Professional Documents

Culture Documents

DJJ10022 REPORT (Fitting)

Uploaded by

Muhd Imran Kasyidi OmarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DJJ10022 REPORT (Fitting)

Uploaded by

Muhd Imran Kasyidi OmarCopyright:

Available Formats

MECHANICAL ENGINEERING DEPARTMENT

DJJ10022 : MECHANICAL WORKSHOP PRACTICE 1 Welding Gas

√ Fitting

Machining

Student Name: Muhammad Imran Kasyidi Bin Omar Lecturer Name: Madam Dr Vaina Malar A/P

Nadarajah

Registeration No.: 24DTP22F2008

Class:

CLO 1: Measure finished product using appropriate measurement instruments. (P3)

CLO 2: Perform fitting, welding and machining works according to Standard Operational Procedure

(SOP). (P4)

CLO 3: Demonstrate an understanding of professional ethics, responsibilities and norms of

engineering practices according to the workshop safety regulation. (A3)

For lecturer only:

12 Mark for CLO 1

Mark for CLO 2

12

DJJ10022 MECHANICAL WORKSHOP PRACTICE 1 pg.1

Title :

FITTING

Objective :

> Know basic workshop processes.

> Read and interpret job drawing.

> Identify, select and use various marking, measuring, holding, striking and

cutting tools & equipments.

> Operate, control different machines and equipments.

> Inspect the job for specified dimensions.

> Adopt safety practices while working on various machines.

Safety

> Give full attention when listening to a description of the rules.

Precaution:

> Wear protective clothing such as glove, goggle and safety shoe.

> Do not play in lab.

> Not too close to the machine is in operator or moving.

> Must wear neat and appropriate in lab.

> Ensure cleanliness the lab on a satisfactory level.

> Have a sense of responsibility to self, partner and equipment in lab.

> Must know where is emergency switch and first aid kit.

Operation > Fitting

Equipment: > Workplace : Mild plate measuring

(CLO 2) > L square

> Hammer

Describe each

> Vernier caliper

equipment

> Scriber

> Chisel

> Hackshaw

> Center punch

> Drill machine (Drill bits size 4mm, 9mm)

> Personal Protective Equipment (PPE) : Glove, goggle, safety shoe.

DJJ10022 MECHANICAL WORKSHOP PRACTICE 1 pg.2

Procedure (CLO 2):

No. Operation/Task Procedure

1 OBJECTIVE : PROJECT A : U-Shape

To make the workpiece be a

U-shape

TOOL REQUIRED :

Hackshaw, hammer, center

punch, scriber, chisel, L

square, vernier caliper

SEQUENCE OF OPERATIONS :

1. Checking

2. Edge preparation

3. Workplace positioning

1. Prepare mild steel piece follow measure that prescribed.

2. File work surface of the work piece to be 90º (measured by

L-square).

3. Mark all dimension by using vernier height gauge.

4. Cut the work piece which is not required by using hacksaw.

5. Remove the work piece is not required using a chisel.

6. File all side of work piece to be 90º.

7. Mark the location of hole using center punch.

8. Drill hole according to the size of diameter required using

post drilling machine.

9. Cut the internal thread according to the size thread hole

using hand tap.

10. Remove the surface of the work piece as a process of

finishing.

DJJ10022 MECHANICAL WORKSHOP PRACTICE 1 pg.3

No. Operation/Task Procedure

2 OBJECTIVE : PROJECT B : T-Shape

To make the workpiece be a

T-shape

TOOL REQUIRED :

Hackshaw, hammer, center

punch, scriber, chisel, L

square, vernier caliper

SEQUENCE OF OPERATIONS :

1. Checking

2. Edge preparation

3. Workplace positioning

1. Prepare mild steel piece follow measure that prescribed.

2. File work surface of the work piece to be 90º measured by

L-square).

3. Mark all dimension by using vernier height gauge.

4. Cut the work piece which is not required by using hacksaw.

5. Remove the work piece is not required using a chisel.

6. File all side of work piece to be 90º.

7. Mark the location of hole using center punch.

8. Drill hole according to the size of diameter required using

post drilling machine.

9. Cut the internal thread according to the size thread hole

using hand tap.

10. Remove the surface of the work piece as a process of

finishing.

DJJ10022 MECHANICAL WORKSHOP PRACTICE 1 pg.4

Measuring

Equipment: 1. Fitting

2. Workpiece : Mild plate measuring

(CLO 1) 3. Personal Protective Equipment (PPE) : Glove, goggle, safety shoe.

Describe each 4. Tools : Hackshaw, hammer, center punch, scriber, chisel, L square, vernier caliper

equipment

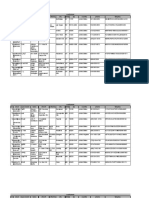

Result (CLO 1):

PROJECT A/B: U-SHAPE & T-SHAPE

Measurement Percentage Error

Part Length Error (mm)

(mm) (%)

60mm 61mm +1mm 1%

30mm 31mm +1mm 1%

U

15mm 17mm +2mm 2%

Thickness (micrometer) 15mm +2mm 2%

60mm 61mm + 1mm 1%

30mm 31mm +1mm 1%

T

15mm 17mm +2mm 2%

Thickness (micrometer) 15mm +2mm 2%

DJJ10022 MECHANICAL WORKSHOP PRACTICE 1 pg.5

Discussion: The fitting practice is a new skills that i have learn to make a shape. At the same time,

we learn to use a right tools and materials when doing work at workshop. Fitting is also

give us more skills and preparation when we work outside later. When we see a result

from the work that we have done together, we are very grateful when we have finish

our work in a sharp time that have given by our lecturer. The talent that our lecturer

have give to us is bring us to a new experience about fitting and more information

about fitting. These project also give us advantage when we work together with our

team and we also can learn many information through share knowledge together.

Conclusion: On the end of this Fitting project I had learn how to use equipment and machinery

such as files, center punch, vernier height gauge and drilling machine. I also learned

how to conduct a project and finish its report.I also learned the importance of fitting

process in engineering field.

DJJ10022 MECHANICAL WORKSHOP PRACTICE 1 pg.6

You might also like

- Fitting ReportDocument18 pagesFitting ReportAriff Azizi67% (3)

- DJJ3032 - Workshop Practice 3 (Lathe Machining)Document8 pagesDJJ3032 - Workshop Practice 3 (Lathe Machining)Afiq Fahmi100% (2)

- Report FittingDocument33 pagesReport FittingNaqiuddin MuhamadNo ratings yet

- Foundry ReportDocument2 pagesFoundry ReportPreavin Kutty Thamotharan50% (2)

- Report Lathe MachineDocument13 pagesReport Lathe Machinehairul akmal0% (1)

- Djj30082 - Mechanical Workshop Practice 3 (Machining) Report 1 (Part A, Clo 2) 1.0 ObjectivesDocument6 pagesDjj30082 - Mechanical Workshop Practice 3 (Machining) Report 1 (Part A, Clo 2) 1.0 Objectivesshirleyna sara100% (1)

- A Lab Report On Fitting Workshop PracticeDocument6 pagesA Lab Report On Fitting Workshop PracticeBilal Mobeen88% (17)

- DJJ 20042 Welding Report 1 - Welding ProcedureDocument15 pagesDJJ 20042 Welding Report 1 - Welding ProcedureMohamad Salleh AbdullahNo ratings yet

- Thermal Equilibrium ExperimentDocument3 pagesThermal Equilibrium ExperimentFish Bone25% (8)

- Gas Welding ReportDocument17 pagesGas Welding ReportNorasilah Chan67% (3)

- Inventor ReportDocument7 pagesInventor Report2cekal50% (2)

- Arc Weld ReportDocument14 pagesArc Weld ReportAsyraf Razali67% (6)

- DJJ 10033-Chapter 5.GEARDocument34 pagesDJJ 10033-Chapter 5.GEARStepianus JtNo ratings yet

- Djj10022 Fitting ReportDocument7 pagesDjj10022 Fitting ReportTamil passang songNo ratings yet

- OAW SMAW Flat WeldingDocument12 pagesOAW SMAW Flat WeldingHaikal SubriNo ratings yet

- Discussion EdmDocument3 pagesDiscussion EdmShamsul Aiman100% (1)

- Bench Work ProceduresDocument7 pagesBench Work ProceduresAniz Farznor SariffuddinNo ratings yet

- Discussion GmawDocument2 pagesDiscussion GmawMuhamad HafizNo ratings yet

- Djj10013-Engineering Drawing: Title: Autocad ReportDocument23 pagesDjj10013-Engineering Drawing: Title: Autocad ReportDhana KumaranNo ratings yet

- Customer: Id Email Password Name Street1 Street2 City State Zip Country Phone TempkeyDocument37 pagesCustomer: Id Email Password Name Street1 Street2 City State Zip Country Phone TempkeyAgus ChandraNo ratings yet

- Date: ............................................................(Assistant’s SignatureDocument8 pagesDate: ............................................................(Assistant’s SignatureThaneswaran BaluNo ratings yet

- JJ 103 Fitting ReportDocument11 pagesJJ 103 Fitting Reportrafiah bazlaaNo ratings yet

- Welding GAS ReportDocument11 pagesWelding GAS Report15 thn50% (2)

- FittingDocument14 pagesFittingMuhd Ashraf67% (3)

- Report FittingDocument1 pageReport FittingNordianaaida Eda67% (3)

- Safety Tips for Arc Welding WorkshopDocument10 pagesSafety Tips for Arc Welding WorkshopHabibah ArbainNo ratings yet

- DJJ1032 Fitting (Hexagon Gauge) : Muhammad Ariff Bin Shukri TeyDocument14 pagesDJJ1032 Fitting (Hexagon Gauge) : Muhammad Ariff Bin Shukri TeyTak ProNo ratings yet

- DJJ20053 Engineering Laboratory 1 (Electrical Technology) : Experiment 1Document4 pagesDJJ20053 Engineering Laboratory 1 (Electrical Technology) : Experiment 1roslelawati75No ratings yet

- DJJ1032 Fitting (Hexagon Gauge) : Muhammad Haffiz Aiman Bin YahayaDocument15 pagesDJJ1032 Fitting (Hexagon Gauge) : Muhammad Haffiz Aiman Bin YahayaTak ProNo ratings yet

- Gas Welding Workshop ReportDocument12 pagesGas Welding Workshop ReportDuventhirenNo ratings yet

- Workshop Technology Case StudyDocument8 pagesWorkshop Technology Case StudyNagulan VegneswaranNo ratings yet

- 3.0 Equipment NO. Tool Equipment Functions 1. L SquareDocument11 pages3.0 Equipment NO. Tool Equipment Functions 1. L SquareOmar DonNo ratings yet

- DJM1012 Mechatronic Workshop Practice-Machining ReportDocument16 pagesDJM1012 Mechatronic Workshop Practice-Machining ReportRachel Ramirez100% (7)

- Milling Report (Indexing)Document23 pagesMilling Report (Indexing)Aiman AlifNo ratings yet

- Report WeldingDocument11 pagesReport WeldingSomasundaram SomanoNo ratings yet

- Report Workshop Gas WeldingDocument6 pagesReport Workshop Gas WeldingDzulkhairie DK0% (1)

- JJ203 MECHANICAL PRACTISE Welding-Report (Arc Tee Joint & Cutting & Brazing)Document9 pagesJJ203 MECHANICAL PRACTISE Welding-Report (Arc Tee Joint & Cutting & Brazing)Ah Tiang100% (1)

- Report MIG WeldingDocument12 pagesReport MIG Weldingyuwaraja0% (2)

- DJJ 10033-Chapter 6 NewDocument43 pagesDJJ 10033-Chapter 6 NewAbbas SeuNo ratings yet

- Arc Welding Techniques ExplainedDocument4 pagesArc Welding Techniques ExplainedFaris Kadesh50% (2)

- Report CadcamDocument9 pagesReport CadcamAmirul ZulfadhliNo ratings yet

- Process and Part Analysis of Sheet Metal FoldingDocument4 pagesProcess and Part Analysis of Sheet Metal FoldingNo NameNo ratings yet

- Locating Principle and LocatorsDocument35 pagesLocating Principle and LocatorsPes Mobile100% (1)

- DJJ10033 DJJ1043 Workshop TechnologyDocument4 pagesDJJ10033 DJJ1043 Workshop Technologykumar21189No ratings yet

- Worksheet: Diploma in Mechanical EngineeringDocument13 pagesWorksheet: Diploma in Mechanical EngineeringGuna SelanNo ratings yet

- Mechanical Engineering CADCAM Practical TaskDocument14 pagesMechanical Engineering CADCAM Practical TaskAmirun AminNo ratings yet

- CNC Report - Kubheran 23DKM18F2033Document10 pagesCNC Report - Kubheran 23DKM18F2033Kubheran SelvathuraiNo ratings yet

- Lab Sheet Djj5113Document27 pagesLab Sheet Djj5113Munisprasad MuniandyNo ratings yet

- DJJ30082 Worksheet Milling ReportDocument9 pagesDJJ30082 Worksheet Milling ReportSakinah KamalNo ratings yet

- Verma PDFDocument4 pagesVerma PDFsachinsaklani23No ratings yet

- GegasDocument18 pagesGegasPiraven Casanova II50% (2)

- Fitting ToolsDocument14 pagesFitting ToolsManoj Lohumi100% (2)

- Report MesinDocument8 pagesReport MesinWan Muhamad FaizNo ratings yet

- Field Trip On Elect ElectDocument13 pagesField Trip On Elect ElectvictorNo ratings yet

- SMAW Welding GuideDocument13 pagesSMAW Welding GuideCheng Yee71% (7)

- A Lab Report On Fitting Workshop Practice PDFDocument6 pagesA Lab Report On Fitting Workshop Practice PDFSorna Kailash50% (4)

- Lab Sheet Tig Mig DJF2012Document3 pagesLab Sheet Tig Mig DJF2012Rahmat Nor Mohd SharifNo ratings yet

- Discussion FoundryDocument1 pageDiscussion Foundryzuhud24No ratings yet

- Lab Report TIGDocument4 pagesLab Report TIGAlimah Azeli50% (2)

- Case Study Eng - Math 3 (Group 1)Document29 pagesCase Study Eng - Math 3 (Group 1)1052 FazliNo ratings yet

- Milling Report Section 5Document9 pagesMilling Report Section 5AbbyNo ratings yet

- DJJ10022 REPORT (Machining)Document6 pagesDJJ10022 REPORT (Machining)Muhd Imran Kasyidi OmarNo ratings yet

- Eimz & Ameer (Gear)Document9 pagesEimz & Ameer (Gear)Muhd Imran Kasyidi OmarNo ratings yet

- Eimz & Ameer (Gear)Document9 pagesEimz & Ameer (Gear)Muhd Imran Kasyidi OmarNo ratings yet

- Duw10022-C05 - Fire SafetyDocument46 pagesDuw10022-C05 - Fire SafetyMuhd Imran Kasyidi Omar100% (1)

- Avoiding Unhealthy Health GoalsDocument13 pagesAvoiding Unhealthy Health GoalsMuhd Imran Kasyidi OmarNo ratings yet

- Mechanical Workshop Gas WeldingDocument6 pagesMechanical Workshop Gas WeldingMuhd Imran Kasyidi OmarNo ratings yet

- Chapter 5Document31 pagesChapter 5Marvin VinasNo ratings yet

- DL1 - Epicyclic Gear Train & Holding Torque ManualDocument4 pagesDL1 - Epicyclic Gear Train & Holding Torque Manualer_arun76100% (1)

- Howden PDFDocument24 pagesHowden PDFskb2550% (2)

- Advances in Cultivation of Commercial Seaweed SpeciesDocument21 pagesAdvances in Cultivation of Commercial Seaweed SpeciesDHEERAJ KUMARNo ratings yet

- Cylinder Head Cover, 6T-830 and 6ta-830 Emissions Certified EngineDocument3 pagesCylinder Head Cover, 6T-830 and 6ta-830 Emissions Certified EngineJose A PerezNo ratings yet

- Install and Configure Computer Networks Training Session PlanDocument9 pagesInstall and Configure Computer Networks Training Session PlanMarvin AlcantaraNo ratings yet

- IAS Mains Electrical Engineering 1994Document10 pagesIAS Mains Electrical Engineering 1994rameshaarya99No ratings yet

- Sophiajurgens Resume EdtDocument2 pagesSophiajurgens Resume Edtapi-506489381No ratings yet

- 07 FSM PDFDocument25 pages07 FSM PDFnew2trackNo ratings yet

- Ett 531 Motion Visual AnalysisDocument4 pagesEtt 531 Motion Visual Analysisapi-266466498No ratings yet

- PqdifsdkDocument2 pagesPqdifsdkrafaelcbscribdNo ratings yet

- COE10205, Other Corrosion Monitoring TechniquesDocument62 pagesCOE10205, Other Corrosion Monitoring Techniquesامين100% (1)

- Analyzing an Anti-Smoking Poster Using a Formalist ApproachDocument20 pagesAnalyzing an Anti-Smoking Poster Using a Formalist ApproachAlphred Jann NaparanNo ratings yet

- Guia Instalacion ENTECDocument15 pagesGuia Instalacion ENTECHislim SaidNo ratings yet

- Homework1 SKKK1113 1112-2Document1 pageHomework1 SKKK1113 1112-2Khairul Anwar Abd HamidNo ratings yet

- Proportional, Solenoid Actuated Flow Control Valves Type SE and SEHDocument16 pagesProportional, Solenoid Actuated Flow Control Valves Type SE and SEHwords2zhigang_612545No ratings yet

- GPS InspectionDocument48 pagesGPS InspectionAhmed AluoshNo ratings yet

- Xpand!2 - User Guide - V1.1Document18 pagesXpand!2 - User Guide - V1.1JamesNo ratings yet

- Performance Evaluation and Life Testing of The SPT-100Document12 pagesPerformance Evaluation and Life Testing of The SPT-100ThaSupaflyNo ratings yet

- Advanced Long Range Proximity Reader PDFDocument1 pageAdvanced Long Range Proximity Reader PDFPhangkie RecolizadoNo ratings yet

- 9607 Syllabus Media StudiesDocument28 pages9607 Syllabus Media StudiesmisterNo ratings yet

- Mcgill Thesis GuidelinesDocument5 pagesMcgill Thesis Guidelinesisabelleonorpaterson100% (2)

- Huawei Technologies Network Router B681Document12 pagesHuawei Technologies Network Router B681Eduardo Vaz RibeiroNo ratings yet

- Oven Nordson ElectronicDocument60 pagesOven Nordson ElectronicDanijela KoNo ratings yet

- Quadratic SDocument22 pagesQuadratic SShawn ShibuNo ratings yet

- Public Authority CasesDocument11 pagesPublic Authority CasesAbhinav GoelNo ratings yet

- A Is Called The Base and N Is Called The Exponent: Grade 7 Math Lesson 21: Laws of Exponents Learning GuideDocument4 pagesA Is Called The Base and N Is Called The Exponent: Grade 7 Math Lesson 21: Laws of Exponents Learning GuideKez MaxNo ratings yet

- 1 National Workshop For Sustainable Built Environment South - South PartnershipDocument14 pages1 National Workshop For Sustainable Built Environment South - South PartnershipRajendra KunwarNo ratings yet

- Grade7Research 1st Quarter MeasuringDocument17 pagesGrade7Research 1st Quarter Measuringrojen pielagoNo ratings yet