Professional Documents

Culture Documents

R.K Construction: Job Hazard Analysis

Uploaded by

Dwitikrushna RoutOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

R.K Construction: Job Hazard Analysis

Uploaded by

Dwitikrushna RoutCopyright:

Available Formats

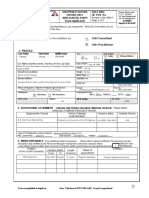

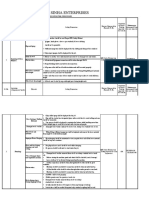

R.

K CONSTRUCTION

JOB HAZARD ANALYSIS

Dept./Section Engineering Services, West Bokaro JHA No.:01

Location of Job Date:20.01.2021

Job Description Glass wool lagging and refractory work

Team Who has done JHA Safety Supervisor 00

Basic job description Potential Hazards Safe Guards / Controls to be put in place Responsibility

1.Shifting of materials(tools, Safety: 1. Shoulder pad should be used Safety Supervisor

PGS sheet, aluminium 1) Heavy load during work ,25 kg for men & 16

sheet ,refractory clay & glass kg for women are the maximum

wool sheet) by Manually & 2) Sharp edges of load,

lifting capacity to be strictly

trolley. trolley.

followed.

3) Obstruction on the Stopper to be used for loaded

way of movement. trolley, in case of standing

position of trolley.

4) Struck by movable 2. Safety gloves to be worn while

vehicles. handling.

3. Good housekeeping is to be

Environment:

NA maintained along the movement

Quality: area.

NA 4. Movement of materials to be along

Ergonomic: the pavement of the road on the

1.Improper working left side of the road.

posture. 5. Proper supervision for wrong

2.Continuation Of work.

procedural working.

Seasonal:

1.Heavy downpour. 6. Small intervals to be provided

2.Lightening between work.

3.High Temperature 7. Rain coat to be provided to

Occupational Health workers.

Hazard: 8. Stop the work & reside inside the

1.Musculoskeletal safe room.

disorder

9. Drinking water facility & ORS.

10. Adequate PPEs usage.

11. Periodic medical check up

Required PPE Required Required Skill/Training Experienced site in-

Tools/Equipment charge/supervisor

Safety shoe,Safety Trolley Training For material handling Available

jacket,Safety helmet,Safety

goggles,nose mask.Hand

gloves

Signature of JHA Team Members

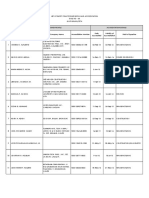

R.K CONSTRUCTION

JOB HAZARD ANALYSIS

Dept./Section JHA No.:

Location of Job Date:

Job Description

Team Who has done JHA Safety Supervisor

Basic job description Potential Hazards Safe Guards / Controls to be put in place Responsibility

2. Work at height(10 m- Safety: 1.Hand rail to be used while ascending. Safety Supervisor

15m) 1.Ascending through Staircase surface to be rough for better grip.

ladder. 2. While working on platform safety

2.Working on platform. harness belt to used mandatory.

3. Fall of materials, The platform to be fixed barricaded.

tools. 3. Materials to be kept at a safe distance

Environment: from edges of the platform.

1.Dusty area Tools to be kept in tool-kit.

2. High noise area 4. Nose-mask should be compulsory while

Quality: working.

1.Absence of height 5. Ear plug should be mandatory while

pass of workers. working.

Ergonomic: 6. Vertigo test with respect to height pass

1.Improper working compulsory for working at height.

posture. 6. Proper supervision during work.

2.Continuation Of work. 7. Break to be provided within work.

Seasonal: 8. Drinking water facility on work site.

1..Humidity 9. Periodic medical check up.

Occupational Health

Hazard:

1.Musculoskeletal

disorder

Required PPE Required Required Skill/Training Experienced site in-

Tools/Equipment charge

Safety shoe, Safety jacket, Hand tools Training before start of job Available

Safety helmet, Safety Training about the following SOP

goggles, nose mask. Hand

gloves, Ear Plug, Harness

Belt

Signature of JHA Team Members

R.K CONSTRUCTION

JOB HAZARD ANALYSIS

Dept./Section JHA No.:

Location of Job Date:

Job Description

Team Who has done JHA Safety Supervisor

Basic job description Potential Hazards Safe Guards / Controls to be put in place Responsibility

3. Removal of cladding Safety: 1.Safety gloves, safety shoes to be used. Safety Supervisor

sheet/aluminium sheets. 1. Sharp, rough edges of 2. Checklist of screw gun machine prior

working tools, sheets start of work.

etc. 3. Checking the full length wire and the

2. Faulty Screw Gun connection before work.

machine. 4. Use of Safety goggles and nose-mask

3. Breakage of during work.

insulation of live 5. Barricade the working platform and the

electric wire. area underneath .

4. Splinters 6. Mandatory use of nose mask.

5. Mis-handling of 7. Mandatory use of ear plug.

sheets, tools etc. 8. Attentive towards the work and the steps

Environment: to be taken carefully.

Dusty area 9. Posture while working to be supervised

Noisy area in proper manner.

Uneven working floor 10. Small break to be provided in between

Quality: the work.

NA 11. Drinking water & ORS to be provided at

Ergonomic: work site.

1.Improper working Adequate ventilation needed.

posture. 12. Timely medical check up to be provided.

2.Continuation Of work.

Seasonal:

1.Humidity

Occupational Health

Hazard:

1.Musculoskeletal

disorder

Required PPE Required Required Skill/Training Experienced site in-

Tools/Equipments charge

Safety shoe,Safety Hand Cutter machine, Training before start of job Available

jacket,Safety helmet,Safety Scissor, Screw gun Training about the following SOP

goggles,nose mask.Hand machine, Hammer,

gloves, Ear Plug, Harness Plier, Screw driver

Belt

Signature of JHA Team Members

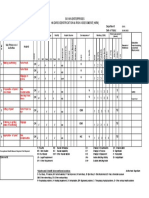

R.K CONSTRUCTION

JOB HAZARD ANALYSIS

Dept./Section JHA No.:

Location of Job Date:

Job Description

Team Who has done JHA Safety Supervisor

Basic job description Potential Hazards Safe Guards / Controls to be put in place Responsibility

4. Removal of old insulation. Safety: 1.Wait for sometime to cool the surface and Safety Supervisor

1.Hot surface usage of adequate PPEs during work.

2. Sharp/rough edge or 2. Attentive towards work and use of safety

surface of wire mesh hand gloves.

and hooks. 3. Usage of full sleeve clothing while

3.Glass wool sheet. handling of glass wool sheet.

4. Slipping of hand 4. Barricade the working platform and the

tools. area below.

Environment: 5. Clean the surface and dispose the scraps

Spread of insulating in the respective bins. Nose mask to be

material fines and dust. worn.

Quality: 6.Use standard pair of scissors for cutting of

Bad quality scissors for old insulation sheet.

cutting . 7. Strict supervision necessary.

Ergonomic: 8. In between the work small breaks to be

1.Improper working provided.

posture. 9. Drinking water facility to be present on

2.Continuation Of work. work site.

Seasonal: Proper air passage to be maintained in the

1.Humidity working area.

Occupational Health 10. Periodic medical check up necessary.

Hazard:

1.Musculoskeletal

disorder

Required PPE Required Required Skill/Training Experienced site in-

Tools/Equipments charge

Safety shoe,Safety Hammer, Plier, Screw Training before start of job Available

jacket,Safety helmet,Safety driver Training about the following SOP

goggles,nose mask.Safety

Hand Gloves, Ear Plug, Safety

Harness Belt

Signature of JHA Team Members

Dept./Section JHA No.:

R.K CONSTRUCTION

JOB HAZARD ANALYSIS

Location of Job Date:

Job Description

Team Who has done JHA Safety Supervisor

Basic job description Potential Hazards Safe Guards / Controls to be put in place Responsibility

5.Making of new glass wool Safety: 1.Safety gloves usage and carefully Safety Supervisor

pad and required size of 1.Sharp edges of handling of tools.

cladding sheet. measurement tape, 2. Machine guard pre-installed prior work

scissors, other hand to be ensured.

tools etc. 3. Connecting point to be safely plugged

2.Electric hand cutting and unplugged.

machine during work. Checking of wires prior work , if any

3. Loose connection or damage found replace the wire

breakage on insulated immediately.

wire. 4. Properly clean the surface area and

Environment: dump the debris in the designated dust bin.

1.Insulating material 5. Strict supervision required during work.

fines and dust. 6. Rest to be provided to workers in

Quality: between the continuous work.

NA 7. Proper ventilation and drinking water

Ergonomic: facility to be available.

1.Improper working 8. Timely medical check up.

posture.

2.Continuation Of work.

Seasonal:

1.Humidity

Occupational Health

Hazard:

1.Musculoskeletal

disorder

Required PPE Required Required Skill/Training Experienced site in-

Tools/Equipments charge

Safety shoe,Safety Hand Cutting Machine, Training before start of job Available

jacket,Safety helmet,Safety Screw driver, Training about the following SOP

goggles,nose mask.Hand Measurement tape,

gloves, ear plug ,Harness Scissors

Belt

Signature of JHA Team Members

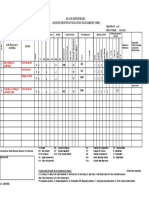

R.K CONSTRUCTION

JOB HAZARD ANALYSIS

Dept./Section JHA No.:

Location of Job Date:

Job Description

Team Who has done JHA Safety Supervisor

Basic job description Potential Hazards Safe Guards / Controls to be put in place Responsibility

6. Fixing new insulation Safety: 1.Safety gloves, safety shoes to be used. Safety Supervisor

1. Sharp, rough edges of 2. Checklist of screw gun machine prior

working tools, sheets start of work.

etc. 3. Checking the full length wire and the

2. Faulty Screw Gun connection before work.

machine. 4. Use of Safety goggles and nose-mask

3. Breakage of during work.

insulation of live 5. Barricade the working platform and the

electric wire. area underneath .

4. Splinters 6. Mandatory use of nose mask.

5. Mis-handling of 7. Mandatory use of ear plug.

sheets, tools etc. 8. Attentive towards the work and the steps

Environment: to be taken carefully.

Dusty area 9. Ensure only standardised materials &

Noisy area tools used.

Uneven working floor 10. Posture while working to be supervised

Quality: in proper manner.

Sub standard insulating 11. Small break to be provided in between

materials & tools used. the work.

Ergonomic: 12. Drinking water & ORS to be provided at

1.Improper working work site.

posture. Adequate ventilation needed.

2.Continuation Of work. 13. Timely medical check up to be provided.

Seasonal:

1.Humidity

Occupational Health

Hazard:

1.Musculoskeletal

disorder

Required PPE Required Required Skill/Training Experienced site in-

Tools/Equipment charge

Safety shoe,Safety Screw gun machine, Training before start of job Available

jacket,Safety helmet,Safety screw driver Training about the following SOP

goggles,nose mask.Hand

gloves, Harness Belt, Ear

plug

Signature of JHA Team Members

R.K CONSTRUCTION

JOB HAZARD ANALYSIS

Dept./Section JHA No.:

Location of Job Date:

Job Description

Team Who has done JHA Safety Supervisor

Basic job description Potential Hazards Safe Guards / Controls to be put in place Responsibility

7. Fixing of cladding sheet Safety: 1.Use elbow length hand gloves, safety Safety Supervisor

1. Sharp, rough edges of shoes to be used.

cladding sheet. 2. Carefully handle the cladding sheets.

2. Slippage of Screw 3. Checking the full length wire and the

Gun machine while connection before work.

working. 4. Strict Supervision and take care of

3. Breakage of worker ,working in the vicinity.

insulation of live 5. Barricade the working platform and the

electric wire. area underneath .

4. Overhead or 6. Mandatory use of nose mask.

sideward structures. 7. Mandatory use of ear plug.

5. Mis-handling of 8. Take steps carefully while working .

sheets, tools etc. 9. Ensure the cladding sheets are

Environment: overlapping and there is no space in

Dusty area between such that external water or any

Noisy area fluid doesn’t get inside insulation sheets.

Uneven working floor 10. Posture while working to be supervised

Quality: in proper manner.

Cladding sheets not 11. Small break to be provided in between

overlapping. the work.

Ergonomic: 12. Drinking water & ORS to be provided at

1.Improper working work site.

posture. Adequate ventilation needed.

2.Continuation Of work. 13. Timely medical check up to be provided.

Seasonal:

1.Humidity

Occupational Health

Hazard:

1.Musculoskeletal

disorder

Required PPE Required Required Skill/Training Experienced site in-

Tools/Equipment charge

Safety shoe,Safety Screw gun machine, Training before start of job Available

jacket,Safety helmet,Safety screw driver Training about the following SOP

goggles,nose mask.Hand

gloves, Ear plug, harness belt

Signature of JHA Team Members

R.K CONSTRUCTION

JOB HAZARD ANALYSIS

Dept./Section JHA No.:

Location of Job Date:

Job Description

Team Who has done JHA Safety Supervisor

Basic job description Potential Hazards Safe Guards / Controls to be put in place Responsibility

8.Refractory Work Safety: 1.a)Take work permit for confined space. Safety Supervisor

1. Confined Space b)Ensure the temperature inside the boiler

Environment: is equal to surrounding air temperature

Dusty area before entering.

Uneven working floor c)Open all inspection window/entrance

Quality: window.

NA d) Keep monitoring at entrance window.

Ergonomic: e) Cross ventilation using exhaust fan.

1.Improper working f) Use only 24V light for illumination inside

posture. confined space.

2.Continuation Of work. g) Ensure oxygen level inside the confined

Seasonal: space is below 19.5% and not above 23.5 %.

1.Humidity h) Positive Isolation of ID fan, FD fan and PA

Occupational Health fan before start of work.

Hazard: 2. Mandatory use of nose mask.

1.Musculoskeletal 3. Take steps carefully while working .

disorder 4. Posture while working to be supervised

in proper manner.

5. Small break to be provided in between

the work.

6. Drinking water & ORS to be provided at

work site.

Adequate ventilation needed.

7. Timely medical check up to be provided.

Required PPE Required Required Skill/Training Experienced site in-

Tools/Equipment charge

Safety shoe,Safety Head pan, Masonry Training before start of job Available

jacket,Safety helmet,Safety Trowel Training about the following SOP

goggles,nose mask.Hand

gloves, harness belt

Signature of JHA Team Members

You might also like

- Concrete & Form Work: Job Safety Analysis Pouring ConcreteDocument1 pageConcrete & Form Work: Job Safety Analysis Pouring ConcreteHortencio Samuel100% (4)

- JHA For Tiling WorkDocument1 pageJHA For Tiling WorkMuhammad Suffyanazwan80% (5)

- Jha For Chipping and Drilling Concrete Step Step Discription Hazards Hazard ControlDocument7 pagesJha For Chipping and Drilling Concrete Step Step Discription Hazards Hazard Controlmark alexies herreraNo ratings yet

- Application Form OSH PractitionerDocument3 pagesApplication Form OSH PractitionerJayvee Baradas Valdez100% (4)

- 39 Jha On Blok Masonary WorkDocument4 pages39 Jha On Blok Masonary WorkDheeraj KumarNo ratings yet

- Jsa PaintingDocument1 pageJsa Paintingclynne despiNo ratings yet

- (Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)Document3 pages(Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)krisNo ratings yet

- Protect yourself from dust and flying debrisDocument5 pagesProtect yourself from dust and flying debrisDwitikrushna RoutNo ratings yet

- JHA For Concreting WorkDocument2 pagesJHA For Concreting WorkTigor GurningNo ratings yet

- Control System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Document7 pagesControl System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Jayson Escamillan100% (1)

- Job Safety Analysis (Jsa) - Water Proofing WorkDocument6 pagesJob Safety Analysis (Jsa) - Water Proofing Worknitish tiwariNo ratings yet

- Excavation Job Safety AnalysisDocument1 pageExcavation Job Safety AnalysisVishal Upadhyay100% (3)

- 02-Job Safety Analysis - Excavation WorkDocument2 pages02-Job Safety Analysis - Excavation Workkhaja asifuddinNo ratings yet

- Job Safety Analysis (Jsa) : Title of Activity / Work: Excavation & TrenchingDocument2 pagesJob Safety Analysis (Jsa) : Title of Activity / Work: Excavation & TrenchingJayendra Patel89% (9)

- Appendix 4 - HIRADC - Site Clearing - Excavation - 00Document3 pagesAppendix 4 - HIRADC - Site Clearing - Excavation - 00Abdul Hafiz Abdul Rahman100% (2)

- Sample JHADocument1 pageSample JHAZubair Khan100% (1)

- Drilling Work by MCDocument1 pageDrilling Work by MCChandruNo ratings yet

- JHA PlumberDocument3 pagesJHA PlumberEko Susanto100% (1)

- Jsa Installing BracketDocument3 pagesJsa Installing BracketHow Chin Engineering Sdn Bhd100% (1)

- Rebar Installation: Job Safety AnalysisDocument1 pageRebar Installation: Job Safety AnalysisRetselisitsoe100% (3)

- Safe Operation and Use of Mobile Jaw CrushersDocument7 pagesSafe Operation and Use of Mobile Jaw Crushersテレブリコ ジェファーソンNo ratings yet

- Traffic Control at Worksites ManualDocument318 pagesTraffic Control at Worksites ManualFisha Lemma100% (1)

- DOQ117A - Quick Kaizen ModelDocument12 pagesDOQ117A - Quick Kaizen ModelShaimae ABOULMAJDNo ratings yet

- King Faisal Air Academy Carpentry JSADocument1 pageKing Faisal Air Academy Carpentry JSAnabeelNo ratings yet

- HAZARD IDENTIFICATION AND RISK ASSESSMENT FOR SUSPENDED CEILING WORKSDocument4 pagesHAZARD IDENTIFICATION AND RISK ASSESSMENT FOR SUSPENDED CEILING WORKSfaizan khanNo ratings yet

- Plumbing Work JSA HSE ProfessionalsDocument1 pagePlumbing Work JSA HSE ProfessionalsStansilous Tatenda NyagomoNo ratings yet

- JSA FOR Fixing of Light FittingsDocument1 pageJSA FOR Fixing of Light Fittingswahyu nugroho100% (1)

- Job Hazards AnalysisDocument3 pagesJob Hazards AnalysismohamedNo ratings yet

- List of Safety Practitioners - 2014Document26 pagesList of Safety Practitioners - 2014JackophiliNo ratings yet

- INSTALLATION SAFETY ANALYSISDocument22 pagesINSTALLATION SAFETY ANALYSISSyed Yousuf Ali100% (1)

- PTW JHA Installation of New Control Panel at WWTPDocument2 pagesPTW JHA Installation of New Control Panel at WWTPPHH9834100% (1)

- JHA Tiles Setting and RetouchingDocument1 pageJHA Tiles Setting and RetouchingPopo Ealdama100% (1)

- JSA Earthpit Construction GeneralDocument4 pagesJSA Earthpit Construction Generalmukka88No ratings yet

- Safety Data Sheet for Lacquer Spot PuttyDocument8 pagesSafety Data Sheet for Lacquer Spot Puttyraighnejames19No ratings yet

- Bricks Messonary Work Job Hazard AnalysisDocument2 pagesBricks Messonary Work Job Hazard AnalysisMc Evans Magallanes100% (1)

- Job Safety Analysis - Cement SiloDocument9 pagesJob Safety Analysis - Cement SiloMohammed Minhaj100% (1)

- GL-01-EHS-032 Guidelines On Work Environment MeasurementDocument8 pagesGL-01-EHS-032 Guidelines On Work Environment MeasurementClarabelle Mae Dela RosaNo ratings yet

- DOCUMENT Piping Insulation Installation and Dismantle Work JHADocument12 pagesDOCUMENT Piping Insulation Installation and Dismantle Work JHAAmirHakimRusli100% (1)

- JHA PaintingDocument9 pagesJHA Paintingperquino oasan100% (1)

- Job Safety Analysis for Brick Work, Tile and Glass RemovalDocument4 pagesJob Safety Analysis for Brick Work, Tile and Glass RemovalSushil Kumar YadavNo ratings yet

- IM-08-B EHS Risk Assessment Welding & Gas CuttingDocument4 pagesIM-08-B EHS Risk Assessment Welding & Gas CuttingGyanendra Narayan Nayak100% (3)

- EPC-3 Gasoline package Assembly & Erection JSADocument3 pagesEPC-3 Gasoline package Assembly & Erection JSAFrancis Vinoj100% (1)

- PTW JHA Partition WorkDocument3 pagesPTW JHA Partition WorkPHH9834No ratings yet

- Jsa For Scaffolding ErectionDocument7 pagesJsa For Scaffolding Erectionnoorul IslamNo ratings yet

- JHA Example - CHC ScenarioDocument2 pagesJHA Example - CHC ScenarioBNCHNo ratings yet

- Jha RebarsDocument7 pagesJha RebarsJaycee QuinNo ratings yet

- JSA For Lifting of RebarsDocument5 pagesJSA For Lifting of RebarsNiraNo ratings yet

- Salient Features of Do 128-13Document12 pagesSalient Features of Do 128-13Ayen CasarenoNo ratings yet

- Sinopec Northen Construction Camp - Tilenga Job Hazard Analysis (Jha)Document3 pagesSinopec Northen Construction Camp - Tilenga Job Hazard Analysis (Jha)Nora Afzam Abd WahabNo ratings yet

- JHA ConcretePlacingOperationDocument3 pagesJHA ConcretePlacingOperationAnonymous XJ9663C6N4No ratings yet

- 5-Risk Assessment For Excavation & Backfilling and Compaction WorksDocument15 pages5-Risk Assessment For Excavation & Backfilling and Compaction WorksAmran HossainNo ratings yet

- JHA For Painting WorkDocument2 pagesJHA For Painting WorkTigor Gurning100% (1)

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument6 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagya100% (1)

- JHA For Installation of Boiler AccessoriesDocument2 pagesJHA For Installation of Boiler Accessoriesperquino oasan100% (3)

- Ultratech Cement Limited - Andhra Pradesh Cement Works: Format For HIRA / JSADocument5 pagesUltratech Cement Limited - Andhra Pradesh Cement Works: Format For HIRA / JSATFattah100% (1)

- Risk Generator Risk AssessmentDocument2 pagesRisk Generator Risk AssessmentBaher MohamedNo ratings yet

- JOB HAZARD ANALYSIS - Electrical WorksDocument9 pagesJOB HAZARD ANALYSIS - Electrical WorksJayson Escamillan100% (1)

- Pool Paint Safety Data SheetDocument9 pagesPool Paint Safety Data SheetNicholson Vhenz UyNo ratings yet

- Demolition JhaDocument2 pagesDemolition JhaElvyn Fabellore HerreraNo ratings yet

- JSA Finishing Temporary FacilitiesDocument6 pagesJSA Finishing Temporary Facilitiesjet Louis Magallones100% (1)

- Jsa PaintDocument2 pagesJsa PaintKhalid NaseemNo ratings yet

- R.K Construction: Job Hazard AnalysisDocument3 pagesR.K Construction: Job Hazard AnalysisDwitikrushna RoutNo ratings yet

- M/S Kalachand Construction Job Hazard Analysis: JHA No.Document4 pagesM/S Kalachand Construction Job Hazard Analysis: JHA No.Dwitikrushna RoutNo ratings yet

- JHA Scrap Handling HazardsDocument2 pagesJHA Scrap Handling HazardsDwitikrushna Rout100% (1)

- 22 - White Washing & Painting (Comp)Document1 page22 - White Washing & Painting (Comp)Dwitikrushna RoutNo ratings yet

- DG Inspection ChecklistDocument1 pageDG Inspection ChecklistDwitikrushna Rout0% (1)

- ManpowerDocument1 pageManpowerDwitikrushna RoutNo ratings yet

- Tools Tackels ListDocument1 pageTools Tackels ListDwitikrushna RoutNo ratings yet

- Swing Grinding JhaDocument6 pagesSwing Grinding JhaDwitikrushna RoutNo ratings yet

- 31 - 2 - Scaffolding (Comp)Document1 page31 - 2 - Scaffolding (Comp)Dwitikrushna RoutNo ratings yet

- M/S Sinha Enterprises: Standard Operating ProcedureDocument5 pagesM/S Sinha Enterprises: Standard Operating ProcedureDwitikrushna RoutNo ratings yet

- Jsa Trial Run of DGDocument3 pagesJsa Trial Run of DGDwitikrushna RoutNo ratings yet

- 26 - Cleaning of Roof & Drain Gutter (Comp)Document1 page26 - Cleaning of Roof & Drain Gutter (Comp)Dwitikrushna RoutNo ratings yet

- Campaign NewDocument2 pagesCampaign NewDwitikrushna RoutNo ratings yet

- 21 - Painting of Structural Building (Comp)Document1 page21 - Painting of Structural Building (Comp)Dwitikrushna RoutNo ratings yet

- Generic Safty ClausesDocument3 pagesGeneric Safty ClausesDwitikrushna RoutNo ratings yet

- Safety Campaign Plan Campaign Theme Month Responsibility Status Action Taken (If Deviated)Document1 pageSafety Campaign Plan Campaign Theme Month Responsibility Status Action Taken (If Deviated)Dwitikrushna RoutNo ratings yet

- Standard Operating Procedure SOP - NO.-01 Joda Date:-19.09.2020Document6 pagesStandard Operating Procedure SOP - NO.-01 Joda Date:-19.09.2020Dwitikrushna Rout0% (1)

- Hazard Mapping: JOB Specification Hazard Related To JOB Required Ppes W.R.T HazardsDocument1 pageHazard Mapping: JOB Specification Hazard Related To JOB Required Ppes W.R.T HazardsDwitikrushna RoutNo ratings yet

- GSPL Manual Revision 00Document110 pagesGSPL Manual Revision 00Dwitikrushna RoutNo ratings yet

- 01 Cleaning A School washroom-JOB PROCEDUREDocument2 pages01 Cleaning A School washroom-JOB PROCEDUREDwitikrushna RoutNo ratings yet

- M/S Pagwin ConstructionDocument5 pagesM/S Pagwin ConstructionDwitikrushna RoutNo ratings yet

- Hira Excavating ManualyDocument2 pagesHira Excavating ManualyDwitikrushna RoutNo ratings yet

- OHS Management Review Procedure for Pagwin ConstructionDocument4 pagesOHS Management Review Procedure for Pagwin ConstructionDwitikrushna Rout100% (1)

- Material Handling BSM Jha - 1Document1 pageMaterial Handling BSM Jha - 1Dwitikrushna RoutNo ratings yet

- Hira Cutting of RodDocument2 pagesHira Cutting of RodDwitikrushna RoutNo ratings yet

- PCC Safety Supervisor: CivilDocument4 pagesPCC Safety Supervisor: CivilDwitikrushna RoutNo ratings yet

- Ofi Compliance - Bhola ChoudhryDocument3 pagesOfi Compliance - Bhola ChoudhryDwitikrushna RoutNo ratings yet

- Hira Plastering Finishing WorkDocument2 pagesHira Plastering Finishing WorkDwitikrushna Rout0% (1)

- Brick Work BSM Jha - 1Document3 pagesBrick Work BSM Jha - 1Dwitikrushna RoutNo ratings yet

- Garudadhwaja Structures (P) Ltd. Job Hazard Analysis: JHA No.:05Document3 pagesGarudadhwaja Structures (P) Ltd. Job Hazard Analysis: JHA No.:05Dwitikrushna Rout0% (1)

- Kapoor Enterprises Jha-1Document3 pagesKapoor Enterprises Jha-1Dwitikrushna RoutNo ratings yet

- The Traffic and Transport System and Effects On Accessibility, The Environment and SafetyDocument9 pagesThe Traffic and Transport System and Effects On Accessibility, The Environment and SafetyLevend KalaçNo ratings yet

- Sigmatherm Thermovit 600 (HR)Document2 pagesSigmatherm Thermovit 600 (HR)shibushineNo ratings yet

- SLIDES FOR CHAP 8 9 Human FactorDocument12 pagesSLIDES FOR CHAP 8 9 Human FactorVisan NaiduNo ratings yet

- December 2019 Worker Killed During Lifting OperationDocument3 pagesDecember 2019 Worker Killed During Lifting OperationStephen TanNo ratings yet

- NSC-400-CE-3110-MOS-01-A-Method Statement For 69kV Transmission Line ConstructionDocument28 pagesNSC-400-CE-3110-MOS-01-A-Method Statement For 69kV Transmission Line ConstructionElisco Pher SalmasanNo ratings yet

- Cmax T3 PDFDocument233 pagesCmax T3 PDFAndrei MihaiNo ratings yet

- PR1428B2-1001 Access Door SealantDocument12 pagesPR1428B2-1001 Access Door SealantstoreairkgNo ratings yet

- Fire Safety Risk AssessmentDocument14 pagesFire Safety Risk AssessmentHani ThaherNo ratings yet

- BS5839 FireClass Consultants GuideDocument256 pagesBS5839 FireClass Consultants GuideSandra Vazquez IglesiasNo ratings yet

- Operator'S ManualDocument124 pagesOperator'S ManualzericardosanchesNo ratings yet

- Blinding & Concrete Method StatementDocument5 pagesBlinding & Concrete Method Statementشاز إياسNo ratings yet

- Industrial Hazard and Safety HandbookDocument2 pagesIndustrial Hazard and Safety HandbookMohamed ElhosinyNo ratings yet

- Yellow Jacket SuperEvac Premium Vacuum Pump OilDocument6 pagesYellow Jacket SuperEvac Premium Vacuum Pump OilJuan Pablo Fernandez Zuñiga0% (1)

- Supervision Plans for Building and Street WorksDocument31 pagesSupervision Plans for Building and Street Worksct_0011No ratings yet

- ESV SMV Frequency Inverter v21-0 enDocument72 pagesESV SMV Frequency Inverter v21-0 enAdam PurnomoNo ratings yet

- Safety of Workers in Indian Mines Study Analysis ADocument9 pagesSafety of Workers in Indian Mines Study Analysis ABhawesh PrasadNo ratings yet

- ROCOL PENETRATING SPRAY datasheetDocument11 pagesROCOL PENETRATING SPRAY datasheetSérgio BarbosaNo ratings yet

- SDS AURAMIX 200 IndiaDocument8 pagesSDS AURAMIX 200 Indiarahul badgujarNo ratings yet

- Safety Case Assessment Policy SummaryDocument6 pagesSafety Case Assessment Policy Summaryoscar moraNo ratings yet

- TWM TW-BH95M4PHDocument30 pagesTWM TW-BH95M4PHغزوان عماد الدين الحسينيNo ratings yet

- Sika MultiPrimer Marine - MSDSDocument12 pagesSika MultiPrimer Marine - MSDSjorgeNo ratings yet

- Installation Risk AssessmentDocument4 pagesInstallation Risk AssessmentMuhammad Umar GondalNo ratings yet

- RA and JSA (Complete Guide)Document45 pagesRA and JSA (Complete Guide)Kamran RazaNo ratings yet

- Roadside Design Guide 3rd Editi - AASHTODocument342 pagesRoadside Design Guide 3rd Editi - AASHTOnichel.alexandreNo ratings yet

- Landslide and Sinkhole Safety TipsDocument2 pagesLandslide and Sinkhole Safety TipsAkiesha BenozaNo ratings yet

- Liebherr-Mcctec Rostock GMBHDocument7 pagesLiebherr-Mcctec Rostock GMBHLopez D NikkoNo ratings yet

- 360 Excavator - Safe OperationDocument21 pages360 Excavator - Safe OperationSanket Satpathy0% (2)

- Hospitality and Venue Management - EditionDocument18 pagesHospitality and Venue Management - EditionWarda LaraibNo ratings yet