0% found this document useful (0 votes)

84 views9 pagesHeat Transfer Calculations

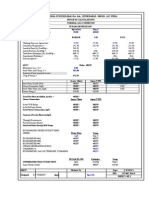

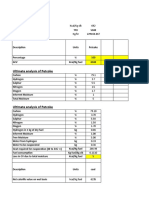

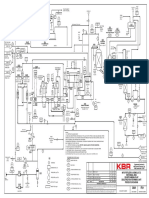

The document contains calculations for heat transfer and pipe sizing for various processes. It includes calculations of feed rate, temperatures, heat load, required area, flow rates, line sizes, and velocities. Pipe sizes were determined based on fluid flow rates and assumed velocities. Heat loads and required heat exchanger areas were found using parameters like latent heat, specific heat, temperature differences and heat transfer coefficients.

Uploaded by

Nitin KurupCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

84 views9 pagesHeat Transfer Calculations

The document contains calculations for heat transfer and pipe sizing for various processes. It includes calculations of feed rate, temperatures, heat load, required area, flow rates, line sizes, and velocities. Pipe sizes were determined based on fluid flow rates and assumed velocities. Heat loads and required heat exchanger areas were found using parameters like latent heat, specific heat, temperature differences and heat transfer coefficients.

Uploaded by

Nitin KurupCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd