Professional Documents

Culture Documents

DC Machine Device: 1 Description

Uploaded by

Nandini JayakumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DC Machine Device: 1 Description

Uploaded by

Nandini JayakumarCopyright:

Available Formats

DC machine device

+

DCM1

DC machine device.......................................................................................................... 1

1 Description ..................................................................................................................... 1

1.1 The DC-machine symbol...................................................................................... 1

1.2 Variables used to define the DC-machine model ............................................. 2

1.3 Theoretical summary ............................................................................................ 2

1.3.1 Main model equations ................................................................................... 2

1.3.2 Mechanical equations.................................................................................... 3

2 Parameters .................................................................................................................... 5

2.1 Main Data................................................................................................................ 5

2.2 Mechanical data..................................................................................................... 5

2.3 Control ..................................................................................................................... 6

2.4 Observe/Scope ...................................................................................................... 6

2.5 Precision ................................................................................................................. 6

2.6 How to control the external mechanical torques .............................................. 6

2.7 Base quantities ...................................................................................................... 7

3 Rules ............................................................................................................................... 7

4 Netlist format.................................................................................................................. 7

5 Load-Flow model .......................................................................................................... 9

6 Steady-state model....................................................................................................... 9

7 Initial conditions............................................................................................................. 9

8 Frequency Scan model ................................................................................................ 9

9 Time-domain representation ....................................................................................... 9

1 Description

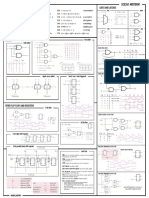

1.1 The DC-machine symbol

The DC-machine device is a 1-phase device. The following figure presents available device pins.

EMTP-EMTPWorks, 2/28/2005 2:00:00 PM Page 1 of 10

1-phase pins for

armature connections

Control bundle for

+

observable signals

1-phase pins for

field winding

Control bundle for

controlled signals

Figure 1 DC machine

1.2 Variables used to define the DC-machine model

The variables used in this model are defined in the following table.

Symbol Description

va Armature winding voltage

vf Field winding voltage

ia Armature winding current

if Field winding current

Ra Armature winding resistance

Rf Field winding resistance

L ff Self-inductance of the field winding

Laa Self-inductance of the armature winding

Laf Mutual inductance between the field and the rotating armature coils

ωrm Mechanical speed

ωbm Base mechanical speed

Pb Rated power of the machine (W)

Te Electromagnetic torque (Nm)

1.3 Theoretical summary

1.3.1 Main model equations

Two voltage equations define the machine model.

The field voltage equation in time-domain is:

dif R 1

(t) = − f if (t) + v f (t) (1)

dt L ff L ff

The armature voltage equation is :

EMTP-EMTPWorks, 2/28/2005 2:00:00 PM Page 2 of 10

dia R L 1

(t) = − a ia (t) − af if (t) ωrm (t) + v a (t) (2)

dt Laa Laa Laa

where L ff and Laa are the self-inductances of the field and armature windings respectively. The

rotor speed is denoted as ωrm , and Laf is the mutual inductance between the field and the

rotating armature coils. The above equations correspond to the equivalent circuit shown in Figure

2.

Rf Laa Ra

+ + +

+ +

+

vf if L ff Laf if ωr va

ia

- -

Figure 2 Equivalent circuit of a DC-machine

The electromagnetic torque developed by a DC machine is given by :

Te = Laf if ia (3)

The equivalent circuit for the steady state solution is the same as the circuit shown in Figure 2,

only now phasor (frequency domain) quantities are used.

1.3.2 Mechanical equations

The simplest model for the mechanical part is the single mass representation as used in stability

studies:

dω

J rm + Dωrm = Te − Tturbine (4)

dt

where:

J is the moment of inertia of rotating turbine-generator mass

ωrm is the mechanical speed

D is the damping coefficient for viscous and wind friction

Tturbine is the torque input to turbine

Te is the electromagnetic torque of the generator

Modeling the mechanical part of a DC-machine with a single mass representation is not

sufficiently accurate in some situations. Unlimited number of masses can be specified to define

the rotor shaft. Each major element is considered to be a rigid mass connected to adjacent

elements by mass less springs. An external torque can be applied on each individual mass.

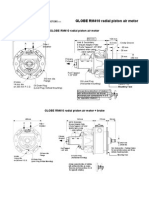

Figure 3 shows a typical 6-mass model.

EMTP-EMTPWorks, 2/28/2005 2:00:00 PM Page 3 of 10

Figure 3 Diagram of the turbine/alternator assembly of the mechanical part

The n-spring-connected rotating masses are then described by the rotational form of Newton’s

second law:

dωrm

J + D ωrm + HSP θrm = Te − Tturbine (5)

dt

where:

J is the diagonal matrix of moments of inertia ( J1 to J5 in Figure 3)

ωrm is the vector of mechanical speeds

θrm is the vector of angular positions

HSP is the tridiagonal matrix of stiffness coefficients

D is the tridiagonal matrix of damping coefficients

Tturbine is the vector of torques applied to the turbine stages (see Tm1 to Tm4 in Figure 3)

Te is the vector of electromagnetic torques of generator (see Tm5 in Figure 3)

The moment of inertia and the stiffness coefficients are normally available from design data. The

spring action of the shaft section between masses i-1 and i creates a torque which is proportional

to the angle twist θrm i − θrm i +1 . The proportionality factor is the stiffness coefficient or spring

constant HSPi i+1 . This spring action torque acts in opposite directions on masses i-1 and i :

Tspring i −1 = −Tspring i = HSPi −1 i ( θrm i −1 − θrm i ) (6)

From equation (6) it can be seen that the HSP matrix has the following form (3 masses case):

⎡ HSP12 −HSP12 0 ⎤

HSP = ⎢⎢ −HSP12 HSP12 + HSP23 −HSP23 ⎥⎥ (7)

⎢⎣ 0 −HSP23 HSP23 ⎥⎦

Three damping effects are included with the damping coefficients, namely the absolute speed self

damping DSDi of mass i, the mutual damping coefficient DSMi i +1 and the mutual damping

coefficient DSMi −1 i . The damping torque acting on mass i is therefore:

Tdamping i = DSDi ωrm i + DSMi −1 i ωrm i − ωrm( i −1 ) + DSMi i+1 ( ωrm i − ωrm i+1 ) (8)

From equation (8) it can be seen that D has the same structure as HSP except that the diagonal

element is now DSDi + DSMi −1 i + DSMi i +1 , as shown in this 3 masses example:

⎡DSD1 + DSM12 −DSM12 0 ⎤

D = ⎢⎢ −DSM12 DSD2 + DSM12 + DSM23 −DSM23 ⎥

⎥ (9)

⎢⎣ 0 −DSM23 DSD3 + DSM23 ⎥⎦

Another damping coefficient, named speed deviation self damping for a given mass (DSR), is

also available. By definition:

Ti = DSRi ( ωm i − ωbm ) (10)

EMTP-EMTPWorks, 2/28/2005 2:00:00 PM Page 4 of 10

where ωbm is the base mechanical (synchronous) speed.

It is difficult to obtain realistic values for these damping coefficients. Fortunately, they have very

little influence on the peak torque value during transient disturbances.

2 Parameters

2.1 Main Data

• Rated voltage: Rated stator terminal voltage of the machine. Used in the

definition of base values upon which pu machine parameters are to applied.

• Rated power: Power rating of the machine. Used in the definition of base

values upon which pu machine parameters are to applied.

• Rated speed: Rated mechanical speed ( ωrm ) of the machine. Used in the

definition of base values upon which pu machine parameters are to applied.

• Electrical parameters: Electrical parameters that define the machine model.

When pu units are specified the rated values above are used for conversion.

• Initialization method: The machine can start from no initial conditions

(option none) or from a steady-state computations (option steady-state). If

the steady-state option is chosen, the steady-state field and armature

currents are required. The steady-state speed is also required. EMTP

automatically calculates the steady-state torque. This constant torque will be

taken as the external torque as long the “Controlled torque start time” is not

exceeded when a mechanical torque control signal is available.

2.2 Mechanical data

• Lock rotor shaft for negative speed: This option allows locking the rotor

shaft if the external torque tends to make the rotor speed negative.

• Number of masses: allows specifying the number of masses to model the

mechanical shaft. The rotor mass is included in this number.

• Index of rotor mass: allows specifying the mass number of the generator or

motor rotor within the interconnected mass-spring shaft system. This number

must be positive and smaller or equal to the number of masses.

• Mechanical parameters for the shaft system: parameters that describe the

masses and connections between masses. See the above section

“Mechanical equations” for more details on the damping coefficients. It is

allowed to specify the fraction (%) of the total external mechanical torque

which is associated with the given mass. If the total is greater than 100% a

scaling factor will be applied.

• Use inertia constant H (s) instead of Moment of inertia: If this option is

unchecked the moment of inertia of the selected mass is specified in kgm2 .

Otherwise the moment of inertia of the mass is specified through the inertia

constant in s. This constant is defined as the ratio of the kinetic energy of the

Jω2

rotating mass at base speed to the rated power : H = bm (11)

2Pb

• Observe, scope and control selections: allows selecting the mechanical

variables that need to be observed by a control system, or need to be

available under the machine scopes, or need to be controlled by an external

control system.

• The mechanical angle of each mass (in rad) can be selected for scope and

observe.

EMTP-EMTPWorks, 2/28/2005 2:00:00 PM Page 5 of 10

• The mechanical speed (in rad/s) of each mass can be selected for scope and

observe.

• The torque (in Nm) between the different sections of the shaft can be

selected for scope and observe.

• The shaft torque Tm_i_j is the torque on the shaft section connecting masses

i and j=i+1.

• The steady-state mechanical torque applied on mass i can only be observed.

The external torque applied on mass i can be controlled.

• Use pu for Scope variables units: allows obtaining all the scope signals in

pu.

• Use pu for Observe and Control variables units: allows obtaining and

generating all observe and control signals in pu.

2.3 Control

• Total mechanical torque: If this option is chosen the total torque applied on

the mechanical shaft is controlled. If this option is selected the independent

mechanical torque applied on each mass of the shaft system (specified in the

mechanical data form) is no more available.

• Use pu for Control variables units: allows using controls signals in pu.

2.4 Observe/Scope

• If the Observe option is selected, the corresponding signal becomes

automatically available in the observe signal bundle of the machine.

• If the Scope option is selected, the selected variable will become available

under machine scopes.

• Use pu for Scope variables units: allows obtaining all the scope signals in

pu.

• Use pu for Observe variables units: allows obtaining all the observe

signals in pu.

2.5 Precision

• Damping factor: Ratio between built-in damping resistors and discretized

inductive elements used in the machine model. Reduce this number when

numerical stability problems are encountered.

• Rotor speed tolerance: Relative tolerance associated with the iterative

solution of rotor speed at each solution time-point.

• Voltage convergence tolerance: Relative tolerance associated with the

iterative solution of voltage at the machine terminals at each solution time-

point. In most cases, when the connected network is not weak, a larger value

of tolerance can be used.

• Maximum iterations in the rotor speed computation: Maximum number of

iterations allowed in the calculation of rotor speed at each solution time-point

2.6 How to control the external mechanical torques

The external mechanical torque applied on each mass composing the mechanical shaft can be

controlled in 2 ways: independent control on each mass or total control. If one option is chosen,

the other is not available.

EMTP-EMTPWorks, 2/28/2005 2:00:00 PM Page 6 of 10

Independent control of the external mechanical torques

In this case the external mechanical torque applied on each mass can be controlled. The

corresponding control signals are available in the control bundle of the dc-machine device if the

torque control option Tm_i has been specified in the mechanical data form. These torques are

negative for a generator and positive for a motor. If this option has been chosen and if no

controlled torque signal has been selected for a mass i then no external torque is applied on this

mass i.

Total control

The total mechanical torque applied on the mechanical shaft can be specified. The fraction of the

total external mechanical torque which is associated with each mass in the mechanical data form

is used to calculate the individual external torque applied on each mass.

If a steady-state initialization has been chosen the electromagnetic torque in steady-state is taken

as the total external mechanical torque. In this case an external torque is applied on each mass in

accordance with the fraction of total external mechanical torque associated with each mass. This

constant torque will be taken as the total external torque as long the “Controlled Torque Start

Time” is not exceeded.

2.7 Base quantities

Parameters of the DC-machine model can be specified in fundamental units or in per units (pu).

The base quantities are as follows:

• Base voltage Vb = Vrated

• Base power Pb = Prated

Pb

• Base current Ib =

Vb

Vb2 Vb

• Base impedance Zb = =

Pb Ib

Pb

• Base torque Tb =

ωbm

Vb

• Base flux Ψ b =

ωbm

3 Rules

Since the symbol of this device is automatically redrawn to account for user specified

configurations, it is not allowed to change it with the symbol editor, to delete pins and change pin

or signal attributes.

4 Netlist format

This device allows method-based scripting. The object data and methods are described in the

script file referenced by the device Script.Open.Dev attribute.

Example of data:

_DCM;DCM2;5;5;s1,s2,s3,s4,s10Tm,

240,3900,127.7,0.6,0.012,240,120,1.8,1,157.318,6.70393,0.8333,5,?m,9,

MS=0 1 1,

1 1 0 0 0 0

0 0 0 0 0

MSu=0 0 0,

PR=100 1e-06 1e-06 300 0,

CTRLu=0,

EMTP-EMTPWorks, 2/28/2005 2:00:00 PM Page 7 of 10

CTRL=1,

OBSu=1 0,

OBS=1 1 1 1 1 1 1 1 1,

Field Description

DCM Part name

DCM2 Instance name for the machine, any name.

5 Total number of pins

5 Number of pins given in this data section

s1 Signal name connected to k-pin of the armature, any name

s2 Signal name connected to m-pin of the armature, any name

s3 Signal name connected to k-pin of the field coil, any name

s4 Signal name connected to m-pin of the field coil, any name

s10Tm, Signal names contained in the control bundle for Observe variables.

240 Rated voltage.

3900 Rated power.

127.7 Rated speed.

0.6 Armature resistance.

0.012 Armature inductance.

240 Field coil resistance.

120 Field inductance.

1.8 Armature Field mutual inductance.

1 Steady state initialization ?

157.318 Steady state speed

6.70393 Steady state armature current

0.8333 Steady state field current

5 Controlled torque start time

?m Request for scopes, sent to scope group Machine, optional

9 Number of scope outputs

Ms= Start mechanical parameters section

011 Lock rotor shaft for negative speed (1 for locking, 0 for don’t lock)

Number of masses

Index of rotor mass

110000 Mechanical data tables (2 masses in this example)

000000

MSu= Start mechanical parameters units specification section

0 Use H instead of moment of inertia

0 Use “pu” for mechanical scope variable units

0 Use “pu” for mechanical observe and control variable units

CTRLu= Use “pu” for mechanical control variable units

CTRL= Start total controlled torque section

1 Control total external torque when 1

PR= Start precision control data section

100 Damping factor

1e-6 Rotor speed tolerance

1e-3 Voltage convergence tolerance

30 Maximum number of iteration in rotor speed computation

OBSu= Start Scope and Observe in “pu” section

0 Use “pu” for scope variable units

1 Use “pu” for observe variable units

OBS= Start Scope and Observe requests

2 1 2 0 2 0 1 0……. Scope and Observe requests: 0 for none, 1 for scope request, 2 for

observe request, 3 for scope and observe request.

EMTP-EMTPWorks, 2/28/2005 2:00:00 PM Page 8 of 10

5 Load-Flow model

This machine is disconnected in the Load-Flow solution.

6 Steady-state model

The steady-state equivalent circuit is shown in Figure 2.

The approach followed for the steady-state initialization of DC-machines is to require the user to

specify the desired rotor speed, field and armature currents instead of the terminal voltage.

The steady-state solution is performed for a non-zero dc frequency (see “Frequency for dc

representation” in the “EMTP Simulation Options”). This device is disconnected for all other

frequencies in the steady-state superposition process.

When the steady-state initialization is used, a small transient can appear at the beginning of the

simulation. This is related to the discretization method in time-domain equations.

The user can decrease the simulation time-step to reduce the small transient at the beginning of

the simulation.

7 Initial conditions

Initial conditions are found from the steady-state solution and the given speed when the device is

initialized in steady-state. State variables are automatically initialized for achieving quick steady-

state in time-domain. The dc-machine can also start with no initial conditions.

8 Frequency Scan model

The DC-machine is disconnected from the rest of the network for a frequency scan solution.

9 Time-domain representation

The time-domain representation of the DC-machine has been already explained in the previous

sections.

In the time-domain solution this device is a nonlinear function. It is solved through the iterative

procedure of EMTP until convergence according to the relative tolerance option for the given

device.

Two parameters controlling the iterative speed loop and the iterative voltage loop can be modified

by the user. Figure 4 shows the iterative process for the dc-machine model.

EMTP-EMTPWorks, 2/28/2005 2:00:00 PM Page 9 of 10

Figure 4 The iterative solution process: speed and voltage loops

EMTP-EMTPWorks, 2/28/2005 2:00:00 PM Page 10 of 10

You might also like

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlFrom EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlRating: 5 out of 5 stars5/5 (1)

- Dynamic Analysis of Direct Current Machines Under Voltage and Load ChangesDocument16 pagesDynamic Analysis of Direct Current Machines Under Voltage and Load ChangeselimadiNo ratings yet

- EEE3001 Lab ManualDocument66 pagesEEE3001 Lab ManualReshab Sahoo100% (1)

- L-9 (DK) (Pe) ( (Ee) Nptel)Document36 pagesL-9 (DK) (Pe) ( (Ee) Nptel)Htet AungNo ratings yet

- Amca05073 PDFDocument6 pagesAmca05073 PDFEmil EneNo ratings yet

- Power System Dynamic ModelingDocument12 pagesPower System Dynamic ModelingSyed Muhammad Munavvar HussainNo ratings yet

- QUBE-Servo 2 First Principles Modeling Workbook (Student)Document6 pagesQUBE-Servo 2 First Principles Modeling Workbook (Student)Albert ForeroNo ratings yet

- Mathematical Modeling of Open Loop PMDC Motor Using Matlab/SimulinkDocument6 pagesMathematical Modeling of Open Loop PMDC Motor Using Matlab/SimulinkSharath KumarNo ratings yet

- Transfer Function of D.c.machine Using Generalised Machine TheoryDocument18 pagesTransfer Function of D.c.machine Using Generalised Machine Theorychethan64% (11)

- ECE330 Power Circuits and Electromechanics: Dr. Nam Nguyen-Quang Fall 2016Document9 pagesECE330 Power Circuits and Electromechanics: Dr. Nam Nguyen-Quang Fall 2016Tran Nguyen KhangNo ratings yet

- Experiment No.03: Mathematical Modeling of Physical System: ObjectiveDocument5 pagesExperiment No.03: Mathematical Modeling of Physical System: ObjectiveSao SavathNo ratings yet

- Reduction of Torque Ripple in DTC For Induction Motor Using Input-Output Feedback LinearizationDocument13 pagesReduction of Torque Ripple in DTC For Induction Motor Using Input-Output Feedback LinearizationRajendra KumarNo ratings yet

- DTrends Feb 2011Document14 pagesDTrends Feb 2011Rui AllenNo ratings yet

- RELAY COORDINATION USING ETAP Ijariie12420Document9 pagesRELAY COORDINATION USING ETAP Ijariie12420Rakesh ShinganeNo ratings yet

- Simulation of Electric Machines and Drive Systems Using Matlab and SimulinkDocument11 pagesSimulation of Electric Machines and Drive Systems Using Matlab and SimulinkmdpkishoreNo ratings yet

- 3 Lab 3: DC Motor Transfer Function Estimation by Explicit MeasurementDocument9 pages3 Lab 3: DC Motor Transfer Function Estimation by Explicit MeasurementRogger MezaNo ratings yet

- Evaluation of Induction MachinesDocument47 pagesEvaluation of Induction MachinesAshwani RanaNo ratings yet

- Modelling and Simulation of Synchronous Machine TRDocument11 pagesModelling and Simulation of Synchronous Machine TRManuelSosaNo ratings yet

- PSAD Slides Lec1 Synchronous Machine ModelDocument56 pagesPSAD Slides Lec1 Synchronous Machine ModelMin Khine KyawNo ratings yet

- Closed-Loop Hybrid Direct Torque Control For Medium Voltage Induction Motor Drive For Performance ImprovementDocument10 pagesClosed-Loop Hybrid Direct Torque Control For Medium Voltage Induction Motor Drive For Performance ImprovementMuhammad UmarNo ratings yet

- High Chopper Frequency Drive of Wound Rotor Induction Motor With A Resistively Loaded Rotor ChopperDocument5 pagesHigh Chopper Frequency Drive of Wound Rotor Induction Motor With A Resistively Loaded Rotor ChopperchandanjuenggNo ratings yet

- Cambio de FrecuenciaDocument20 pagesCambio de FrecuenciaDarness Castillo RodriguezNo ratings yet

- Twin Rotor Mimo System: Experiment No: 5Document8 pagesTwin Rotor Mimo System: Experiment No: 5sameer sultanNo ratings yet

- Exercises On Relay Settings - MemoDocument7 pagesExercises On Relay Settings - Memomoses kakwenaNo ratings yet

- Dynamic Analysis Guide PDFDocument14 pagesDynamic Analysis Guide PDFasifNo ratings yet

- Dynamic Analysis Guide PDFDocument14 pagesDynamic Analysis Guide PDFABDULLAHNo ratings yet

- Dynamic Analysis Guide PDFDocument14 pagesDynamic Analysis Guide PDFVijay PNo ratings yet

- Dynamic Analysis GuideDocument14 pagesDynamic Analysis GuideR Siva KumaranNo ratings yet

- Dynamic Analysis Guide PDFDocument14 pagesDynamic Analysis Guide PDFJuniorNo ratings yet

- Dynamic Analysis Guide PDFDocument14 pagesDynamic Analysis Guide PDFPankajDhobleNo ratings yet

- Dynamic Analysis GuideDocument14 pagesDynamic Analysis GuideEduardo LópezNo ratings yet

- Dynamic Analysis GuideDocument14 pagesDynamic Analysis GuideMULAGONDLA DINESH REDDYNo ratings yet

- Damping: A Guide To Linear Dynamic Analysis WithDocument14 pagesDamping: A Guide To Linear Dynamic Analysis WithThyaga RajNo ratings yet

- Dynamics PDFDocument14 pagesDynamics PDFDiksith WilliamNo ratings yet

- Dynamic Analysis GuideDocument14 pagesDynamic Analysis GuideKumar NishantNo ratings yet

- Dynamic Analysis Guide PDFDocument14 pagesDynamic Analysis Guide PDFhjklmlkNo ratings yet

- Dynamic Analysis GuideDocument14 pagesDynamic Analysis Guidemirza_munir_baig995No ratings yet

- Dynamic Analysis GuideDocument14 pagesDynamic Analysis Guidesfrancois21100% (1)

- Dynamic Analysis Guide PDFDocument14 pagesDynamic Analysis Guide PDFDiksith WilliamNo ratings yet

- Dynamic Analysis GuideDocument14 pagesDynamic Analysis GuiderihabNo ratings yet

- AC DC FormulasDocument9 pagesAC DC FormulasJay Mark BalaneNo ratings yet

- Working Principles Need of Dynamic Modeling and Accurate Control of Motor Drives Dynamic Modeling of DC Machine Control of DC MachineDocument23 pagesWorking Principles Need of Dynamic Modeling and Accurate Control of Motor Drives Dynamic Modeling of DC Machine Control of DC MachineAli ZahidNo ratings yet

- Chapter 8 - SynchronousDocument12 pagesChapter 8 - SynchronousLin ChongNo ratings yet

- Icems 2019 8921951Document5 pagesIcems 2019 8921951Amir NazirNo ratings yet

- Operation Characteristics Improvement of Linear Synchronous Motor With Half-Wave Rectified Self ExcitationDocument4 pagesOperation Characteristics Improvement of Linear Synchronous Motor With Half-Wave Rectified Self ExcitationHuong ThaoNo ratings yet

- Power System Analysis: Fault Analysis Tom Overbye and Ross BaldickDocument35 pagesPower System Analysis: Fault Analysis Tom Overbye and Ross Baldicka_r_vijayanand6550No ratings yet

- Paper 6Document4 pagesPaper 6Aisha ShaikhNo ratings yet

- Lab Manual: Control Systems Design and Analysis: Using The Quanser Controls Board For NI ELVIS IIIDocument12 pagesLab Manual: Control Systems Design and Analysis: Using The Quanser Controls Board For NI ELVIS IIImishtinilNo ratings yet

- Analysis of Electrical Machines BankDocument66 pagesAnalysis of Electrical Machines BankChilambarasan MadhappanNo ratings yet

- Digital Simulation of Field-Oriented ControlDocument8 pagesDigital Simulation of Field-Oriented ControlNishantNo ratings yet

- Larning Objectives: Lab 2: Introduction To Matlab/ Psim Simulation Applied To Half-Wave RectifierDocument8 pagesLarning Objectives: Lab 2: Introduction To Matlab/ Psim Simulation Applied To Half-Wave RectifierMO 'No ratings yet

- Experiment # 2: Analysis of A Three-Phase Power System by Using Simpower System Blockset of MatlabDocument10 pagesExperiment # 2: Analysis of A Three-Phase Power System by Using Simpower System Blockset of MatlabHafsa IjazNo ratings yet

- Power Quality Improvement in DC Drives Using Matlab/SimulinkDocument5 pagesPower Quality Improvement in DC Drives Using Matlab/SimulinkwisdombasedcomputingNo ratings yet

- Fundamentals of Pe PDFDocument37 pagesFundamentals of Pe PDFchinmay pattnayakNo ratings yet

- PAPER 2003 05 en RMS Measuring Principles in The Application of Protective Relaying and MeteringDocument22 pagesPAPER 2003 05 en RMS Measuring Principles in The Application of Protective Relaying and MeteringNirmala AllamNo ratings yet

- Predictive Torque Control of Permanent Magnet Synchronous Motor Drive With Reduced Switching FrequencyDocument6 pagesPredictive Torque Control of Permanent Magnet Synchronous Motor Drive With Reduced Switching FrequencyYerramsetty SreekanthNo ratings yet

- Wcecs2009 - pp545-549 Computer LoadsDocument5 pagesWcecs2009 - pp545-549 Computer LoadsYogesh MsdNo ratings yet

- Answer (454.57W and 250W) : Power Electronics and Electrical Drives Work Sheet Department of Electromechanical EngDocument2 pagesAnswer (454.57W and 250W) : Power Electronics and Electrical Drives Work Sheet Department of Electromechanical EngDilamo FelekeNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- SEQ - impeDANCE 3-Phase AlternatorDocument7 pagesSEQ - impeDANCE 3-Phase AlternatorNandini JayakumarNo ratings yet

- Zbus 19e120Document4 pagesZbus 19e120Nandini JayakumarNo ratings yet

- ECE241H1 - 20199 - 661580945892ECE241 Midterm Cheat SheetDocument2 pagesECE241H1 - 20199 - 661580945892ECE241 Midterm Cheat SheetNandini JayakumarNo ratings yet

- Harolds Discrete Math Flip Flops Cheat Sheet 2020Document6 pagesHarolds Discrete Math Flip Flops Cheat Sheet 2020Nandini JayakumarNo ratings yet

- Flipflop TablesDocument6 pagesFlipflop TablesNandini JayakumarNo ratings yet

- Caterpillar CG 137-8/12 Service and Rebuild ManualDocument128 pagesCaterpillar CG 137-8/12 Service and Rebuild Manualdave fowlerNo ratings yet

- Model 260 BrochureDocument7 pagesModel 260 BrochureasdsNo ratings yet

- CD500 FHA Operators Manual Rev 03 - 03 PDFDocument127 pagesCD500 FHA Operators Manual Rev 03 - 03 PDFSteve HopkinsNo ratings yet

- Electrical SystemsDocument24 pagesElectrical SystemsLokeshNo ratings yet

- Storage Feeder: Constant Yarn Tension, Fewer Knitting FaultsDocument2 pagesStorage Feeder: Constant Yarn Tension, Fewer Knitting FaultscobaNo ratings yet

- Me 2209 Electrical Engineering Lab ManualDocument45 pagesMe 2209 Electrical Engineering Lab ManualSai Karthi100% (1)

- PELTON Turbine - TPA - Ecowatt Hydro - IREMDocument5 pagesPELTON Turbine - TPA - Ecowatt Hydro - IREMrabei romulusNo ratings yet

- Introduction of Electrical MachinesDocument21 pagesIntroduction of Electrical MachinesUmair MansoorNo ratings yet

- GLOBE RM410 Radial Piston Air MotorDocument6 pagesGLOBE RM410 Radial Piston Air MotorAbdul Ghofur El AfasyNo ratings yet

- Energies 12 03279Document20 pagesEnergies 12 03279ShadNo ratings yet

- AF-3100 Series: General-Purpose High-Performance Inverter Maintenance ManualDocument88 pagesAF-3100 Series: General-Purpose High-Performance Inverter Maintenance Manualhoang dungNo ratings yet

- AllSem23 MAKAUTDocument81 pagesAllSem23 MAKAUTAmit Bikram MishraNo ratings yet

- 33kV Breaker SpecDocument19 pages33kV Breaker SpecBala KumaranNo ratings yet

- Placement Brochure - NIT GoaDocument34 pagesPlacement Brochure - NIT GoaSujit NairNo ratings yet

- Refrigerator: Service ManualDocument49 pagesRefrigerator: Service ManualCesar Calderon GrNo ratings yet

- DC MotorsDocument7 pagesDC MotorsKelvin LiewNo ratings yet

- Paper TE-2Document8 pagesPaper TE-2Sandro SiagianNo ratings yet

- Stator End Winding Vibration and Temperature Rise MonitoringDocument8 pagesStator End Winding Vibration and Temperature Rise MonitoringAnonymous BBX2E87aHNo ratings yet

- A Noobs Guide To UfopoliticsDocument18 pagesA Noobs Guide To UfopoliticsPraveen240679No ratings yet

- WEG Datasheet DS13095026Document2 pagesWEG Datasheet DS13095026stefancuandreiNo ratings yet

- EE8353 - EDC Anna University Old Question PapersDocument16 pagesEE8353 - EDC Anna University Old Question PapersveenaNo ratings yet

- HV Cast Iron Motors - HXR - 042005Document12 pagesHV Cast Iron Motors - HXR - 042005Alfredo Jose Ramirez MelgarejoNo ratings yet

- Iec 60034 30Document14 pagesIec 60034 30Isaac Diaz100% (1)

- Exp 3Document6 pagesExp 3DHINESH JNo ratings yet

- A4 - TeSys U - EN (Web)Document82 pagesA4 - TeSys U - EN (Web)jorge eduardoNo ratings yet

- Panasonic Kx-mb2025 2030 Service ManualDocument313 pagesPanasonic Kx-mb2025 2030 Service Manualatif38567% (6)

- Fan Power and Heat CalculatorDocument5 pagesFan Power and Heat CalculatorAnonymous oVRvsdWzfBNo ratings yet

- Automatic Coil Winding MachineDocument10 pagesAutomatic Coil Winding Machineayesha sakhiNo ratings yet

- DP Pump CatalogueDocument16 pagesDP Pump CatalogueJust RysdanNo ratings yet

- Induction Motors CDocument557 pagesInduction Motors CMarivee Dollosa100% (2)