Professional Documents

Culture Documents

Cooper Crouse Hinds Cooprcd00005 5C4 5C0

Uploaded by

Paul DvidOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cooper Crouse Hinds Cooprcd00005 5C4 5C0

Uploaded by

Paul DvidCopyright:

Available Formats

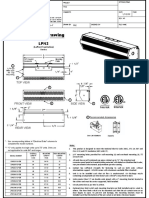

5C-4 EDS Factory Sealed Cl. I, Div.

1 & 2, Groups B*,C,D

Cl. II, Div. 1, Groups E.F.G

Explosionproof

Dust-lgnitionproof

Pushbutton Stations Cl. II, Div. 2, Groups F,G Raintight

Front Operated, 600VAC Heavy Duty, Cl. Ill Wet Locations

Dimensions Pg. 5C-2 NEMA3,7B*CD,9EFG

EDS2184 EDS2190

Single Gang

Normal Pos. 1 Circuit 2 Circuits 2 Circuits

Universal Universal 1 Open-A

1 Closed-B

Marking f Specify Specify START-STOP

unless

otherwise

specified

A B

Diagram *•1*

tlA JLlJL __L_ AlA

• • • • • • •

Replacement

Pushbuttons i ED11 ED12 ED12**

Enclosure with Pushbuttons

Dead End

Hub Size Cat. # Cat.# Cat. #

1

/2 EDS1184 EDS115

3/4 EDS2184 EDS2190 EDS215

1 EDS3184 EDS3190 EDS315

Through Feed

1

/2 EDSC1184 EDSC1190 EDSC115

3/4 EDSC2184 EDSC2190 EDSC215

1 EDSC3184 EDSC3190 EDSC315

Normal Pos. 2 Circuits 2 Circuits

Universal 1 Open-A

1 Closed-B

Markingt Specify Specify

A B

Diagram HA ALA _J_ Ml*.

• • • • • •

Replacement

Pushbuttons t ED12 ED12**

Enclosure with Pushbuttons

Dead End

Hub Size Cat. #§ Cat. #§

* Class I,I, Group B: Consider

Consii using EPS series pushbuttons, see page 5C-12. All enclosures listed above can be modified for

1

/2 EDS1155 Class I, Group B, Div. 1 usage.

use Add suffix GB to the Cat. No. Seals must be installed within 1'/2" of each conduit opening in

3/4 EDS2192 EDS2155 Division 1. These products

products are suitable for Group B, Div. 2 as listed, without external seals. In Canada, for Group B applications

1 EDS3192 EDS3155 consult

suit factory.

Through Feed * * Two

Twouniversal

universalcontact

contactblocks,

I must be wired as two circuits, with one normally open and one normally closed.

Vfe EDSC1192 EDSC1155 § Single external button op

3/4 EDSC2192 EDSC2155

t Standard markings avail:

1 EDSC3192 EDSC3155

START OFF RESET LIGHT ON EMERGENCY OPEN DOWN RAISE

STOP RUN TRIP HAND FORWARD CLOSE IN LOWER

ON JOG TEST AUTOMATIC REVERSE UP OUT

^ For replacement pushbuttons, see page 4C-6.

Copyright" 2000 Cooper Industries, Inc.

5C-0 EPS and EDS Factory Sealed Cl. 1, Div. 1 & 2, Groups B*,C,D Explosionproof

Cl. II, Div. 1 , Groups E,F,G Dust-lgnitionproof

Control Devices and Manual Cl. II, Div. 2 , Groups F,G Raintight

GROUSE-HINDS* Motor Starting Switches Cl. III

NFf\/lA 3 7R *CD

Wet Locations

^H \J LJ ,QFFfi

\J l_l \J

Dimensions Pg. 5C-2

L

1 *|M| Y If 1 ^J' "/

Application: • Shafts - stainless steel Certifications and

Factory sealed enclosures are installed in a • Shaft bushings - stainless steel

rigid metallic conduit system for surface • Rocker handle and pushbutton guards - Compliances:

mounting adjacent to or remote from type 6/6 nylon • NEC/CEC:

equipment being controlled and are used: • Sealing enclosures - copper-free aluminum Class I, Division 1 & 2, Groups B*,C,D

• to prevent arcing of enclosed device from Class II, Division 1, Groups E,F,G

causing ignition of a specific hazardous Standard Finishes: Class II, Division 2, Groups F,G

atmosphere or atmospheres external to the Feraloy iron alloy - electrogalvanized and Class III

enclosure aluminum acrylic paint • NEMA/EEMAC: 3,7B*CD,9EFG

• in industrial areas such as chemical plants, • Copper-free aluminum - natural • UL Standard: 894, 698

oil and gas refineries, paint and varnish • Type 6/6 nylon - black • CSA Standard: C22.2 No. 30

manufacturing plants, gasoline bulk loading • Stainless steel - natural

terminals, grain elevators, grain processing

industries, coal processing or handling areas,

or metal handling or finishing areas where Options:

atmosphere may contain hazardous gases The following special options are available

and/or dust from the factory by adding suffix to Cat. No.

• in non-hazardous areas where sturdy,

durable enclosures are required

• in conjunction with magnetic starters or

contactors for remote control of motors Suffix to be

Manual motor starting switch enclosures are Added to

used: Description Cat. #

• for manual starting of small ac or dc motors

Emergency "Stop" button (momentary) - front operated red mushroom button S111

• to provide manual starting and stopping

and, in the case of units with heaters, motor Lockout provision on front operated pushbutton cover (standard on buttons

running protection marked "OFF" and "STOP") S153

For 24 VDC operation on pilot lights S300

Features: Three-position selector switches with modified operation:

Factory sealed devices have many distinct

Momentary contact clockwise operation, spring return to center, maintained

advantages: contact counter-clockwise operation S634

• reduce installation problems

• eliminate external seals Momentary contact counter-clockwise operation, spring return to center,

• lower installation costs maintained contact clockwise operation S635

• improve safety Bodies and covers (single and two gang units) - copper-free aluminum SA

• are used with general purpose snap and

pushbutton type switches Where indicated in the catalog listings, EDS units suitable for Class I, Division 1,

• standard neoprene covers for front Group B usage can be supplied. EFS units are suitable for Class I, Division 1,

operated pushbuttons. Prevents Group B as standard GB

accumulation of dirt and entrance of water Maintained contact mushroom head with lockout and guard. Maximum one per cover

around operating shafts and cannot be used with a pilot light with a transformer or another standard pushbutton... S769

• mounting lugs and taper tapped hubs with

integral bushings

• large machine screws for fastening covers

to bodies EDS bodies and factory sealed cover and device sub-assemblies are available for field

• lockout provisions on front operated push assembly (see pages 4C-10 to 12).

button (marked "STOP" and "OFF") and

selector switch covers

• lockout hole for padlock having Vi" hasp is

provided when used with covers for front

iever and side rocker type operation

• close tolerances in machining of wide,

mating flanges and journalled shafts and

bearings for front button operation, produces

flametightness of enclosure joints

• on enclosures with front lever and side

rocker type operating handles, threaded type

shafts and bushings are used to ensure Suffix S769

flametightness

• dead end (EPS or EDS) or through feed

(EFSC or EDSC) hubs -1/2" to 1" sizes

Standard Materials:

• Bodies - Feraloy* iron alloy (U.S.); copper-

free aluminum (Canada).

• Front operated pushbutton and pilot light

' See Options: suffix GB

covers - Feraloy iron alloy

• Side operated type pushbutton covers -

copper-free aluminum

Copyright" 2000 Cooper Industries, Inc.

You might also like

- Series DS2 Compact Valve - G1/8 FeaturesDocument9 pagesSeries DS2 Compact Valve - G1/8 FeaturesBiswanath LenkaNo ratings yet

- Series DS2 Compact Valve - G1/2 FeaturesDocument9 pagesSeries DS2 Compact Valve - G1/2 FeaturesBiswanath LenkaNo ratings yet

- Series DS2 Compact Valve - G1/4Document9 pagesSeries DS2 Compact Valve - G1/4Biswanath LenkaNo ratings yet

- Fire Alarm Systems - Conventional Manual Call Points For Ex AreasDocument4 pagesFire Alarm Systems - Conventional Manual Call Points For Ex AreasaNo ratings yet

- Crouse Hinds - ENR Dead Front InterlockedDocument2 pagesCrouse Hinds - ENR Dead Front InterlockedCarlos Hernández ValenzuelaNo ratings yet

- Explosion Proof Directional Control Valve Type Ed6 Serie 6X Directive Atex Et IecexDocument12 pagesExplosion Proof Directional Control Valve Type Ed6 Serie 6X Directive Atex Et IecexRenjithSivaNo ratings yet

- DP1 ValveDocument3 pagesDP1 ValveBiswanath LenkaNo ratings yet

- "Fuel" Gauge: Curtis Instruments, IncDocument11 pages"Fuel" Gauge: Curtis Instruments, IncGonzalo D'AddarioNo ratings yet

- Caja de PasoDocument1 pageCaja de PasoEdwin CaroNo ratings yet

- 5266 Controls: Safety Exhaust (Dump)Document12 pages5266 Controls: Safety Exhaust (Dump)Julio Vazquez MorenoNo ratings yet

- LG OtisDocument58 pagesLG OtisAhmed Al-RabayahNo ratings yet

- O/D Main Switch & O/D OFF Indicator Light CircuitDocument3 pagesO/D Main Switch & O/D OFF Indicator Light CircuitsalusfrankNo ratings yet

- L1 - Q3. L3. L2.: Filter Not Needed On Soft Starter Circuit?Document1 pageL1 - Q3. L3. L2.: Filter Not Needed On Soft Starter Circuit?Konge Thethtunaung100% (1)

- D129 Dual Class A Initiating Circuit: Installation InstructionsDocument4 pagesD129 Dual Class A Initiating Circuit: Installation InstructionsAhmad SaeedNo ratings yet

- L-1 Butterfly Valve InstallDocument9 pagesL-1 Butterfly Valve InstallgerardtrNo ratings yet

- T Installation Guide (6F2S1910) 1.6Document2 pagesT Installation Guide (6F2S1910) 1.6Bear DguNo ratings yet

- Service ManualDocument3 pagesService Manualyomismooo32No ratings yet

- Pistola Estroboscópica SAMDocument16 pagesPistola Estroboscópica SAMaudioimagenNo ratings yet

- 4C Eds / Efs Series Control Stations: Flexstation Control Station ComponentsDocument5 pages4C Eds / Efs Series Control Stations: Flexstation Control Station ComponentsAlex RamirezNo ratings yet

- 4C DSD Cover and Device Sub-Assemblies: Manual Motor StartersDocument3 pages4C DSD Cover and Device Sub-Assemblies: Manual Motor StartersJC InquillayNo ratings yet

- Omron RelayDocument19 pagesOmron Relaycherif yahyaouiNo ratings yet

- SPEC. FOR ANNUNCIATORS FOR ELECTRICAL SUBSTATIONS rg6s911381051 - 001Document4 pagesSPEC. FOR ANNUNCIATORS FOR ELECTRICAL SUBSTATIONS rg6s911381051 - 001Muthiah MuruganNo ratings yet

- RT9173Document10 pagesRT9173duplakave30No ratings yet

- 2N3958 DatasheetDocument5 pages2N3958 Datasheetjose santosNo ratings yet

- Danfoss Pressure SwitchDocument10 pagesDanfoss Pressure SwitchRoshan JaiswalNo ratings yet

- Special Use Maintenance Switch Cut Sheet UL LISTEDDocument2 pagesSpecial Use Maintenance Switch Cut Sheet UL LISTEDgemcom8828No ratings yet

- Acs140 - Guia RapidoDocument18 pagesAcs140 - Guia RapidoRicardo FachinelloNo ratings yet

- b1x b2x Ds PDFDocument2 pagesb1x b2x Ds PDFscibduser001No ratings yet

- NO Qty. Unit Job Progress Remark Job Description: PT Titan JayaDocument2 pagesNO Qty. Unit Job Progress Remark Job Description: PT Titan JayaTitan Jaya AutomationNo ratings yet

- Mil DTL 26482HDocument86 pagesMil DTL 26482HImran HashmiNo ratings yet

- LM317TDocument13 pagesLM317Tapi-3711187100% (1)

- Overview Data Sheets: F 3223: 4 Fold Input ModuleDocument4 pagesOverview Data Sheets: F 3223: 4 Fold Input ModulemohamadziNo ratings yet

- Ejb EnclosuresDocument8 pagesEjb EnclosuresMarito VallejitosNo ratings yet

- AIC2354 1A Synchronous PWM/PSM Step-Down DC/DC Converter: Features DescriptionDocument13 pagesAIC2354 1A Synchronous PWM/PSM Step-Down DC/DC Converter: Features DescriptionRenato HernandezNo ratings yet

- LM317, NCV317 1.5 A Adjustable Output, Positive Voltage RegulatorDocument12 pagesLM317, NCV317 1.5 A Adjustable Output, Positive Voltage RegulatorSalseroInfanteNo ratings yet

- Model and CodeDocument6 pagesModel and CodeTiennghia BuiNo ratings yet

- Sony - WM Ex190 Ex192Document16 pagesSony - WM Ex190 Ex192gabriele eccaNo ratings yet

- LPN2 Unheated Sanitation SubmittalsDocument2 pagesLPN2 Unheated Sanitation SubmittalsGabriel Ortiz MNo ratings yet

- Proportional Pressure Reducing Valve, Pilot Operated Types DRE and ZDREDocument10 pagesProportional Pressure Reducing Valve, Pilot Operated Types DRE and ZDREPatrick ByronNo ratings yet

- Cooper Medc Datasheet BG PB 6ds067 Issue T - 2Document4 pagesCooper Medc Datasheet BG PB 6ds067 Issue T - 2Dijith JhansiNo ratings yet

- DTC Always ON Malfunction in ECU: Circuit DescriptionDocument3 pagesDTC Always ON Malfunction in ECU: Circuit DescriptionErln LimaNo ratings yet

- OMRON MK3P Relay-1Document13 pagesOMRON MK3P Relay-1Antonio TancevNo ratings yet

- Shridhan VfsDocument4 pagesShridhan VfssandeepNo ratings yet

- Boss DM-2 Delay: InstructionsDocument8 pagesBoss DM-2 Delay: InstructionscarlazNo ratings yet

- Temperature SwitchDocument6 pagesTemperature Switchkriss05No ratings yet

- Burker Valve 5282Document4 pagesBurker Valve 5282Anonymous hj273CMNo ratings yet

- Dual-Channel Synchronous DC/DC Step-Down Controller With 5V/3.3V LdosDocument26 pagesDual-Channel Synchronous DC/DC Step-Down Controller With 5V/3.3V LdosMichael VolaNo ratings yet

- 1DP1 PDFDocument5 pages1DP1 PDFsimionovskiNo ratings yet

- Features Applications: D D D D D D D D D D D D D D DDocument15 pagesFeatures Applications: D D D D D D D D D D D D D D DĐịnh Xuân HàNo ratings yet

- Pneumatics: Tiger 2000 5/2 Solenoid/Solenoid ValveDocument1 pagePneumatics: Tiger 2000 5/2 Solenoid/Solenoid ValveDevanda HanifanNo ratings yet

- FDC6329L Integrated Load Switch: FeaturesDocument4 pagesFDC6329L Integrated Load Switch: FeaturesranelcomNo ratings yet

- Ypu 2Document47 pagesYpu 2deividNo ratings yet

- Servo Válvula NeumaticaDocument30 pagesServo Válvula NeumaticaJaime VelazquezNo ratings yet

- Wandfluh D - PPM22 - ME Proportional Throttle ValveDocument4 pagesWandfluh D - PPM22 - ME Proportional Throttle ValveGabriel OyedemiNo ratings yet

- 6F GUE, GUB Junction BoxesDocument6 pages6F GUE, GUB Junction BoxesRicardo TitoNo ratings yet

- 1A Low Dropout Linear Regulator: General DescriptionDocument11 pages1A Low Dropout Linear Regulator: General DescriptionTito NavarroNo ratings yet

- Voltage Regulator: - Adjustable Output, PositiveDocument13 pagesVoltage Regulator: - Adjustable Output, PositiveFkgame SlotsNo ratings yet

- Connector Industry: A Profile of the European Connector Industry - Market Prospects to 1999From EverandConnector Industry: A Profile of the European Connector Industry - Market Prospects to 1999No ratings yet

- Shop Group: Conical Spring WashersDocument2 pagesShop Group: Conical Spring WasherssciucNo ratings yet

- DJJ40142 LAB SHEET Machining (Surface)Document3 pagesDJJ40142 LAB SHEET Machining (Surface)Khair Muhammad ZikriNo ratings yet

- JFE Structural SteelDocument38 pagesJFE Structural SteelboysitumeangNo ratings yet

- Material SpecificationDocument9 pagesMaterial SpecificationMuthu GaneshNo ratings yet

- Elastic Properties and Young Modulus For Some MaterialsDocument4 pagesElastic Properties and Young Modulus For Some MaterialsKarina S. CalderonNo ratings yet

- ASTM-F844 Washers, Steel, Plain (Flat), Unhardened For General UseDocument5 pagesASTM-F844 Washers, Steel, Plain (Flat), Unhardened For General UseleandroschroederNo ratings yet

- Woven Wire Mesh Products ApplicationsDocument27 pagesWoven Wire Mesh Products ApplicationsCFTM - Casa de Filtración y Telas Metálicas.No ratings yet

- Parasitic Vol Casting PDFDocument29 pagesParasitic Vol Casting PDFABHISHEK SHARMANo ratings yet

- Unit 4 Answers FinalDocument14 pagesUnit 4 Answers FinalAditya BishtNo ratings yet

- Stainless and Electrical Steels - Machinability-RatingDocument1 pageStainless and Electrical Steels - Machinability-RatinggoggerNo ratings yet

- Man 183 - 1Document22 pagesMan 183 - 1Aleks SenaNo ratings yet

- NASA Process Specification For Nickel PlatingDocument10 pagesNASA Process Specification For Nickel PlatingRam ViswanathanNo ratings yet

- Yavana Soldier On Bharhut Frieze An InduDocument6 pagesYavana Soldier On Bharhut Frieze An InduR. FortalNo ratings yet

- Inar Profiles Pvt. LTD., Kotturu, Industrial Area, Visakhapatnam, Andhrapradesh, IndiaDocument14 pagesInar Profiles Pvt. LTD., Kotturu, Industrial Area, Visakhapatnam, Andhrapradesh, IndiaSreedhar Patnaik.MNo ratings yet

- Astm A194 - 22Document12 pagesAstm A194 - 22MOHD FHAIRUZ BIN WAHID STUDENTNo ratings yet

- CIEN 3093 Construction Materials and Testing November 25, 2019Document3 pagesCIEN 3093 Construction Materials and Testing November 25, 2019acurvz2005No ratings yet

- Metal Protective OilDocument2 pagesMetal Protective OilGuillermo Gonsales100% (1)

- Basinox 318: MMA Electrodes Stainless and Heat Resistant SteelsDocument1 pageBasinox 318: MMA Electrodes Stainless and Heat Resistant SteelsbrunizzaNo ratings yet

- The Units of Measurements For Civil Engineering WorksDocument4 pagesThe Units of Measurements For Civil Engineering Workskrishnashankar9_3743No ratings yet

- EZ Series Slurry Pump: Excellence Pump Industry Co., LTDDocument7 pagesEZ Series Slurry Pump: Excellence Pump Industry Co., LTDAgung Bakdo TriyonoNo ratings yet

- PMI ProcedureDocument9 pagesPMI ProcedureKarrar TalibNo ratings yet

- Porcelain Fused To Metal CrownDocument17 pagesPorcelain Fused To Metal CrownAhmad SalehNo ratings yet

- Asme Sec Ix Guide PDFDocument144 pagesAsme Sec Ix Guide PDFCHARLES Anthonyraj100% (1)

- Juntas Antisismicas U - AyvazDocument4 pagesJuntas Antisismicas U - AyvazAnonymous ZBdivmRoNo ratings yet

- 5.2 Piping Specifications - No.P11 1 Pipe: ConsultantDocument49 pages5.2 Piping Specifications - No.P11 1 Pipe: ConsultantkasvikrajNo ratings yet

- KP THMA Fe-Al-Ni-Co-CuDocument4 pagesKP THMA Fe-Al-Ni-Co-CuCésar GNo ratings yet

- CSWIP 3.2 Multiple ChoiceDocument10 pagesCSWIP 3.2 Multiple Choicerandhir kumar jha0% (1)

- F2882-12 Standard Specification For Screws, Alloy Steel, Heat Treated, 170 Ksi Minimum Tensile StrengthDocument5 pagesF2882-12 Standard Specification For Screws, Alloy Steel, Heat Treated, 170 Ksi Minimum Tensile StrengthhugoNo ratings yet

- Drilling Operations l3 NotesDocument21 pagesDrilling Operations l3 Notesishimwe kwizera willyNo ratings yet

- Tecumseh Compressor Company: IndexDocument21 pagesTecumseh Compressor Company: IndexKankranRahulNo ratings yet