Professional Documents

Culture Documents

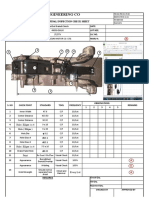

Countermeasure Verification Sheet - VULCAN

Uploaded by

Abhishek DahiyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Countermeasure Verification Sheet - VULCAN

Uploaded by

Abhishek DahiyaCopyright:

Available Formats

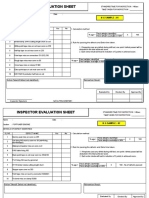

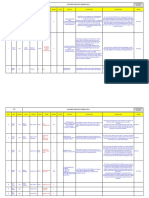

Supplier Self Decleration Countermeasure Adherence Check Sheet

Sr. Date of Countermeasure Month:-

Part No / Name Problem

No. Occurance 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

1.Cutter life validation started to freeze its life.

O

2.Training given to operator, Supervisor and

O

AC4C171 quality inspector.

1 30/1/2021 Burr issue

Casing Cap 171

3. Opl displayed. O

4. Next 3 lots will be dispatched with identification.

O

1.Work instruction made for setting pcs handling

O

and NG part handling

2.OPL displayed O

AC4C172

2 29/3/2021 Short fill

Casing Cap 172

3. Defect updated in Eye chart O

4.100% visual inspection added for next 3 lots to

O

monitor effectiveness.

1.Check point added in machine check sheet to

O

AM3C035 check channel loose condition

3 20/4/2021 Collar damage

M6 Flange Nut 2.Training provided to concern persons

O

1.Training Given to concern persons

O

2.OPL displayed

3.100% Marking will be done on thread from next

O

AM3C028 lot

4 26/4/2021 Thread miss

NUT ADJUSTER

4.100% checked will be written on packet X

5.Inspectors poision cake test frequency increased

X

to once in a week

1. Eye Chart Updated. O

2. Chips removal frequency decided to neglect

O

AC4C171 accident due to chips stuckon tool.

5 27/4/2021 No chamfer

Casing Cap 171 (Operator will remove chips each hour coming out

3. Eye Chart Updated. O

4. 100% visual inspection will be done to detect

O

such kind of issue.

1. Training given to whole dept for Accidential part

O

handling.

2. Separate Rejection box for this types of defects

O

implement.

AC4C172 3. Defect Eye Chart displayed

6 31/7/2021 Profile NG O

Casing Cap 172 (This type of problem not faced in past) Skill man

power

4. Workfreeze for casing

procedure cap machines.

updated for handling of OK &

O

NG material.

5. OPL Displayed. 100% checking start for this

O

material before dispatch to customer End.

Supplier Self Decleration Countermeasure Adherence Check Sheet

Sr. Date of Countermeasure Month:-

Part No / Name Problem

No. Occurance 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

1. Tool resharpening & replacement frequency

O

decided.

Dimension 4.0+0.2

mm observed 2. OPL display for this problem O

AC4C222

7 7/8/2021 undersize found

Casing Cap 222

upto 3.89 to 3.92 3. Training given to all operators. O

mm

4. 100% checking start for this material before

O

dispatch to customer End.

1.Training Provided to concern persons O

Burr in groove 2. OPL displayed O

AC4C170

8 20/9/2021 observed in Casing

Casing Cap 170

Cap 170 3. Defect Updated in Eye chart O

4. Part will be inspected by Automatic Sorting

X

Machine

1. Training provided to all concern persons

O

2. OPL displayed

3. 100% visual inspection will be done for mixing

Other part mixed O

AM3C035

9 21/9/2021 with M6 Flange Nut

M6 Flange Nut 4. Marking will be done on flange of the nut to

AM3C035F O

detect mix-up in next 3 Lots

5.Inspection will be start on automatic sorting

O

machine

1.Profile gauge to be implemented for inspection

X

AC2C006 Wrong Part mix-up

10 23/9/2021 2. Training provided to concern persons O

Casing Cap 006 with Casing cap 006

3. OPL Displayed O

1. Training given to all concerns

O

AC2C032

11 05-10-2021 Collar Shape NG 2. OPL displayed O

Casing Cap 032

3.WI displayed for setting

NA

1. Training given to all concerns

O

AM3C035

12 13/12/2021 Thread miss 2. OPL displayed O

M6 Flange Nut

3.Preventive maintenance will be done on

NA

holidays or when machine has no load to avoid

manual inspection. Approved By

Prepared By Implemented- Approved By

Legand

Removal - X

You might also like

- Fault Manager Diagnosis Sheet - Beta 1 - M&M LCVDocument6 pagesFault Manager Diagnosis Sheet - Beta 1 - M&M LCVVickyNo ratings yet

- MK Tron Auto Part: Procedure of Leak TestingDocument1 pageMK Tron Auto Part: Procedure of Leak Testingsachin kadamNo ratings yet

- 8D Indicator Light Can't Turn Off Rev 1Document5 pages8D Indicator Light Can't Turn Off Rev 1Dr. Alois FabianiNo ratings yet

- Foreign material presence Chefsen 10142344-108KLF V3Document13 pagesForeign material presence Chefsen 10142344-108KLF V3g.cuachaNo ratings yet

- Vision: MR003/01/P Update Instructions MRDocument6 pagesVision: MR003/01/P Update Instructions MRАндрей РодионовNo ratings yet

- Confirmation of Diagnosis: Excess of Clearance Between Piston and LinerDocument2 pagesConfirmation of Diagnosis: Excess of Clearance Between Piston and Linerakamalapuri388No ratings yet

- Spin Box Change (PCB)Document1 pageSpin Box Change (PCB)Alejandro Alvarado RamosNo ratings yet

- List of InspectionDocument17 pagesList of InspectionNQTNo ratings yet

- Casco HM2-PT (Ansi Z89 1) PDFDocument4 pagesCasco HM2-PT (Ansi Z89 1) PDFAndres Antonio Moreno CastroNo ratings yet

- Toshiba Motor Repair ReportDocument9 pagesToshiba Motor Repair ReportMuhad KochunniNo ratings yet

- Product Specification: (V) Preliminary Specifications Final SpecificationsDocument34 pagesProduct Specification: (V) Preliminary Specifications Final SpecificationsAndres DugarteNo ratings yet

- Field Service Report: Table of ContentsDocument5 pagesField Service Report: Table of Contentsrasyid alamNo ratings yet

- Electric ANSI Strikes EL900 InstructionsDocument2 pagesElectric ANSI Strikes EL900 Instructionsolivier.bigouretNo ratings yet

- Product Specification: Preliminary Specifications (V) Final Specifications Model NameDocument34 pagesProduct Specification: Preliminary Specifications (V) Final Specifications Model Namehekebat319No ratings yet

- 2.1.9 Surface Scratch Examination Metal-Clad FoilDocument1 page2.1.9 Surface Scratch Examination Metal-Clad FoilApinan NamkanisornNo ratings yet

- Service: ManualDocument53 pagesService: ManualFlorian LeordeanuNo ratings yet

- Service: ManualDocument27 pagesService: ManualAnonymous UserNo ratings yet

- Evaluation - Fortuner 2018Document3 pagesEvaluation - Fortuner 2018mithun bvNo ratings yet

- 802870-D Optistar LE PM ChecklistDocument4 pages802870-D Optistar LE PM ChecklistDanilo MirandaNo ratings yet

- MZ0001-001-PH-00345 Rev1 - Method of Statement Piping STS 1-2 MLV 109-110-111Document16 pagesMZ0001-001-PH-00345 Rev1 - Method of Statement Piping STS 1-2 MLV 109-110-111Saule Larry GrigioniNo ratings yet

- Ijin ListrikDocument1 pageIjin ListrikBayu Rengga CendymardanaNo ratings yet

- Inspection and Maintenance of Drillpipe E-BookDocument39 pagesInspection and Maintenance of Drillpipe E-BookPhan Trong HuanNo ratings yet

- OEM TC - 50T Web SlingDocument4 pagesOEM TC - 50T Web SlingNiranjan KumarNo ratings yet

- Task 53-10-00-252 16. Fuselage To Wing Attach Fitting Lugs Special Detailed InspectionDocument4 pagesTask 53-10-00-252 16. Fuselage To Wing Attach Fitting Lugs Special Detailed Inspectionworm_stellNo ratings yet

- Ffu 0000027 01Document4 pagesFfu 0000027 01Karunia LestariNo ratings yet

- Examining Headlights and BulbsDocument5 pagesExamining Headlights and BulbsAleksandar KnezevicNo ratings yet

- Stryker x8000 Xenon Light Source Service Manual - CompressDocument71 pagesStryker x8000 Xenon Light Source Service Manual - CompressAdan MartinezNo ratings yet

- Diagnostics Doc For 14L - 22L - Service Tool VersionDocument8 pagesDiagnostics Doc For 14L - 22L - Service Tool VersionMuruganNo ratings yet

- Maintain Medical Equipment SafelyDocument60 pagesMaintain Medical Equipment SafelyaltamiroNo ratings yet

- Maintain Hydra RackerDocument2 pagesMaintain Hydra Rackermohamed hamedNo ratings yet

- Complaint Summary All.2014Document15 pagesComplaint Summary All.2014Sameer SaxenaNo ratings yet

- Manual of Instructions, Use and Maintenance: SlingoferDocument62 pagesManual of Instructions, Use and Maintenance: SlingoferDamirRichterNo ratings yet

- Lifting Fibre Nylon Slings ChecklistDocument2 pagesLifting Fibre Nylon Slings Checklistmohamed Abo-EwishaNo ratings yet

- 104-EMP-01 Rev 0 - Drilling Hook Level III Inspection-USA OnlyDocument10 pages104-EMP-01 Rev 0 - Drilling Hook Level III Inspection-USA OnlyJuan LorenzoNo ratings yet

- Magneto Service Bulletin ChecklistDocument15 pagesMagneto Service Bulletin ChecklistNasr PooyaNo ratings yet

- TANK INSPECTION REPORT OF TANK-4 JUBA P.PDocument9 pagesTANK INSPECTION REPORT OF TANK-4 JUBA P.PVPN NetworkNo ratings yet

- Welding CheckDocument1 pageWelding CheckAgnesha A KempkesNo ratings yet

- User Manual: Manufactured by ItalyDocument66 pagesUser Manual: Manufactured by ItalyRaul Angel Perez AbadNo ratings yet

- Sample Test ReportDocument8 pagesSample Test Reportk.mehaboob bashaNo ratings yet

- Eni's Program for Electrical Installation Checks and TestsDocument59 pagesEni's Program for Electrical Installation Checks and TestsAhmed MediniNo ratings yet

- AEN134Document7 pagesAEN134qaisarsabirNo ratings yet

- 072 90 13 ChipDetectorDocument6 pages072 90 13 ChipDetectorblackhawkNo ratings yet

- Temperature Rise TestDocument36 pagesTemperature Rise Testdeltastarconstruction.servicesNo ratings yet

- LHMX - Lesson Learned MatrixDocument3 pagesLHMX - Lesson Learned MatrixMoises Adolfo Garcia CardonaNo ratings yet

- Evaluation - Innova Ip 2018Document6 pagesEvaluation - Innova Ip 2018mithun bvNo ratings yet

- Accutron Service Manual Series 218 PDFDocument52 pagesAccutron Service Manual Series 218 PDFtunimao100% (1)

- Accutron Service Manual Series 218 PDFDocument52 pagesAccutron Service Manual Series 218 PDFRichardNo ratings yet

- 33K6-4-168-1 Rev 30 April 2019 OPTICAL FLATS AND MIRRORSDocument16 pages33K6-4-168-1 Rev 30 April 2019 OPTICAL FLATS AND MIRRORSNunyaNo ratings yet

- FINAL INSPECTION CHECK SHEET Maru A 01-02-2021Document6 pagesFINAL INSPECTION CHECK SHEET Maru A 01-02-2021Ulfsaar KhanNo ratings yet

- SMS Verf - Rev01Document2 pagesSMS Verf - Rev01Ansi MalikNo ratings yet

- MPM 811 04 01Document2 pagesMPM 811 04 01Mousa PetrolNo ratings yet

- Plant Inspector Fact Sheet - Evaluating Pitting CorrosionDocument1 pagePlant Inspector Fact Sheet - Evaluating Pitting CorrosionIkeNo ratings yet

- Thermal Scanning and Preventive MaintenanceDocument5 pagesThermal Scanning and Preventive MaintenanceRoland VenguaNo ratings yet

- CM FormatDocument7 pagesCM FormatAjith Kumar RNo ratings yet

- Manual de Instalare Detector de Miscare Quad PIR Cu Senzor de Soc Si Geam Spart DSC LC-102PIGBSSDocument2 pagesManual de Instalare Detector de Miscare Quad PIR Cu Senzor de Soc Si Geam Spart DSC LC-102PIGBSSgheorghe.radisNo ratings yet

- VibMatters September 2016 Final DownloadDocument7 pagesVibMatters September 2016 Final DownloadfazzlieNo ratings yet

- Sullair 900 1150Document24 pagesSullair 900 1150ssinokrotNo ratings yet

- CE03 Hydraulic Testing of Pressure VesselsDocument5 pagesCE03 Hydraulic Testing of Pressure VesselsTafireyi TeveraNo ratings yet

- Samsung g245cDocument23 pagesSamsung g245cEduardo Cervantes GarzonNo ratings yet

- UntitledDocument15 pagesUntitledAbhishek DahiyaNo ratings yet

- Wire Dfect MatrixDocument2 pagesWire Dfect MatrixAbhishek DahiyaNo ratings yet

- Casing Cap O.D OversizeDocument2 pagesCasing Cap O.D OversizeAbhishek DahiyaNo ratings yet

- Master List of Formats: SR No. Format No. Format Name New Format Number Rev. No./DateDocument14 pagesMaster List of Formats: SR No. Format No. Format Name New Format Number Rev. No./DateAbhishek DahiyaNo ratings yet

- NPD Parts SheetDocument2 pagesNPD Parts SheetAbhishek DahiyaNo ratings yet

- Departmental Objective - MarketingDocument1 pageDepartmental Objective - MarketingAbhishek DahiyaNo ratings yet

- M5 ScrewDocument1 pageM5 ScrewAbhishek DahiyaNo ratings yet

- Quote Digital Printng SignageDocument1 pageQuote Digital Printng SignageAbhishek DahiyaNo ratings yet

- United Housing Foundation vs. Forman PDFDocument3 pagesUnited Housing Foundation vs. Forman PDFAya BaclaoNo ratings yet

- KENDRIYA VIDYALAYA NO.1 VASCO DA GAMA, GOA PERIODIC TEST -2 2021-22 CLASS XI ENGLISH COREDocument4 pagesKENDRIYA VIDYALAYA NO.1 VASCO DA GAMA, GOA PERIODIC TEST -2 2021-22 CLASS XI ENGLISH CORESOHAN DASNo ratings yet

- Is the US Stock Market in a Bubble? Signs to Watch ForDocument2 pagesIs the US Stock Market in a Bubble? Signs to Watch ForLeslie LammersNo ratings yet

- Master Data:: Bulk Upload - ZME11Document32 pagesMaster Data:: Bulk Upload - ZME11veeramaniNo ratings yet

- Auditing Assignment Audit Committee BenefitsDocument5 pagesAuditing Assignment Audit Committee BenefitsKehfulwara KhanNo ratings yet

- McDonald's Resources OverviewDocument5 pagesMcDonald's Resources OverviewPrarthana RaiNo ratings yet

- Project Management: Kendall & Kendall Systems Analysis and Design, 9eDocument91 pagesProject Management: Kendall & Kendall Systems Analysis and Design, 9eSeçkin KaymakNo ratings yet

- ReportDocument4 pagesReportAlly M. EulalioNo ratings yet

- 2 - New Market Entry Strategy 2019Document28 pages2 - New Market Entry Strategy 2019Sherzod AxmedovNo ratings yet

- Office of The Assistant Engineer, Lid & Ew Section Perumbalam GPDocument2 pagesOffice of The Assistant Engineer, Lid & Ew Section Perumbalam GPaneeshp_4No ratings yet

- ElementDocument3 pagesElementMaiko Gil HiwatigNo ratings yet

- Amazon SAP ERP Case ProjectDocument5 pagesAmazon SAP ERP Case Projectjem heartNo ratings yet

- JD 0001 - General ManagerDocument2 pagesJD 0001 - General ManagerAigene PinedaNo ratings yet

- CH 10. Globalization of Ethical Decision Making. Ed.10Document39 pagesCH 10. Globalization of Ethical Decision Making. Ed.10Karola MocanNo ratings yet

- Chapter 10 Test BankDocument48 pagesChapter 10 Test BankRujean Salar AltejarNo ratings yet

- India's Balance of Payments Crisis and It's ImpactsDocument62 pagesIndia's Balance of Payments Crisis and It's ImpactsAkhil RupaniNo ratings yet

- Big Data AnalyticsDocument31 pagesBig Data AnalyticsTushar SawantNo ratings yet

- Electrical Engineering Company ProfileDocument16 pagesElectrical Engineering Company ProfileBash GroupNo ratings yet

- Government and Corporate Social Responsibility (GCSR) Chapter 1: Strategic Public Policy Vision for CSRDocument4 pagesGovernment and Corporate Social Responsibility (GCSR) Chapter 1: Strategic Public Policy Vision for CSRLouelie Jean AlfornonNo ratings yet

- Bill of Excange Book by Chief HashiDocument61 pagesBill of Excange Book by Chief HashiElNo ratings yet

- Bedri Managerial Economics ExamDocument3 pagesBedri Managerial Economics ExamBedri M AhmeduNo ratings yet

- INTRODUCTION To Bank of BarodaDocument11 pagesINTRODUCTION To Bank of BarodaNithinNo ratings yet

- Revit Structure 4 User GuideDocument728 pagesRevit Structure 4 User GuidehernawanmhNo ratings yet

- Final Project - A STUDY OF GROWTH PROSPECTS OF ONLINE REATAILORS AND E-COMMERCE IN INDIADocument94 pagesFinal Project - A STUDY OF GROWTH PROSPECTS OF ONLINE REATAILORS AND E-COMMERCE IN INDIAhariiNo ratings yet

- Chapter 1: Purchasing and Supply Chain ManagementDocument23 pagesChapter 1: Purchasing and Supply Chain ManagementUyên DươngNo ratings yet

- MR - Economic and Financial Analysis of Planning The Menu in Aqua Caffe and Food RestaurantDocument100 pagesMR - Economic and Financial Analysis of Planning The Menu in Aqua Caffe and Food RestaurantAdhemar C. Rosas (adechoes1112)No ratings yet

- Cost of DebtDocument6 pagesCost of DebtrajisumaNo ratings yet

- Organizing The EnterpriseDocument38 pagesOrganizing The EnterpriseAngelie AnilloNo ratings yet

- IMC Plan - Nhóm 5 - PowerpointDocument25 pagesIMC Plan - Nhóm 5 - PowerpointQuỳnh Lai PhươngNo ratings yet

- Chapter 1: Cash and Cash Equivalents Expected Question(s) :: Cash On Hand Cash Fund Cash in BankDocument8 pagesChapter 1: Cash and Cash Equivalents Expected Question(s) :: Cash On Hand Cash Fund Cash in BankJulie Mae Caling MalitNo ratings yet