Professional Documents

Culture Documents

Evaluation - Innova Engine 2018

Evaluation - Innova Engine 2018

Uploaded by

mithun bv0 ratings0% found this document useful (0 votes)

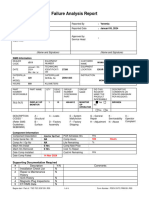

6 views6 pagesThis document contains an inspector evaluation sheet to assess an inspector's performance in identifying defects in engine samples. It consists of details of defects identified in 3 samples with 10 possible defects in each. The inspector's score is calculated based on the percentage of total defects identified, deducting points for any defects passed and for additional time taken over the standard 180 seconds for inspection. The inspector's signature is required at the bottom to verify the assessment.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document contains an inspector evaluation sheet to assess an inspector's performance in identifying defects in engine samples. It consists of details of defects identified in 3 samples with 10 possible defects in each. The inspector's score is calculated based on the percentage of total defects identified, deducting points for any defects passed and for additional time taken over the standard 180 seconds for inspection. The inspector's signature is required at the bottom to verify the assessment.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views6 pagesEvaluation - Innova Engine 2018

Evaluation - Innova Engine 2018

Uploaded by

mithun bvThis document contains an inspector evaluation sheet to assess an inspector's performance in identifying defects in engine samples. It consists of details of defects identified in 3 samples with 10 possible defects in each. The inspector's score is calculated based on the percentage of total defects identified, deducting points for any defects passed and for additional time taken over the standard 180 seconds for inspection. The inspector's signature is required at the bottom to verify the assessment.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 6

INSPECTOR EVALUATION SHEET STANDARD TIME FOR INSPECTION : 180sec

TIME TAKEN FOR INSPECTION : _____________

Name : Date :

Section INNOVA ENGINE

N G SAMPLE : 01

DETAILS OF DEFECT IDENTIFIED

SL NO. DEFECT NAME Yes No 1. Calculation method

1 Packing tape miss near Conn No 509&551

Total defects identified

% age = X 100

Total defects available in W/H

2 Point tape miss near Conn No 261&182

3 Cross tape NG on Clamp 3F490

2. Rule for passing the defects and Extra time taken.

4 Branch routing NG near Conn No 127

1. If inspector pass any defect during skill test, one point / defect passed will be

deducted in the total aceived score.

5 Protector half lock on Prot 82817-0K270

2. Each extra minute will lead to reduction of 2 points in achieved score.

6 Color tape miss near Conn No 210

LA terminal fixing NG (Obs;half lock ter Total defects identified

7 % age = X 100 - No.of defects passed

600&1600) Total defects available in W/H

8 Clamp 52090 direction wrong

9 P/No label fixing NG

10 Extra color point tape near Prot 82817-0K300

Action Taken(If Defect not identified) : Reinspection Result:

Evaluated By Checked By Approved By

Inspector Signature MSSL/TRG/VI/IE/IENG/01

INSPECTOR EVALUATION SHEET STANDARD TIME FOR INSPECTION : 180sec

TIME TAKEN FOR INSPECTION : _____________

Name : Date :

Section INNOVA ENGINE

N G SAMPLE : 02

DETAILS OF DEFECT IDENTIFIED

SL NO. DEFECT NAME Yes No 1. Calculation method

1 Packing tape position NG Conn No 509

Total defects identified

% age = X 100

Total defects available in W/H

2 Dummy seal miss on Conn No 138

3 P/No label fixing view NG

2. Rule for passing the defects and Extra time taken.

4 Cross tape miss on clamp 3F490

1. If inspector pass any defect during skill test, one point / defect passed will be

deducted in the total aceived score.

5 Half lap tape miss on Prot 82817-0K310

2. Each extra minute will lead to reduction of 2 points in achieved score.

6 Extra point tape on Conn No 233 branch

Total defects identified

7 Prot half lock on Prot 82817-0K350 % age = X 100 - No.of defects passed

Total defects available in W/H

8 Stopper open conn no 509

9 Tie band mis on clamp 50300 near Conn No 39

10 CVR fixing NG on Conn No 203

Action Taken(If Defect not identified) : Reinspection Result:

Evaluated By Checked By Approved By

Inspector Signature MSSL/TRG/VI/IE/IENG/01

INSPECTOR EVALUATION SHEET STANDARD TIME FOR INSPECTION : 180sec

TIME TAKEN FOR INSPECTION : _____________

Name : Date :

Section INNOVA ENGINE

N G SAMPLE : 03

DETAILS OF DEFECT IDENTIFIED

SL NO. DEFECT NAME Yes No 1. Calculation method

1 Point tape miss near Conn No 551&509

Total defects identified

% age = X 100

Total defects available in W/H

2 Grommet fixing tape color wrong

3 P/No label fixing position wrong

2. Rule for passing the defects and Extra time taken.

4 Half lock on Prot 82817-0K270

1. If inspector pass any defect during skill test, one point / defect passed will be

deducted in the total aceived score.

5 Branch routing NG Conn No 55&209

2. Each extra minute will lead to reduction of 2 points in achieved score.

6 Stopper open Conn No 135

Total defects identified

7 Half lap tape miss on Prot 82817-0K350 % age = X 100 - No.of defects passed

Total defects available in W/H

8 Dummy seal miss in Conn No 261

9 Clamp 10410 direction Wrong

10 Tie band miss near Prot 82817-0K300

Action Taken(If Defect not identified) : Reinspection Result:

Evaluated By Checked By Approved By

Inspector Signature MSSL/TRG/VI/IE/IENG/01

You might also like

- Magic The Gathering Tournament Rules PDF2Document50 pagesMagic The Gathering Tournament Rules PDF22980232No ratings yet

- Spread Option Run and Shoot OffenseDocument24 pagesSpread Option Run and Shoot OffenseEdmond Eggleston Seay III100% (52)

- Sel-487v Relay Test For CapacitorDocument21 pagesSel-487v Relay Test For CapacitorSentaNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Red670 Distance Line DifferentialDocument23 pagesRed670 Distance Line DifferentialRatheesh KumarNo ratings yet

- Boxing by Philadelphia Jack OBrienDocument260 pagesBoxing by Philadelphia Jack OBrienSilver Sentinel100% (1)

- MiCOM P443 - Dist. Protn. Relay - Test FormatDocument8 pagesMiCOM P443 - Dist. Protn. Relay - Test FormatarunNo ratings yet

- ARKAN SHADES Welding Inspection & Paint InspectionDocument2 pagesARKAN SHADES Welding Inspection & Paint InspectionSpectex dubaiNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- As Per The Schematic Drawings The Contents in This Test Format Can Be ModifiedDocument12 pagesAs Per The Schematic Drawings The Contents in This Test Format Can Be ModifiedAlexNo ratings yet

- Site Test Report Ng-Sa Name of Substation: Al-Tawdihiyah 132/33KV SubstationDocument7 pagesSite Test Report Ng-Sa Name of Substation: Al-Tawdihiyah 132/33KV SubstationSyed Abbas100% (1)

- FAR D6R LH Final Drive FailureDocument9 pagesFAR D6R LH Final Drive Failurealisa alainaNo ratings yet

- Site Inspection and Test Record: Al - Babtain S/S 8715 (132/13.8 KV)Document3 pagesSite Inspection and Test Record: Al - Babtain S/S 8715 (132/13.8 KV)m khNo ratings yet

- 7SR1587 Voltage and Frequency RelayDocument4 pages7SR1587 Voltage and Frequency RelayAnonymous dH3DIEtzNo ratings yet

- Pre-Inspection Checklist For BlastingDocument1 pagePre-Inspection Checklist For BlastingTwin Bulls100% (3)

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Compressive Strength of Concrete Core BS EN 12504-1: Project InformationDocument2 pagesCompressive Strength of Concrete Core BS EN 12504-1: Project Informationraja qammarNo ratings yet

- Evaluation - Fortuner 2018Document3 pagesEvaluation - Fortuner 2018mithun bvNo ratings yet

- Evaluation - Innova Ip 2018Document6 pagesEvaluation - Innova Ip 2018mithun bvNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Report:: F CF CriticaiDocument2 pagesReport:: F CF CriticaiArun HarshanNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- QAR-QD418-5 Rod-Front Susp 797 (191-8043)Document6 pagesQAR-QD418-5 Rod-Front Susp 797 (191-8043)Irwanto ManafNo ratings yet

- 410 CTDocument2 pages410 CTSARAVANAN ANo ratings yet

- Painting Inspection Report: Project: Abu Dhabi Future Schools Program (Phase 9) Gayathi-Abu DhabiDocument4 pagesPainting Inspection Report: Project: Abu Dhabi Future Schools Program (Phase 9) Gayathi-Abu DhabiSpectex dubaiNo ratings yet

- Preparacion de SuperficieDocument5 pagesPreparacion de SuperficieJulio HuancaNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Gpti Qicl J931 Mut 019Document3 pagesGpti Qicl J931 Mut 019uselessinstaid52No ratings yet

- 02-Singl Joint 1Document8 pages02-Singl Joint 1Abdou BoucheritNo ratings yet

- Gpti Qicl J931 Mut 002Document2 pagesGpti Qicl J931 Mut 002uselessinstaid52No ratings yet

- Gpti Qicl J931 Mut 041Document3 pagesGpti Qicl J931 Mut 041uselessinstaid52No ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- 86 Lockout Auxiliary Relay Site Test Report: Mechanical Checks & Visual InspectionDocument2 pages86 Lockout Auxiliary Relay Site Test Report: Mechanical Checks & Visual InspectionJaikaran DanNo ratings yet

- Gpti Qicl 032Document2 pagesGpti Qicl 032uselessinstaid52No ratings yet

- Q4160 CertificationsDocument27 pagesQ4160 Certificationskarthikeyan kaliyaperumalNo ratings yet

- 8D Response Report: Congrats To TeamDocument2 pages8D Response Report: Congrats To Teamsumeetsaini88No ratings yet

- Tracespec: Global Resources LTDDocument1 pageTracespec: Global Resources LTDTrustEmmaNo ratings yet

- Far ZBN41205Document4 pagesFar ZBN41205yeremia kristianNo ratings yet

- GIR-TVI-002 - NDE Inner Enclosure Missing Bolts Report - R1Document19 pagesGIR-TVI-002 - NDE Inner Enclosure Missing Bolts Report - R1junclarcNo ratings yet

- 05-Manual Tang 1Document1 page05-Manual Tang 1Abdou BoucheritNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- VTR 20 KP+FollowersDocument20 pagesVTR 20 KP+FollowersANDRES LLAGUARIMAY CHIPANANo ratings yet

- Sub Acb-06 Ammeter-2Document2 pagesSub Acb-06 Ammeter-2wazakifyNo ratings yet

- 86 Lockout Auxiliary Relay Site Test Report: Mechanical Checks & Visual InspectionDocument2 pages86 Lockout Auxiliary Relay Site Test Report: Mechanical Checks & Visual InspectionJaikaran DanNo ratings yet

- 07 Mpi Report - 1Document12 pages07 Mpi Report - 1Abdou BoucheritNo ratings yet

- In-Process Inspection Report For Infant Incubator Parts9Document1 pageIn-Process Inspection Report For Infant Incubator Parts9Hilario AlinabonNo ratings yet

- L&T QapDocument2 pagesL&T Qapsriram.5230No ratings yet

- Safety Compliance Testing For Fmvss No. 218 Motorcycle HelmetsDocument5 pagesSafety Compliance Testing For Fmvss No. 218 Motorcycle HelmetsLiliana GonzálezNo ratings yet

- Red670 - Line Diff 55onlyDocument11 pagesRed670 - Line Diff 55onlyMohd SalehNo ratings yet

- J50 055 XFR (T) 301Document14 pagesJ50 055 XFR (T) 301Anonymous dH3DIEtzNo ratings yet

- QA-033 Outgoing Inspection Checklist Rev.GDocument1 pageQA-033 Outgoing Inspection Checklist Rev.GChoo Wei MingNo ratings yet

- Digital Micro-Ohm MeterDocument2 pagesDigital Micro-Ohm MeterjamilNo ratings yet

- EFR-01F - Earthing Boss PDFDocument1 pageEFR-01F - Earthing Boss PDFBumi AzarakhNo ratings yet

- Indra: Cabinet NameDocument1 pageIndra: Cabinet NameBoualem AisNo ratings yet

- Report of Wet Fluorescent Magnatic Particle Test of Weld JointDocument1 pageReport of Wet Fluorescent Magnatic Particle Test of Weld Jointkevin desaiNo ratings yet

- 11-03-2020 C1 Gland Steam Super Heater - UTDocument4 pages11-03-2020 C1 Gland Steam Super Heater - UTDave CheungNo ratings yet

- 2 - Installation Method Statement Annexure I II IVDocument4 pages2 - Installation Method Statement Annexure I II IVSameer AhamedNo ratings yet

- Alfanar Co.: Site Test Report Ng-Sa Name of Substation: Dammam Housing 115/13.8KV Substation # 1Document15 pagesAlfanar Co.: Site Test Report Ng-Sa Name of Substation: Dammam Housing 115/13.8KV Substation # 1Jayabal GnanaprakasamNo ratings yet

- 2008 Miami Dolphins Media GuideDocument641 pages2008 Miami Dolphins Media GuideMiami DolphinsNo ratings yet

- De Thi HSG Tieng Anh Lop 10 Tinh Vinh Phuc Nam Hoc 2011 2012Document9 pagesDe Thi HSG Tieng Anh Lop 10 Tinh Vinh Phuc Nam Hoc 2011 2012Duy QuốcNo ratings yet

- Ping Pong ReceiptDocument2 pagesPing Pong ReceiptjaneNo ratings yet

- Ripe School Inspection ReportDocument9 pagesRipe School Inspection Reportapi-109004180No ratings yet

- 5 Basic Fundamentals For Goalkeeper Training PDFDocument3 pages5 Basic Fundamentals For Goalkeeper Training PDFI-shark Bashori100% (1)

- Latihan Hortatory ExpostionDocument5 pagesLatihan Hortatory Expostionvivin ALESHANo ratings yet

- Tissue PerfusionDocument70 pagesTissue PerfusionAlexNo ratings yet

- Land Rover Discovery BrochureDocument130 pagesLand Rover Discovery BrochureDIRECT USINENo ratings yet

- Street Hype Newspaper June 19-30, 2013Document24 pagesStreet Hype Newspaper June 19-30, 2013Patrick MaitlandNo ratings yet

- Listening 1Document2 pagesListening 1Thuan ThuyNo ratings yet

- Sub-District Results 15 Feb 2022Document8 pagesSub-District Results 15 Feb 20225rm55gtq5tNo ratings yet

- CV Jony Van de Velde EnglishDocument1 pageCV Jony Van de Velde Englishapi-293139688No ratings yet

- D'Andre Allen English SBADocument14 pagesD'Andre Allen English SBANIGHT GUIDENo ratings yet

- Bicycle Century Training: by James WannopDocument59 pagesBicycle Century Training: by James WannopCarl SmithNo ratings yet

- MapDocument40 pagesMapHexy ManucianNo ratings yet

- Racquetball RulesDocument1 pageRacquetball RulesGiang LeNo ratings yet

- Aulas 26102015Document27 pagesAulas 26102015samukaelsoncastroNo ratings yet

- MIL PeTaDocument2 pagesMIL PeTaAaron James AbutarNo ratings yet

- 1 - Gulfstream Park RetrospectosDocument8 pages1 - Gulfstream Park RetrospectosviscocheaNo ratings yet

- IspDocument108 pagesIspAnh Huỳnh0% (1)

- Robin HoodDocument5 pagesRobin HoodSimona RusuNo ratings yet

- Sports Corruption 2021 s9Document28 pagesSports Corruption 2021 s9Seven StreamsNo ratings yet

- 2012 African Women's Handball ChampionshipDocument6 pages2012 African Women's Handball ChampionshippopularsodaNo ratings yet

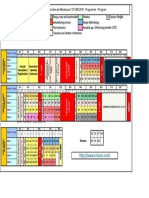

- Congrès Tunisien de Mécanique COTUME 2018: Programme / ProgramDocument1 pageCongrès Tunisien de Mécanique COTUME 2018: Programme / ProgramHassenKhlifiNo ratings yet

- Kindermann Stefan - Leningrader System, 2002Document208 pagesKindermann Stefan - Leningrader System, 2002sycil100% (1)

- Schumacher PortfolioDocument90 pagesSchumacher PortfolioWTC Control - Sebastián AguileraNo ratings yet

- Unit 01 Leisure Activities Lesson 2 A Closer Look 1Document16 pagesUnit 01 Leisure Activities Lesson 2 A Closer Look 1Linh HồNo ratings yet