling and no appreciation of the ‘safe’ load to lift,

double the 25kg limit.

Lack of other options explored by the Foreman, e.g. rolling the barrels

with rope restraints

Lack of hazard awareness by the foreman

Lack of Safety culture on the site

No STARRT card used

No risk assessment conducted

Mitigating Measures:

Site supervision must know and follow safe work practices; e.g. Construction HS&E Toolkit.

Proper training on hazard identification to be given to the workers, safe material handling.

Risk assessment for unloading barrels to be conducted and method

statement used.

Lifting equipment to be provided when the task requires it to avoid

manual handling of heavy objects.

Work Zone Managers to reinforce the Safety culture.

Section Heads and Site Engineers shall ensure that all work groups

under their supervision are equipped and perform their duties in a safe

manner.

Procedure Reference:

M-BCW-000000-GH00-PRO-000009, Manual Material Handling

You might also like

- TBT LogDocument9 pagesTBT LogfatehNo ratings yet

- SWP 04 Lifting OperationDocument4 pagesSWP 04 Lifting Operationমমিন মানবNo ratings yet

- Cranes and HoistsDocument3 pagesCranes and HoistsAditya Raj MishraNo ratings yet

- Lifting and Hoisting: Fabrication Site Construction Safety Recommended Practice - Hazardous ActivitiesDocument3 pagesLifting and Hoisting: Fabrication Site Construction Safety Recommended Practice - Hazardous ActivitiesjoosuasinagaNo ratings yet

- 2020 06 - SAFETY ALERT - Unsafe RiggingDocument1 page2020 06 - SAFETY ALERT - Unsafe RiggingzaimNo ratings yet

- TSK5UG GWO BST Manual Handling: The National Access and Rescue CentreDocument29 pagesTSK5UG GWO BST Manual Handling: The National Access and Rescue Centreromedic36No ratings yet

- JSA-Loading UnloadingDocument2 pagesJSA-Loading Unloadingsubhanmusadiq82% (55)

- OHDC Lifting ProcedureDocument12 pagesOHDC Lifting ProcedureHamid Ali100% (1)

- E 29 GP 002 Lifting and Hoisting RecordingDocument12 pagesE 29 GP 002 Lifting and Hoisting RecordingIbama MirillaNo ratings yet

- COP 29 Lifting Equipment and MachineryDocument17 pagesCOP 29 Lifting Equipment and MachineryTuvshindalai GanbatNo ratings yet

- Safety Alert: Crane Lifting Operation Results in A FatalityDocument2 pagesSafety Alert: Crane Lifting Operation Results in A FatalityIsaac AnthonyNo ratings yet

- Safety Alert: "Struck By" Incident Results in Leg InjuryDocument1 pageSafety Alert: "Struck By" Incident Results in Leg InjurycbalavivekanandanNo ratings yet

- CH 13 Materials Handling and StorageDocument18 pagesCH 13 Materials Handling and Storagezahid_497No ratings yet

- Safe Lifting Operations in The WorkplaceDocument14 pagesSafe Lifting Operations in The WorkplacetlalovićNo ratings yet

- COP 29 Lifting Equipment and MachineryDocument21 pagesCOP 29 Lifting Equipment and MachineryJacques ScheepersNo ratings yet

- IMCASF - Sept 20Document6 pagesIMCASF - Sept 20Shivkumar JadhavNo ratings yet

- 2 - 15 Lifting & Supporting LoadsDocument8 pages2 - 15 Lifting & Supporting LoadsRuhul YaminNo ratings yet

- SWP 025 Mechanical Lifts and Suspended LoadsDocument3 pagesSWP 025 Mechanical Lifts and Suspended Loadsknabpsho100% (1)

- Lessons Learned - RWC - Marunda - 2 Jul 2015Document1 pageLessons Learned - RWC - Marunda - 2 Jul 2015Anonymous cKdbnUHNo ratings yet

- Quick Start Summary 1 Who Needs To Know About These RequirementsDocument58 pagesQuick Start Summary 1 Who Needs To Know About These Requirementsjapv_pasNo ratings yet

- Manual Handling WeightsDocument21 pagesManual Handling Weightsbatfink182100% (1)

- Safety Alert: Offloading Pipe HazardsDocument1 pageSafety Alert: Offloading Pipe HazardsTFattahNo ratings yet

- 1760 - RA - 010 - Risk Assessment - Installation of Electrical Equipment and Panels 26FEB15Document8 pages1760 - RA - 010 - Risk Assessment - Installation of Electrical Equipment and Panels 26FEB15NirmalKumarSelvarajNo ratings yet

- IMCASF - Sept 20Document6 pagesIMCASF - Sept 20Shivkumar JadhavNo ratings yet

- Batch PlantDocument11 pagesBatch PlantJupiterN-hNo ratings yet

- Workers Finger Pinched While Working On Tool in RackDocument2 pagesWorkers Finger Pinched While Working On Tool in RackShafri ArifinNo ratings yet

- Risk Assess T-07 - Mobile Crane OperationsDocument2 pagesRisk Assess T-07 - Mobile Crane OperationsMAB AliNo ratings yet

- OHSA Guidance Use of Excavators For Lifting OpsDocument6 pagesOHSA Guidance Use of Excavators For Lifting Opscrane zona10No ratings yet

- JSA Loading UnloadingDocument3 pagesJSA Loading UnloadingRajendra100% (1)

- Jsa For Pre-Cast Column ErectionDocument19 pagesJsa For Pre-Cast Column ErectionKhuda BukshNo ratings yet

- IMCA Safety Flash 09/19Document4 pagesIMCA Safety Flash 09/19Harman SandhuNo ratings yet

- Lifting Hazards & Crane SafetyDocument26 pagesLifting Hazards & Crane SafetynincatNo ratings yet

- IMCASF - Aug 17Document7 pagesIMCASF - Aug 17Shivkumar JadhavNo ratings yet

- HiraDocument11 pagesHiraNilamSanjeev Kumar SinghNo ratings yet

- Liftingoperationsafetyppt 230220111908 487c851eDocument39 pagesLiftingoperationsafetyppt 230220111908 487c851emamuNo ratings yet

- December 2019 Worker Killed During Lifting OperationDocument3 pagesDecember 2019 Worker Killed During Lifting OperationStephen TanNo ratings yet

- 03.safety Campaign March 2022 - LiftingDocument5 pages03.safety Campaign March 2022 - LiftingHSE99 BHDCNo ratings yet

- Guidebook For Lifting Supervisors PDFDocument13 pagesGuidebook For Lifting Supervisors PDFBeste Ardıç Arslan100% (1)

- RISK ASSESSMENT - Carpentry WorkDocument6 pagesRISK ASSESSMENT - Carpentry WorkbalajiNo ratings yet

- CH 13 Materials Handling and StorageDocument20 pagesCH 13 Materials Handling and StorageMohammad-Yasser LantudNo ratings yet

- Lifting Plan HseDocument22 pagesLifting Plan HseRamod Kumar100% (3)

- Safety AlertDocument8 pagesSafety AlertPT. Bahana Cipta Internusa bciNo ratings yet

- Sandline Flagging Operation Results in FatalityDocument2 pagesSandline Flagging Operation Results in FatalityReda AL-mesbahNo ratings yet

- Procedure For LiftingDocument7 pagesProcedure For LiftingAbideen RaheemNo ratings yet

- Safe Lifting Procedure 2Document6 pagesSafe Lifting Procedure 2angelaNo ratings yet

- Equipment Overturned Into TrenchDocument1 pageEquipment Overturned Into TrenchEjaz AhmadNo ratings yet

- Imcasf20 18Document6 pagesImcasf20 18Era ErmerraNo ratings yet

- 2022 09 - SAFETY ALERT - Unsafe Lifting With Forklift - enDocument1 page2022 09 - SAFETY ALERT - Unsafe Lifting With Forklift - enzaimNo ratings yet

- Risk Assessment - PLCC Cable and GIB Testing 26DEC15 - Rev 0Document7 pagesRisk Assessment - PLCC Cable and GIB Testing 26DEC15 - Rev 0NirmalKumarSelvarajNo ratings yet

- Lifting Supervisors Guidebook Revised 2014Document15 pagesLifting Supervisors Guidebook Revised 2014Abn BK100% (1)

- JPPL Ehs 19 03 SWP 02Document12 pagesJPPL Ehs 19 03 SWP 02MohamedSaidNo ratings yet

- Quick Start Summary 1 Who Needs To Know About These RequirementsDocument70 pagesQuick Start Summary 1 Who Needs To Know About These RequirementsAlex Sandro Borges PereiraNo ratings yet

- LTI - Lost FingerDocument1 pageLTI - Lost FingerMohammedNo ratings yet

- HASCO Crane and Lifting Campaign July 2022Document18 pagesHASCO Crane and Lifting Campaign July 2022shahid052No ratings yet

- Lifting Procedure of Transmission LineDocument4 pagesLifting Procedure of Transmission LineDhaneswar SwainNo ratings yet

- BeaconenglishDocument1 pageBeaconenglishCms Stl CmsNo ratings yet

- Guidebook For Lifting SupervisorsDocument13 pagesGuidebook For Lifting SupervisorsSrinivasan Reddy100% (5)

- NEBOSHDocument6 pagesNEBOSHJONAS VIMBANENo ratings yet

- M Bac 000000 GH00 Mem 000045Document1 pageM Bac 000000 GH00 Mem 000045manuel agostinhoNo ratings yet

- M Bac 000000 GH00 Mem 000066Document2 pagesM Bac 000000 GH00 Mem 000066manuel agostinhoNo ratings yet

- M Bac 000000 GH00 Mem 000047Document1 pageM Bac 000000 GH00 Mem 000047manuel agostinhoNo ratings yet

- M Bac 000000 GH00 Mem 000044Document1 pageM Bac 000000 GH00 Mem 000044manuel agostinhoNo ratings yet

- M Bac 000000 GH00 Mem 000042Document1 pageM Bac 000000 GH00 Mem 000042manuel agostinhoNo ratings yet

- M Bac 000000 GH00 Mem 000067Document2 pagesM Bac 000000 GH00 Mem 000067manuel agostinhoNo ratings yet

- M Bac 000000 GH00 Mem 000043Document1 pageM Bac 000000 GH00 Mem 000043manuel agostinhoNo ratings yet

- Tds Voltex Ds Emea en 201605 v10Document5 pagesTds Voltex Ds Emea en 201605 v10manuel agostinhoNo ratings yet

- VOLTEX DS For Shotcrete or ContaminatedDocument4 pagesVOLTEX DS For Shotcrete or Contaminatedmanuel agostinhoNo ratings yet

- HE 00399 Sika WT Series EngDocument3 pagesHE 00399 Sika WT Series Engmanuel agostinhoNo ratings yet

- Sika Swell - P ProfilesDocument5 pagesSika Swell - P Profilesmanuel agostinhoNo ratings yet

- Polyproofx 1: Technical DatasheetDocument2 pagesPolyproofx 1: Technical Datasheetmanuel agostinhoNo ratings yet

- Sika® ViscoCrete® - Sika ConcreteDocument4 pagesSika® ViscoCrete® - Sika Concretemanuel agostinhoNo ratings yet

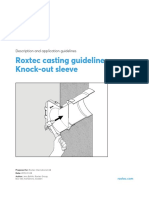

- Roxtec Casting Guidelines - Knock-Out Sleeve: Description and Application GuidelinesDocument8 pagesRoxtec Casting Guidelines - Knock-Out Sleeve: Description and Application Guidelinesmanuel agostinhoNo ratings yet

- MRT-X 1845Document6 pagesMRT-X 1845manuel agostinho100% (1)

- Fibertex Geotextiles: Product Data SheetDocument2 pagesFibertex Geotextiles: Product Data Sheetmanuel agostinhoNo ratings yet