Professional Documents

Culture Documents

Piper Alpha MORT

Piper Alpha MORT

Uploaded by

Ghulam MurtazaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Piper Alpha MORT

Piper Alpha MORT

Uploaded by

Ghulam MurtazaCopyright:

Available Formats

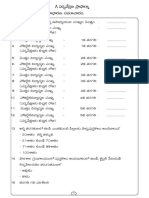

MORT - Management Oversight & Risk Tree

b1

SD1 MB3

2009 Revision by SD1

Technical

Information

Systems LTA

SD1 5

The Noordwijk Risk b6

MB1

f6

SD5

Initiative Foundation Damage to

people or assets Losses

Future

Undesired

Events a1

Technical

Information

LTA

5 a2

Data

Collection

LTA

8 a3

Data

Analysis

LTA

9 a4

Triggers to

Risk Analysis

LTA

10

a5

Audit &

Appraisal

LTA

10

Document Reference: NRI-2 (2009). T 1

For use with the MORT Users' Manual (NRI-1)

Communication Single Priority Use of

Unplann

Published and distributed by the Knowledge

of Knowledge Monitoring Previous Routine Health Event Problem

Planned

Change -ed Change New Info

LTA Plan A.I. info Inspections Monitoring Sensitivity

Noordwijk Risk Initiative Foundation LTA

LTA LTA LTA LTA LTA

Fixes LTA

LTA LTA LTA

Oversights Assumed b1 7 b2 7

P.O. Box 286, 2600 AG Delft, & Omissions Risks

b3 8 b5 8 b7 8 b9 9 b13 10 b14 10 b15 10 b16 10 b17 10

Learning

Upstream

The Netherlands. Independ-

ent review

from

Audits

S/M 1 R 56 Workers

LTA LTA LTA

b4 8 b6 8 b8 9

20th December 2009

Based on Internal External

Email: Info@nri.eu.com Known

Existing No Known Communication Communication Priority Status

R1 R2 R3 R4 Rn Precedent Problem Statistics Display

Website: www.nri.eu.com Precedent

Knowlege LTA LTA

List LTA LTA LTA

c1 6 c2 6 c3 7 c4 7

b10 9 b11 9 b12 9

ISBN 978-90-77284-09-4

Specific Management

Control Factors System Factors

LTA LTA

S 1 M 37 Codes & List of Local Solution Prev. Network Network Network Network

Manuals Experts Knowledge Research Inv/anal Research Structure Operation Structure Operation SA2

SA2

LTA LTA LTA LTA LTA LTA LTA LTA LTA LTA

d1 6 d2 6 d3 6 d4 6 d5 6 d6 6 d7 7 d8 7 d9 7 d10 7 Stabilisation

& Restoration

LTA

34

Accident

Stabilisation Occurrence

Oil leaks from Accident & Restoration

Policy Implementation Risk Management

PSV-504 LTA of Policy LTA System LTA

LTA

SA1 1 SA2 34

SA2 MA1 37 MA2 MA3 42

Prevention Emergency Action

Rescue and Medical Dissemination Restoration &

of Follow-on (Firefighting, etc.)

Salvage LTA Services LTA of Information Rehabilitation

Accidents LTA LTA LTA

Potentially Vulnerable Events and Energy a1 34 a2 35 a3 35 a4 36 a5 36 a6 36

Controls & a1 a1 a1 a1

Harmful Energy People c24 Barriers LTA

Flows Leading to

Flow or Condition SC4 or Objects SC3 MB3 Accident/Incident Planning Execution RM Implementation RM Assurance

Monitor- Risk Analysis Review of

SB4 Process of Plan Policy of RM Policy Programme

SB1 1 SB2 4 SB3 5 33 ing Process LTA RM System

LTA LTA LTA LTA LTA

LTA LTA

a1 37 a2 40 a3 41 MB1 42 MB2 42 MB3 42 MB4 55 MB5 56

MA2

Execution Op Rehab- Restor- Absorb

Non-functional Control of Events and Plan

Non-functional Functional Functional People Barriers & Relevant to of Plan LTA Continuity ilitation ation Loss

People or Work and Barriers LTA Energy LTA

Energy Flow Energy Flow or Objects Controls LTA Accident Transfers LTA LTA LTA R12 b6 36

Objects Process LTA b2 34

b1 34 b3 36 b4 36 b5 36

a1 2 a2 2 a2 4 SC1 5 SC2 31 SC3 33 SC4 33

a1 4

SB3 SB1

Specification Use of Leader- Capability Support Time & Delays Caused Aims Prog Docum- Assurance Prog Assurance Prog

Barriers LTA Barriers LTA of Plan Feedback Activities

ship LTA LTA Budget & Policy Scope entation Organisation Services

LTA LTA R12 b7 41 Failure LTA

LTA LTA LTA LTA LTA LTA LTA

b1 37 b2 39 b3 40 b4 40 b5 40 b6 40 b8 41 Personnel and/ Task

a1 55 a2 55 a3 55 a4 55 a5 56 a6 56 Training & Response

SD6 SD6 Notification or Equipment Logistics Performance

Experience Delay

LTA Changes LTA Errors

LTA R11 c6 35

Control Diversion Control of c5 35

Control Control Control Control People Evasive Action On the On Persons Separate in c1 34 c2 34 c3 34 c4 35 b3

Impracticable of Use of Energy Impracticable Exposure Between SD5

LTA LTA LTA Energy Source or Objects Time or Place

LTA LTA LTA Task

Task

R1

b2 2

R3 Methods, Specification of Communication

2 b2 4 Schedule Budgets Account- Performance

Performance

b1 b3 3 b4 3 b1 4 b3 4 b4 4 a1 31 a2 32 a3 33 a4 33 Criteria, Responsibilities Plan Authority Progres-

a1 a1 a1 Analyses LTA ability Errors

Errors RM Assurance Comm-

LTA LTA LTA LTA sion of

LTA LTA c8 40 Staff Perform- ittees

40 40 b3 improv’t

c1 37 c2 38 c3 38 c4 38 c5 39 c6 c7 ance LTA LTA

SD5 LTA

b1 55 b2 55 b3 55

b3

Control Divert SD5

Impracticable Means of None Barrier Did Not Use

LTA Evasion

R2 Evasion Impracticable Possible Failed

c1 3 c2 3 LTA Line Staff Task Inform-

R4 R9

b1 31 b3 Guidance

c2 4 b2 32 Respons- Respons- Assign- ation and

c1 4

ibility ibility ment Flow Directives

LTA LTA LTA LTA LTA

d1 38 d2 38 d3 38 d4 39 d5 39

Task Concepts and Design and

D/N Requirements

Performance Development

Provide LTA LTA

R10 Error

c1 32 c2 32 42

b3 a1 a2 46

SD5

Technical Supervision Support of Technical Definition of Risk Analysis Specification Information Energy Human Factors Inspection Maintenance Specification Conting- Indep- Config- Docu- Fast Design Acceptance

Operational Criteria for Life Cycle Arrange- Environ- Emrgncy Disposal

Information Inspection Maintenance & Staff Supervision Information Goals & Tolerable Criteria of Requirements Search Control (Ergonomics) Planning Planning of Operational Shutdown ency endant uration mentation Action

Readiness Procedures Analysis LTA ment ment Planning & Change Control

Systems LTA LTA LTA Performance LTA LTA System LTA Risks LTA LTA LTA LTA LTA Review LTA LTA LTA Readiness LTA Provision Planning Review Control Control Cycle

LTA LTA LTA LTA LTA LTA LTA LTA LTA Processes LTA

LTA LTA

SD1 5 SD2 11 SD3 12 SD4 12 SD5 14 SD6 29 b1 42 b2 43 b3 43 b4 44 b5 45 b6 a1 45 b7 45 b8 46 b9 47 b10 a1 49 b11 a1 49 b12 49 b13 50 b14 41 b15 52 b16 52 b17 52 b18 53 b19 53 b20 53 b21 53 b22 53

SD1 SD3 SD4 SD6 SD1 SD1 SD3 SD4

Supvn Detection or Performance

Time Correction of

Continuity Errors

LTA Hazards LTA b6 b6 c18

LTA SD3 SD4 SD5 ES&H Perform Change Solution Rqmt for D/N Controls & Super-

Goals & Measure- Automatic Manual Personnel Personnel

a1 14 a2 14 a3 14 a4 18 Goals &

Analysis Precedence Scope Life Cycle Substitute vision

Risks not Risks not ment Scale

Safer Control Controls Barriers LTA Selection Motivation

Sequence LTA Analysis

Defined Defined LTA LTA Energy LTA LTA LTA LTA LTA

LTA Env'l LTA Extend-

c2 c5 c8 b1 c1 43 c2 43 Plan c4 43 Analytical c6 44 Required c8 44 c14 45 c16 46 c18 c24 47 c31 50 c33 51 Training c35 52

Impact ed Use 46 c20 46 c22 47 Test & Task Monitor

Detection of Correction of SC2 SA2 MA2 MB4

LTA Methods Alternatives

Analysis Analysis

SB3

Qualifica- & Qualif-

LTA Procedures D/N ication

Points

Hazards LTA Hazards LTA LTA LTA LTA tion LTA Meet Criteria LTA

Safe LTA

c3 43 c5 43 c7 44 c15 46 c17 46 D/N

b1 14 b2 16 Task Errors in Emergency Energy c30 50 c32 50 c34 52 c36 52

Limit Warnings

Performance Performance of Shut-off Release

Errors Unrelated Tasks Energy LTA

Errors LTA

Verification of Interface Config-

Technical c19 46 c21 46 c23 47

Ops/Maint b3 18 b4 28 b5 28

Readiness LTA Support uration Incident Local

& Testing

LTA LTA LTA has occurred National Codes &

a1 11 a2 11 a3 11 a4 11 Supv Laws Byelaws

Detection Time Workforce Interdept D/N Correct House-

Checklist Postponed keeping Judgem- Customer National Ergo- Task Task Interface Error Match to Match Spec. Code Standard- Accept- Control

LTA Plan LTA LTA Input LTA Co-ord in Time c10 45

& Internat'nl

c12 45 Internal nomics Predict- Hardware to Task & Warnings Lockouts of Work Compliance isation of ance of Change

LTA ent LTA & Stake- Analysis Allocation Design LTA

LTA R5

c6 16

Emergency Codes & Standards knowledge Change Equipmnt LTA LTA Conditions Verification Parts Criteria Process

Allowed Errors in holders LTA LTA ion LTA

c1 14 c2 15 c3 16 c4 16 c5 16 c7 17 c8 17 c9 17 Prohibited Performance Stds LTA LTA LTA LTA LTA LTA LTA LTA

Activities Unrelated c28 48

Did not Activities Errors c9 45 c11 45 c13 45 c25 47 c26 47 c27 47 c29 49 d5 50 d7 51 d9 51 d11 51 d13 51 c37 53 c39 53 c41 54 c43 54

tasks

Specify Procedure Follow-up

c16 28 c17 28 c18 b3 28 c19 28

Check LTA LTA SD5

D/N Engine- Design

b1 11 b3 11 b5 11 Logs & Supv's Change Match Emergcy Task Comms Testing Reliab-

Relate to Authority Budget Time ering Description

Compet Monitor to Users Provisions Sequence Interfaces ility & QA

Criteria Diagrams Review Prior Studies LTA

LTA -ence Plan LTA LTA LTA LTA LTA LTA LTA LTA LTA

LTA LTA

LTA LTA Events

LTA d6 50 d8 51 d10 51 d12 51 c38 53 c40 54 c42 54 c44 54

b2 11 b4 11 d1 15 d2 15 d3 15 d4 15 d5 17 d6 17 d7 17 39 Display

39 Media-

39 Control

39

Definition

of Users Design tion Design

LTA LTA LTA LTA

d1 48 d2 48 d3 48 d4 48

Task-Specific Task-Specific Personnel

Task Pre-Task Task

Risk Assessment Risk Assessment Procedures Performance

Assignment Briefing Discrepancy

Not Performed LTA D/N agree W

LTA LTA

c11 18 c12 20 Situation c15 23

c10 18 c13 22

c14 22

High Potential

Not Identified

R6

Low

Potential

d9 19

Task-Specific

Risk Analysis

LTA

Recommended

Risk Controls

LTA

Personnel

Selection

LTA

Training

LTA

Consideration

of Behavioural

Variation LTA

Personnel

Motivation

LTA

(Provisional) Assumed Risks

d8 18 d10 20 d11 21 d12 23 d13 23 d14 24 d15 25

MORT Reference Description of (Provisional) Assumed Risks Judgement

R6 The staff might though low risk. Although pump-A & B were both faulty. Bad

Supv

Job General

Task Task No Verific- Supervisor Leadership Perform Personal

Task Compat- Testing Directive Avail- Adapt- Use not Criteria Testing Methods Normal is Interest Obstacles Motivation Pressure blind was not installed might it be assumed that the line will not be pressurized as pump is under maintenance. Bad

Analysis Analysis Knowledge LTA Execution LTA Clarity ation Observa- Correction LTA & Example Conflict R10

Analysis ibility of control ability ability Mandatory LTA LTA Training LTA Variability LTA Punishing Building to perform Prog LTA

Not Reqd Not Made LTA to Use tion LTA

LTA LTA LTA R7 LTA e24 25 LTA

LTA LTA LTA e12 22 Production from Tartran, MCP01 and Claymore was continue by assuming the situation in control at

e3 19 e4 20 e5 20 e13 23 e14 23 e15 23 e17 23 e19 23 e20 24 e22 24 e23 24 e26 25 Non- e28 26 e30 26 e31 27 e32 27

e1 18 e2 19 e6 21 e7 21 e8 21 e9 21 e10 22 e11 22 Trainer Group R11

Definition Time Perform is Piper. Bad

Skills Norms

of Needs Changes Pressure Rewarded

LTA Conflict

LTA

e16 23 e18 23 e25 e27 26 e29 26 R12 Maintenance of pump-A was delayed due to unavailability of spares. PSV-504 job was not completed on Bad

e21 24

urgent basis. The delay was caused, by assuming pump-B will remain in operation till pump-A

Supv Technical Hazard Re-instru Enforce- With With Deviant

Use of maintenance completion.

Budget Time Time Scope ction LTA ment Super- Traits

Authority Judgem- Workers’ Information Selection

LTA Others

LTA LTA Input LTA Systems LTA LTA LTA LTA visor R8 f17 27

LTA ent LTA

f12 24 f13 24 f15 27 f16 27

f11 21

f1 19 f2 19 f3 19 f4 19 f5 20 f6 20 f7 20 f9 21

SD1

Budget Analytical

LTA Skill LTA

f8 20 f10 21

b5 a5

SD3 SD4 SD6 MA2 MB4

SD3 SD4 SD6

Hazard Hazard Maintenance Support of

Inspection

Identifica- Prioritisa- Supervisors

LTA LTA

tion LTA tion LTA LTA

g1 21 g2 21 12 12 29

b10 b11

MB1 MB1

Research Standards Use of

Plan Execution Plan Execution Support & Directives Resources

LTA LTA LTA LTA LTA LTA LTA

An event, usually a fault or AND Gate - Requires the coexistence of all D/N Did not a2 29 a4 29 a6 30

oversight, expressed in generic gate inputs to produce output. a1 12 a2 13 a1 12 a2 13 Response

Help & Info

terms. Exchange Resources to Risk

D/NP Did not provide Training Referrals

An event described by a basic OR Gate - Requires any one gate input to LTA LTA LTA

LTA

component or part failure. It marks produce output. If more than one input, the Environment, Safety a1 29 a3 29 a7 30

output will still occur. ES&H a5 29

the lowest level of development & Health

in the tree.

Conditional gate (either AND or OR) - Inputs Specification Log Task Specification Analysis Point of Task

Condition F/T Failed to Analysis Caused Time Performance Caused Time Performance

An event where sequence is ended Input produce the output provided the condition of Plan LTA of Failures Access of Plan LTA of Failures operation

for lack of information or solutions. is true. Failure LTA Errors Failure LTA Errors

LTA Less than adequate LTA LTA LTA log LTA

The event may be transferred to b1 b2 b3 b4 b5 b6

Constraint symbol - Applies conditions to b1 12 b2 13 b3 13 b4 13 b5 13 b6 b3 13 12 13 13 13 13 b3 13

"Assumed Risks". SD5 SD5

gate or output. W With

An event that is satisfactory. Training Access to Access to Co-ord of

Triangle - Used to transfer sequence to RM Risk Management Expertise Equipment Resources

another location on page. LTA

LTA LTA LTA

An event that is normally Transfer to Assumed Risk branch - denotes Co-ord- Compet- Co-ord- Compet- b1 29 b2 29 b3 29 b4 29

Inspect- Inventory Maintain Plan not Schedule

expected to occur. Rn problems for which there is no practicable Frequency ination ence ination ence

ability -ability Complete LTA

countermeasure LTA LTA

LTA LTA LTA LTA LTA LTA

c1 12 c2 12 c3 12 c4 12 c5 12 c1 12 c2 12 c3 12 c4 12 c5 12

NRI-2, Second Edition, August 2009. Revised by John Kingston, Floor Koornneef, Jaap v.d. Ruit, Rudolf Frei, and Philippe Schallier. Major revision of MORT 1992,

US Department of Energy, drawn by John Kingston.

You might also like

- Auditing Checklist ISO27701 - Draft - 01 - Landscape RV MBv1Document16 pagesAuditing Checklist ISO27701 - Draft - 01 - Landscape RV MBv1kazo188% (8)

- Multiple Choice Questions On HTML CSS Javascript With AnswersDocument10 pagesMultiple Choice Questions On HTML CSS Javascript With AnswersKhaled Abdulaziz100% (4)

- Tewkesbury Active Travel MapDocument2 pagesTewkesbury Active Travel MapSidney ByrneNo ratings yet

- Manual de Servicio Samsung Galaxy S6 EdgeDocument137 pagesManual de Servicio Samsung Galaxy S6 EdgeToni ViloriaNo ratings yet

- Zoning MapDocument1 pageZoning MapJoban BrarNo ratings yet

- Eda Scripting LanguagesDocument7 pagesEda Scripting LanguagesManchiramesh GupthaNo ratings yet

- OASES Functions and Features Version 6.0 PDFDocument94 pagesOASES Functions and Features Version 6.0 PDFhasnain zaidiNo ratings yet

- VERTICAL SEALANT QTY at SUBTERRANEAN1Document7 pagesVERTICAL SEALANT QTY at SUBTERRANEAN1Mohammed Abu NassarNo ratings yet

- BASEMENT-1 ABS STORE LOCATION (1) Layout1Document1 pageBASEMENT-1 ABS STORE LOCATION (1) Layout1rNo ratings yet

- Builtup Area Diagram Sc.1:100: Sanitation StatementDocument1 pageBuiltup Area Diagram Sc.1:100: Sanitation StatementShiwangi NagoriNo ratings yet

- Pablo Fernando Ramirez TesissDocument1 pagePablo Fernando Ramirez TesissAngel MedinaNo ratings yet

- Fuel Tanl ConcDocument1 pageFuel Tanl ConcAyman ZakariaNo ratings yet

- AAC Goals Grid 2pg 6-10Document2 pagesAAC Goals Grid 2pg 6-10Cesar Gutierrez NegredoNo ratings yet

- MS-AD-538-1F - Food Hall - Hydration - Microwave Station - Type 1Document2 pagesMS-AD-538-1F - Food Hall - Hydration - Microwave Station - Type 1RIJO JamesNo ratings yet

- Red River ValleyDocument1 pageRed River ValleysppainistanNo ratings yet

- Plano Clave Señalizaciones PDFDocument16 pagesPlano Clave Señalizaciones PDFFernando Gastañaga FloresNo ratings yet

- Acmv Layout For Office First Floor and Terrace Floor Paln-R3-1f-HvacDocument1 pageAcmv Layout For Office First Floor and Terrace Floor Paln-R3-1f-HvacNagendra EtikalaNo ratings yet

- April 19, 2021 Official Zoning Map FullDocument1 pageApril 19, 2021 Official Zoning Map FullMasoom Sawaira DhmNo ratings yet

- Norzagaray Heights Resettlement Project: Brgy. Bitungol, Norzagaray, BulacanDocument1 pageNorzagaray Heights Resettlement Project: Brgy. Bitungol, Norzagaray, BulacanXyrile ß IngilloNo ratings yet

- Zoning 1703Document1 pageZoning 1703Eggs BenedictNo ratings yet

- Sm-g781b PCB Layout Galaxy s20 Fe 5gDocument2 pagesSm-g781b PCB Layout Galaxy s20 Fe 5gAlex RobsonNo ratings yet

- Circuit Diagram Legends: U80C RAC 47430253 Electrical SchematicDocument2 pagesCircuit Diagram Legends: U80C RAC 47430253 Electrical Schematicroparts clujNo ratings yet

- A - Ward: SCALE 1:6000Document1 pageA - Ward: SCALE 1:6000Somesh MhatreNo ratings yet

- District 20Document1 pageDistrict 20Genna ContinoNo ratings yet

- Plano 02Document1 pagePlano 02David RoyerNo ratings yet

- 818 MAS DTD PLN LANDSCAPE 2-IndcDocument1 page818 MAS DTD PLN LANDSCAPE 2-IndcYaseer BhattiNo ratings yet

- Estructural Sevilla 01Document1 pageEstructural Sevilla 01Difracol EmpresaNo ratings yet

- 15024a - s6 - AP - 002 - First Floor PlanDocument1 page15024a - s6 - AP - 002 - First Floor PlanPERVEZ AHMAD KHANNo ratings yet

- 15024a - s6 - AP - 001-Ground Floor PlanDocument1 page15024a - s6 - AP - 001-Ground Floor PlanPERVEZ AHMAD KHANNo ratings yet

- MD-RA-3.2: Ifc - Added PiecemarksDocument1 pageMD-RA-3.2: Ifc - Added PiecemarksEmmanuel BahenaNo ratings yet

- Ordenacion Urbanistica A ColorDocument1 pageOrdenacion Urbanistica A Colorlore y terryNo ratings yet

- Bee Line MapDocument2 pagesBee Line MapCristián A. Muñoz MellaNo ratings yet

- MBTA Revised-Bus-Network-Map (Static) 2022-10-27Document1 pageMBTA Revised-Bus-Network-Map (Static) 2022-10-27khaders6682No ratings yet

- Owner Owner Consultant: BetterhomeDocument1 pageOwner Owner Consultant: BetterhomeMamado099No ratings yet

- Final Drawing - With Coordinates-08-01-2021.-ModelDocument1 pageFinal Drawing - With Coordinates-08-01-2021.-ModelVKT TiwariNo ratings yet

- Monitoring Proforma 2022Document9 pagesMonitoring Proforma 2022Ravikumar BadraNo ratings yet

- Basement LayoutDocument1 pageBasement LayoutKetaki RanalkarNo ratings yet

- HAHC AL 0 FD AR 01 02 OverviewDocument1 pageHAHC AL 0 FD AR 01 02 OverviewNWA INT General Trading & ContractingNo ratings yet

- 22 00404 FUL-P 102 Proposed Site Plan-PA A1 LandscapeDocument1 page22 00404 FUL-P 102 Proposed Site Plan-PA A1 LandscapemalehaleNo ratings yet

- DragDocument1 pageDragjyidouNo ratings yet

- River View South-FinalDocument1 pageRiver View South-FinalAryan MalikNo ratings yet

- STRR Land Use Ao Combine Main SheetDocument1 pageSTRR Land Use Ao Combine Main SheetRammohan PushadapuNo ratings yet

- POLYTRON T5112 51160 51161VUM BT9chs PDFDocument1 pagePOLYTRON T5112 51160 51161VUM BT9chs PDFHasanUddin100% (1)

- 1 Vectors and ScalarsDocument15 pages1 Vectors and ScalarsLai Jing WeiNo ratings yet

- Architectural Tender Amendment No. 7 Drawing: Construction DrawingsDocument1 pageArchitectural Tender Amendment No. 7 Drawing: Construction Drawingsme kwc36No ratings yet

- 10 603110 0000100201 Mah Civ SHD 000102 - 02Document1 page10 603110 0000100201 Mah Civ SHD 000102 - 02ibrahemomr9993No ratings yet

- 09Document1 page09Hugo Valentino Gonzalez CifuentesNo ratings yet

- 3512B & 3516B Engines With Premium Electrical System Wiring Harness For Marine PropulsionDocument2 pages3512B & 3516B Engines With Premium Electrical System Wiring Harness For Marine PropulsionMehdi Chakroune100% (2)

- (Column Size) : (Grey Mat Tile Finish)Document1 page(Column Size) : (Grey Mat Tile Finish)Prdeep SinghNo ratings yet

- Av. Las Retamas: Plano de LocalizaciónDocument1 pageAv. Las Retamas: Plano de LocalizaciónDiana MachacaNo ratings yet

- Ant e 0107 G Ed 3003 Planta General Rev 2 v01Document2 pagesAnt e 0107 G Ed 3003 Planta General Rev 2 v01claudio3aNo ratings yet

- Typical T-Intersection On Single Highway With Left-Turn LanesDocument1 pageTypical T-Intersection On Single Highway With Left-Turn Lanesahmed.almakawyNo ratings yet

- Mozart Allegro in D KV 626b 16Document3 pagesMozart Allegro in D KV 626b 16hyw63064955No ratings yet

- Worcester Ward MapDocument1 pageWorcester Ward MapNeal McNamaraNo ratings yet

- Distribucion de Graderias-P-BDocument1 pageDistribucion de Graderias-P-BMarcos montero naviaNo ratings yet

- CS Acero M 1Document1 pageCS Acero M 1William FigueNo ratings yet

- TROMBONEDocument2 pagesTROMBONEasesoria.jonacarrascoNo ratings yet

- Gigabyte GA-P75-D3 r1.1 BoardviewDocument2 pagesGigabyte GA-P75-D3 r1.1 BoardviewDip888No ratings yet

- Av. 450 Años-Model5 PDFDocument1 pageAv. 450 Años-Model5 PDFPablo Helio Mieles PoloNo ratings yet

- VH Ad 2 VHHH Aoc 3Document1 pageVH Ad 2 VHHH Aoc 3NmNo ratings yet

- Battery DesulfatorsDocument4 pagesBattery DesulfatorsAlex MaianoNo ratings yet

- Discuss Both View EssayDocument4 pagesDiscuss Both View EssayUyen VuNo ratings yet

- Novostella 20W 60W 100W Smart Flood Light User ManualDocument1 pageNovostella 20W 60W 100W Smart Flood Light User ManualFranklin LuqueNo ratings yet

- General Specifications: SSS7740 PRM Advanced Diagnosis ServerDocument4 pagesGeneral Specifications: SSS7740 PRM Advanced Diagnosis ServerapisituNo ratings yet

- Correction: Brand: Model: Model Year: Vin: Engine: Transmission: Brand: Model: Engine: TransmissionDocument2 pagesCorrection: Brand: Model: Model Year: Vin: Engine: Transmission: Brand: Model: Engine: Transmissionأمجد راضي هادي /A1No ratings yet

- Photowatt Pw500: - 12V Photovoltaic Module - JboxDocument3 pagesPhotowatt Pw500: - 12V Photovoltaic Module - JboxSergeNo ratings yet

- en Quick Setup Guide VEGAPULS 6X Two Wire 4 20 MA HARTDocument28 pagesen Quick Setup Guide VEGAPULS 6X Two Wire 4 20 MA HARTSagetunov AryaNo ratings yet

- General Aviation Solutions: Setting The Course For Nextgen Air NavigationDocument27 pagesGeneral Aviation Solutions: Setting The Course For Nextgen Air NavigationIKMAL HAKIM NABIL IKMALNo ratings yet

- Etika Dan Regulasi, UU ITE, HKIDocument23 pagesEtika Dan Regulasi, UU ITE, HKIFahan AdityaNo ratings yet

- Iso Iec - 26514 2008Document11 pagesIso Iec - 26514 2008gbungerNo ratings yet

- Modules: Modules Description: 1. Admin ModuleDocument3 pagesModules: Modules Description: 1. Admin ModuleAkshay VarmaNo ratings yet

- SABIS® Webschool - PrepListDocument1 pageSABIS® Webschool - PrepListyousef olabi0% (1)

- Nediger Infographics 2019Document14 pagesNediger Infographics 2019Elai OrtegaNo ratings yet

- Hotel Management System: Analysis and Design ModelsDocument21 pagesHotel Management System: Analysis and Design ModelsMaria Dasilva MarichoyNo ratings yet

- EEE Final 2021Document605 pagesEEE Final 2021SantoshNo ratings yet

- Unit-I Electronic Commerce Environment and Opportunities 1.backgroundDocument14 pagesUnit-I Electronic Commerce Environment and Opportunities 1.backgroundPriyadarshini PatilNo ratings yet

- IEEE 802.15.4 and Zigbee OverviewDocument22 pagesIEEE 802.15.4 and Zigbee OverviewShiv GaneshNo ratings yet

- Schuler Electronics Instructor CH14 Electronics ComtrolDocument30 pagesSchuler Electronics Instructor CH14 Electronics ComtrolRíõ EscanillaNo ratings yet

- PC Express List PriceDocument2 pagesPC Express List Priceallan john santosNo ratings yet

- (DOC) soal ukom perawat dan Kunci Jawaban Lengkap.docx - ايدل فاترشه - Academia.edu PDFDocument1 page(DOC) soal ukom perawat dan Kunci Jawaban Lengkap.docx - ايدل فاترشه - Academia.edu PDFMuna S. KeylaNo ratings yet

- Scalance XB 000Document63 pagesScalance XB 000ahmedwwwNo ratings yet

- Snap On Meter TrainingDocument93 pagesSnap On Meter TrainingjoeNo ratings yet

- Duoscan PagDocument4 pagesDuoscan PagathenaartemisNo ratings yet

- ID Manajemen Pemeliharaan Bus Transjakarta PDFDocument19 pagesID Manajemen Pemeliharaan Bus Transjakarta PDFSachrul SidiqNo ratings yet

- Electric Protection System in Thermal Power PlantsDocument17 pagesElectric Protection System in Thermal Power PlantsPriyatham GangapatnamNo ratings yet

- Grundfos Packaged Solutions: Grundfos Americas Brookshire, TX 77423 WWW - Grundfos.usDocument8 pagesGrundfos Packaged Solutions: Grundfos Americas Brookshire, TX 77423 WWW - Grundfos.usJhon Jairo Arango MarquezNo ratings yet