Professional Documents

Culture Documents

Lifting Fibre Nylon Slings Checklist

Uploaded by

mohamed Abo-Ewisha0 ratings0% found this document useful (0 votes)

8 views2 pagesCopyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views2 pagesLifting Fibre Nylon Slings Checklist

Uploaded by

mohamed Abo-EwishaCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 2

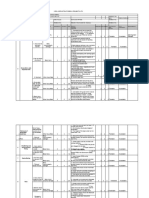

JIHAR Project LIFTING MACHINES AND LIFTING TACKLE

INSPECTION CONTROL - FIBRE ROPES / NYLON Frequency: Monthly

DEPARTMENT___________________________ YEAR_______________

1ST 2ND 3RD 4TH LEGEND

ID LOCATION Month Month Month Month

NO

CHECK ACTION CHECK ACTION CHECK ACTION CHECK ACTION 1. FIBRE ROPE NOTE

1.1 Wear/Abrasions. Do not "tick". Write OK or use

1.2 Mechanical damage. the number of the specific

1.3 Broken / cut / powdered fibres. deviation given in the legend

1.4 Displaced yarns / strands. alone. If the equipment is

1.5 Flattening of strands. defective it must be tagged-

1.6 Discolouration of rope. "Defective" and must be reported

1.7 Condition of inner strands. to the person responsible for

1.8 Exposure to corrosives. equipment repair. If the

1.9 Exposure to heat. equipment is beyond repair it

2. HOOKS should be destroyed and

2.1 Spread in throat opening. discarded. New equipment to

2.2 Cracked, nicked, chafed. replace the discarded equipment

2.3 Wear on eye. must be provided to discourage

2.4 Wear on clevis. the use of make shift equipment.

2.5 Wear on saddle. CORRECTIVE ACTION

2.6 Wear on load pin. (Indicate the action to be taken in

2.7 Side bending. the ACTION column by number as

3. SHACKLES indicated in the key below.

3.1 General condition. Specify the exact repairs to be done

3.2 Wear on pin/threads. on a works requisition or job card.

3.3 Max. mass load (SWL) marked. 1. None - in good state of repair.

CARE OF ROPE IN USE 2. Replace fibre rope.

The factors of safety for different types 3. Equipment to be cleaned.

of rope are as follows: 4. Fit safety latch on hook.

Nylon =9 5. Provide proper storage rack.

Polyester =9 6. Beyond repair - discard.

Polypropylene =6 7. Other - specify:

Manila =5

Sisal =5

DATE OF INSPECTION These factors are for average use,

INSPECTOR'S unusual loading requires higher factors.

INITIALS/ SIGNATURE

SPOT CHECK / AUDIT

(Date and initials)

You might also like

- HIRA for machanical workDocument8 pagesHIRA for machanical workshahhussain1031No ratings yet

- Rohan Builders (India) PVT - LTD: Concreting Rbipl MR - Vilas Kadam / MR - Sunil Shinde Main Plant and Road WorkDocument3 pagesRohan Builders (India) PVT - LTD: Concreting Rbipl MR - Vilas Kadam / MR - Sunil Shinde Main Plant and Road WorkAbhaySngh100% (1)

- Risk Assessment - Al Qabil - SamarDocument3 pagesRisk Assessment - Al Qabil - SamarFebilaNo ratings yet

- Risk - Batching Plant OperationsDocument6 pagesRisk - Batching Plant Operationsmechajay2002100% (1)

- Jsa Rig Engine Service 750 HRSDocument1 pageJsa Rig Engine Service 750 HRSAdel AlKhedawyNo ratings yet

- TRA For Fabrication, Cutting, Grinding and WeldingDocument3 pagesTRA For Fabrication, Cutting, Grinding and WeldingSaif Ali100% (1)

- Risk Assessment - HorizonDocument5 pagesRisk Assessment - HorizonFebilaNo ratings yet

- JSA 17-Rev.01 - Flange tightening jobDocument2 pagesJSA 17-Rev.01 - Flange tightening jobgolusinghdataNo ratings yet

- HIRA FOR ESP OUTLET PANNALDocument5 pagesHIRA FOR ESP OUTLET PANNALshahhussain1031No ratings yet

- Piling Works Safety AnalysisDocument6 pagesPiling Works Safety AnalysisamizanNo ratings yet

- 18 Fire Fighting Equipment Control Checklist - Doc NEWDocument2 pages18 Fire Fighting Equipment Control Checklist - Doc NEWDanaiNo ratings yet

- HIRA FOR CEMENT MILLDocument6 pagesHIRA FOR CEMENT MILLshahhussain1031No ratings yet

- 7-609 Back Filling HiraDocument1 page7-609 Back Filling Hirar2mgt28ssvNo ratings yet

- Risk Assessment For K.B. Come Clean Ltd. 2023-2024Document22 pagesRisk Assessment For K.B. Come Clean Ltd. 2023-2024kasiaNo ratings yet

- Clarion DX425 (Manual)Document16 pagesClarion DX425 (Manual)TateszNo ratings yet

- Risk Assesment of Brick & Block WorkDocument3 pagesRisk Assesment of Brick & Block WorkGyanendra SrivastavaNo ratings yet

- Hot Work TRA Workshop NightDocument3 pagesHot Work TRA Workshop Nightmarvin100% (1)

- VIBRATOR - C52JSA-200 - N90 Changing Vibrator Axle - 25-12-12Document4 pagesVIBRATOR - C52JSA-200 - N90 Changing Vibrator Axle - 25-12-12hechame TamerhouletNo ratings yet

- JSA-Rig Down TDS & Torque Beam AlgeriaDocument1 pageJSA-Rig Down TDS & Torque Beam Algeriamadjid bobNo ratings yet

- JHA FOR SMP 2Document7 pagesJHA FOR SMP 2Rohit TharseNo ratings yet

- Risk assessment for pump dismantling workDocument3 pagesRisk assessment for pump dismantling workHiralal PattanayakNo ratings yet

- Jubail United Petrochemical Company (United) Job Safety Analysis - Worksheet (Attachment V)Document4 pagesJubail United Petrochemical Company (United) Job Safety Analysis - Worksheet (Attachment V)Muhammad Umar GondalNo ratings yet

- Power Tools JsaDocument1 pagePower Tools JsanabeelNo ratings yet

- Task Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)Document3 pagesTask Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)andreNo ratings yet

- 5-Year Maintenance On Hydra RackerDocument2 pages5-Year Maintenance On Hydra Rackermohamed hamedNo ratings yet

- Aluminium CanopyDocument5 pagesAluminium CanopyRaja NasirNo ratings yet

- Jsa For - SRPDocument3 pagesJsa For - SRPVijay chauhanNo ratings yet

- Adjust Brake On Draw WorksDocument1 pageAdjust Brake On Draw WorksReda BoualiNo ratings yet

- HIRA of Anti Termite.Document1 pageHIRA of Anti Termite.Gyanendra SrivastavaNo ratings yet

- Jha - Mcdo Bago AplayaDocument4 pagesJha - Mcdo Bago AplayaRoc FarmNo ratings yet

- Risk Assessment For Curtain Wall & Glazing InstallationDocument4 pagesRisk Assessment For Curtain Wall & Glazing InstallationChristos Loutrakis50% (2)

- Air Conditioner Service Manual Safety PrecautionsDocument56 pagesAir Conditioner Service Manual Safety PrecautionsJesus TubiñezNo ratings yet

- Hira BCN 22aDocument33 pagesHira BCN 22aDhaneswar SwainNo ratings yet

- excavationDocument3 pagesexcavationKoneti JanardhanaraoNo ratings yet

- Master JSA 2052U Blower Removal & Installation Manual LiftingDocument6 pagesMaster JSA 2052U Blower Removal & Installation Manual LiftingOvais FarooqNo ratings yet

- Job Safety Analysis (JSA) - Using Power Tools DateDocument1 pageJob Safety Analysis (JSA) - Using Power Tools DatenabeelNo ratings yet

- Week Day Remarks S S M T W T FDocument1 pageWeek Day Remarks S S M T W T Fwei heNo ratings yet

- Lifting Risk AssessmentDocument4 pagesLifting Risk AssessmentMohamedSaid100% (1)

- ABDULRAHMANDocument1 pageABDULRAHMANAdel AlKhedawyNo ratings yet

- Jsa No: 00 - Piling WorksDocument4 pagesJsa No: 00 - Piling WorksUMUTNo ratings yet

- 2.preheater Building HiraDocument2 pages2.preheater Building HirasgcworkjpflNo ratings yet

- JHRA Risk Assessment for Cast in Place WallDocument55 pagesJHRA Risk Assessment for Cast in Place WallArnold AlamaniNo ratings yet

- Falih Falih SDN SDN BHD BHD JOB Job Safety Safety Analysis Analysis Jsa/Piling Jsa/Piling 1 1 of OF5 5 Doc. Doc. No. NO. Page No. NODocument9 pagesFalih Falih SDN SDN BHD BHD JOB Job Safety Safety Analysis Analysis Jsa/Piling Jsa/Piling 1 1 of OF5 5 Doc. Doc. No. NO. Page No. NOSreejith SureshNo ratings yet

- JSA Aircond Ducting WorkDocument1 pageJSA Aircond Ducting WorkRashidi Rahman100% (4)

- JSA - Batching Plant OperationDocument3 pagesJSA - Batching Plant OperationNisith SahooNo ratings yet

- Construction Work JsaDocument21 pagesConstruction Work Jsaitsumar632No ratings yet

- 15.tube Bundle Puller.Document3 pages15.tube Bundle Puller.Mohammad Fazal Khan100% (1)

- Qatar Liquefied Gas Company Limited JSA FormDocument7 pagesQatar Liquefied Gas Company Limited JSA FormMohammad Fazal KhanNo ratings yet

- HIRA FOR KILN _8Document6 pagesHIRA FOR KILN _8shahhussain1031No ratings yet

- Risk Assessment - Method of Statement Hydraulic Cylinder Bearing Replacement-Tian Kun HaoDocument3 pagesRisk Assessment - Method of Statement Hydraulic Cylinder Bearing Replacement-Tian Kun HaoFebilaNo ratings yet

- Risk Assessment RT Marine West Pier (Ok)Document29 pagesRisk Assessment RT Marine West Pier (Ok)jeyesbelmenNo ratings yet

- JSA For Childrens RoomDocument3 pagesJSA For Childrens Roomkalai selvanNo ratings yet

- UntitledDocument5 pagesUntitledPranayNo ratings yet

- 045 - KFAA-NAS-JV-RA-45-F07-20 - Substructure Concrete Works (Cast-In-Situ) Rev.0Document7 pages045 - KFAA-NAS-JV-RA-45-F07-20 - Substructure Concrete Works (Cast-In-Situ) Rev.0Zubair Ahmed KhaskheliNo ratings yet

- CE05 Working in A SubstationDocument4 pagesCE05 Working in A SubstationTafireyi TeveraNo ratings yet

- Job Safety Analysis: How To Use This FormDocument4 pagesJob Safety Analysis: How To Use This Formjithin shankar100% (1)

- JHA For Concreting WorkDocument3 pagesJHA For Concreting WorkRavi thokalNo ratings yet

- Service: ManualDocument27 pagesService: ManualAnonymous UserNo ratings yet

- DMP (05.07) Dep Fuj Anchor.Document2 pagesDMP (05.07) Dep Fuj Anchor.김순혁No ratings yet

- The Stability of Frames: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionFrom EverandThe Stability of Frames: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNo ratings yet

- LSR Safe Mechanical Lifting Toolbox TalkDocument13 pagesLSR Safe Mechanical Lifting Toolbox Talkmohamed Abo-EwishaNo ratings yet

- LSR Safe Mechanical Lifting Toolbox TalkDocument13 pagesLSR Safe Mechanical Lifting Toolbox Talkmohamed Abo-EwishaNo ratings yet

- LSR Confined Space Toolbox TalkDocument12 pagesLSR Confined Space Toolbox Talkmohamed Abo-EwishaNo ratings yet

- Aga Psms Workshop Pge Andre Da Costa-3-1-16 Rev For WebDocument16 pagesAga Psms Workshop Pge Andre Da Costa-3-1-16 Rev For Webmohamed Abo-EwishaNo ratings yet

- HSE Accommodation Inspection ChecklistDocument2 pagesHSE Accommodation Inspection Checklistmohamed Abo-EwishaNo ratings yet

- Tank Erection Risk Assessment - UTAMDocument3 pagesTank Erection Risk Assessment - UTAMmohamed Abo-Ewisha100% (1)

- 13 11Document2 pages13 11mohamed Abo-EwishaNo ratings yet

- MLL Weekly Inspection CheDocument3 pagesMLL Weekly Inspection CheSyahrudinNo ratings yet

- Electrical Risk Assessment - UTAMDocument3 pagesElectrical Risk Assessment - UTAMmohamed Abo-EwishaNo ratings yet

- P - Ahmed KamelDocument3 pagesP - Ahmed Kamelmohamed Abo-EwishaNo ratings yet

- Procedure For Hses Performance MeasurementDocument12 pagesProcedure For Hses Performance Measurementmohamed Abo-Ewisha100% (1)

- Ayman Abd-Allah - Resume - Safety EngineerDocument2 pagesAyman Abd-Allah - Resume - Safety Engineermohamed Abo-EwishaNo ratings yet

- Cv8262197 Mohamed Abo Ewisha HseqDocument4 pagesCv8262197 Mohamed Abo Ewisha Hseqmohamed Abo-EwishaNo ratings yet

- New Microsoft Excel Worksheet-1Document2 pagesNew Microsoft Excel Worksheet-1mohamed Abo-EwishaNo ratings yet

- مستند جديد ٢٠١٨-٠٢-٠٤Document1 pageمستند جديد ٢٠١٨-٠٢-٠٤mohamed Abo-EwishaNo ratings yet

- Safety Plan 2Document14 pagesSafety Plan 2mohamed Abo-EwishaNo ratings yet

- Electrical Risk Assessment - UTAMDocument3 pagesElectrical Risk Assessment - UTAMmohamed Abo-EwishaNo ratings yet

- CV - Ahmed MostafaDocument3 pagesCV - Ahmed Mostafamohamed Abo-EwishaNo ratings yet

- Belal Abdel HamidDocument12 pagesBelal Abdel Hamidmohamed Abo-EwishaNo ratings yet

- Safety Plan 2Document14 pagesSafety Plan 2mohamed Abo-EwishaNo ratings yet

- Advert, Workshop Foreman WVI 2204022Document4 pagesAdvert, Workshop Foreman WVI 2204022mohamed Abo-EwishaNo ratings yet

- Use Plant Walkthroughs To Enhance Process Safety Risk 2473Document28 pagesUse Plant Walkthroughs To Enhance Process Safety Risk 2473mohamed Abo-EwishaNo ratings yet

- CV MahmoudDocument4 pagesCV Mahmoudmohamed Abo-EwishaNo ratings yet

- Mechanical Risk Assessment - UTAMDocument3 pagesMechanical Risk Assessment - UTAMmohamed Abo-EwishaNo ratings yet

- CV New - 2Document2 pagesCV New - 2mohamed Abo-EwishaNo ratings yet

- Pipefitting: Basic EngineeringDocument40 pagesPipefitting: Basic Engineeringmohamed Abo-EwishaNo ratings yet

- Rescued DocumentDocument1 pageRescued Documentmohamed Abo-EwishaNo ratings yet

- Meha S-NewCV-August 2017-2017-12-9 - 11-51-06Document3 pagesMeha S-NewCV-August 2017-2017-12-9 - 11-51-06mohamed Abo-EwishaNo ratings yet

- PART 2 Site Specific Safety OrientationDocument3 pagesPART 2 Site Specific Safety Orientationmohamed Abo-EwishaNo ratings yet

- Serious Occurrence ReportDocument2 pagesSerious Occurrence Reportmohamed Abo-EwishaNo ratings yet

- CCTmanual 56Document226 pagesCCTmanual 56Jim Barrón GarcíaNo ratings yet

- 241-Article Text-1014-1-10-20201017Document8 pages241-Article Text-1014-1-10-20201017derismurib4No ratings yet

- Filtrair Filter Media VNF M1 Series ENDocument2 pagesFiltrair Filter Media VNF M1 Series ENThái Hòa GiangNo ratings yet

- OK - EndUserGuideHoseSafetyInstituteDocument8 pagesOK - EndUserGuideHoseSafetyInstituteSunil GhosalkarNo ratings yet

- Incremental and Newton Methods Lab ReportDocument10 pagesIncremental and Newton Methods Lab ReportAbde RrahimNo ratings yet

- Hazardous Waste Identification GuidanceDocument105 pagesHazardous Waste Identification GuidanceMiguel TorresNo ratings yet

- Quantum Free Electron Theory: Sommerfeld's ModelDocument8 pagesQuantum Free Electron Theory: Sommerfeld's ModelNeelam KapoorNo ratings yet

- Feed Water Heater ModellingDocument64 pagesFeed Water Heater ModellingSIVA KAVYANo ratings yet

- VTBS 20-3DDocument1 pageVTBS 20-3Dwong keen faivNo ratings yet

- Assignment 1 (Total Marks: 70) EEE 323: Power System IIDocument2 pagesAssignment 1 (Total Marks: 70) EEE 323: Power System IIShahriar SauravNo ratings yet

- Architecture in The AnthropoceneDocument265 pagesArchitecture in The Anthropoceneziyad fauziNo ratings yet

- Build a Homebrew Pre-Amplified MicrophoneDocument3 pagesBuild a Homebrew Pre-Amplified MicrophoneMacario Imbudo BukatotNo ratings yet

- Air Pollution Sources & EffectsDocument2 pagesAir Pollution Sources & EffectsJoanne Ash MajdaNo ratings yet

- A Review of Cyber-Physical System Research Relevant To The Emerging It Trends: Industry 4.0, Iot, Big Data, and Cloud ComputingDocument22 pagesA Review of Cyber-Physical System Research Relevant To The Emerging It Trends: Industry 4.0, Iot, Big Data, and Cloud ComputingFleetNo ratings yet

- Advances in The Study of The Genetic Disorders PDFDocument484 pagesAdvances in The Study of The Genetic Disorders PDFhayamasNo ratings yet

- Atoms & Ions Worksheet 1 /63: Atomic Number and Mass NumberDocument4 pagesAtoms & Ions Worksheet 1 /63: Atomic Number and Mass Numbercate christineNo ratings yet

- Fe412farm Module N Cost BenefitDocument34 pagesFe412farm Module N Cost BenefitYaswanth NaikNo ratings yet

- IR Spectroscopy Identification GuideDocument28 pagesIR Spectroscopy Identification GuideAby JatNo ratings yet

- All ProblemsDocument107 pagesAll ProblemsjoshiabhijeetNo ratings yet

- Nominal Pipe Size, Nominal Diameter & Outside Diameter For PipesDocument1 pageNominal Pipe Size, Nominal Diameter & Outside Diameter For PipesmdnorNo ratings yet

- A Perspective in Accelerated Orthodontics With Aligner Treatment 2017 Seminars in OrthodonticsDocument7 pagesA Perspective in Accelerated Orthodontics With Aligner Treatment 2017 Seminars in Orthodonticsdruzair007No ratings yet

- The Spring, Energy Accumulator A Mechanical WatchDocument5 pagesThe Spring, Energy Accumulator A Mechanical WatchismbllNo ratings yet

- Hospitality Case StudiesDocument26 pagesHospitality Case StudiesKarthik PalaniswamyNo ratings yet

- Future Visualized in The Movie BrazilDocument16 pagesFuture Visualized in The Movie BrazilsloutfyNo ratings yet

- Life Saving Appliance: Personal Life-Saving Appliances Lifeboats & Rescue Boats LiferaftsDocument18 pagesLife Saving Appliance: Personal Life-Saving Appliances Lifeboats & Rescue Boats Liferaftsdafa dzaky100% (1)

- Sunningdale School Notes Summer 2022Document12 pagesSunningdale School Notes Summer 2022sunningdaleschoolNo ratings yet

- BA Anchor Data SheetDocument17 pagesBA Anchor Data SheetbrodieNo ratings yet

- Congruence and Similarity PDFDocument18 pagesCongruence and Similarity PDFAldo HutagalungNo ratings yet

- Viscous Fluid Flow Ch1-Preliminary Concepts: Kfupm ME 532-172Document40 pagesViscous Fluid Flow Ch1-Preliminary Concepts: Kfupm ME 532-172Majid KhanNo ratings yet

- SP18368 Automotive Radar Comparison 2018 Sample 2Document33 pagesSP18368 Automotive Radar Comparison 2018 Sample 2Chipisgood YuNo ratings yet