Professional Documents

Culture Documents

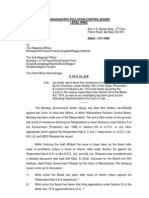

MPCB FO Site Inspection Procedure

Uploaded by

Alpha StaturoryOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MPCB FO Site Inspection Procedure

Uploaded by

Alpha StaturoryCopyright:

Available Formats

The inspection procedure of Maharashtra Pollution Control Board

The field officer from the Maharashtra Pollution Control Board is assigned to carry out inspection

under the provisions of various environmental legislations.

At the time of entry into the industry premises, the field officer serves a notice of entry and

inspection to the responsible person of the industry.

In the presence of the responsible person of the industry the officer carries out inspection, which

includes, verification of the following :

1. Operation of plant(s), product(s) being manufactured with quantity, material balance, pollution

load etc.

2. Status of operation of Environment Management System comprising of control measures for

liquid, gaseous and solid wastes

3. Sources and Generation of liquid, gaseous and solid wastes and how their treatment &

disposals are conducted at the facility.

4. Number of outlets provided for disposal of liquid effluent/ emissions and compliance thereof

versus the conditions in the consent granted

5. Maintenance of records in the form of logbooks etc. at the industry premises.

6. Number of emission stacks / vents / boilers etc. and compliance thereof versus conditions in

the consent granted.

7. Operational status of treatment systems/pollution control system.

8. During the inspection and sampling of the industrial unit the inspection officer ( in presence of

industry representatives) shall collects sample(s) of waste water, gaseous emission(s) and

hazardous waste(s), as and where the inspection officer feels necessary, depending upon the

environmental circumstances.

9. Availability of various utilities and consumption of resources viz. water, fuels electricity etc.,

10. At the end of the inspection visit, the officer issues written instructions to the industry for the

non-compliances observed, if any, and they are brought to notice the industry representatives

with required corrective measures.

11. The inspection officer also lists suggestions (based on their earlier experience) to take

additional measures so as to reduce pollution load at source or to improve treatability of the

wastes discharged.

A check list of the documents, which inspection officer might verify during its visit is also

suggested with procedure and are as follows:

Valid Consent copy

Environment clearance copy (if required)

Water Consumption Data

Effluent Treatment Plant Logbook

Air Pollution Control Measures Logbook

Hazardous Waste Generation and Disposal Records and Logbooks

Production details (RG – 1 Register/Excise statement/ any other Govt. Competent authority

submissions/annual reports)

Raw Material details (RG – 11 Register/Stock inventory )

Electricity Bills

Statutory Submission

Any other document related to industry if required

*********

You might also like

- CHK ListDocument21 pagesCHK ListbqdianzNo ratings yet

- U.P Pollution Control Board: List of Documents To Be Attached Along With The Consent ApplicationsDocument4 pagesU.P Pollution Control Board: List of Documents To Be Attached Along With The Consent ApplicationsSarthak ShuklaNo ratings yet

- Procedure For Monitoring and MeasurementDocument2 pagesProcedure For Monitoring and MeasurementSAKTHIVEL ANo ratings yet

- Waste Management PlanDocument2 pagesWaste Management PlanVIVO AGGREGATES RESOURCES CORPORATION100% (3)

- CPCB NormsDocument5 pagesCPCB NormsDushyant BhosaleNo ratings yet

- ES-RQ-220 Waste Manangement RequirmentsDocument14 pagesES-RQ-220 Waste Manangement RequirmentsGautam Vijay SimhaNo ratings yet

- Disposal SiteDocument7 pagesDisposal SiteSiphumelele QithiNo ratings yet

- Day 2 LLDA Inspection Protocol 2023 - ED - FinalDocument112 pagesDay 2 LLDA Inspection Protocol 2023 - ED - FinalReagan HernandezNo ratings yet

- Guidelines For Self-Monitoring and Reporting by The IndustryDocument10 pagesGuidelines For Self-Monitoring and Reporting by The IndustryMuhammad SadiqNo ratings yet

- Pollution Control ProgramDocument1 pagePollution Control ProgramWenaNo ratings yet

- Waste Management - Procedure 12Document10 pagesWaste Management - Procedure 12Sonia ChipuNo ratings yet

- Documentation Required For Periodic GMP Compliance Inspection Annex 1 JPDocument5 pagesDocumentation Required For Periodic GMP Compliance Inspection Annex 1 JPspam_discardNo ratings yet

- Module 2Document4 pagesModule 2Ikhwan AlifNo ratings yet

- 6x Fact Sheet Dry Abrasive Blasting PDFDocument2 pages6x Fact Sheet Dry Abrasive Blasting PDFDwi SutiknoNo ratings yet

- National Turf Industry Delivery Assessment Guides Final DrafDocument38 pagesNational Turf Industry Delivery Assessment Guides Final DrafAhmed SayedNo ratings yet

- Industrial User Inspection and Sampling Manual For POTWsDocument282 pagesIndustrial User Inspection and Sampling Manual For POTWsburnt_crustNo ratings yet

- Unit 4 Environmental Audit: DR P.ShobharaniDocument22 pagesUnit 4 Environmental Audit: DR P.Shobharaniharika kolli100% (1)

- WWDP RequirementsDocument2 pagesWWDP Requirementsallan paolo neveidaNo ratings yet

- WWDP Requirements PDFDocument2 pagesWWDP Requirements PDFPure GreenNo ratings yet

- Checklist of Requirements Wastewater Discharge Permit (WWDP) - Online ApplicationDocument2 pagesChecklist of Requirements Wastewater Discharge Permit (WWDP) - Online ApplicationJai McKinleyNo ratings yet

- WWDP Requirements PDFDocument2 pagesWWDP Requirements PDFPure GreenNo ratings yet

- Prior To The Purchase of Control Equipment,.Experience Has T" 1"Ffi:Triffit :ffi :T:Ii, :L 'Il:':Xi :T"H"LDocument11 pagesPrior To The Purchase of Control Equipment,.Experience Has T" 1"Ffi:Triffit :ffi :T:Ii, :L 'Il:':Xi :T"H"LPhoebe Sam Siow YiNo ratings yet

- Basic GMP Checklist For Pharmaceutical PlantsDocument30 pagesBasic GMP Checklist For Pharmaceutical PlantsPrem Goel100% (10)

- Auditoria STDocument10 pagesAuditoria STroyvindasNo ratings yet

- List of Requirements - DENR & LLDA Certificates/permitsDocument3 pagesList of Requirements - DENR & LLDA Certificates/permitsatguintu50% (2)

- Iocl Eia Report For GuwahatiDocument12 pagesIocl Eia Report For GuwahatiNaruttam DasNo ratings yet

- Detail How The Organization Monitors The Quality of Utilities To Minimize Product Contamination RiskDocument5 pagesDetail How The Organization Monitors The Quality of Utilities To Minimize Product Contamination RiskDana SeyfarthNo ratings yet

- Check List For Pollution ControlDocument3 pagesCheck List For Pollution ControlkanstvmNo ratings yet

- Environmenta AuditingDocument43 pagesEnvironmenta Auditingsethu anand100% (1)

- GMP Observations in ProductionDocument2 pagesGMP Observations in ProductionDharmesh PatelNo ratings yet

- Example Paint Booth Filter Agency Operation & Maintenance PlansDocument3 pagesExample Paint Booth Filter Agency Operation & Maintenance PlansHOLYNo ratings yet

- CFS Audit Procedure 3Ts EnglishDocument10 pagesCFS Audit Procedure 3Ts EnglishJetesh DevgunNo ratings yet

- Hazardous and Other Waste Rules 2016Document3 pagesHazardous and Other Waste Rules 2016bhavesh sangtaniNo ratings yet

- CGC HACCP ChecklistDocument9 pagesCGC HACCP ChecklistmahmoodabdellatifNo ratings yet

- Pre-Audit Document Request ListDocument6 pagesPre-Audit Document Request ListAngadNo ratings yet

- COMAHDocument5 pagesCOMAHAkalya RavirajNo ratings yet

- Import of Lead ScrapUsed Lead Acid Batteries - Requirements and Standard Operating ProcedureDocument16 pagesImport of Lead ScrapUsed Lead Acid Batteries - Requirements and Standard Operating ProcedureRanveer Singh MahwarNo ratings yet

- CountryprofileDocument13 pagesCountryprofileKBFNo ratings yet

- All Check List SafetyDocument5 pagesAll Check List SafetynormalNo ratings yet

- SOP LeadDocument7 pagesSOP LeadKishan MauryaNo ratings yet

- Water - DAO 2003-39Document12 pagesWater - DAO 2003-39HjktdmhmNo ratings yet

- Proof of ComploanceDocument3 pagesProof of ComploanceMarco Paolo MagayNo ratings yet

- Lab EstablishmentDocument121 pagesLab EstablishmentSadia Sharmin NilimaNo ratings yet

- Correspondence 298268Document3 pagesCorrespondence 298268sjmpakNo ratings yet

- Potable Water GPPDocument6 pagesPotable Water GPPLWNo ratings yet

- Sofco Nfpa 25 FormDocument5 pagesSofco Nfpa 25 FormVin BdsNo ratings yet

- PDF CIS CIS Information Sheet ProcedureDocument10 pagesPDF CIS CIS Information Sheet ProcedureAgain MishraNo ratings yet

- Ciprs/Cgc Haccp/Ciprs+ Haccp Audit Checklist Audit InformationDocument10 pagesCiprs/Cgc Haccp/Ciprs+ Haccp Audit Checklist Audit InformationKurniawan Eka SaputraNo ratings yet

- Environmental Science Midterm ReviewerDocument9 pagesEnvironmental Science Midterm ReviewerJes GarciaNo ratings yet

- GMP Checklist: Location and SurroundingsDocument29 pagesGMP Checklist: Location and SurroundingsBrian WilliamsNo ratings yet

- Law Evidence SampleDocument29 pagesLaw Evidence SampleadityaNo ratings yet

- 18 FRSTF Paper 59 - EngDocument6 pages18 FRSTF Paper 59 - Engasdasd1414196No ratings yet

- Annex V Document List: Converged Assessment. Collaborative Action. Improved Working ConditionsDocument3 pagesAnnex V Document List: Converged Assessment. Collaborative Action. Improved Working ConditionsBayu Irawan sgi88% (8)

- Duties and Responsibilities of A Pollution Control OfficerDocument2 pagesDuties and Responsibilities of A Pollution Control Officer2GO Corporate HSENo ratings yet

- BPM8 1 SP ProcessDocument13 pagesBPM8 1 SP ProcessAlvin IpNo ratings yet

- OPRP 2 Management of Pest ControlDocument2 pagesOPRP 2 Management of Pest ControlAnggerNo ratings yet

- GPCB Infor CcaDocument4 pagesGPCB Infor CcaTejas PatelNo ratings yet

- SOP - Ready Mix Annual Facility AuditDocument2 pagesSOP - Ready Mix Annual Facility AuditTri widiyah VitantiNo ratings yet

- Manual for the Implementation of Environmental, Health, and Safety Standards for the Control of Locusts: December 2021From EverandManual for the Implementation of Environmental, Health, and Safety Standards for the Control of Locusts: December 2021No ratings yet

- SLHT Grade 7 CSS Week 5 Without Answer KeyDocument6 pagesSLHT Grade 7 CSS Week 5 Without Answer KeyprinceyahweNo ratings yet

- Rich Gas and Lean GasDocument7 pagesRich Gas and Lean GasManish GautamNo ratings yet

- Reviewer For Bookkeeping NCIIIDocument18 pagesReviewer For Bookkeeping NCIIIAngelica Faye95% (20)

- Faculty Vitae 1. Name: C.TamilselviDocument2 pagesFaculty Vitae 1. Name: C.Tamilselvisadeeskumar.dNo ratings yet

- Movie Review of THORDocument8 pagesMovie Review of THORSiva LetchumiNo ratings yet

- AC7140 Rev CDocument73 pagesAC7140 Rev CRanga100% (1)

- 3S Why SandhyavandanDocument49 pages3S Why SandhyavandanvivektonapiNo ratings yet

- Intermediate Programming (Java) 1: Course Title: Getting Started With Java LanguageDocument11 pagesIntermediate Programming (Java) 1: Course Title: Getting Started With Java LanguageRickCy Perucho PccbsitNo ratings yet

- Avanquest Perfect Image V.12 User GuideDocument174 pagesAvanquest Perfect Image V.12 User GuideShafiq-UR-Rehman Lodhi100% (1)

- Portfolio Eelco Maan - 06-2017Document25 pagesPortfolio Eelco Maan - 06-2017tungaas20011No ratings yet

- Grammar Review A2-B1Document5 pagesGrammar Review A2-B1Lena Silva SouzaNo ratings yet

- Manual Bms8n2 e LowDocument58 pagesManual Bms8n2 e Lowzoranbt80_324037655No ratings yet

- Components of Vectors Prepared By: Victor Rea OribeDocument17 pagesComponents of Vectors Prepared By: Victor Rea OribeGerone Tolentino AtienzaNo ratings yet

- Management Glossary - Musa KamawiDocument50 pagesManagement Glossary - Musa KamawiKazi Nazrul IslamNo ratings yet

- Game On Series BibleDocument28 pagesGame On Series Bibleapi-513832615No ratings yet

- Mech VibrationDocument14 pagesMech VibrationSquakx BescilNo ratings yet

- Corporate Profile of Multimode GroupDocument6 pagesCorporate Profile of Multimode GroupShaheen RahmanNo ratings yet

- Grade 7 First Quarter ExamDocument3 pagesGrade 7 First Quarter ExamBILLY JOE ARELLANONo ratings yet

- Accounting For A Service CompanyDocument9 pagesAccounting For A Service CompanyAnnie RapanutNo ratings yet

- Esp8285 Datasheet enDocument29 pagesEsp8285 Datasheet enJohn GreenNo ratings yet

- Risk Assessment For ExcavationDocument6 pagesRisk Assessment For ExcavationAhmed GamalNo ratings yet

- PD750-01 Engine Data Sheet 12-29-20Document4 pagesPD750-01 Engine Data Sheet 12-29-20Service Brags & Hayes, Inc.No ratings yet

- UV-Visible Systems - Operational Qualification - Col23 PDFDocument10 pagesUV-Visible Systems - Operational Qualification - Col23 PDFIsabelle PlourdeNo ratings yet

- Fall 20122Document98 pagesFall 20122DobarCovek67% (3)

- Program Logic FormulationDocument69 pagesProgram Logic FormulationIan OffemariaNo ratings yet

- Esp Kelompok 2Document19 pagesEsp Kelompok 2Taufiq DiNo ratings yet

- File 1) GRE 2009 From - Nov - 18 PDFDocument84 pagesFile 1) GRE 2009 From - Nov - 18 PDFhuyly34No ratings yet

- What On Earth Is A MainframeDocument132 pagesWhat On Earth Is A MainframeCarlos DantasNo ratings yet

- Applied Computational AerodynamicsDocument15 pagesApplied Computational AerodynamicsjoereisNo ratings yet

- Stating Like and DislikesDocument2 pagesStating Like and DislikesDavid ArdiantoNo ratings yet