Professional Documents

Culture Documents

Sesiขn #6 (PM) - Tratamiento, Intervenciขn, Prevenciขn y Supervisiขn (Psicologกa Industrial) - Anejo #1

Uploaded by

Luz N. FernándezOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sesiขn #6 (PM) - Tratamiento, Intervenciขn, Prevenciขn y Supervisiขn (Psicologกa Industrial) - Anejo #1

Uploaded by

Luz N. FernándezCopyright:

Available Formats

ti uie Training

use on-the-job training has the potential for disrupting the production

process, many companies prefer vestibule training; that is, establishing a

lated workspace in a separate training facility. (A vestibule is a hail-

er entrance foyer between the outer door of a building and its main

. In the early days of American industry, vestibule schools were

ized just inside the doors of industrial plants to introduce new work-

their jobs with a few weeks of specialized training. The word vestibule

used in this context to denote that the training program is like an entry-

av or passageway the employee must traverse before getting to the job

Using the same kind of equipment and operating procedures as the

ac :al work situation, a vestibule training program relies on skilled instruc-

, rather than experienced workers and supervisors, to teach new work-

how to perform their jobs.

There are several advantages to vestibule training. Because its sole

urpose is training, there is no pressure to maintain a given level of pro-

ctrvity. Trainees do not have to be concerned about making costly or

embarrassing errors or about damaging production equipment. They can

ntrate on learning the skills necessary to be successful on the job.

The greatest disadvantage of vestibule training is the cost. The orga-

tion must equip the facility and maintain a teaching staff. This expense

particularly burdensome when there are not enough new workers to

make full use of the training facility.

if the training situation does not correspond closely to the work situ-

negative transfer of training will occur, and the trainees may need

on-the-job instruction once they start to work. This problem can

t- aggravated by the common industry practice of using obsolete equip-

eat, retired from the production floor, in the training facility. However,

vestibule training program is properly designed, staffed, and equipped,

can be an effective training technique.

Apprenticeship

t,rhaps the earliest recorded training method still in use today is the

apprenticeship program for skilled crafts and trades in private-sector in-

dustries such as construction and manufacturing. Programs are available

plumbers, carpenters, electronics technicians, painters, and auto me-

_tunics, among others. Conducted in the classroom and on the job, ap-

,7renticeship involves extensive background preparation in the craft as well

actual work experience under the guidance of experts.

Apprenticeships average 4 to 6 years. The standard procedure is for

the trainees to agree to work for a company for a fixed period in return for

(lapter 6 tra niu and 1

You might also like

- Practical Guide To Work Study [Revised Edition]From EverandPractical Guide To Work Study [Revised Edition]Rating: 4 out of 5 stars4/5 (1)

- BridgingTheGap ApprenticeshipPlaybook April-2021Document74 pagesBridgingTheGap ApprenticeshipPlaybook April-2021TALENTA INSAN GEMILANGNo ratings yet

- Concepts of Training and DevelopmentDocument24 pagesConcepts of Training and DevelopmentPrafful AgarwalNo ratings yet

- Training Session Evaluation FormDocument15 pagesTraining Session Evaluation FormJoseGocelaTaporocJr.0% (1)

- Organization Management Answer Sheet Week 1 q2Document14 pagesOrganization Management Answer Sheet Week 1 q2Maestro MertzNo ratings yet

- IntroductionDocument1 pageIntroductionSon Yong75% (4)

- Modern Methods of Vocational and Industrial TrainingFrom EverandModern Methods of Vocational and Industrial TrainingNo ratings yet

- Welcome Remarks (OJT Virtual Orientation)Document2 pagesWelcome Remarks (OJT Virtual Orientation)Lipa City CampusNo ratings yet

- Ch08 Training and Developing EmployeesDocument39 pagesCh08 Training and Developing Employeesremon4hrNo ratings yet

- Structured On-the-Job Training: Unleashing Employee Expertise in the WorkplaceFrom EverandStructured On-the-Job Training: Unleashing Employee Expertise in the WorkplaceRating: 5 out of 5 stars5/5 (3)

- Training and DevelopmentDocument37 pagesTraining and DevelopmentAnushka GargNo ratings yet

- Education & Training in Psyhiatric CareDocument11 pagesEducation & Training in Psyhiatric Carepreeti sharma73% (11)

- Training & Development Notes Training & Development NotesDocument24 pagesTraining & Development Notes Training & Development NotesMonikamit TushirNo ratings yet

- Cement Division Technical Training Tools: 090519 Technicaltrainingtools DescriptionDocument6 pagesCement Division Technical Training Tools: 090519 Technicaltrainingtools Descriptionrupesh soniNo ratings yet

- Ece Ojt Narrative Report Summer 2014Document3 pagesEce Ojt Narrative Report Summer 2014Eunice Jane Bolgado-Doctor100% (4)

- Vestibule TrainingDocument4 pagesVestibule TrainingMonica ManharNo ratings yet

- Session 10Document3 pagesSession 10Nikhil SharmaNo ratings yet

- Training MethodsDocument9 pagesTraining Methodsaswathi1No ratings yet

- Training MethodsDocument15 pagesTraining MethodsBhaven TamakuwalaNo ratings yet

- What You're Not Measuring Could Be Affecting Your ProductivityDocument5 pagesWhat You're Not Measuring Could Be Affecting Your ProductivityQuelmis De La Cruz Vilca AmesquitaNo ratings yet

- Case Study - Human ResourceDocument6 pagesCase Study - Human ResourceErna Limbaco Salva AmoresNo ratings yet

- Vestibule Training MethodDocument8 pagesVestibule Training MethodRohit NairNo ratings yet

- PSY 292 Employee Training Methods IDocument11 pagesPSY 292 Employee Training Methods ISasha LimNo ratings yet

- Developing Human ResourcesDocument89 pagesDeveloping Human ResourcesSäñtosh ÄdhïkärïNo ratings yet

- A Study On Effectiveness of Training Hindusthan Motors LTDDocument9 pagesA Study On Effectiveness of Training Hindusthan Motors LTDBalaji KrishnanNo ratings yet

- Chapter FourDocument11 pagesChapter FourAbdu YaYa AbeshaNo ratings yet

- 3 TypesDocument2 pages3 TypesHadia ZafarNo ratings yet

- Employee Training & Development: Ashish Sehrawat Puneet NandaDocument7 pagesEmployee Training & Development: Ashish Sehrawat Puneet NandamohitgeetNo ratings yet

- Assignment Mam Aqsa 0124Document4 pagesAssignment Mam Aqsa 0124ali burhan tahirNo ratings yet

- Vestibule TrainingDocument1 pageVestibule Trainingdarkprinze50% (2)

- Vestibule Training: BY G.Hari KrishnaDocument9 pagesVestibule Training: BY G.Hari KrishnaHari KrishnaNo ratings yet

- Methods of TrainingDocument15 pagesMethods of TrainingDarrel DsouzaNo ratings yet

- RootsDocument93 pagesRootsPavoNo ratings yet

- Week 9Document17 pagesWeek 9kielaustin1968No ratings yet

- WK 4 Human Resource Training and Development - 1 - 1Document15 pagesWK 4 Human Resource Training and Development - 1 - 1kenlay makanaNo ratings yet

- Unit 3 Employee Training and DevelopmentDocument23 pagesUnit 3 Employee Training and Developmentkumar sahityaNo ratings yet

- SUMMARY REPORT InternDocument3 pagesSUMMARY REPORT Internnur amanina ayuniNo ratings yet

- People ManagementDocument2 pagesPeople Managementjulie dead100% (1)

- Jacquiline C. Dañez Bsie-IvgkDocument23 pagesJacquiline C. Dañez Bsie-IvgkPatricia Andrea UgayNo ratings yet

- Elgi FinalDocument85 pagesElgi FinalPavoNo ratings yet

- Ojt Prelim LMS Lesson ProperDocument7 pagesOjt Prelim LMS Lesson Propercaasiraymond33No ratings yet

- On The Job and Off The Job Training AdvantagesDocument6 pagesOn The Job and Off The Job Training AdvantagesMuddasir Anita100% (1)

- Executive SummaryDocument5 pagesExecutive SummarySahejaj NooraniNo ratings yet

- Important 1 Marks QuestionDocument3 pagesImportant 1 Marks Questionkirti chettyNo ratings yet

- BUS 375 Technological Based Employee TraniningDocument11 pagesBUS 375 Technological Based Employee TraniningMoazzam ShahNo ratings yet

- Reviewer Work Based LearningDocument8 pagesReviewer Work Based LearningJannalyn FabroNo ratings yet

- Chapter IVDocument5 pagesChapter IVRodelbert LopezNo ratings yet

- LTT Capability-ListDocument8 pagesLTT Capability-ListTan Chin Tuan MichaelNo ratings yet

- Southeast University: Assignment ForDocument8 pagesSoutheast University: Assignment ForMRDEWANNo ratings yet

- Modern Textiles Is in The Business of Producing Garments and Has An Average Annual Turnover of Rs 3 BillionDocument2 pagesModern Textiles Is in The Business of Producing Garments and Has An Average Annual Turnover of Rs 3 BillionVikram KumarNo ratings yet

- Unit 4Document10 pagesUnit 4kaicaras16No ratings yet

- Work Based TrainingLinkDocument8 pagesWork Based TrainingLinkDanilo CumpioNo ratings yet

- Chapter 20 - TrainingDocument4 pagesChapter 20 - TrainingAliNo ratings yet

- Training and Development in HALDocument58 pagesTraining and Development in HALyoganthmurthy100% (1)

- Introduction To Employee Training and DevelopmentDocument23 pagesIntroduction To Employee Training and Developmentazamislam727843No ratings yet

- Training For Aseptic Processing EnvironmentsDocument2 pagesTraining For Aseptic Processing EnvironmentsNaim KhandakerNo ratings yet

- Difference Between Apprenticeship and InternshipDocument5 pagesDifference Between Apprenticeship and Internshipchicken pork adoboNo ratings yet

- Evaluate The Various Methods That Network Rail Uses To Train and Develop Its EmployeesDocument2 pagesEvaluate The Various Methods That Network Rail Uses To Train and Develop Its EmployeesjannatNo ratings yet

- Work at Height Assessor Course CentreDocument7 pagesWork at Height Assessor Course Centrekqgcnxejd100% (1)

- Format of Monthly Accomplishment ReportDocument6 pagesFormat of Monthly Accomplishment ReportAli AquinoNo ratings yet

- Module 1 TvtedDocument4 pagesModule 1 Tvtedphilmark dalitNo ratings yet

- Case Study 2 Personnel ManagementDocument4 pagesCase Study 2 Personnel ManagementLymar Von EcapNo ratings yet

- Ways/Methods of TrainingDocument5 pagesWays/Methods of TrainingNoon Laghari BalochNo ratings yet

- Portfolio Project: EDUC 765: Trends and Issues in Instructional DesignDocument21 pagesPortfolio Project: EDUC 765: Trends and Issues in Instructional Designapi-361466236No ratings yet

- Act 1 - Prof Ed 10Document2 pagesAct 1 - Prof Ed 10Dadz CoraldeNo ratings yet

- Module 1: Introduction To Work-Based Learning/trainingDocument3 pagesModule 1: Introduction To Work-Based Learning/trainingDexisne RoseNo ratings yet

- Blue Altitude Human Factors Refresher Aviation MaintenanceDocument1 pageBlue Altitude Human Factors Refresher Aviation MaintenancesebastienNo ratings yet

- Nea - Gov.sg - List of WSQ Training Modules For Cleaning PWM - 20220906, 2022Document13 pagesNea - Gov.sg - List of WSQ Training Modules For Cleaning PWM - 20220906, 2022Amani NavitaNo ratings yet

- Training and Devlopment Voltas Ltd. Final PrintDocument81 pagesTraining and Devlopment Voltas Ltd. Final PrintPrabhat SharmaNo ratings yet

- Introduction To Human Resource Development: Werner & Desimone (2006) 1Document33 pagesIntroduction To Human Resource Development: Werner & Desimone (2006) 1Sapna Snehal ChauhanNo ratings yet

- On The-Job-Training Experience at PersonivDocument3 pagesOn The-Job-Training Experience at PersonivCharle TsaiNo ratings yet

- SMPC Delivery and Assessment Guide v1 June 2022Document37 pagesSMPC Delivery and Assessment Guide v1 June 2022idontlikeebooksNo ratings yet

- APTA-RT-OP-S-005-03 Rev 3-Operations Control Center-OCCDocument17 pagesAPTA-RT-OP-S-005-03 Rev 3-Operations Control Center-OCCSocrates MoralesNo ratings yet

- BTS 07Document21 pagesBTS 07Rajni KumariNo ratings yet

- Narrative - Leynard D.V ColladoDocument48 pagesNarrative - Leynard D.V ColladoLeynard ColladoNo ratings yet

- PORTFOLIO Simple Sample GuideDocument6 pagesPORTFOLIO Simple Sample GuideLady Jane CainongNo ratings yet

- Task of Training FunctionDocument9 pagesTask of Training FunctionGaurav SharmaNo ratings yet

- NARRATIVEDocument16 pagesNARRATIVEcontactskantaoNo ratings yet

- Walmart'S Human Resource ManagmentDocument9 pagesWalmart'S Human Resource ManagmentHai HelloNo ratings yet

- Sample NETDocument21 pagesSample NETikatal20No ratings yet

- Narrative ReportDocument2 pagesNarrative ReportJohn Cedric BoocNo ratings yet

- Eoi For Training Partner Empanelment.v2Document38 pagesEoi For Training Partner Empanelment.v2Deepak BamNo ratings yet

- Narrative ReportDocument46 pagesNarrative ReportAllen MonzonNo ratings yet

- Format-Sa-Portfolio Ni JettdelosreyesDocument23 pagesFormat-Sa-Portfolio Ni JettdelosreyesHec KerNo ratings yet

- UntitledDocument43 pagesUntitledCristine ArcillasNo ratings yet

- Name of Company Address of Company Name of Company Representative1 (See Page 4) Position of Company Representative1 (See Page 4)Document5 pagesName of Company Address of Company Name of Company Representative1 (See Page 4) Position of Company Representative1 (See Page 4)HatdogNo ratings yet

- MANA 7336 JSW Chapter 7Document65 pagesMANA 7336 JSW Chapter 7ath5063No ratings yet

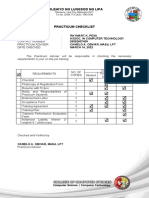

- Kolehiyo NG Lungsod NG LipaDocument3 pagesKolehiyo NG Lungsod NG LipaSharmine MalaluanNo ratings yet

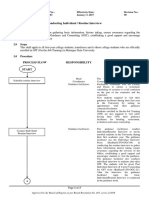

- Conducting Individual / Routine Interview: 1.0 ObjectiveDocument3 pagesConducting Individual / Routine Interview: 1.0 ObjectiveSean Palacpac-ResurreccionNo ratings yet

- Internship AgreementDocument2 pagesInternship AgreementAL Vincent MiravallesNo ratings yet

![Practical Guide To Work Study [Revised Edition]](https://imgv2-1-f.scribdassets.com/img/word_document/245836753/149x198/e8597dfaef/1709916910?v=1)