Professional Documents

Culture Documents

Evaluation - Fortuner 2018

Uploaded by

mithun bv0 ratings0% found this document useful (0 votes)

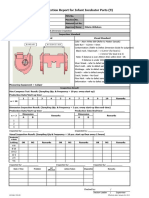

6 views3 pagesThis document contains an inspector evaluation sheet to assess an inspector's performance in identifying defects in the Fortuner engine section. It lists 10 potential defects that could be present across 3 samples. The inspector's score is calculated based on the percentage of total defects identified, with points deducted for any defects passed over or for additional time taken over the standard inspection time. An inspector signature is required on the completed evaluation sheet.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document contains an inspector evaluation sheet to assess an inspector's performance in identifying defects in the Fortuner engine section. It lists 10 potential defects that could be present across 3 samples. The inspector's score is calculated based on the percentage of total defects identified, with points deducted for any defects passed over or for additional time taken over the standard inspection time. An inspector signature is required on the completed evaluation sheet.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views3 pagesEvaluation - Fortuner 2018

Uploaded by

mithun bvThis document contains an inspector evaluation sheet to assess an inspector's performance in identifying defects in the Fortuner engine section. It lists 10 potential defects that could be present across 3 samples. The inspector's score is calculated based on the percentage of total defects identified, with points deducted for any defects passed over or for additional time taken over the standard inspection time. An inspector signature is required on the completed evaluation sheet.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 3

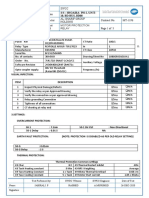

INSPECTOR EVALUATION SHEET STANDARD TIME FOR INSPECTION : 140sec

TIME TAKEN FOR INSPECTION : _____________

Name : Date :

Section : FORTUNER ENGINE

N G SAMPLE : 01

DETAILS OF DEFECT IDENTIFIED

SL NO. DEFECT NAME Yes No 1. Calculation method

1 Waterproof washer damage on conn no 540

Total defects identified

% age = X 100

Total defects available in W/H

2 LA terminals are halflock

3 Binderclamp 26470 cutting length short on cot

2. Rule for passing the defects and Extra time taken.

4 White point tape miss on cot near conn no 258

1. If inspector pass any defect during skill test, one point / defect passed will be

deducted in the total achieved score.

5 Half lap tape on cot near conn no 233

2. Each extra minute will lead to reduction of 2 points in achieved score.

6 Point tape miss on connectors 531,532,530

Total defects identified

7 Rough tape miss near conn no 85 % age = X 100 - No.of defects passed

Total defects available in W/H

8 Cross tape miss on clamp 3F490

9 Extra point tape on cot near conn no 60

10 828170k510 protector half lock on cot

Action Taken(If Defect not identified) : Reinsertion Result:

Evaluated By Checked By Approved By

Inspector Signature MSSL/TRG/VI/IE/FE/01

INSPECTOR EVALUATION SHEET STANDARD TIME FOR INSPECTION : 140sec

TIME TAKEN FOR INSPECTION : _____________

Name : Date :

Section : FORTUNER ENGINE

N G SAMPLE : 02

DETAILS OF DEFECT IDENTIFIED

SL NO. DEFECT NAME Yes No 1. Calculation method

1 Dummy seal miss on conn no 265

Total defects identified

% age = X 100

Cot fixing NG near by conn no 39 (act=fixing, Total defects available in W/H

2

obs=freetape)

3 Waterproof washer miss on conn no 9

2. Rule for passing the defects and Extra time taken.

4 P/NO lable fixing NG

1. If inspector pass any defect during skill test, one point / defect passed will be

deducted in the total achieved score.

5 Black point tape on cot near conn no 258&182

2. Each extra minute will lead to reduction of 2 points in achieved score.

6 PVC fixing NG near by grommet

Total defects identified

7 37170 binder clamp cutting length short % age = X 100 - No.of defects passed

Total defects available in W/H

8 Stopper open conn no 303

9 Point tape miss on near by connector 500&501

10 Tie bend miss on clamp 50300

Action Taken(If Defect not identified) : Reinsertion Result:

Evaluated By Checked By Approved By

Inspector Signature MSSL/TRG/VI/IE/FE/01

INSPECTOR EVALUATION SHEET STANDARD TIME FOR INSPECTION : 140sec

TIME TAKEN FOR INSPECTION : _____________

Name : Date :

Section : FORTUNER ENGINE

N G SAMPLE : 03

DETAILS OF DEFECT IDENTIFIED

SL NO. DEFECT NAME Yes No 1. Calculation method

1 Binder clamp 26470 miss on cot near conn no 257

Total defects identified

% age = X 100

Total defects available in W/H

2 Cot fixing NG near conn no 29 (act=fixing,obs=freetape)

3 White point tape miss on cot

2. Rule for passing the defects and Extra time taken.

4 LA terminals are halflock

1. If inspector pass any defect during skill test, one point / defect passed will be

deducted in the total achieved score.

5 Extra point tape on PVC near grommet

2. Each extra minute will lead to reduction of 2 points in achieved score.

6 Conn no 532 stopper open

Total defects identified

7 PVC fixing NG near conn no 255 % age = X 100 - No.of defects passed

Total defects available in W/H

8 P/NO lable fixing tape colour NG

9 Grommet direction wrong

10 82815-0k270 protector half lock

Action Taken(If Defect not identified) : Reinsertion Result:

Evaluated By Checked By Approved By

Inspector Signature MSSL/TRG/VI/IE/FE/01

You might also like

- Lifting Equipment ChecklistDocument4 pagesLifting Equipment ChecklistRuzaini MohamedNo ratings yet

- The Hero ofDocument5 pagesThe Hero ofkhushnood aliNo ratings yet

- Check List For Pre Commissioning of MV SwitchgearDocument2 pagesCheck List For Pre Commissioning of MV Switchgeararuna100% (9)

- Sel-487v Relay Test For CapacitorDocument21 pagesSel-487v Relay Test For CapacitorSentaNo ratings yet

- Site Inspection and Test Record: Al - Babtain S/S 8715 (132/13.8 KV)Document3 pagesSite Inspection and Test Record: Al - Babtain S/S 8715 (132/13.8 KV)m khNo ratings yet

- Site Test Report Ng-Sa Name of Substation: Al-Tawdihiyah 132/33KV SubstationDocument7 pagesSite Test Report Ng-Sa Name of Substation: Al-Tawdihiyah 132/33KV SubstationSyed Abbas100% (1)

- Red670 Distance Line DifferentialDocument23 pagesRed670 Distance Line DifferentialRatheesh KumarNo ratings yet

- WÄRTSILÄ VASA 9R32 5377eng PDFDocument394 pagesWÄRTSILÄ VASA 9R32 5377eng PDFRonald Bienemi Paez75% (4)

- Fmea Fta ModuleDocument156 pagesFmea Fta ModuleIan Maldonado100% (1)

- As Per The Schematic Drawings The Contents in This Test Format Can Be ModifiedDocument12 pagesAs Per The Schematic Drawings The Contents in This Test Format Can Be ModifiedAlexNo ratings yet

- Site Inspection and Test Record: 1. General Data and InformationDocument5 pagesSite Inspection and Test Record: 1. General Data and InformationSohail AhmedNo ratings yet

- Pictorial Atlas of Botulinum Toxin Injection. Dosage Localization Application. (1) PDF PDFDocument2 pagesPictorial Atlas of Botulinum Toxin Injection. Dosage Localization Application. (1) PDF PDFTeng Lip Yuen50% (4)

- Bts Bt21Document46 pagesBts Bt21Sarita E Schz100% (5)

- Commissioning of Electrical SystemsDocument14 pagesCommissioning of Electrical SystemsRatheesh Kumar100% (1)

- 7SR1587 Voltage and Frequency RelayDocument4 pages7SR1587 Voltage and Frequency RelayAnonymous dH3DIEtzNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Manual of Botulinum Toxin Therapy: Second EditionDocument4 pagesManual of Botulinum Toxin Therapy: Second Editiondharma0% (1)

- Critical Theory of Social Suffering - Emmanuel RenaultDocument22 pagesCritical Theory of Social Suffering - Emmanuel RenaultFilosofo São Paulo100% (1)

- Evaluation - Innova Engine 2018Document6 pagesEvaluation - Innova Engine 2018mithun bvNo ratings yet

- Evaluation - Innova Ip 2018Document6 pagesEvaluation - Innova Ip 2018mithun bvNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- TG Control Oil Filter Isolation - Cleaning Charging ProcedureDocument8 pagesTG Control Oil Filter Isolation - Cleaning Charging ProcedurePurna NayakNo ratings yet

- In-Process Inspection Report For Infant Incubator Parts9Document1 pageIn-Process Inspection Report For Infant Incubator Parts9Hilario AlinabonNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Ir Test FormDocument2 pagesIr Test FormNelson ColoNo ratings yet

- Red670 - Line Diff 55onlyDocument11 pagesRed670 - Line Diff 55onlyMohd SalehNo ratings yet

- Report:: F CF CriticaiDocument2 pagesReport:: F CF CriticaiArun HarshanNo ratings yet

- Wi Opr-001 Method For Insulation Resistance TestDocument2 pagesWi Opr-001 Method For Insulation Resistance TestYusuf AlfathonyNo ratings yet

- QCV Key Test CertifiactesDocument1 pageQCV Key Test CertifiactesShashank RajputNo ratings yet

- 05-Manual Tang 1Document1 page05-Manual Tang 1Abdou BoucheritNo ratings yet

- 86 Lockout Auxiliary Relay Site Test Report: Mechanical Checks & Visual InspectionDocument2 pages86 Lockout Auxiliary Relay Site Test Report: Mechanical Checks & Visual InspectionJaikaran DanNo ratings yet

- Rustomjee Work Permit Format - R1Document8 pagesRustomjee Work Permit Format - R1Nikhil ManjrekarNo ratings yet

- Transformer Commissioning AccessoriesDocument4 pagesTransformer Commissioning Accessoriesmohan babuNo ratings yet

- Site Inspection and Test Record: Automatic Reclosing Abb Rex 521 10631056/00 1 of 3Document3 pagesSite Inspection and Test Record: Automatic Reclosing Abb Rex 521 10631056/00 1 of 3m khNo ratings yet

- 07 Mpi Report - 1Document12 pages07 Mpi Report - 1Abdou BoucheritNo ratings yet

- Inspection Release Note: ChevronDocument3 pagesInspection Release Note: ChevronHassan M. OsmanNo ratings yet

- Painting Inspection Report: Project: Abu Dhabi Future Schools Program (Phase 9) Gayathi-Abu DhabiDocument4 pagesPainting Inspection Report: Project: Abu Dhabi Future Schools Program (Phase 9) Gayathi-Abu DhabiSpectex dubaiNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- 86 Lockout Auxiliary Relay Site Test Report: Mechanical Checks & Visual InspectionDocument2 pages86 Lockout Auxiliary Relay Site Test Report: Mechanical Checks & Visual InspectionJaikaran DanNo ratings yet

- Inspection: AIR Winch Ingersoll RandDocument19 pagesInspection: AIR Winch Ingersoll RandAbdou BoucheritNo ratings yet

- PTW - BlastingDocument4 pagesPTW - BlastingJaya Prakash100% (1)

- Doosan Power Systems Indai PVT Limited: System CalibrationDocument3 pagesDoosan Power Systems Indai PVT Limited: System CalibrationBalkishan DyavanapellyNo ratings yet

- Test Performed By: SWCC Witness: SWCC Engineer: Date of Test Name: Jabirali. P Rashed A.Murshed 26-DEC-2020 SignatureDocument5 pagesTest Performed By: SWCC Witness: SWCC Engineer: Date of Test Name: Jabirali. P Rashed A.Murshed 26-DEC-2020 SignatureAnonymous dH3DIEtzNo ratings yet

- Inspection Report IN SECPL DCM 001Document1 pageInspection Report IN SECPL DCM 001maheshpanditNo ratings yet

- Air Bag Handout PDFDocument102 pagesAir Bag Handout PDFinnomatheuNo ratings yet

- Electrical Test Sheet: Ele/Tss/At 300 X Commissioning E 4Document18 pagesElectrical Test Sheet: Ele/Tss/At 300 X Commissioning E 4ecsuperalNo ratings yet

- ITP FOR Electrical Switch GeaarDocument20 pagesITP FOR Electrical Switch Geaarmohan babuNo ratings yet

- QCV Test CertificatesDocument1 pageQCV Test CertificatesShashank RajputNo ratings yet

- VTR 20 KP+FollowersDocument20 pagesVTR 20 KP+FollowersANDRES LLAGUARIMAY CHIPANANo ratings yet

- QAR-QD418-5 Rod-Front Susp 797 (191-8043)Document6 pagesQAR-QD418-5 Rod-Front Susp 797 (191-8043)Irwanto ManafNo ratings yet

- Multiproduct CalibratorDocument8 pagesMultiproduct CalibratorKazi AlimNo ratings yet

- Inspection Report: Khodiyar Spring IndustriesDocument1 pageInspection Report: Khodiyar Spring IndustriesVinay KumarNo ratings yet

- Countermeasure Verification Sheet - VULCANDocument2 pagesCountermeasure Verification Sheet - VULCANAbhishek DahiyaNo ratings yet

- Gpti Qicl J931 Mut 002Document2 pagesGpti Qicl J931 Mut 002uselessinstaid52No ratings yet

- 02-Singl Joint 1Document8 pages02-Singl Joint 1Abdou BoucheritNo ratings yet

- DAYmate S Installation Qualification - Qualios 01078 - Version 6.0Document6 pagesDAYmate S Installation Qualification - Qualios 01078 - Version 6.0Sebastian Jake JohnNo ratings yet

- Mock Drill Report IA FAILUREDocument4 pagesMock Drill Report IA FAILURE00083583rfNo ratings yet

- Ce PSCDocument7 pagesCe PSCsagar masandNo ratings yet

- MTPL-OM-PPM-CL-005 - PPM Checklist For FencingDocument2 pagesMTPL-OM-PPM-CL-005 - PPM Checklist For FencingVeerendra YduvanshiNo ratings yet

- TR-22004-L-Mtl - Test Report On TV Knob StickerDocument2 pagesTR-22004-L-Mtl - Test Report On TV Knob StickerAshraaf aushiNo ratings yet

- Gpti Qicl 032Document2 pagesGpti Qicl 032uselessinstaid52No ratings yet

- ARGUS ReportDocument22 pagesARGUS ReportNguyễn Tường MinhNo ratings yet

- Induction Cap Sealing Machine Performance Qualification Report - Pharmaceutical UpdatesDocument5 pagesInduction Cap Sealing Machine Performance Qualification Report - Pharmaceutical UpdatesChetan Ganesh RautNo ratings yet

- Chapter 8 PronounDocument10 pagesChapter 8 PronounMiharu NishaNo ratings yet

- 27 August To 02 SeptemberDocument16 pages27 August To 02 SeptemberpratidinNo ratings yet

- Activity: Parameter Quantitative Research Qualitative ResearchDocument2 pagesActivity: Parameter Quantitative Research Qualitative ResearchCezanne CruzNo ratings yet

- WEBSITE PHP PresentationDocument13 pagesWEBSITE PHP Presentationbalajidharani1978700No ratings yet

- State QuotaDocument3 pagesState QuotaSHREEWOODNo ratings yet

- Chapter 13 The Hamsa (Udhav Gita)Document7 pagesChapter 13 The Hamsa (Udhav Gita)Vishnu Prakash NangathNo ratings yet

- Grade 11aDocument3 pagesGrade 11aTr LynnNo ratings yet

- Unit 2 (RC 5)Document18 pagesUnit 2 (RC 5)hrishita.bhandaryNo ratings yet

- 03804257ZA Ind E0 PDFDocument59 pages03804257ZA Ind E0 PDFDumebiNo ratings yet

- GEETHICS Lesson 1 and 2 PDFDocument2 pagesGEETHICS Lesson 1 and 2 PDFMargarita Lucis Manalo-AlcantaraNo ratings yet

- (IDT-6753) Creates Confusion Num Sent - JIRADocument1 page(IDT-6753) Creates Confusion Num Sent - JIRARatul NandyNo ratings yet

- Angels Among UsDocument4 pagesAngels Among UsLanny CarpenterNo ratings yet

- Marginal CallDocument3 pagesMarginal Calllexredondo22No ratings yet

- Review of LiteratureDocument18 pagesReview of LiteratureVimal VickyNo ratings yet

- M24-Plate Heat ExcahngerDocument16 pagesM24-Plate Heat ExcahngerAlexNo ratings yet

- Ful Flo A SeriesDocument10 pagesFul Flo A Seriesrodruren01No ratings yet

- A Southern Song Dynasty Amitābha Triad Painting Reconsidered PDFDocument17 pagesA Southern Song Dynasty Amitābha Triad Painting Reconsidered PDFfourshare333No ratings yet

- Science Grade 3Document8 pagesScience Grade 3Mark Louie Alonsagay FerrerNo ratings yet

- Development Proposal ReportDocument37 pagesDevelopment Proposal ReportsyafiqszNo ratings yet

- Psychometric Evaluation of The Albanian Version of Tosca 3 To Measure Shame and GuiltDocument6 pagesPsychometric Evaluation of The Albanian Version of Tosca 3 To Measure Shame and GuiltMirela Cojocaru StetcoNo ratings yet

- Service Delivery in Rural Areas: by Dennis PoppDocument13 pagesService Delivery in Rural Areas: by Dennis PoppnathanrengaNo ratings yet

- How To Use Prepositions PDFDocument4 pagesHow To Use Prepositions PDFVikash Kumar0% (1)

- Position Department Annual Salary LocationDocument2 pagesPosition Department Annual Salary LocationdasdasNo ratings yet

- Literature ReviewDocument14 pagesLiterature Reviewniftiangautam70% (2)