Professional Documents

Culture Documents

HIRA of Anti Termite.

Uploaded by

Gyanendra SrivastavaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HIRA of Anti Termite.

Uploaded by

Gyanendra SrivastavaCopyright:

Available Formats

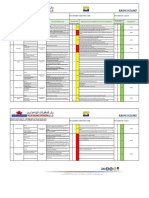

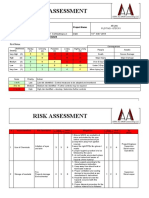

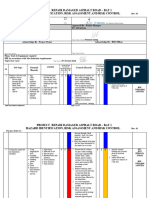

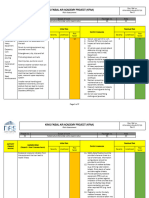

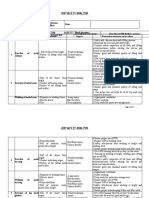

Risk Assessment Of Anti termite.

Resultant Risk Additional Control

Sr No. Sub activity Hazards Risk Severity Probability Control Measure Severity Probability Resultant Risk Risk Level

Risk Level Measures

1.Tool box talk shall be conducted for the 1.Never store any food items

activity to communicate the specific hazard to in the storage area.

all concerned workers. 2.Use proper manual

handling procedures and

1.Musculoskeletal 2.Required PPE's to be used. steps.

disorder due to 3.Do not store in 3.Physical 3 1 3 L

1.Improper manual Handling. handling. container without lid to cover it. fit workers to be engaged for

1 Unloading & Storage. 3 4 12 H

2.Hit to man or Material. the work. 4.Provide fire

2.Physical injury. 4.Provide rain water protection for storage extingusher with sand bucket.

3.Property damage. area.

5.Display MSDS at Storage loacation.

6.Display chemical specific warning sign.

7.Stack all material in proper

manner avoid over height.

1.Safe access/egress towards the work

1.Major/Minor injury. location.

1.Slip/Trip/Fall hazard. 2.Training to all workers.

2. Handling heavy objects. 3.Compaction Machine must be

2.Eye injury.

3. Struck by/against heavy inspected before use.

Surface levling &

2 equipment. 3 3 9 M 4.Experienced worker to operate the 3 1 3 L

Compaction. 3.Hearing loss.

4.Flying debris. compacting machine.

4. Musculoskeletal

5.Vibration. 5.Ensure full time supervision for work.

disorder due to

6.Noise 6.Job specific PPE must be used.

vibration.

1.Tool box talk shall be conducted for the

concerned workers.

2.Required PPE to be used.

1.Major/Minor injury. 3.Nailing object to be

3 Nailing to earth 1.Hit by nailing object. 3 2 6 M check before use. 3 1 3 L

1.Insecticide contact & Inhalation. 1.Respiratory 1.Area were chemical mixing should be on a 1.Work shall be performed in

2. diseases. specified location. close supervision.

Chemical burn. 2.Drowsiness, 2.Only trained worker shall conduct the 2.Site safety should inform

3.Fail to safe work procedure. Headache & mixing of insecticide. workers working adjacent to

Dizziness. 3.Concern staff shall the application area that they

4 Chemical Mixing 3.Skin Burn. 4 4 16 H demonstrate knowledge of pesticide label and should have at 30 mtrs radius 3 1 3 L

Material Safety Data Sheet prior to mixing of away.

4.Eye injury. chemicals.

4.Job specific

must be used.

1.Unexperinced worker. 1.Physical Injury (eye 1.Assure all tools are must be checked before 1.First-aid facilities should be

2.Defective equipment. 3.Inhalation and Hand). 2.Lungs use. available at site.

by worker. 4.Exposure to chemical Infection. 3.Skin 2.The workers should control the 2.Site emergency

during manual handling. irritation. pressure and chemical spillage. procedure must be aware.

5 Chemical spray 4 3 12 H 3.Making 3.Assure hand 3 1 3 L

sure that the tank cap is tightly closed before washing facility with soap

switching the machine. 4. shall be available at site.

Job specific PPE must be used

1.Proper collection and disposal of empty

container / drums as per project waste

management procedure.

2.Empty drums storage area should

Environmental 1.Environment be specified.

6 1. Hazardous Wastages 3 3 9 M 3.prevent ground contamination. 3 1 3 L

Concerns damaged

1.Maintain good housekeeping in the working

area.

3.Remove the empty drums for

working area on immediate basis.

1.Used by worker for other activity. 3.Stored empty drm send to

Disposal of empty 1.Physical injuries.

7 3 3 9 M authorized party. 2 1 2 L

drum. (eye and skin).

2.Unauthrized party. 4.Store

empty drum must be counted and seprate

with lock and key untill not disposed.

You might also like

- Job Activity Hazard Effect Control Measures: Project in ChargeDocument3 pagesJob Activity Hazard Effect Control Measures: Project in Chargeperquino oasanNo ratings yet

- Basic Occupational Safety and Health TrainingDocument5 pagesBasic Occupational Safety and Health TrainingAUST BNo ratings yet

- Jsa For Scaffolding Erection & DismentlingDocument7 pagesJsa For Scaffolding Erection & Dismentlingsanath adhikary100% (5)

- JHA For Shuttring and DeshuttringDocument2 pagesJHA For Shuttring and DeshuttringTigor GurningNo ratings yet

- Risk Assessment Physics and Ece LaboratoryDocument8 pagesRisk Assessment Physics and Ece LaboratorydbrucalNo ratings yet

- Risk Assessment RT Marine West Pier (Ok)Document29 pagesRisk Assessment RT Marine West Pier (Ok)jeyesbelmenNo ratings yet

- HIRAC RegisterDocument41 pagesHIRAC RegisterPNCPL PLANNINGNo ratings yet

- JSA - Scaffolding Erection and Dismantling Work.Document3 pagesJSA - Scaffolding Erection and Dismantling Work.hitech.birlacyrNo ratings yet

- Risk - Batching Plant OperationsDocument6 pagesRisk - Batching Plant Operationsmechajay2002100% (1)

- Jsa For Scaffolding ErectionDocument7 pagesJsa For Scaffolding Erectionnoorul IslamNo ratings yet

- HIRA of Plaster Work.Document4 pagesHIRA of Plaster Work.Gyanendra SrivastavaNo ratings yet

- AHA - Earthworks (Excavation, Compaction, Backfilling and Filling) - REV-1 (3-9-2019)Document8 pagesAHA - Earthworks (Excavation, Compaction, Backfilling and Filling) - REV-1 (3-9-2019)Eyal BabuNo ratings yet

- AHA - Asbestos Abatement-11-11-2019Document7 pagesAHA - Asbestos Abatement-11-11-2019Eyal BabuNo ratings yet

- Job Safety Analysis Foundation WorkDocument3 pagesJob Safety Analysis Foundation WorkMihirduttaNo ratings yet

- Risk Assessment For Chilled Water CladdingDocument2 pagesRisk Assessment For Chilled Water CladdingHAMIDULLAH MNo ratings yet

- 7-609 Back Filling HiraDocument1 page7-609 Back Filling Hirar2mgt28ssvNo ratings yet

- Risk Assessment - Al Qabil - SamarDocument3 pagesRisk Assessment - Al Qabil - SamarFebilaNo ratings yet

- Back Filling WorksDocument3 pagesBack Filling WorksAbdul Ghaffar100% (1)

- Hirac - Repair Damaged Asphalt Road - Blok 1Document14 pagesHirac - Repair Damaged Asphalt Road - Blok 1Widyardi SaputraNo ratings yet

- 2.preheater Building HiraDocument2 pages2.preheater Building HirasgcworkjpflNo ratings yet

- M/S Gubbi Civil Engineer: Hazard Identification & Risk AnalysisDocument3 pagesM/S Gubbi Civil Engineer: Hazard Identification & Risk AnalysisHARSHADNo ratings yet

- New Sop Piant WorkDocument6 pagesNew Sop Piant WorkBALAL AKRAMNo ratings yet

- RA - 11 (K2 Paste.Document4 pagesRA - 11 (K2 Paste.alla malikNo ratings yet

- AHA - Aluminum Windows Installation - 14-3-2019 Revie-2Document6 pagesAHA - Aluminum Windows Installation - 14-3-2019 Revie-2Eyal BabuNo ratings yet

- Omn01ard - Jsa-Installation of Light Sensor at Top of JS and SS SkidsDocument3 pagesOmn01ard - Jsa-Installation of Light Sensor at Top of JS and SS Skidshechame TamerhouletNo ratings yet

- Risk Assessment For Admin BuildingDocument6 pagesRisk Assessment For Admin BuildingmurthyNo ratings yet

- 045 - KFAA-NAS-JV-RA-45-F07-20 - Substructure Concrete Works (Cast-In-Situ) Rev.0Document7 pages045 - KFAA-NAS-JV-RA-45-F07-20 - Substructure Concrete Works (Cast-In-Situ) Rev.0Zubair Ahmed KhaskheliNo ratings yet

- R.K Construction: Job Hazard AnalysisDocument8 pagesR.K Construction: Job Hazard AnalysisDwitikrushna Rout100% (1)

- Elephant Project - Sayakha GujaratDocument8 pagesElephant Project - Sayakha Gujaratalla malikNo ratings yet

- Jsa No 18 New BarrictionDocument4 pagesJsa No 18 New BarrictionSushil Kumar YadavNo ratings yet

- Manual Handling (Risk Assessment)Document3 pagesManual Handling (Risk Assessment)khurram shahzadNo ratings yet

- Loading Dolomite and Mill Scale To Vessel With Silo HopperDocument6 pagesLoading Dolomite and Mill Scale To Vessel With Silo HopperMahendren JayapalanNo ratings yet

- Elephant Project - Sayakha GujaratDocument8 pagesElephant Project - Sayakha Gujaratalla malikNo ratings yet

- Shuttering WorksDocument3 pagesShuttering WorksAbdul GhaffarNo ratings yet

- Tile WorkDocument1 pageTile WorknabeelNo ratings yet

- Safe Work Method Statement: (See Below)Document6 pagesSafe Work Method Statement: (See Below)Siddharth P100% (1)

- Risk Assessment Welding and CuttingDocument2 pagesRisk Assessment Welding and CuttingdaddyanataNo ratings yet

- Jsa Insulation WorkDocument20 pagesJsa Insulation WorkazerNo ratings yet

- GeneralscaffoldingworkDocument3 pagesGeneralscaffoldingworkwisdom ukuejeNo ratings yet

- JSA 17-Rev.01 - Flange Tightening JobDocument2 pagesJSA 17-Rev.01 - Flange Tightening JobgolusinghdataNo ratings yet

- RA-Suspended Gypsum, Metallic Tiles Celling WorksDocument4 pagesRA-Suspended Gypsum, Metallic Tiles Celling Worksfaizan khanNo ratings yet

- Hira For Steel Structural Erection WorkDocument26 pagesHira For Steel Structural Erection Workகண்ணன் ரவிச்சந்திரன்No ratings yet

- Heights Safe Working atDocument7 pagesHeights Safe Working atHendrias Ari SujarwoNo ratings yet

- Risk Assessment Ubderground Electric Power SupplyDocument4 pagesRisk Assessment Ubderground Electric Power SupplySameer Abdul RaufNo ratings yet

- HIRA For Watching PlantDocument13 pagesHIRA For Watching PlantVikash Kumar RayNo ratings yet

- Carefour RA-For Block Works and Plastering WorksDocument17 pagesCarefour RA-For Block Works and Plastering Worksfaizan khanNo ratings yet

- Risk AssesmentDocument2 pagesRisk AssesmentSatish KumarNo ratings yet

- Boiler JSADocument42 pagesBoiler JSApankajbhatt376No ratings yet

- Shuttering WorksDocument5 pagesShuttering Worksprasanna okNo ratings yet

- Job Safety Analysis - Work SheetDocument4 pagesJob Safety Analysis - Work Sheetrickie7809No ratings yet

- Safety AssignmentDocument4 pagesSafety AssignmentHytham RiadNo ratings yet

- JSA - Erection Boiler Install (SFILEDocument35 pagesJSA - Erection Boiler Install (SFILEHilman NugrahaNo ratings yet

- AHA - Installation of Doors and Wooden Items - 27-3-2019 RevDocument6 pagesAHA - Installation of Doors and Wooden Items - 27-3-2019 RevEyal BabuNo ratings yet

- Job Safety Analysis Foundation WorkDocument3 pagesJob Safety Analysis Foundation WorkMihirdutta75% (4)

- ER-MO-03 Electrical Work On The Nacelle and TowerDocument13 pagesER-MO-03 Electrical Work On The Nacelle and TowerAlex IgnatNo ratings yet

- Elephant Project - Sayakha GujaratDocument8 pagesElephant Project - Sayakha Gujaratalla malikNo ratings yet

- Risk Assessment Project 3Document3 pagesRisk Assessment Project 3luxorNo ratings yet

- Risk Assessment SD Sliding DoorDocument7 pagesRisk Assessment SD Sliding DoorDarius AdeNo ratings yet

- Ecology of Root PathogensFrom EverandEcology of Root PathogensS.V. KrupaNo ratings yet

- Hot Work PermitDocument2 pagesHot Work PermitGyanendra SrivastavaNo ratings yet

- Checklist For Gas Cutting SetDocument1 pageChecklist For Gas Cutting SetGyanendra SrivastavaNo ratings yet

- Risk Assessment of Barricading WorkDocument3 pagesRisk Assessment of Barricading WorkGyanendra SrivastavaNo ratings yet

- HIRA of Welding Work.Document1 pageHIRA of Welding Work.Gyanendra SrivastavaNo ratings yet

- Monthly Safety Activity Plan Mar-2024Document1 pageMonthly Safety Activity Plan Mar-2024Gyanendra SrivastavaNo ratings yet

- Method Statement of Barricading WorkDocument2 pagesMethod Statement of Barricading WorkGyanendra SrivastavaNo ratings yet

- Risk Assesment of Brick & Block WorkDocument3 pagesRisk Assesment of Brick & Block WorkGyanendra SrivastavaNo ratings yet

- Risk Assessment of Cantilever ScaffoldDocument1 pageRisk Assessment of Cantilever ScaffoldGyanendra Srivastava100% (1)

- Risk Assesment of Brick & Block WorkDocument40 pagesRisk Assesment of Brick & Block WorkGyanendra Srivastava0% (2)

- Question 1. A. Booked B. Missed D. Pronounced: JaneDocument4 pagesQuestion 1. A. Booked B. Missed D. Pronounced: JaneThuận NgyễnNo ratings yet

- ISO 20121 Event Sustainability (Iso20121)Document12 pagesISO 20121 Event Sustainability (Iso20121)Tim SunderlandNo ratings yet

- Municipal Solid Waste Management in Asia: A Comparative AnalysisDocument14 pagesMunicipal Solid Waste Management in Asia: A Comparative AnalysisHugo Dario Machaca CondoriNo ratings yet

- Contingency Approach To ManagementDocument16 pagesContingency Approach To ManagementMuabeNo ratings yet

- Reflection On FS 2Document3 pagesReflection On FS 2Chelca Angela RamosNo ratings yet

- Sustainable Forest ManagementDocument26 pagesSustainable Forest ManagementAkanksha kushwahaNo ratings yet

- ĐỀ SỐ 1Document6 pagesĐỀ SỐ 1Hải Đăng PhạmNo ratings yet

- 5E Model For Integrated STEM LessonDocument4 pages5E Model For Integrated STEM LessonEmran AlwaqfiNo ratings yet

- 10 Decembrie 2023Document170 pages10 Decembrie 2023Petra-Svetlana MelinteNo ratings yet

- Practice For Unit 3Document8 pagesPractice For Unit 3Ngọc Huyền Lê0% (1)

- Nistru Sumar EN-finalDocument36 pagesNistru Sumar EN-finaloanastoica1307No ratings yet

- Environmental Science 1Document14 pagesEnvironmental Science 1Jael Rose CondezNo ratings yet

- Lets Talk About Climate Change Fun Activities Games - 710Document2 pagesLets Talk About Climate Change Fun Activities Games - 710Alejandro ArcosNo ratings yet

- Engineering Report On Surface Water Drainage Plan, Denbigh, Clarendon July 2, 2016 - 220110 - 112838Document5 pagesEngineering Report On Surface Water Drainage Plan, Denbigh, Clarendon July 2, 2016 - 220110 - 112838mark walcottNo ratings yet

- 2018 Hok Design AnnualDocument201 pages2018 Hok Design Annualwilfredo zepedaNo ratings yet

- X-Pruf PolyLiner PVCDocument2 pagesX-Pruf PolyLiner PVCAmr RagabNo ratings yet

- UNIVERSITY OF LA SALETTE INC LPPPPPPDocument4 pagesUNIVERSITY OF LA SALETTE INC LPPPPPPAlexis A. AguilarNo ratings yet

- Harmonized National Research and Development Agenda. (HNRDA) (2017-2022)Document5 pagesHarmonized National Research and Development Agenda. (HNRDA) (2017-2022)Torong VNo ratings yet

- Synthesis in Public Administration by Marjorie F PacioDocument2 pagesSynthesis in Public Administration by Marjorie F Paciomarjorie pacioNo ratings yet

- pg10 - Application For Development Within Green Belt Zone Under Section 16 of The Town Planning OrdinanceDocument3 pagespg10 - Application For Development Within Green Belt Zone Under Section 16 of The Town Planning OrdinanceLi Tsz ChunNo ratings yet

- Amel Manning Scott Koger 2017Document6 pagesAmel Manning Scott Koger 2017Chris WrightNo ratings yet

- Does Your Data Center Follow ASHRAE TC 9.9 Thermal Guidelines For Data Processing Environments - Sunbird DCIMDocument2 pagesDoes Your Data Center Follow ASHRAE TC 9.9 Thermal Guidelines For Data Processing Environments - Sunbird DCIMGeorgiaNo ratings yet

- Literature Review On Sustainable Development - The Spirit and Critics of SD and SdgsDocument19 pagesLiterature Review On Sustainable Development - The Spirit and Critics of SD and SdgsTrivesh MakenNo ratings yet

- GP Graded EssayDocument3 pagesGP Graded EssayMaxim PortikNo ratings yet

- Unit - 2 Environmental Science 2nd Semester - Bright MedicoDocument22 pagesUnit - 2 Environmental Science 2nd Semester - Bright Medicoudaywal.nandiniNo ratings yet

- Seerat AssignmentDocument15 pagesSeerat AssignmentGursimran SinghNo ratings yet

- A Theoretical Study On Evolution of Organisational Climate, Theories and DimensionsDocument7 pagesA Theoretical Study On Evolution of Organisational Climate, Theories and DimensionsJack-Jet Tabigo-onNo ratings yet

- Eegp17-01 GTF Full Report Final For Web Posting 0402Document202 pagesEegp17-01 GTF Full Report Final For Web Posting 0402Agurtzane GimenoNo ratings yet

- Script For Project Speech: Slide 1: IntroDocument5 pagesScript For Project Speech: Slide 1: IntroNguyen Ngoc MinhNo ratings yet

- Solid Waste Project AssinmentDocument27 pagesSolid Waste Project AssinmentAsmerom MosinehNo ratings yet