Professional Documents

Culture Documents

PACCapabilities Brochure

PACCapabilities Brochure

Uploaded by

imant197812gmail.com0 ratings0% found this document useful (0 votes)

14 views16 pagesOriginal Title

PACCapabilitiesBrochure

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views16 pagesPACCapabilities Brochure

PACCapabilities Brochure

Uploaded by

imant197812gmail.comCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 16

Aerospace

Attention to the

smallest detail is

‘mandatory when

manufacturing bigh

performance filer

‘elements Capable of

1 micron

sized particles. Pall

controls every aspect

of the manujacturtig

filers wilt protect

CHALLENGE PALL TO CREATE A SOLUTION FOR You

Change Creates Challenges...

‘The aerospace and military industries have

experienced dramatic changes due to the rapid

evolution of technology. These changes in your business

have caused us to rethink ours. At Pall, we've refocused

our efforts and re-engineered our operation to meet

your changing needs, We've made significant

investments in new technology ourselves; technology

that allows us to design, manufacture and customize

precision products more quickly and efficiently than

ever before. We've

consolidated all of our

efforts in this industry into

‘one operation —

Pall Aeropower Corporation,

a wholly owned subsidiary of

Pall Corporation. We are well

equipped to help you succeed

in today’s competitive global

marketplace.

Investment in Stateoftbeart 3D

Modeling Workstations bas reduced the

lime required to design and

manufacture complex manifolds

Who can meet these challenges?

Pall Aeropower can.

Pall Corporation

is a specialty materials and

engineering company with

the broadest-based

fiitration and

separations

capabilities in the

world. We serve a

diverse, global

customer base in three

‘major markets: Health Care,

Aeropower and Fluid Processing.

Boemg 707

With more than one bilion dollars

in sales and more than 50 years of

experience, we have dedicated

ourselves to applying innovative

technologies and scientific

research to solve complex ‘MI Main Bate Tanke

customer problems.

Our technology met early success

in the aerospace market. The

development of Rigimesli’media

was instrumental in the success of

the Boeing 707 airliner. We are

proud to have been a part of such

milestones as the first successful

USS, satellite launch, man’s first

visit to the moon, and a number of

unique technological

Naina pcre breakthroughs that were of

particular aid to the military

during Desert Storm.

CHALLENGE PALL

(Our focus on total comtamination

control iniproves system performance

and operational safety

TO CREATE A SOLUTION FOR You

Pall Aeropower Corporation

is the world’s leading designer and manufacturer of

sophisticated fluid clarification products for the commercial and

military aircraft, milita

y marine and military mobile markets.

Working with equipment and component manufacturers in

these markets, Pall custom de that remove

ns product

harmful system contaminants. These optim

component service life and improve the operating reli

Ability of

all fluid systems

Our capabilities and experience have grown with the industry

Pall has taken a leadership role in the development of many

standard products and specifications in conjunction with the

articipants

in virtually every aerospace program that has required liquid or

U.S. Government and other customers, We've been

{gas filtration, One example is the leadership position taken by

Pall on the congressionally mandated

ASHRAE committee tasked with improving

cabin air filtration on commercial airliners.

Our expertise is in defining contamination

control requirements for your systems as

well as customizing our products to suit

applications.

Significant investments

accelerate the design

Pall’s major capital investments in technology, manufacturing

equipment and our facilities have significantly enhanced our

precision products. ability to rapidly design and ce optimized 5

contamination control products. Multiple CATIA workstations

have been installed allowing designers to perform

comprehensive evaluation on these products before they are

built. Manufacturing programs

are developed from the CATIA

designs and downloaded

directly to our new CNC multi-

axis machining centers.

Statistical Process Control (SPC)

has been automated at these

centers dramatically improving

in-process inspection. Our

qualification and acceptance

test facilities have also been

and manufacture of

upgraded, streamlining the

entire production proc

CATIA%, a rapid building Computer Aided Design tool,

allows designers to run comprehensive tests on products

before they are built. These investments enable the

design, manufacture and

testing of our products to be completed in-house, including

the creation of our own proprietary filter media. We control

the entire process from beginning to end and maintain a

strict adherence to total product quality.

CATIA ts a registered trademark of Dassault Systemes

Our extensive product line includes a full HYDRAULIC MANIFOLD: This high

aay of mantle elements and Caan eae

indicators. Among them are well known integral bypass and relief valves with

weight, simplified maintenance and

and

products in the industry such as:

Define the problem...

design, create, assemble and test the solution.

Customer and Pall 3D modeling of the new

Acropower engineering ‘Filter manifold desien.

team meet for a filter

‘manifold design review.

PRESSURE SWING ADSORBERS: PURIFIERS: Pll Fluid Purifiers

Pro orbers

all known and suspected chemteat Jrom

warfare vapor fluids

fncluding the

new gonoration of chemteat

detectable lev without altering the physical

‘or chemical properties of the

warfare agents known as°Carbon treated fluid

Breakers” or “Filter Penetrants

Filter Housings

A The computeratded

design (CAD) ts translated

{nto a computer atded

manufacturing (CAM

program.

HYDRAULIC MANIFOLD: This

Hydraulic Manifold incorporates

sopbisticated vatving to control

flutd sransfer between systems and

‘4 modular base design permiting

{fast removal of the manifold

‘without loss of fluid oF the need to

remove plumbing,

“Y Precision machining

using state-of-the-art

equipment at Pall

New Port Richey: FZ

manufacturing facilis

A. Pals corrugator

ensures consistent

leating of filter

clement media pack,

DIRT ALERT“:The Dirt Alert filter

Clement incorporates a diagnostic

ayer which can be removed

‘onsite for easy inspection of

captured debris, reveating

valuable information about

the system's operating

F conaution

{¥. Openatar programs a Key manufacturing

computer numerically dimensions are measured

controlled (CNC), electronically and the

‘multéacei, multipatate, ‘outpus ts forwarded t0 a

bortsontal machining ‘computer for Statistical

center Process Control (SPC).

A. Assembly and acceptance

lest of byydrauic manifold

fn Pall Aeropower's

Skydrol Lab

Assemply of a diet stage A. ter elements are

filter element designed endcapped in automated

to merease service life rotary carousel

‘and enbance operational

HYDRAULIC MANIFOLD: Our AQUISEP®:The Aquasep

Hydraulic Manifolds incorporate Ligquid/Liquld Coatescer ts

shutoff diaphragms tn the bead to designed to remove water

bout cavities to prevent the loss of _from the new generation of

‘stem flute during filter element ‘advanced jet fuels sticb as

replacement and prevents bot! JP8+100.

installation without an included

‘flter element.

— CHALLENGE PALL TO CREATE A SOLUTION FOR You

A worldwide

commitment to

Pall has long been known for its commitment to providing

an unparalleled level of customer support and service.

Product quality and prompt delivery are undergoing

continual improvement. In addition, we're available to aid in

contamination

control solutions.

problem solving, system recommendations and the sharing

of scientific information. We work with you every step of

the way to ensure you're provided with a custom-designed

solution to your contamination control concems.

e field a large team globally 10 maximize our avail

to you - our customer.

lability

Pall Acropower supports you

with services ranging from

‘Overhaul and Repair of our

components to fulfilling spare

parts requirements. Our

Customer Support

‘organization operates

according to Air Transport

Association guidelines for all

fielded components.

© Sates Offices ~ Pall Corporation

Hield Representatives ~ Russell Associates

Manufacturing Plants

eee

SIS and RED Facilities

Distributors ~ PAS & Satair

Reservoir Vent Filter/Dnyer provides Chance Filter (LCE) ts a point of

‘optimum protection agatnst use fter that protects flutd system

moisture andl solid particulates components from catastrophic

centering open fluid systems Saitire caused by system

VENT FILTER DRYER-THe Pett LAST CHANGE FILTER: A Last

generated particles

— CHALLENGE PALL

Work with the people

who are not only

experts in their

industry...but also

understand yours.

For the more challenging problems, Pall

bas bighty trained personnel available

1 assist you with your needs.

TO CREATE A SOLUTION FOR YoU

Pall engineers and scientists are experts in the many

applications throughout the Aerospace and Military

industries where Pall technology contributes to minimizing

fluid system component wear, thus extending component

life and reducing equipment downtime

Our application engineers and design engineers have

extensive first-hand knowledge of the fluid clarification

challenges of your industry. Their experience ensures that

the solutions they devise for your applications can be

integrated into your systems easily and efficiently.

‘The Scientific and Laboratory Services group

(SLS) works with customers, provid

ig the

assistance needed to solve more complex

system contamination control problems.

is unique in the industry and has a global

reach with over 400 scientists and engineers

deployed at more than twenty well-

equipped laboratories throughout the world

igh

CABIN AIR: Cabin Atr CENTRISEP™ The Contrisep Air

Filtration elements remove Cleaner ta biebly efferent

bathogenic bacteria and virus compact, selfscavenging device

Jrom recirculated cabin at that removes damaging

significantly lowering the risk particulate contamination from

‘of contracting infections in engine inlets, bleed at. cooling

fair and environmental

conditioning systems

: ;

jow and into the future

Some of the developments pioneered by Pall illustrate our

ongoing commitment to furthering contamination control

technology for the commercial aerospace and military defense

industries,

Graywater

Treatment System

Developed to meet current

and future national and

international effluent discharge

standards, the Pall Graywater

offer

pollution prevention

capabilities that allow Naval

Vessels extended operational

Treatment Systen

time in environments

nsitive waters and the ability to utilize ports which don’t

have pier-side waste collection facilities. The system separates

the gt

contaminant) stream and a purified permeate stream. The

ms — a retentate (concentrated

purified permeate stream meets the necessary environmental

requirements to be discharged directly into inkand and coastal

waters.

CHALLENGE

PALL

engine maintenance

replacement. The Pall team developed a solution ~ a di

TO CREATE A SOLUTION FOR You

Aquasep* Coalescer

Current coalescer technology is not effective in

removing “free water” contamination from

today’s advanced jet fuels such as JP8+100, Pall

Acropower is working with the Air Force, the

Navy and a leading engine manufacturer in

testing new coalescer technology that will

effectively remove “free water” contamination

from JP8+100 jet fuel. SLS is working on the

standards committee involved with this project

and will be directly responsible for setting up

a large scale facility to test the effectiveness

of Pall’s unique coalescer at high operational

flow rates.

Dual Stage

Filtration System

The formation of lubricant

thermal breakdown products

within jet engines can result in

the plugging of the lubrication

system filters, often requiring

shut down of the engine in

flight. This could interrupt or

abort a flight and require

ind, in some cases, even engine

al-stage

filtration system where the second stage is used as a back-up if

the primary filter clogs, thus preventing the need to shut down

the engine in flight

Put Pall on your team.

Pall customers are assured of unparalleled quality and extensive

customer support. Please contact a Pall representative, so we

can show you how Pall can help you:

© Enhance system performance

© Reduce system component wear

© Reduce equipment downtime

ixtend system service interval

© Monitor and reduce environmental impact

Our commitment to you is a simple one - Pall

Aeropower stands ready to be part of your team,

applying our technology and resources to your

‘fluid clarification challenges.

Challenge us to create a solution for you.

}—- CHALLENGE PALL

Pall supports

our customers with

in-field services.

TO CREATE A SOLUTION FOR YoU

RUSSELL ASSOCIATES

Russell Associates, Pall’s wholly owned subsidiary, ts your technical

representative in the field They are the liaison between your system

developers and Pall Aeropower's Application and Design Engineers. Russell

is one of the nation’s leading manufacturers’ representatives with regional

offices located in all of the most bighly concentrated aerospace and defense

conters in the US. and Canada.

Pas

PAS, a division of Russell Associates, is the stocking distributor of atrerapt

filters for Pall Aeropower As the largest supplier of aireraft filters in the

North American commercial airline aftermarket, they maintain a multi-

million dollar inventory of aircraft and helicopter filters. PAS ts also a

major supplier of fter kits, customdesigned for easy installation and

labeled to conform with your maintenance practices. The PAS team offers

‘superior customer support through highly-trained experts in the fleld, same

day shipment of most parts, and maintains an AOG service for after hours

emergencies,

SarUR

Satair provides filter product stocking distributor support beyond North

and South America. They specialize in the efficient and reliable distribution

of aircraft parts on a global basts, representing a smal but carefully.

‘Selected group of companies. In addition, Satair can supply a bighty

knowledgeable level of technical support and prides itself on on-tine

delivery of product Satair is known for its immediate and reliable response,

with electronic links between all Satair offices worldwide.

SEMINARS

As an additional service, Pall provides scientific and technical seminars

encompassing the subjects of fluid clarification, filtration, and solids

separation. These programs are presented by senior application engineers

and scientists and are tailored to your specific needs.

WEB SITE

Pall Aeropower can be contacted via the World Wide Web. This site features

information that allows our customers to keep current with the latest.

developments in Pall technology: Contact us at btipy//www pall.com

aerospace

Pall Aeropower Corporation

5175 Rio Vista Dive

(Clearwater, FL33760

727.539.8448 phone

727°535.0401 fax

ppace@pal.com e-mal

Frttration. Separation. Solution.

Visit us on the web at www.pall.com/aerospace

at Corporation has oes and ante troupe the worl cts wich ae

‘nom ar a Sar Koes Vaya Men, he Nara hw dane

‘ova, Pour Puts eo: Fusun, Snopor, Span, Sue, Suez. Tn

‘elt Staci wether at naman

cpa tpn GE mie

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- FT8 Technical - SpecsDocument36 pagesFT8 Technical - Specsimant197812gmail.comNo ratings yet

- 19 AEL Service Guide C E AllDocument2 pages19 AEL Service Guide C E Allimant197812gmail.comNo ratings yet

- PRD Doc Pdi 908163-Eds-3446-1-0250-000-En Sen Ain V1Document1 pagePRD Doc Pdi 908163-Eds-3446-1-0250-000-En Sen Ain V1imant197812gmail.comNo ratings yet

- Dokumen - Tips - High Temperature CP An Ca Sensors For Ge LM Applicationswwwaesse Misureitncmsdataia6110vm Sensors For LM v10pdfpdfDocument2 pagesDokumen - Tips - High Temperature CP An Ca Sensors For Ge LM Applicationswwwaesse Misureitncmsdataia6110vm Sensors For LM v10pdfpdfimant197812gmail.com100% (1)

- 劳伦斯3500系列阀 en zh-CNDocument4 pages劳伦斯3500系列阀 en zh-CNimant197812gmail.comNo ratings yet

- GS16 Gas Valve - en.zh-CNDocument4 pagesGS16 Gas Valve - en.zh-CNimant197812gmail.comNo ratings yet

- Koutsaki Eleni Dip 2020Document96 pagesKoutsaki Eleni Dip 2020imant197812gmail.comNo ratings yet

- 热力发电厂职业健康与安全指南Document34 pages热力发电厂职业健康与安全指南imant197812gmail.comNo ratings yet

- 44-Zok 27 SDS4524Document10 pages44-Zok 27 SDS4524imant197812gmail.comNo ratings yet

- PRD Doc Buw 669897-00001 Sall Ain V8Document76 pagesPRD Doc Buw 669897-00001 Sall Ain V8imant197812gmail.comNo ratings yet

- 赌博障碍的认知功能缺陷及神经基础Document7 pages赌博障碍的认知功能缺陷及神经基础imant197812gmail.comNo ratings yet

- Machinery Health™ Sensor: PR 9350 / K 20 315, Linearer WegaufnehmerDocument28 pagesMachinery Health™ Sensor: PR 9350 / K 20 315, Linearer Wegaufnehmerimant197812gmail.comNo ratings yet

- 95-8704-5.1 - (X3301 Enhanced) - WebDocument48 pages95-8704-5.1 - (X3301 Enhanced) - Webimant197812gmail.comNo ratings yet

- Adapt 3701 44 Aeorderivative Datasheet 100m8649l 0Document18 pagesAdapt 3701 44 Aeorderivative Datasheet 100m8649l 0imant197812gmail.comNo ratings yet

- 1LA7133-4AA61 Datasheet enDocument1 page1LA7133-4AA61 Datasheet enimant197812gmail.com100% (1)

- UntitledDocument19 pagesUntitledimant197812gmail.comNo ratings yet

- 西门子SGT5 2000EDocument8 pages西门子SGT5 2000Eimant197812gmail.comNo ratings yet

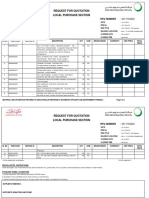

- Request For Quotation Local Purchase Section: RFQ NumberDocument2 pagesRequest For Quotation Local Purchase Section: RFQ Numberimant197812gmail.comNo ratings yet

- Development of A Data-Driven Model For Marine Gas .En - ZH-CNDocument13 pagesDevelopment of A Data-Driven Model For Marine Gas .En - ZH-CNimant197812gmail.comNo ratings yet

- Goodview Turbine Serives: Since 1999Document34 pagesGoodview Turbine Serives: Since 1999imant197812gmail.comNo ratings yet

- 流动形式 M 进⽔⼝ A 流动形式 O A&C奥特莱斯 流动形式 P A&C⼊⼝ B 奥特莱斯: Circor公司Document4 pages流动形式 M 进⽔⼝ A 流动形式 O A&C奥特莱斯 流动形式 P A&C⼊⼝ B 奥特莱斯: Circor公司imant197812gmail.comNo ratings yet

- Appendix N - Capacity Expansion StudyDocument67 pagesAppendix N - Capacity Expansion Studyimant197812gmail.comNo ratings yet

- BHCS18711F EX2100 Factsheet - R1Document2 pagesBHCS18711F EX2100 Factsheet - R1imant197812gmail.comNo ratings yet

- Silo - Tips Siemens Ag 2015 All Rights Reserved Answers For EnergyDocument28 pagesSilo - Tips Siemens Ag 2015 All Rights Reserved Answers For Energyimant197812gmail.comNo ratings yet

- Wartsila 50 DFDocument96 pagesWartsila 50 DFimant197812gmail.comNo ratings yet

- Gas Turbine Seminar - 19Document54 pagesGas Turbine Seminar - 19imant197812gmail.comNo ratings yet

- Gea-S1252c Controlst Fact SheetDocument2 pagesGea-S1252c Controlst Fact Sheetimant197812gmail.comNo ratings yet

- Turbine Parts RepairDocument11 pagesTurbine Parts Repairimant197812gmail.comNo ratings yet

- Power Systems H-Gas Turbines - en.zh-CNDocument22 pagesPower Systems H-Gas Turbines - en.zh-CNimant197812gmail.comNo ratings yet

- Design and Test of The FT8 Gas TurbineDocument9 pagesDesign and Test of The FT8 Gas Turbineimant197812gmail.comNo ratings yet