Professional Documents

Culture Documents

Fluid System 5000B4x

Uploaded by

mohamed Hesham0 ratings0% found this document useful (0 votes)

4 views2 pagesHi-G Dryer Specs and manual

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHi-G Dryer Specs and manual

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views2 pagesFluid System 5000B4x

Uploaded by

mohamed HeshamHi-G Dryer Specs and manual

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

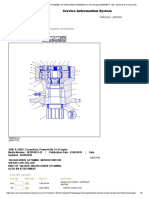

Series 5000 BDHC

Double Header Mud Cleaner

VGS Configuration Optional

High “G” force, high volume

Introducing the 5000B DHC, FSI’s latest

advance in high volume linear motion mud

cleaners. FSI has designed this unit to

achieve optimum performance. Even in

the most challenging applications, the

5000B DHC achieves consistently high

throughput. Processing rates vary with

slurry content, percent solids and viscosity.

Exceptional reliability

Simplicity is the essence of every FSI

design. Permanently sealed vibrators

make lubrication systems totally

The FSI Difference unnecessary. Low 80-dB motor vibration

eliminates the need for hearing protection.

Each of the unit’s four pre-tensioned

• High “G” Force screen panels can be installed or

• 34 ft² [3.16 m²] screening area replaced independently of each other.

Replacement of each screen panel takes

• Simple Design less than three minutes and requires only

• Rugged and Reliable a light to medium-weight hammer.

• High Performance Lowest maintenance cost

• Low maintenance FSI equipment have the lowest

operational and maintenance costs in the

• Quick screen panel changes industry. Routine maintenance is

• Small footprint extremely minimal. Simple visual checks

of screen panels, deck rubbers, inflation

• No lubrication of air spring assemblies and quarterly

• Low noise torque checks of the vibrator motor bolts

are all that is required. Fluid Systems, Inc.

• 2000 GPM [454.2 m³/hr] keeps you on-line for decades of trouble-

free performance. It’s that simple.

Houston Office New Orleans Office

16619Aldine Westfield Rd 2808 Engineers Road

Houston, TX 77032 Belle Chasse, LA 70037

832-467-9898 504-393-1804

www.FluidSystems.com FAX: 832-467-9897 FAX: 504-393-5166

093003

Series 5000 BDHC

Double Header Mud Cleaner

General Specifications

Series: Series 5000 Mud Cleaner

Model: B3 DHC

Motors: Two each 1800, 1500 or 1200 rpm

exp. proof or non-exp. proof available

Bearings: Permanently sealed and lubricated

Motion: Linear, 0.13" A (1800), 0.156” A (1500),

0.23” A (1200), 4.5 “G”

VGS: Force adjustable to 8.0 “G” maximum

Deck adjustment: Adjustable 0° to 5° uphill

Screens: Four each 29" x 42” pretensioned

panels with Wedgelok fasteners

Screening area: 34 ft2 [3.16 m2]

Overall dimensions: 131 1/2" L x 65 1/2" W x 105 5/8" H

3340mm x 1664mm x 2681mm

Header capacity: 2000 GPM total [454.2 m3/hr]

Fluid Systems, Inc. Screen Sales, Manufacturing & Engineering

16619AldineWestfield Rd •Houston TX 77032 • TEL 832-467-9898 • FAX 832-467-9897

Sales & Service

2808 Engineers Road • Belle Chasse, LA 70037 • TEL 504-393-1804 • FAX 504-393-5166

Sales@FluidSystems.com

You might also like

- Series 20L DD: Linear Power ShakerDocument2 pagesSeries 20L DD: Linear Power ShakerJhon SimancaNo ratings yet

- Cat 345 GC: Hydraulic ExcavatorDocument4 pagesCat 345 GC: Hydraulic ExcavatorArvind HarryNo ratings yet

- Hydrostatic Vibratory Plate: A Trusted CompactorDocument2 pagesHydrostatic Vibratory Plate: A Trusted Compactorhamdi galipNo ratings yet

- Ficha Técnica de Equipo BDP 51/1500 CDocument4 pagesFicha Técnica de Equipo BDP 51/1500 CtscostaapartadoNo ratings yet

- ZX200 SpecDocument28 pagesZX200 SpecnoviNo ratings yet

- VGS Linear Power Drier: Series 29126 "3D" Double Deck DrierDocument2 pagesVGS Linear Power Drier: Series 29126 "3D" Double Deck DrierSarah PerezNo ratings yet

- Aph6585vibratoryplatesellsheetmss 1062 07 En200305Document2 pagesAph6585vibratoryplatesellsheetmss 1062 07 En200305Apo ghasan Al shargapiNo ratings yet

- En CTL Range Brochure B4500130 04-2018 LowResDocument8 pagesEn CTL Range Brochure B4500130 04-2018 LowResVinod GuptaNo ratings yet

- CD 518 HV VFD Brochure Rev 2Document6 pagesCD 518 HV VFD Brochure Rev 2Nurullah BöğüşNo ratings yet

- PC8000-6 Super Shovel: 700-720 Ton 1,540,000-1,590,000 LBDocument8 pagesPC8000-6 Super Shovel: 700-720 Ton 1,540,000-1,590,000 LBgerardoNo ratings yet

- Cat 349D2: Hydraulic ExcavatorDocument2 pagesCat 349D2: Hydraulic ExcavatorAkhmad SebehNo ratings yet

- Cat 330 GC: Hydraulic ExcavatorDocument4 pagesCat 330 GC: Hydraulic ExcavatorArvind HarryNo ratings yet

- GF/LL Forest Machines: Superior Performance Simple OperationDocument4 pagesGF/LL Forest Machines: Superior Performance Simple OperationValery GandelNo ratings yet

- The World's Most Versatile Concrete Products Machine: BenefitsDocument2 pagesThe World's Most Versatile Concrete Products Machine: BenefitsumbertiNo ratings yet

- 3 Gardner Denver Compressor Bulletin 13-9-209 - 2nd - 9-03Document2 pages3 Gardner Denver Compressor Bulletin 13-9-209 - 2nd - 9-03Sebastian SalazarNo ratings yet

- 2006 QGB7.5-15 HPDocument4 pages2006 QGB7.5-15 HPjoelmerazNo ratings yet

- Vertical Turret Lathe Imo Kd4S 40: AnlagenbauDocument6 pagesVertical Turret Lathe Imo Kd4S 40: AnlagenbauSamik MukherjeeNo ratings yet

- Arx Malbikunarvaltarar Fra AmmannDocument24 pagesArx Malbikunarvaltarar Fra AmmannhathamphanNo ratings yet

- 313D2 L SmallDocument2 pages313D2 L SmallArvind HarryNo ratings yet

- Specification of Cat 320cDocument28 pagesSpecification of Cat 320cDan AbellaNo ratings yet

- Walk-Behind Roller: A 2-In-1 MachineDocument2 pagesWalk-Behind Roller: A 2-In-1 MachineAndré LinharesNo ratings yet

- CS PDFDocument2 pagesCS PDFArvind HarryNo ratings yet

- Red Rhino 5000 Series Mini Crusher: Technical SpecsDocument2 pagesRed Rhino 5000 Series Mini Crusher: Technical SpecsMohammed AttiaNo ratings yet

- 308CCR Series Spec SheetDocument24 pages308CCR Series Spec SheetBang Kojek100% (4)

- BPU 5545 - Plate CompactorDocument2 pagesBPU 5545 - Plate CompactorDustin WinnNo ratings yet

- Top Drive 750 Product SheetDocument2 pagesTop Drive 750 Product SheetMehdi SoltaniNo ratings yet

- 314C LCR ExcavatorDocument24 pages314C LCR ExcavatorMarco YeppaNo ratings yet

- Compaction LiteratureDocument2 pagesCompaction LiteratureAmílcar DuarteNo ratings yet

- ADH 2045 Product Data Sheet EnglishDocument2 pagesADH 2045 Product Data Sheet Englishkarthikeyan1992No ratings yet

- 7200 Brochure EnglishDocument4 pages7200 Brochure Englishalesker.alekperov71No ratings yet

- Dr416i Brochure English PDFDocument12 pagesDr416i Brochure English PDFDAVID ARCA VALERONo ratings yet

- QESQ2738 CB2.X (03A) Simplified F - and - BDocument2 pagesQESQ2738 CB2.X (03A) Simplified F - and - BEdsonNo ratings yet

- 390F L BenefitDocument2 pages390F L BenefitArvind HarryNo ratings yet

- PC3000 6 Aess785 00 PDFDocument8 pagesPC3000 6 Aess785 00 PDFdonbowoNo ratings yet

- Sales Manual PDFDocument90 pagesSales Manual PDFtaufiqharto100% (1)

- CD518 HV Product Brochure Rev3Document6 pagesCD518 HV Product Brochure Rev3Evanilson NogueiraNo ratings yet

- HTC 950 RX - A Remote Controlled Floor GrinderDocument5 pagesHTC 950 RX - A Remote Controlled Floor Grinderdaothi_diemkieuNo ratings yet

- Vipac Roller SpecificationsDocument2 pagesVipac Roller SpecificationsMuhaimin100% (2)

- 320CL HEX SpecalogDocument24 pages320CL HEX SpecalogBudi Waskito DPNo ratings yet

- Dynapac Tandem Asphalt RollersDocument12 pagesDynapac Tandem Asphalt Rollerseunice19970315No ratings yet

- ARR 1575 Brochull de Venta InglesDocument2 pagesARR 1575 Brochull de Venta InglesKerbin Enrique NuñezNo ratings yet

- Catálogo Excavadora Hidráulica PC600LC 8 in WebDocument24 pagesCatálogo Excavadora Hidráulica PC600LC 8 in WebnachoNo ratings yet

- 600178d Globalmax 1508Document2 pages600178d Globalmax 1508Hafidz HusniNo ratings yet

- Machine Introduction & Technical Data Specification: Vertical Machining Center MS-500 Twin PalletDocument8 pagesMachine Introduction & Technical Data Specification: Vertical Machining Center MS-500 Twin PalletCristian PavanNo ratings yet

- CB14-Specalog EnglishDocument8 pagesCB14-Specalog EnglishIvanNo ratings yet

- Ls Series Washer Extractors: Designed To LastDocument4 pagesLs Series Washer Extractors: Designed To LastTom DavidcsNo ratings yet

- 320C PDFDocument24 pages320C PDFMichael DuvanNo ratings yet

- Spesifikasi HCR 910 DSDocument7 pagesSpesifikasi HCR 910 DSYudi YusufNo ratings yet

- Bridgeport Series I - BrochureDocument2 pagesBridgeport Series I - BrochureVVNo ratings yet

- Catalog Underfloor Wheel Lathe Simple and Tandem enDocument4 pagesCatalog Underfloor Wheel Lathe Simple and Tandem enbagus diwangkoroNo ratings yet

- Balanced Eliptical Motion Shale Shaker (BEM-600)Document6 pagesBalanced Eliptical Motion Shale Shaker (BEM-600)LoganBohannonNo ratings yet

- Product CatalogueDocument6 pagesProduct CatalogueBvitalizeNo ratings yet

- 120X Series: Features & BenefitsDocument2 pages120X Series: Features & BenefitsCojanu CozminNo ratings yet

- L&T-CASE 1107: Vibratory CompactorDocument3 pagesL&T-CASE 1107: Vibratory Compactorsblnt2008100% (2)

- Router Family BrochureDocument15 pagesRouter Family BrochurealexNo ratings yet

- Doosan VMC BVM 5700Document16 pagesDoosan VMC BVM 5700Jesus D. Gutierrez G.No ratings yet

- 14 Compactador Cat LisoDocument12 pages14 Compactador Cat LisoVictor Leandro Hurtado LopezNo ratings yet

- Microprocessor Architectures and Systems: RISC, CISC and DSPFrom EverandMicroprocessor Architectures and Systems: RISC, CISC and DSPRating: 4 out of 5 stars4/5 (1)

- Architectural PlansDocument2 pagesArchitectural PlansJackielou Marmojada DomaelNo ratings yet

- Arifin Efendi Swing Drive 320DDocument3 pagesArifin Efendi Swing Drive 320DTommy AdityaNo ratings yet

- Automation Systems: "A Reliable Partner in Your Automation Journey"Document90 pagesAutomation Systems: "A Reliable Partner in Your Automation Journey"Ali Hasan MahdiNo ratings yet

- Camperfiladas Asme 16 5Document8 pagesCamperfiladas Asme 16 5klara23No ratings yet

- An Easy To Understand Guide To 21 CFR Part 11Document72 pagesAn Easy To Understand Guide To 21 CFR Part 11Mia Bratos100% (2)

- Types of RAMDocument2 pagesTypes of RAMCerina Avergonzado BuendiaNo ratings yet

- Isa S84.01 PDFDocument110 pagesIsa S84.01 PDFmohammed el erianNo ratings yet

- Lifting Lug Calculation - Concrete BucketDocument3 pagesLifting Lug Calculation - Concrete Bucketali akbarNo ratings yet

- Cap 8 Livro PDFDocument36 pagesCap 8 Livro PDFDiogo FonaNo ratings yet

- BTS InstallationDocument20 pagesBTS Installationsujit760099% (88)

- Flat JacksDocument3 pagesFlat JackschristopherapssNo ratings yet

- Moblization Plan-CDocument7 pagesMoblization Plan-CTanveer IqbalNo ratings yet

- Ariel Corporation - Arielcorp - Com15Document1 pageAriel Corporation - Arielcorp - Com15Anwar Sadat100% (1)

- NCR Cassette Magnet ConfigurationDocument1 pageNCR Cassette Magnet Configurationantonysolenc100% (1)

- Doosan DBC130 Mechanical Repair ManualDocument157 pagesDoosan DBC130 Mechanical Repair ManualDarryl Hardt80% (5)

- Solid Short Notes PDFDocument32 pagesSolid Short Notes PDFsanjeet singh kainturaNo ratings yet

- PPTDocument56 pagesPPTSulman ShahzadNo ratings yet

- Multi Core ProcessorsDocument7 pagesMulti Core ProcessorsBhavin Joshi100% (5)

- SJVMDocument3 pagesSJVMMukesh NegiNo ratings yet

- Wooden PanelingDocument47 pagesWooden PanelingRashim SharmaNo ratings yet

- Skip Cycle EngineDocument8 pagesSkip Cycle Enginekumar_yogesh223881No ratings yet

- Working Principle of Submersible PumpDocument5 pagesWorking Principle of Submersible PumpSatinder saini100% (1)

- Chemical Reaction Question PaperDocument17 pagesChemical Reaction Question PapershivamNo ratings yet

- CatalogueBuilding2015 AdnotatDocument708 pagesCatalogueBuilding2015 AdnotatOctavian GrigoreNo ratings yet

- 10 11648 J Ijmsa 20130203 14 PDFDocument5 pages10 11648 J Ijmsa 20130203 14 PDFRima AroraNo ratings yet

- Intro To Inkscape Lesson 3Document6 pagesIntro To Inkscape Lesson 3api-234298405No ratings yet

- Astm A961-21Document9 pagesAstm A961-21psytembeNo ratings yet

- 2019 - Chapter 31F Marine Oil Terminals 7Document1 page2019 - Chapter 31F Marine Oil Terminals 7sidhappy86No ratings yet

- Breckwell Pellet Stove PartsDocument1 pageBreckwell Pellet Stove PartsHelicon1No ratings yet