Professional Documents

Culture Documents

LC 03 Tad - at Has - v2 - Approve - p28

Uploaded by

Manoj H MOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LC 03 Tad - at Has - v2 - Approve - p28

Uploaded by

Manoj H MCopyright:

Available Formats

2 4 6 8 10 12 14 16 18

C/L OF BEARING

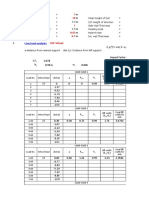

150MT CRANE LOAD CHART GENERAL NOTES:

5500 5500 5500 5500 5500 5500 5500 5500

C/L OF BEARING

2400

CC CRIBS CONNECTIONS & CRANE CAPACITY (IN MT) SPECIFICATIONS

CLAMPING ARRANGEMENT AS 44000 STAGE-6 BOOM LENGTH (M)

1. ALL DIMENSIONS ARE IN MM.

PER RDSO/B/1484/4R1 BEARING C/C WORKING MEMBER/DETAILS SPECIFICATION

RADIUS (M)

2. ALL LEVELS ARE IN METER.

CC CRIBS WITH ISA 75X75X8 2 4 6 8 10 12 14 16 18 21.1 25.4 29.5 35.1 LAUNCHING GIRDERS

600 SQ EACH BLOCK

STAGE-4 1. AVAIL TRAFFIC AND POWER BLOCK OF 4 HOURS. 3. ALL STRUCTURAL STEEL FOR ERECTION CONFORM TO IS-2062-2011 -GRADE-B0, E-250 FULLY

5500 5500 5500 5500 5500 5500 5500 5500 3.5M 90.0 - - - ALL GUSSET PLATES IS:2062-2011 GR-B0 QUALITY,

600 600 2. LAUNCHING GIRDERS (SPLICED LOCATION) AND RAILS SHALL BE REMOVED ONLY BETWEEN

VERTICAL ISA-50X50X6 KILLED AND NORMALIZED.

AT 1500 C/C

ALL STIFFENERS PLATES GRADE E-250

44000 LG. -1000mm 4.0M 90.0 75.0 60.0 - 4. ALL BOLTS & NUTS SHALL CONFIRM TO IS:4000-1992 AND IRS B1-2001

25 DIA HOLDING

CRIB CAPS WITH ISA-75X75X8 STAGE-2 BEARING C/C 1. BSG GIRDER SHALL BE LIFTED USING HYDRAULIC JACK OF 250MT CAPACITY (GRID-B & D) TO

JACK-250MT JACK-250MT GRIDS-17 & 1 AS SHOWN IN ELEVATION. ALL BRACING MEMBERS

5. ALL WELDS SHALL CONFIRM TO IS:816 & SHOULD BE 8MM MIN. U.N.O.

UNDER EACH CRIB RDSO/B-10414/R 3. THE BSG SHALL BE FURTHER LIFTED ABOVE THE ROLLING BEAMS ABOUT 100 TO 150mm USING

800 PLATFORM SHS 50X50X4.0 4.5M 90.0 75.0 60.0 -

DOWN BOLTS

ERECT BUILT UP BEAMS WITH B3-4-ISMB600 (LAUNCHING GIRDER) USING 1X150 T CRANE OVER MS CHQD. PL. @ 200 C/C WELDED 4MM CRIBS CONNECTIONS, CLAMPS etc.. RDSO/B1-1484/4R1

LINKS 8TOR 250 C/C RAIL FORMATION LVL. JACKS AT JACKING POINTS AND WOODEN BLOCKS AT BEARING POINTS FOR REMOVING OF

6MM THK THK

5.0M 90.0 72.5 60.0 38.0 6. NO DIMENSIONS SHOULD BE SCALED/MEASURED FROM THE DRAWING. ONLY WRITTEN

C/L OF BEARING

1. THE PROPOSED BSG SHALL BE ASSEMBLED OVER THE CRIB LOCATIONS ABOUT 1200mm CC CRIBS. IS: 3757-1992, IS: 4000-1992,

C/L OF BEARING

BOTH WAYS

12 tor 125 C/C LAUNCHING GIRDERS, CC CRIBS, RAIL CLUSTER BEAMS AND SLEEPERS ETC (RAILWAY SPAN 6MM WELD 6.0M 87.8 66.8 60.0 38.0

ALL BOLTS & NUTS DIMENSIONS SHOULD BE FOLLOWED.

2. JACK SHALL BE REMOVED AND BSG SHALL BE PLACED OVER ROLLING CAGE & BSG SHALL BE CC CRIB CONNECTIONS, CLAMPS etc.. IRS-B1-2001

B/W TOP & BOTTOM ABOVE GROUND LEVEL. ALL ROUND

7. CONSTANT WATCH AND PRECAUTIONARY ARRANGEMENT (SUCH AS SAFETY

450

8 6

RDSO/B1-1484/4R1

SIDE SLEWED USING JACKS OF 30T CAPACITY. FORCE SHALL BE APPLIED AT BOTTOM BEAM OF BRACING GRID-10 TO 17). 7.0M 79.6 61.2 59.1 38.0 WELDING PROCEDURE & QUALITY IS: 9595, IS: 814, IS: 816

FND BOTTOM LVL: 2. BOTH ARCHES AND CROSS BEAMS WITH ISMB 600 ALONG WITH TOP CONNECTING BEAMS 3600X1800

ISA 75X75X8 ON ALL

3600X1800 =12500=

HORIZONTAL

ISMC150 AT 1000C/C NET/HARNESS/HELMET) SHALL BE MADE AVAILABLE DURING ERECTION OF THE TEMPORARY

99.807 M20-150 THK PCC

BSG AT BEARING LOCATION SIMULTANEOUSLY AT BOTH ENDS OF BSG. ALSO, WEDGE FACES WITHIN CRIBS 4. JACKING FORCE SHALL BE APPLIED TO SUPPORT THE BSG. WOODEN PLANKS ABOUT 100 to (LENGTH-1000mm)

8.0M WOODEN PLANKS, BLOCKS IS: 883-1994

AS PER RDSO DRAWING RDSO/B/10414 SHALL BE MADE. 6 ISMA-50X50X6 69.60 56.1 52.7 38.0

STRUCTURES & LAUNCHING OF BOW STRING GIRDER.

8150*

8150*

150mm SHALL BE REMOVED AT CENTER LINE OF BEARING. AT 1000C/C

300

3. METALLISING AND PAINTING SHALL BE DONE ALONG WITH TESTS TO VERIFY THE QUALITY OF ARRESTORS (FIXED TO RAILS USING RAIL CLAMPS) SHALL BE USED TO AVOID OVER ROLLING OF LAUNCHING GIRDER 9.0M 61.20 52.1 49.3 38.0 52Kg RAILS IS: 3443-1980

1800 1800 1800 1800 1800 1800 1800 1800 1800 1800 1800 1800 1800 1800 5. NOW JACK SHALL BE LOWERED UP TO THE LEVEL OF WOODEN PLANKS. AGAIN SUPPORT THE

DETAIL -X2 8. THE ERECTION WORK NEAR RAILWAY TRACK SHALL BE EXECUTED UNDER SUPERVISION OF

HYDRAULIC HYDRAULIC BSG DURING PUSHING. SLEWING SHALL BE DONE AT RATE OF 173.2MM/SEC. PULLING WIRE ROPE-32 DIA IS: 14268-1995

WELDING WORK AND LIFTING OPERATION SHALL START. NOTE: ALL MATERIAL SHALL CONFORM TO IS:2062-2011

1200

4000

300 TH COMPACTED 3600 SQ. SQ. SQ. SQ. SQ. SQ. SQ. 3600 SQ. SQ. SQ. SQ. SQ. SQ. SQ. =13140= GRADE-A, E-250 10.0M 54.1 48.1 45.9 38.0 RAILWAY SUPERVISOR.

JACK-250MT JACK-250MT BSG ON JACK TO REMOVE WOODEN PLANKS ABOUT 100 to 150mm.

450

LAYER OF MOORUM

150 4. HYDRAULIC JACK OF 250T IS ARRANGED TO LIFT THE BSG & TO ERECT THE CRIBS STAGE BY 3. SLEWING SHALL BE STOPPED ONCE THE BSG REACHES OVER CC CRIBS ALONG GRID- E/1, G/1, M25 CONCRETE-RCC

450

450

FOUNDATION DETAILS FOR -F1 1200 1200 1200 1200 1200 1200 1200 9. FLAG MAN ON EITHER SIDE SHALL BE POSTED DURING THE BLOCK PERIOD BY RAILWAY.

300

150 1200 1200 1200 1200 1200 1200 1200 12.0M 43.2 41.3 39.6 34.2

F3 F2 F2 F2 F2 F2 F2 F2 F3 F3 F2 F2 F2 F2 F2 F2 F2 F3 6. THE LOWERING OPERATION CONTINUED TO PLACE THE "BSG" TO ITS FINAL POSITION OVER THE IS: 456-2000

SECTIONAL VIEW STAGE AT ALL THE FOUR JACKING LOCATIONS OF BSG (600MM FROM C/L OF BEARINGS). E/9 & G/9 ROLLING CAGE SHALL BE ARRESTED USING WEDGES. M20 CONCRETE- PCC

150 150

600

3000 3000 3000 3000 3000 3000 3000

600

6000 3000 3000 3000 3000 3000 3000 3000 6000 BEARINGS. 14.0M 34.3 35.1 34.5 30.6 10. BANNER FLAG ON EITHER SIDE WILL BE ERECTED AS PER IRPWM ON EITHER SIDE OF TRACK.

4000 6000 300 300 300 300 300 300 300 6000 4. BSG GIRDER SHALL BE LIFTED USING HYDRAULIC JACK OF 250MT CAPACITY (GRID-E & G) TO 300 300 300 300 300 300 300 Fe500 HYSD REINFORCEMENT BARS IS: 1786-2008

7. AT ALL THE FOUR BEARING LOCATIONS LOWERING OPERATION SHALL BE DONE CRANE CAPACITY 150 MT 11. BEFORE EXECUTION OF WORK SITE-IN-CHARGE SHOULD INSURE THAT THE DIMENSIONS GIVEN IN

ATTACH THE ROLLERS UNDER EACH VERTICAL HANGERS FOR LONGITUDINAL PULLING AS "DET-X1" X2 WINCH MECHANISM TYPE POWER DRIVEN ONLY

THIS DRAWING ARE VERIFIED AT SITE.

150

SIMULTANEOUSLY NOT MORE THAN 100 to 150mm AT A TIME . NO. OF CRANES USED 1 NOS

FRL :99.257

FRL :99.257

6500 4 @ 600 = 2400 STAGE-2 SHOWN IN ELEVATION. STAGE-4 BOW STRING GIRDER RDSO/B-10414 SERIES

12. ALL THE WORK SHALL BE DONE PREFERABLY IN DAY LIGHT, IF BY ANY REASON, IT HAS TO BE

M20-150 THK PCC STAND-BY CRANE 1 NOS

ELEVATION ALONG GRID- B & D ELEVATION ALONG GRID B & D ISMC 300 B/B AT EACH CRIB GAD DRG NO- SWR/CN/BNC/BR/183/ALT-1-2020

CONTINUED ALL BEYOND SUNSET. THE AREA SHALL BE LIGHTED BY FLOOD LIGHT.

28 28 28

17 17 1 LOCATIONS OPERATING RADIUS (REQ) 14 M SWR/CN/BNC/ST/14-2022

7 SUB STRUCTURE DRG-

150

WOODEN BLOCK

6500 3000

1200

300 13. AT THE TIME OF EXECUTION OF WORK AT SITE, RESPECTIVE RAILWAY AUTHORITIES SHALL BE

BOOM LENGTH (REQ) 35.1 M

6500

Ø20

M25-450 THK RCC F2 F2 F2 F2 F2 F2 PLATFORM WITH CONSULTED

46 46 46 SHEETING PLATE 75 % CRANE LIFTING CAPACITY 0.75 X 30.6 X 1 = 22.9 MT

3000

3000

1800

00 A 28 A A 28 A A 28 14. TRACK SHALL BE PROTECTED IN ACCORDANCE WITH CLAUSE 807 AND 808 OF INDIAN

SQ.

3000

AL2 3000 3000 3000 REQUIRED LIFTING LOAD 8.0MT

AL1 BRAC RAILWAYS P.WAY MANUAL.

6500

2750

2750

300 1800 14050 1800

1200 ING

F2

Ø20 ISMC ING BRACING

F3 600 F2 F2 F2 F2 F2 F2 F2 F3 600 F3 600 F2 F2 F2 F2 F2 F2 F2 F3 600 F3 F2 F2 F2 F2 F2 F2 F2 F3 BRAC 100

554

3000

3000

3000

4 @ 600 = 2400

2800 3300 00 300 100 ISA 75X75X8 ON ALL "IT IS CERTIFIED THAT WEIGHT OF GIRDERS ARE 8T. HENCE BY USING 15. CRS SANCTION SHOULD BE OBTAINED FOR LAUNCHING OF GIRDER OVER RAILWAY TRACK.

ISMC

730

44000 DR2

3000

3000

1800

B B B

4000

B B 1X150MT CAPACITY CRANE WITH DULY ADOPTING 14.0M RADIUS &

SQ.

FACES WITHIN CRIBS

1710

BEARING C/C

ACTIVITY TABLE 16. TRAFFIC AND POWER BLOCKS TO BE ARRANGED FOR ERECTION OF STEEL GIRDERS OVER

8400*

BOOM LENGTH 35.1M WHICH IS ADEQUATE TO LIFT THE GIRDERS

1511 @ 3=4533

ELEVATION ALONG GRID

ELEVATION ALONG GRID

7500 JACK-250MT JACK-250MT JACK-250MT JACK-250MT RAILWAY TRACK.

F2

2300

WITH 75% EFFICIENCY". S.No. DESCRIPTION OF ACTIVITY DURATION

B3-4 ISMB600

B3-4 ISMB600

B3-4 ISMB600

B3-4 ISMB600

DR1

BOTH FACE

300

6500 17. TEMPORARY TOWER STAGING ADJOINING THE RAILWAY TRACK SHALL BE ERECTED UNDER

ISMC 100

CC CRIBS

C 100 CE

ALL THE CRIBS MODULES SHALL BE ERECTED ALONG

ISM TH FA

6570

6570

CONNECTIONS &

BRACINGS WITH BRACING. ERECTION OF BUILT-UP GIRDER SPEED RESTRICTION NON-STOP AND 20KMPH & INFRINGING TRACK TO BE BLOCKED.

BO

CLAMPING

2500

450 PROVIDED ALONG ALL CC CRIB EQUIPMENT LIST

1200 ARRANGEMENT AS (RAILWAY SPAN) USING CRANES OF CAPACITY AS 18. ALL HOR. & VERT. CLEARANCES OF PROPOSED TEMPORARY ARRANGEMENTS CONFIRM TO

7000

F1 F1 F1 F1 F1 F1 GRIDS ON BOTH FACE DESCRIPTION CAPACITY QTY(NOS) 4 HOURS

PER STAND BY TOTAL BLOCK-1 SHOWN AND FIXING FIRMLY BY WELDING.

ENARC

RDSO SCHEDULE OF DIMENSIONS.

1 TO 9

1 TO 9

2750

TM052

RDSO/B/1484/4R1 22 04 26 PULLING THE BSG OVER RAILWAY SPAN USING PULLING

6500 ROLLER SET 100MT

2500

19. ALL NECESSARY SAFETY PRECAUTIONS SHALL BE TAKEN WHILE WORKING NEAR RAILWAY

4000

4000

C C C C C

11000

6000

6500

AL1 AL2 AL1 AL2 AL1 AL2 ING WINCHES TILL IT REACHES THE OTHER END OF THE PIER

9800

13140

13140

14600

15600

BRAC TRACK FOR PROTECTION OF TRESPASSERS WORKMEN AND RAIL TRAFFIC.

C/L OF CARRIAGEWAY BRAC 100 HYDRAULIC LIFTING JACK 250MT 04 02 06

LH16 LH16 LH16

ISMC ISMC ING BEARINGS.

F1

K

K

3000 LH17 LH17 LH17 100 RAIL FORMATION 20. SCHEME OF ACTIVITIES OUTSIDE RAILWAY TRACK AREA MAY BE MODIFIED / ALTERED TO SUIT

7000

2750

AC

AC

AC

K

K

K

BOTH FACE

02 02 04

K

HYDRAULIC PUSHING JACK 30MT

AC

AC

AC

2500

3000

AC

AC

AC

6000

''M''

ISMC 100

450

C 100 CE

LVL

150

TR

TR

TR

300

LOWER THE GIRDER OVER BEARINGS WITH JACKS AND

6500

300

4 HOURS SITE CONDITIONS AT THE TIME OF EXECUTION, WITHOUT COMPROMISING ON THE STRUCTURAL

ISM TH FA

TR

TR

TR

6570

6570

TR

TR

TR

K

Ø20

6500

RE

RE

RE

PULLING WINCH 50MT 02 02 04

AC

K

FOUNDATION DETAILS FOR -F1

K

BLOCK-2 FIXING OF AC SHEET AND POLYPROPYLENE NET BELOW

RE

RE

RE

AC

3000

XG

XG

XG

3000

AC

Ø20

BO

TU

TU

TU

00

& SAFETY ASPECTS.

TR

TU

TU

TU

F FU

F FU

F FU

FE

FE

FE

TR

00 PLAN VIEW

TR

RESTRAINING WINCH 50MT 02 02 04 THE BOWSTRING GIRDER.

F FU

F FU

F FU

6000 6000 6000

RE

''N''

2750

O

RE

2500

XG

JACK FORCE

300

21. SAFETY NET SHALL BE PROVIDED UNDER THE GIRDERS WHILE FIXING THE BRACING AND

O

TU

B3-4 ISMB600

15 1200 15 15

/L

/L

/L

TU

O

F3 600 JACK-250MT F2 F2 F2 F2 F2 F2 JACK-250MT

F3 600 F3 600 F2 F2 F2 F2 F2 F2 F3 600 F3 F2 F2 F2 F2 F2 F2 F3 TYPICAL CROSS SECTION ALONG ALL CRIB GRIDS

F FU

11 11

FE

/L

11

/L

/L

WIRE ROPE 100MT 04 02 06

C

F FU

/L

/L

/L

1800

C

5 5 5 SHUTTERING WORK. ALTERNATIVELY 4MM THK. MS PLATE SHOULD BE PERMANENTLY WELDED

BLOCK-3 REMOVAL OF REMAINING CC CRIBS, BRACINGS OVER

3000

3000

3000

O

2 HOURS

C

LH16

3000

3000

1800

D D D D D

/L

O

SQ.

RAILWAY SPANS AND CLEARING THE SITE.

/L

C LH17 PULLING WINCH PULLING WINCH PULLING WINCH NOTE- OVER RUNNING TRACKS HAVING 25KV OVERHEAD TRACTION.

/L

2266

CC CRIBS CONNECTIONS &

C

2300

3300 35

C

2700 CLAMPING ARRANGEMENT AS CAPACITY-50MT CAPACITY-50MT CAPACITY-50MT

3000

3000

730

74

300

JACK-250MT JACK-250MT

F2

300

F1 F1 1. ALL EQUIPMENTS TO BE TESTED WITH 125% OF ESTIMATED LOADS 22. ALL ROLLING ARRANGEMENT/ROLLERS SHALL BE PROVIDED BELOW VERTICAL HANGERS ONLY.

700

PER RDSO/B/1484/4R1 600

F3 F2 F2 F2 F2 F2 F2 F2 F3 300 F3 600 F2 F2 F2 F2 F2 F2 F2 F3 600 F2 F2 F2 F2 600 F3 F2 F2 F2 F2 F2 F2 F2 F3

2. THE CAPACITY CHECK CERTIFICATE OF EQUIPMENT SHALL BE SUBMITTED TO THIS 23. MAXIMUM BASE PRESSURE ON SOIL IS = 9.78T/M2 WITH ALLOWABLE BEARING CAPACITY

730

748

=2800=

3000

3000

1800

1800

TO HASSAN TO MYSURU CC CRIBS WITH ISA 75X75X8 E E E E E

SQ.

SQ.

2233

2300

7500 58 58 58 OFFICE DULY SIGNED & STAMPED BY SUPPLIER & LAUNCHING AGENCY.

6500

610 1000

58

1000 824 =2800= 600 SQ EACH BLOCK 00 B1-3 ISMB600 00 B1-3 ISMB600 B1-3 ISMB600 00 B2-4 ISMB600 B1-3 ISMB600 B1-3 ISMB600 ASSUMED =12T/M2 FOR NORMAL CASE AND 10.64T/M2 WITH ALLOWABLE BEARING

ELEVATION ALONG GRID

ELEVATION ALONG GRID

470 6500 ADDITIONAL ROLLER

875

720 00 740 736 TO MYSURU JACK-250MT JACK-250MT TO MYSURU JACK-250MT JACK-250MT TO MYSURU

F2

F2

6500 TO HASSAN TO HASSAN TO HASSAN 35 200 FOR SAFETY PURPOSE CAPACITY= 15T/M2 FOR WIND LOAD CASE. ENGINEER AT SITE SHALL CONFIRM THE MAXIMUM

625

200 420

2750

7

BOTH FACE

BOTH FACE

CRIB CAPS WITH ISA-75X75X8 RESTRAINING WINCH RESTRAINING WINCH 4 RESTRAINING WINCH 150X150X25 THK

ISMC 100

ISMC 100

150X150X25 THK

BEARING PRESSURE ON SOIL SHALL NOT EXCEED SAFE BEARING PRESSURE AND SUBMIT THE TEST

C 100 CE

C 100 CE

2500

45600 PIER C/C A5

2750

2750

25 DIA HOLDING UNDER EACH CRIB PLATE

CAPACITY-50MT CAPACITY-50MT CAPACITY-50MT

ISM TH FA

ISM TH FA

A3 1200

6570

6570

3000 WOODEN PACKING 900 900 PLATE

DOWN BOLTS

3000 REPORT FOR OFFICIAL RECORDS. ALL THE FOUNDATION TOP LEVELS ARE KEPT AT RAIL

BO

BO

SUITE TO SITE 150X150X25 THK

6500

4000 4000 4000

7000

LINKS 8TOR 300 C/C RAIL FORMATION LVL. 2ISMC 150 150X150X25 THK

Ø20 58 450 58 450 58 PLATE PLATE 2ISMC 150 250

PER ROD

FORMATION LEVEL.

6500

00 00

ISMC 300 B/B

ISMC 300 B/B

00

ISMC 300 B/B

BOTH WAYS

10000

2750

58

ISMC 300 B/B

ISMC 300 B/B

ISMC 300 B/B

ISMC 300 B/B

ISMC 300 B/B

ISMC 300 B/B

ISMC 300 B/B

ISMC 300 B/B

ISMC 300 B/B

ISMC 300 B/B

ISMC 300 B/B

ISMC 300 B/B

ISMC 300 B/B

ISMC 300 B/B

ISMC 300 B/B

ISMC 300 B/B

ISMC 300 B/B

ISMC 300 B/B

ISMC 300 B/B

ISMC 300 B/B

ISMC 300 B/B

PER ROD

250

Ø20 00 F1 F1 F1 F1 F1 F1

2500

12 tor 150 C/C

ISMC 300 B/B

ISMC 300 B/B

ISMC 300 B/B

ISMC 300 B/B

ISMC 300 B/B

ISMC 300 B/B

ISMC 300 B/B

ISMC 300 B/B

ISMC 300 B/B

ISMC 300 B/B

ISMC 300 B/B

ISMC 300 B/B

ISMC 300 B/B

00 RH16 RH17 2ISMC 150

2750

2750

4000

4000

4000

9500

6000

2ISMC 150

41O11'40'' 00 B/W TOP & BOTTOM 41O11'40'' 41O11'40'' 41O11'40'' 24. GRADE OF CONCRETE=M25, THE GRADE OF PCC=M20, THE GRADE OF STEEL FE500 AS PER IS

300

11000

PER ROD PER ROD

9800

150

13140

14600

13140

1&9

1&9

C/L OF CARRIAGEWAY

4000

4000

MIN.

FND BOTTOM LVL: F F F F F 1786-2008.

C/L OF CARRIAGEWAY C/L OF CARRIAGEWAY C/L OF CARRIAGEWAY

7000

99.957 M20-150 THK PCC

13140

16100

2750

END CROSS BEAM

25. NO WELDING SHALL BE DONE AND TEMPORARY GIRDERS/BEAMS WILL BE SIMPLY SUPPORTED

2500

RH17 RH17 RH17 700 150

F1

F1

6000

2750

2750

300

RH16 RH16 RH16 MIN.

ON TRESTLES.

BOTH FACE

BOTH FACE

875

B3-4 ISMB600

B3-4 ISMB600

B3-4 ISMB600

B3-4 ISMB600

14 14 14 14

''M''

ISMC 100

ISMC 100

C 100 CE

C 100 CE

625

00 00 00 00

ISM TH FA

ISM TH FA

30DIA. BAR WITH THREAD 30DIA. BAR WITH THREAD

26. LIFTING JACKS SHALL BE OF 250MT CAPACITY. ACTUAL CAPACITY REQUIRED 60MT.

6570

6570

0 =2800= 300 TH COMPACTED 0 0 0

CL VERTICALS

3000 AT TOP AND BOTTOM

950

2500

BOTTOM LONG.BEAM BOTTOM LONG.BEAM AT TOP AND BOTTOM

LAYER OF MOORUM

BO

BO

HSFG 10.9 GRADE

L BEARING

1505 1756 1750

HSFG 10.9 GRADE

2800 150 FOUNDATION DETAILS FOR -F2 150 35

74 OF BSG OF BSG 27. FOR DETAILS OF CC CRIB CONNECTIONS, CLAMP ETC.. USED FOR TEMPORARY ARRANGEMENT

''N''

6500 300

300

F1 F1

875

6500 SECTIONAL VIEW

F3 F2 F2 F2 F2 F2 F2 F2 F3 F3 600 JACK-250MT

F2 F2 F2 F2 F2 F2 F2 JACK-250MT

F3 600 600 F2 JACK-250MT F2 F2 JACK-250MT

F2

600

F3 F2 F2 F2 F2 F2 F2 F2 F3 REFER RDSO DRG NO-RDSO/B-1484/4R.

625

30DIA. BAR WITH THREAD 30DIA. BAR WITH THREAD

2750

2300

150 150

C

3000 AT TOP AND BOTTOM AT TOP AND BOTTOM 28. DIRT WALLS SHOULD NOT BE CONSTRUCTED BEFORE ERECTION WORK AND PROVISION FOR

2750

3000

3000

1800

1800

G 13 G G 13 G G 13

SQ.

SQ.

3000 HSFG 10.9 GRADE HSFG 10.9 GRADE

150

98 98 9 2000 ANCHORING THE WINCHES ON ABUTMENTS SHOULD BE DONE.

44000 3000 B1-3 8ISMB600

2260

7 B1-3 ISMB600 7 B1-3 ISMB600 7 B2-4 ISMB600 B1-3 ISMB600 B1-3 ISMB600

ROLLERS

6500

730

TYP.

F2

F2

8150* 8

BEARING C/C Ø PLATE-25THK PLATE-25THK WOODEN PACKING AS PER IS 883-1994 PLATE-25THK WOODEN PACKING AS PER IS 883-1994 900 29. IN CASE PULLING WINCH-2X50MT IS NOT ACCOMMODATED ON ABUTMENT, SAME MAY BE

GIRDER BOTT.

PLATE-25THK

6500

M20-150 THK PCC

10000

20

GIRDER TOP.

2750

610 1000 Ø20 00 PULLING WINCH AR1 RESTRAINING WINCH PULLING WINCH AR1 RESTRAINING WINCH PULLING WINCH AR1 RESTRAINING WINCH 250 WIDE 250 WIDE END FACE PL. 250 WIDE END FACE PL. 250 WIDE

FIXED ON GROUND AT APPROPRIATE PLACE FOR EASEMENT OF PULLING.

2750

9500

END FACE PL.

606 00 35 STIFF. PL. 8 25THK-450 WIDE 8 25THK-450 WIDE END FACE PL.

3 @ 600 = 1800 CAPACITY-50MT CAPACITY-50MT CAPACITY-50MT CAPACITY-50MT CAPACITY-50MT STIFF. PL.

:108.657*

:107.407*

370 720 74 CAPACITY-50MT 20THK-200X400 25THK-450 WIDE 8 25THK-450 WIDE

12 12 12 12 20THK-200X400

50 1000 827 50 AR2 50 AR2 CRANE

50 AR2

WEDGE (IS 883-1994) FIXED TO RAILS 25Ø BOLT-10.9 Gr.

25Ø BOLT-10.9 Gr. STIFF. PL.

20THK-200X400

25Ø BOLT-10.9 Gr. STIFF. PL.

20THK-200X400

FLANGE PLATE-20THK 30. FORCE ON EACH PULLING AND RESTRAINING WINCH IS 3.57MT. CAPACITY OF 50MT IS

AR1 0

740 733 M25-300 THK RCC 0 0 250MT 0 HSFG HSFG

HSFG WEDGE (IS 883-1994) FIXED TO RAILS ADOPTED AT SITE AT EACH POINTS. ALL WINCH SHALL BE POWER DRIVEN TYPE ONLY. ENGINEER

2750

WITH REMOVABLE C-TYPE

UR2 UR2 UR2 1050

WITH REMOVABLE C-TYPE 25Ø BOLT-10.9 Gr. WEB PLATE-16THK @ 250 C/C

2750

RAIL CLAMPS 12 THK STIFFENER 12 THK STIFFENER

UR1 UR1 UR1 500 ROLLER FRAME RAIL CLAMPS 500 HSFG AT SITE SHALL ENSURE GOOD CONDITION OF WINCH AND ITS PARTS AT TIME OF LAUNCHING

875

(TYP.) (TYP.)

AR2 MIN. MIN. ROLLER FRAME

625

ROLLER 100T CAPACITY

OF BSG. THE BSG SHALL BE PUSHED AT THE RATE OF 173.2 MM/SEC.

3 @ 600 = 1800

BRACINGS RESISTANCE GUIDE ROLLER GUIDE ROLLER RESISTANCE

FORCE =5MT FORCE =5MT

300

300

ISMC100 BRACKET BRACKET

1550 1250 8MM WELD ROLLER FRAME ROLLER FRAME 31. STEEL WIRE ROPE CONFORMING TO (IS-14268-1995) SHALL BE TIED AT TOP CHORD (RIDGE OF

3000

434 ALL ROUND

UR2 100X700X16 THK PL. GUIDE ROLLER GUIDE ROLLER 100X700X16 THK PL.

A2 BOW) ON BOTH SIDES OF BSG TO ENSURE STABILITY AGAINST UNDULATIONS / UNSYMMETRICAL

PLACED IN GROOVE I/S MS C-TYPE CLAMP-300MM 8 A2 8 PLACED IN GROOVE INSIDE MS C-TYPE CLAMP-300MM

52Kg RAIL ROLLER 100T CAPACITY 52Kg RAIL ROLLER 100T CAPACITY

UR1 10 11 12 13 14 15 16 17 18 1 2 3 4 5 6 7 8 9 GUSSET PL. 10 11 12 13 14 15 16 17 18 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 1 2 3 4 5 6 7 8 9 WOODEN SLEEPER AS PER IS:2062-2011

WOODEN SLEEPER

AS PER IS:2062-2011 ACTIONS DURING MOVING / PULLING CONDITION.

STAGE BEFORE LAUNCHING : WOODEN MAT @500mm C/C WOODEN MAT @500mm C/C

PLAN BEFORE LAUNCHING AS PER GAD

375

-10THK.

(250X150) OVER ISMB 600 (250X150) OVER ISMB 600

376

1. PREPARE WELL COMPACTED LEVELED GROUND UP TO TRACK NOTE: PLAN OF 2nd STAGE GUSSET PL. BRACINGS PLAN OF 4th STAGE PLAN OF 6th STAGE 100X700X16 THK PL. AT ALL SPANS

WOODEN PACKING

100X700X16 THK PL. AT ALL SPANS

WOODEN PACKING

SPECIAL NOTES

-10THK. PLACED IN GROOVE INSIDE 8 PLACED IN GROOVE INSIDE

FORMATION LEVEL AS SHOWN FOR ASSEMBLY OF BOW STRING GIRDER FOLLOWING ARE THE SUB-STRUCTURE DETAILS AS PER SITE EXECUTION: ISMC100

CC CRIBS

WOODEN SLEEPER 25X25X50LONG

J BOLT-20Ø

WOODEN SLEEPER 25X25X50LONG

J BOLT-20Ø

BATTEN PL.16THK BATTEN PL.16THK

8MM WELD 275 500 500 500 500 500 500 500 500 500 500 500

OVER CC CRIBS. ALL ROUND

BATTEN PL.16THK

150 WIDE 27Ø HOLE FOR 25Ø BOLT 150 WIDE 27Ø HOLE FOR 25Ø BOLT 1. ALL THE CRIBS TO RDSO DRG.NO.B-1484/4 SHOULD BE USED. UNEVEN AND BLUNT EDGE CRIBS

BATTEN PL.16THK

2. SOIL BEARING PRESSURE OF AS MENTIONED SHALL BE ENSURED AT SITE. 1. LHS SPAN OF BSG WILL NOT BE CONSTRUCTED TILL BSG LAUNCHING OPERATION. 150 WIDE HARD WOOD SLEEPER

8

840

THROUGHOUT @ 1000 C/C

840

THROUGHOUT @ 1000 C/C

150 WIDE HARD WOOD SLEEPER ARE NOT PERMITTED. MONOLITHIC ACTION OF CRIBS SHOULD BE ENSURED BY PROVIDING

500 C/C 250x150x900 @ 500 C/C GIRDER O/O 3-ISMB600 BATTEN PL. -2X16THK 4-ISMB600 500 C/C 250x150x900 @ 500 C/C

NECESSARY SOIL STABILIZATION & COMPACTION SHALL BE CARRIED 2. RH16, RH17, UR1 & UR2: PIER AND PIER CAP COMPLETED AT SITE. LAUNCHING GIRDER

3 ISMB600

27Ø HOLE FOR 25Ø BOLT

-1000LG.-150WIDE @ 500C/C

DOG SPIKES GIRDER O/O

27Ø HOLE FOR 25Ø BOLT LAUNCHING GIRDER SUITABLE HORIZONTAL AND VERTICAL BRACING ON TOP AND FOUR SIDES WITHOUT

150

THROUGHOUT @ 1000 C/C 4 ISMB600

THROUGHOUT @ 1000 C/C

OUT BY ENGINEER-IN CHARGE AT SITE TO ENSURE SBC IS MORE THAN THE 3. LH16, LH17 ONLY PIERS CASTED AT SITE. INFRINGING THE RUNNING TRACKS. ENGINEER AT SITE SHOULD ENSURE THE SPECIFICATION OF

DETAIL-M DETAIL-N HW PACK

MAXIMUM PRESSURE AT FOUNDATION LEVEL OF CRIBS. 4. DR1, DR2 FOOTING & PIER NOT CASTED AT SITE. FOUNDATION DETAILS FOR -F2 RDSO/B-10414/R RDSO/B-10414/R 1800 SQ.-150MM THK. HW PACK

ON CC CRIBS

1800 SQ.-150MM THK. ON CC CRIBS

CRIBS.

BATTEN PL.16THK

5. AL1 & AL2 (BSG PIERS) NOT CASTED AT SITE. SAME NOT SHOEN IN FURTHER PLAN VIEW SEC A3-A3 150 WIDE DETAIL-X1 FOR GIRDER A5 SEC A5-A5 2. THE TEMPORARY ARRANGEMENT HAS BEEN CHECKED FOR CONSIDERING THE SELF WEIGHT OF

TO MYSURU TO MYSURU TO MYSURU A3

STAGES OF LAUNCHING. AT BEARING LOCATION OF BSG (4-ISMB 600) AT EACH VERTICAL HANGERS OF BSG THE STRUCTURE EXCLUDING DECK SLAB AND CONSTRUCTION LIVE LOAD.

9000

9000

DETAIL-X1 FOR GIRDER

L BEARING

3600

6. ALL THE GIRDERS AND SLABS WILL BE ERECTED ONLY AFTER BSG LAUNCHING. 10 THK PLATE FLANGE PLATE-20THK (3-ISMB 600) 680 3. THE SUPER IMPOSED DEAD LOAD i.e, WEARING COAT , R.C.PARAPET, FOOT PATH HAVE NOT

188

7. FURTHER STAGES ONLY SUB-STRUCTURE DETAILS WILL BE SHOWN IN PLAN AND CC CRIBS CONNECTIONS & 12

188 12 60 475

BEEN TAKEN FOR DESIGN PURPOSE.

10

20

CLAMPING ARRANGEMENT AS 12 THK PLATE

ELEVATION AS PER SITE EXECUTION TILL DATE. TO HASSAN TO HASSAN "DETAIL-S" TO HASSAN 6 6

PLATE 700x100X16 THK.

700

8

4. THE ENGINEER-IN-CHARGE SHALL ENSURE THAT THE INDIVIDUAL CRIBS ARE INTERCONNECTED

C

PER RDSO/B/1484/4R1 12 THK PLATE

R75

66 TYP.

TO HASSAN 600 600 BSG BOTTOM CHORD

8. BSG LAUNCHING WILL BE DONE ONLY FOR RHS SPAN. CC CRIBS WITH ISA 75X75X8 STIFF. ANGLE 100X100X10 60 35

8 J-BOLT 20 DIA WITH SUFFICIENT NUMBER OF CLAMPS AND PROPERLY BRACED. BEARINGS SHOULD BE

243

GIRDER TOP. GIRDER TOP. 600 GIRDER TOP. 10 THK PLATE TYP. HSFG 8.8 Gr.

600

232

600 SQ EACH BLOCK WELDED 6THK TO GUSSET PL. & WEB PLATE-16THK

250

6760 45600 PIER C/C 6760 45600 PIER C/C 6760 45600 PIER C/C PROPERLY PROTECTED WHILE LAUNCHING OF BSG.

100

104810

200

:108.557* JACK-250MT :108.557* JACK-250MT :108.557* 100

45600 PIER C/C CRIB LEG

160

TO MYSURU 12 THK PLATE 12 THK PLATE 100Ø40 THK

44000 BEARING C/C

B1- 3 ISMB600 ISMC100 6 B1- 3 ISMB600 MS SQ. BAR "DET-A" B1- 3 ISMB600 B2- 4 ISMB600 B1- 3 ISMB600 MS ROLLER STIFF. PLATE-12THK 5. CONTROLLED CONCRETE WITH WEIGH BATCHING SHALL BE USED AND THE WORK SHALL BE

2400*

2400*

CRIB CAPS WITH ISMC-100 808 6 451 PLATE-C: 39

10

44000 BEARING C/C GIRDER BOTT. 6 44000 BEARING C/C GIRDER BOTT. 44000 BEARING C/C GIRDER BOTT.

42000 CLEAR SPAN

25 DIA HOLDING UNDER EACH CRIB

BOG LEVEL : 106.52 :107.657* BOG LEVEL : 106.52 :107.657*

1000 X 25 X 25

1075X910X25 BOG LEVEL : 106.52 :107.657* 88

100 ØX40 THK

27

25.5Ø HOLE SUPERVISED BY AXEN HAVING EXPERIENCE IN BRIDGE CONSTRUCTION .

500

250

DOWN BOLTS ISMC 100 A4 A4 J-BOLT 20 DIA HARD WOOD SLEEPER

ISMC100

610 BOG LEVEL : 106.52 1800 1800 1800 ''Y'' 1800 1800 1800 1800 1800 1800 1800 ''Y'' 1800 1800 1800 1800 1800 1800 1800 BOTH FACE 1800 1800 1800 1800 ''Y'' 1800 1800 1800 1800 10 THK PLATE 188 95 6. THE GRADUAL RELEASE OF SPEED RESTRICTIONS SHALL BE AS PER PARA 637(1)(f) OF INDIAN

365

250x150x900 @ 500 C/C

477

827 LINKS 8TOR 250 C/C RAIL FORMATION LVL. 700

PIER TOP :106.033 PIER TOP :105.640 42000 CLEAR SPAN

SQ. SQ. SQ. SQ. SQ. SQ. SQ.

42000 CLEAR SPAN

SQ. SQ. SQ. SQ. SQ. SQ. SQ. SQ. SQ. SQ.

42000 CLEAR SPAN

SQ. SQ. SQ. SQ. SQ. SQ. SQ. SQ.

12

BOTH WAYS

RAILWAY PERMANENT WAY MANUAL.

20

PIER TOP :105.421 12 tor 125 C/C DETAIL OF GUIDE ROLLER

SECTION A4-A4 DETAIL OF ROLLER FRAME

2192

2000

ISMC 100 ISMC 100 ISMC 100 ISMC 100 ISMC 100 ISMC 100 ISMC 100 ISMC 100 ISMC 100 ISMC 100 ISMC 100 ISMC 100 ISMC 100 ISMC 100 ISMC 100 ISMC 100 ISMC 100

2493

200

900

PIER TOP :105.261 J-BOLT 20 DIA

1090

2100

1473 BOTH FACE BOTH FACE BOTH FACE BOTH FACE BOTH FACE 200 BOTH FACE BOTH FACE BOTH FACE BOTH FACE BOTH FACE M20 DIA BOLTS BOTH FACE BOTH FACE BOTH FACE BOTH FACE BOTH FACE BOTH FACE BOTH FACE

B/W TOP & BOTTOM 7. NEW STEEL CRIBS OF SIZE 600 X 600 X 1800 SHALL BE USED AND CRIBS ALREADY DISTORTED OR

450

7265*

6525

6525

6525

1400 GUSSET PL.-8THK C 100 CE

HSFG 8.8 Gr.

900 900

250

1000

100

VC

3600X1800 3600X1800 3600X1800 3600X1800 52 Kg RAIL WITH NUTS ISM TH FA 3600X1800 3600X1800

6525

''X'' ''X'' ''X''

1000 1280 GUSSET PL.-8THK

FND BOTTOM LVL: BO

DAMAGED WITH BENT ENDS SHALL NOT BE USED.

8150*

8150*

8150*

8150*

8150*

8150*

2700 1050 99.807 M20-150 THK PCC

600

2800 0 0 0 E 0 WOODEN SLEEPER 0

10 CE

0

10 CE

3300 2800 10 CE

C 100 CE C 100 CE C 100 CE 10 CE DETAIL-X 10 C

C 100 CE C 100 CE C 100 CE 10 CE

C 100 CE C 100 CE C 100 CE C 100 CE C 100 CE 8. CC CRIBS ARE DESIGNED FOR HEIGHT OF 11M MAXIMUM.

3774

5694

19130 (SK) 7708 (SK) 7708 (SK) 9254 (SK) C FA C FA DETAIL-Y 19130 (SK) 7708 (SK) 7708 (SK) 9254 (SK) C FA

ISM TH FA ISM TH FA C FA 19130 (SK) 7708 (SK) 7708 (SK) ISM TH FA 9254 (SK) C FA

ISM TH FA ISM TH FA C FA

3141

ISM TH FA ISM TH FA ISM TH FA

300

ISM TH ISM TH FA ISM TH FA ISM TH FA ISM TH @ 500 C/C ISM TH

ISM TH ISM TH ISM TH

13380 (SK) 7708 (SK) 7708 (SK) 15003 (SK)

5521

1200 BO BO BO BO BO BO BO BO 52 KG RAIL TO BE ATTACHED

PULLING 14396 (SQ) 5800 (SQ) 5800 (SQ) 6964 (SQ) BO BO BO BO BO RESTRAINING PULLING 14396 (SQ) 5800 (SQ) 5800 (SQ) 6964 (SQ) BO BO RESTRAINING PULLING 14396 (SQ) 5800 (SQ) 5800 (SQ) 6964 (SQ) BO BO RESTRAINING Foot Path

9. * DIMENSIONS SHOWN ARE TO BE VERIFIED AT SITE DURING EXECUTION.

10069 (SQ) 5800 (SQ) 5800 (SQ) 11290 (SQ) 1200 2000 PL. 900X10THK WITH ISMB-600 Divide

r

WINCH -2X50MT FGL :99.510 WINCH -2X50MT WINCH -2X50MT FGL :99.510 WINCH -2X50MT WINCH -2X50MT FGL :99.510 WINCH -2X50MT Road

2000 1676 1676 RL :99.995 1676 1676 1676 RL :99.995 1676 8 1676 1676 RL :99.995 1676 SEC. A2-A2

300

300

300

300

300

300

300

300

300

300

300

300

300

300

300

300

300

300

300 TH COMPACTED

10. ENGINEER IN-CHARGE SHALL ENSURE THE GOOD CONDITION & CONFIRM THE ADEQUACY OF

300

300

300

300

300

300

300

M20 DIA BOLTS

450

450

450

450

FGL :99.920 FGL :99.920 FGL :99.920

450

450

FGL :99.510 6000 FGL :99.810 FGL :99.810 WOODEN PACKING FGL :99.810

1676 1676 RL :99.995 1676 FGL :99.920 LAYER OF MOORUM F3 F2 F2 F2 F2 F2 F2 F2 F3 F3 F2 F2 F2 F2 F2 F2 F2 F3 F2 F2 F2 F1 1F F2 F3 F2 F2 F2 F2 F2 F2 F2 F3

FGL :99.810 150 FGL :99.740 FGL :99.740 -25 THK FGL :99.740

EACH ELEMENTS (ROPE, HOOK. CRANE ETC..) USED IN REGARDS TO LAUNCHING OF BSG.

450

054

FGL :99.740

150 FOUNDATION DETAILS FOR -F3 FRL :99.257 FRL :99.257 FRL :99.257

750

750

750

650 650 PACKING PL.

750

750

750

650 650 FRL :99.257 FND LVL: 6000 3000 3000 3000 3000 3000 3000 3000 6000 FND LVL: FND LVL: 6000 3000 3000 3000 3000 3000 3000 3000 6000 FND LVL: FND LVL: 3000 3000 3000 3000 6000 3000 3000 3000 3000 3000 3000 3000 6000 FND LVL:

SECTIONAL VIEW STOPPER PL. 4000 0004

11. FOR ANY CC CRIB INFRINGEMENT WITH EXISTING PIER/PIER CAP, SAME SHALL BE SUITABLY

4000

98.507 98.507 98.507 98.507 98.507 98.507 Path

100X50WIDE-20THK

5000

3000 3000 3000 3000 3000 3000 Foot

BR

Divider

150 150 8 8 Road

4800

@ 500 c/c

18604 (SK) 16611 (SK)

6000 24353 (SK) 10861 (SK) 24353 (SK) 10861 (SK) 24353 (SK) 10861 (SK)

san

Bus

Sta

nd

SHIFTED/RELOCATE AT SITE BY ENGINEER IN-CHARGE.

14000 (SQ) 12500 (SQ) 14000 (SQ) 12500 (SQ) 14000 (SQ) 12500 (SQ)

150

Foot Path

4700

1000

Has

6000

14000 (SQ) 12500 (SQ)

5900

2500 52 Kg RAIL 8

1000

2500 3000

t

Exi

FND LVL :94.510 FND LVL :94.510 CLUSTERS FND LVL :94.510 SAFETY NOTES

nd

1200

3000 M20-150 THK PCC

s Sta

FND LVL :94.510

1200

6500 AR1 AR1 AR1

Bu

6 @ 600 = 3600 FND LVL :93.920 FND LVL :93.920 FND LVL :93.920 Foot

Path

FND LVL :93.920 7500 FND LVL :93.810 FND LVL :93.810 FND LVL :93.810

AR2 AR2 BATTEN PL.16THK AR2 er Path

1. ADEQUATE SAFETY MEASURE FOR RUNNING TRAIN SHALL BE ADOPTED WHILE DOING THE EARTH

Foot

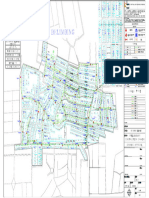

CL OF PRO. ROB IN LIEU OF LC No.3

Divid

FND LVL :93.810 FND LVL :93.740 FND LVL :93.740 27Ø HOLE FOR 25Ø BOLT FND LVL :93.740

CH:857

CAUTION INDICATOR

Road

AR1 6500 M25-450 THK RCC 150 WIDE

FND LVL :93.740 RH17 RH17 THROUGHOUT @ 1000 C/C RH17 BETWEEN HASSAN AND SAKKALESHPURA STATIONS

AR2 6500 RH16 RH16 RH16 WORK BELOW THE TRACK.

ELEVATION BEFORE LAUNCHING AS PER GAD RH16

RH17 800 m 715 m

r Cons

tructi

on

2. DURING CONSTRUCTION OF BRIDGE THE EXISTING TRACK SHALL BE PROTECTED SUITABLY BY

EP

4-ISMB600 der Unde Court

CH:1627

SPEED INDICATOR

d Divi District

3 @ 600 = 1800

DOG SPIKES Roa

IMPOSING NECESSARY SPEED RESTRICTION BY PROVIDING TEMPORARY ENGINEERING

TERMINATION

30 m t Path

INDICATOR

10 11 12 13 15 16 17 18 1 2 3 4 5 6 7 8 9 10 11 12 13 15 16 17 18 1 2 3 4 5 6 7 8 9 10 11 12 13 15 16 17 18 1 2 3 4 5 6 7 8 9 Foo

try

CH: 2422

INDICATORS.

En

83.63

RD

RD

83.633

3000

nd

er

s Sta

Divid

d

30

Roa

3. DURING CONSTRUCTION OF PROPOSED BRIDGE PROPER SAFETY PRECAUTIONS TO BE TAKEN

Bu

HW PACK

T

HSFG BOLT

24 DIA-8.8GR. LENGTH OF STAGE-2 STAGE-4 1800 SQ.-150MM THK.

ON CC CRIBS STAGE-6 SKLR SC

mP ER

Foot

Path

WHILE EXECUTING FOUNDATION WORK CLOSE EXISTING FOUNDATION INCLUDING IMPOSING

EACH BOLT = 675 mm 30 RD

CC CRIB ELEVATION ALONG GRID- E ELEVATION ALONG GRID- E ELEVATION ALONG GRID- E HAS GI

OF SPEED RESTRICTION IF REQUIRED.

DETAIL- S SC

200

mP R

ANGLE-75X75X8

(REFER STAGE-4 FOR MARKING)

20 DE

GIR 4. THE GRADUAL RELEASE OF SPEED RESTRICTION SHALL BE AS PER PARA 637(1)(f) OF IRPWM.

Ch:1682

RAIL FORMATION LVL. lex

Foo

t Path

PS

m ER

C

ial

Co

mp 5. NECESSARY SHORING ARRANGEMENTS TO BE MADE TO PROTECT EXISTING BRIDGE STRUCTURE

300/450

30 RD erc

WHEREVER NECESSARY.

SPEED INDICATOR

225

GI mm

Co

ri

T

6. JOINT PROCEDURE ORDER ON SAFETY RELATED ISSUES PERTAINING TO WORK SITE IN

TERMINATION

wa

de ly

CH:1737

INDICATOR

am Supp

sh

CAUTION INDICATOR

30

150

CH:942

CONSTRUCTION PROJECTS (Lt. No. W339/SAFETY PRECAUTION Dt: 18-02-2011) VIDE CTE Lt. No.

un

i Ch ty

ri e

Sr ctrici

sh offic

250

r

ide

Div

SWR/W.247/SAFETY AT WORK SPOT Dt: 20-06-2017 IS TO BE STRICTLY FOLLOWED.

wa

Ele

de ly

ad

un pp

BOW STRINGER GIRDER

FIXING ARRANGEMENT OF ANCHOR BOLT

30 m

CH:2507

Ro

13140

am y Su

FOUNDATION DETAILS FOR -F3 BOW STRINGER GIRDER

13140 7. DURING EXECUTION OF WORK THE MATERIAL / EQUIPMENTS SUCH AS RELEASED MATERIALS

i Ch cit

WITH CC CRIB AND RCC SLAB

h

t Pat

Sr tri

BEARING C/C

5

PLAN VIEW BOW STRING

50.00 m

ec

Foo

715 m 800 m

Ø7

WEDGE FIXED TO RAILS BEARING C/C ETC. SHOULD NOT INFRINGE THE TRAIN. ALL SAFETY MEASURES TO BE TAKEN BY ENGINEER - IN -

El

910 =12500= 2700

RE PANEL APPROACH

GIRDER (BSG)

2 4 6 8 10 12 14 16 18 IS 883-1994 =12500= BEARING

730

ISA 130x130x10 120 @ 5 = 600 720 1000 CHARGE DURING EXECUTION.

150

LAUNCHING GIRDER

300 800 SQ. ABT

250T CAPACITY DR-

5500 5500 5500 5500 5500 5500 5500 5500

JACK. ACTUAL FORCE-60T 8. SUITABLE SAFETY BARRICADING IS REQUIRED TO BE PROVIDED WHENEVER WORK IS BEING

M20 BOLTS

KEY PLAN SHOWING THE TRACK PROTECTION DIAGRAM,

25

52 Kg RAIL BOTTOM CROSS BEAM

100

130 WEB

DR-4

700 EXECUTED PARALLEL TO THE RUNNING TRACK.

1100

HSFG 8.8 Gr.

BOTTOM CROSS BEAM

SQ.

44000

MIN. (PARA 807, 808, 814, ANNX-8/3 OF IRPWM-2020)

2300

55

BEARING C/C WOODEN PACKING (WRAPPED ALL ROUND 9. SAFETY PRECAUTIONS MUST BE ENSURED AS PER ABOVE RELEVANT JPOs OF ZONAL RAILWAY

41 0K 0m

CH:1/600

WOODEN PACKING AT

62 ILS

STAGE-5

ABT

2.5 1.3 mph

10 5.0

TA

AL3

0% 8m

3

BOW STRING

LE EE S DE

250T CAPACITY (NOT TO SCALE)

DR- ABT

JACKING LOCATION WITH HARD METAL STRIP PLATE SAFETY WOODEN BLOCKS 600 AND INSTRUCTIONS OF RAILWAY BOARD.

SP DIU E

156

AR3

600

RA RV

BEARING LVL BEARING LVL GIRDER (BSG)

CU

8 ABT

JACK.

SE NG D

TH

AGAINST DISLOCATION OF BLOCKS) 1000x1000

50

LH1 UR

C/L OF BEARING

106.520 106.520 JP 10. WORKING AREA SHALL BE BARRICADED TO ENSURE SAFETY OF TRACK OPERATION ON

2400*

WOODEN BLOCKS NOTE: NECESSARY TEMPORARY ENGINEERING INDICATORS VIZ. CAUTION, SPEED AND TERMINATION

18

2 RH

C/L OF BEARING

DR-

1. CENTER LINE OF REMAINING CRIB SUPPORTS SHALL BE MARKED AS SHOWN IN RUNNING LINES.

1200

1200

C/L OF BEARING

250T CAPACITY 1000x1000

UR3

RDSO/B-10414/R INDICATOR WITH RETRO REFLECTIVE TO BE PROVIDED SUITABLY BY ENIGNEER-IN CHARGE AT THE APPROACHES 7

LH1

50

PLAN AND ELEVATION. 50 55 25 JP RCC PEDESTAL JP JP RCC PEDESTAL JP JACK. ACTUAL FORCE-60T 610 1090

B

610 11. WHILE CARRYING OUT PREPARATORY WORK AT PLATFORMS NECESSARY PRECAUTIONS

17

ARRESTING OF BSG

1 SLA

Bridge

RH

DR-

MS C-TYPE CLAMP-300MM 6

C/L OF PIER

2

LH1 UR

FOUNDATION LIST 2. RCC SLAB SHALL BE CAST FOR REMAINING CC CRIBS.

130

RCC PEDESTAL SHOULD BE TAKEN TO AVOID UNSAFE CONDITIONS.

t Path

130

55

1800

1800

ISMC 300 B/B AS PER IS:2062-2011

2

Bridge

Foo

6525

6525

AL- 16

STAGE-3 3. REMAINING CC CRIBS ALONG WITH BRACING SHALL BE ERECTED AS SHOWN IN 12. PROTECTIVE SCREEN OF STANDARD DIMENSION TO BE PROVIDED ALONG THE ENTIRE LENGTH

RH

14600 14600 1100 SQ.

1100

R

UR1

STAGE-1

DE

2192

2000

1 2 3 4 5 6 7 8 9

25

THE PLAN AND ELEVATION.

GIR

TYPE SIZE SECTION J1-J1 LAUNCHING GIRDER OF PROPOSED FOB / ROB OVER THE TRACK WITHOUT ANY GAP.

TRACK

OF

CL

0M

G

RIN

0.0 2

4. LAUNCHING GIRDER- B1 & B2 FOR THE REMAINING CC CRIBS SHALL BE ERECTED 1090 1000

AR-

WOODEN BLOCK

44

5500 5500 5500 5500 5500 5500 5500 5500 13. ERECTION / LAUNCHING WORK OVER RUNNING LINE SHALL BE CARRIED OUT UNDER TRAFFIC

ST

ILS 0m

TA 0.0 ph

TRACK

W

OF

1. CC CRIB COLUMNS WITH FOOTING-F3 ALONG GRID- B & D LOCATIONS

CL

DE 11 Km 0m

MS PLATE - R 700

BO

J2 MS 1200 LG. PLAN VIEW OF DETAIL-A E 45 4.3

R

USING CRANE OF 1X150MT CAPACITY AS SHOWN IN PLAN AND ELEVATION BOTTOM MAIN BEAM

DE

BLOCK UNDER THE SUPERVISION OF CONCERNED DyCE.

RV

LC.NO : 3 AT

Km:1/600-700

1'40"

10 %

d

CU DIUSD

1. CENTER LINE OF CRIB SUPPORTS SHALL BE MARKED AS SHOWN IN DRG.

Roa

2.5

700x300x25 250

GIR

41°1

44000 130 C- CLAMP

F1 4000X4000X450 SHALL BE BUILT SIMULTANEOUSLY STAGE BY STAGE WHILE LIFTING OF BSG. ISA 130x130x10 OF BOWSTRING GIRDER 6000 6000 RA EE TH

250

alt

LAUNCHING GIRDER

G

SP NG

Asph

M20 BOLTS

WITH POWER AND LINE BLOCK OF 2 HOURS. 125

RIN

00

2. RCC SLAB SHALL BE CAST FOR SUPPORTING THE CC CRIBS. ALL TOP BEARING C/C J1 50 55 25 J1 MS BAR

LE

SE

CH:1/7

14. IN ELECTRIFIED TERRITORY EARTHING TO BE DONE AND CERTIFIED BY TRD OFFICIALS BEFORE

ST

2. CC CRIB COLUMN WITH FOOTING-F3 ARE TO SUPPORT BSG WHILE HSFG 8.8 Gr. MS PL.-Q: 20THK 2700

W

42000

Ø75

5. THE BSG SHALL BE PULLED USING WINCH OF CAPACITY 2X50T CAPACITY TILL IT 600 x 25 x 25 PLATE - S

BO

ER-3 TE

POWER BLOCK IS CANCELED.

ROB IN LIEU OF

GIRD POSI

LC.NO : 3 AT Ch:1682

0M

FOUNDATIONS SHALL BE MAINTAINED AT FORMATION LEVEL. -225X250

RE PANEL APPROACH

COM

Chain

Pully

BUILDING UP OF CRIB. CC CRIB COLUMNS ALONG GRID- A ARE REQUIRED WELDED 525 x 375 x 25 RAIL LVL: 99.995 RAIL LVL: 99.995 EFF. SPAN IMP. NOTE:

lt Road

5

C/L OF BEARING

40 40

d

REACHES PIER BEARINGS CENTERS OF AR1 & AR2 AS SHOWN IN PLAN AND 120 @ 6 = 600

Roa

P1

15. GIRDER MUST BE ADEQUATELY SECURED IMMEDIATELY AFTER LAUNCHING.

C/L OF BEARING

CC CRIB CONNECTIONS, CLAMPS etc..

F2 3000X3000X300

TE

3. CC CRIBS SHALL BE ERECTED FOR THE FOOTINGS FOR ABOUT 1200MM AS

300

WEDGE FIXED TO RAILS

GIRD POSI

8

8M

80

alt

Aspha

WHILE PUSHING THE BSG.

ER-1

HYDRULIC JACK 1200

COM

RDSO/B1-1484/4R1

Asph

ENGINEER IN CHARGE AT SITE SHALL CONFIRM

ER

SC

GIRD

ELEVATION WITH POWER AND LINE BLOCK OF 2 HOURS.

20mP

Wall

16. WORK HAS TO BE EXECUTED UNDER SUPERVISION OF AN EXPERIENCED AND COMPETENT

375

Compound

SHOWN ALONG GRID A TO D ONLY AT THE LOCATION OF VERTICALS BRACING 30 t CAPACITY

WEB

3

3. ALL THE CRIBS SHALL BE ERECTED UPTO LAUNCHING GIRDER LEVELS AND ISA 75X75X8 ON ALL M20 BOLTS 100 THAT THE "BSG" IS LIFTED/LOWERED P1

P1

Under Construction

HANGERS FOR ASSEMBLING OF "BSG". MIN.

ER C

4 RAILWAY ENGINEER.

School Campus

School Building

FACES WITHIN CRIBS

DETAIL-A (STAGE-6)

GIRD mPS

SIMULTANEOUSLY AT ALL 4-JACKING POINTS TO

St. Philomeina

28 DIA HOLE

Buildings

SHALL BE BRACED AS SHOWN WITH ENSURING NECESSARY WELDING. 3600X1800 3600X1800 ISA 130x130x10 HSFG 8.8 Gr.

17.6

25 55 50

2

ER

F3 6000X3000X450

Don Boscho

P1

SC

ISMC 300 B/B

& Commercial

GIRD

525 17. ADHERENCE OF PROVISIONS OF SOD TO BE ENSURED AND VISIBILITY OF SIGNAL TO BE

20mP

4. CC CRIBS ALONG GRID E TO G SHALL BE ERECTED ALONG WITH J2 ARRANGEMENT AT BEARING AVOID ANY UNSYMMETRICAL JACKING ACTION

8150*

8150*

ER

Institute

PSC

Station

GIRD

7000 7000

Residential

17.6m

Man Hole

1

MH

CHECKED AFTER COMPLETION OF WORK.

P1

MH

TYP. DETAIL OF CROSS BEAM

To RailWay

BRACING, LAUNCHING GIRDER (3 ISMB600) WITH RAIL CLUSTER & ISMC 300 B/B

FOR LIFTING / LOWERING OF BSG AT SUPPORTS.

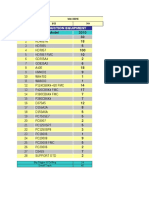

You might also like

- China Huafeng Dongli Zhbzg1Document14 pagesChina Huafeng Dongli Zhbzg1bunpheng hengNo ratings yet

- JCB Seal Kit 3dx Model 2011 Seal Kit 332y 6440Document5 pagesJCB Seal Kit 3dx Model 2011 Seal Kit 332y 6440Anuj Yadav100% (1)

- OSD Span Fabrication Details With PicsDocument17 pagesOSD Span Fabrication Details With PicsIndra Nath MishraNo ratings yet

- Temporary Bus Stop DesignDocument101 pagesTemporary Bus Stop DesignPratheepaArumugam100% (1)

- IrcDocument9 pagesIrcAshwani KesharwaniNo ratings yet

- Nepal's Aerial RopewaysDocument11 pagesNepal's Aerial RopewaysKiran KuikelNo ratings yet

- Structural Designs (Ultimate) : Force Lever Arm Moment V Ult M UltDocument1 pageStructural Designs (Ultimate) : Force Lever Arm Moment V Ult M Ultmbhanusagar.keynesNo ratings yet

- Ngineering Preadsheets - Co.uk: Analysis of Equal Span Continuous Beams With Uniformly Distributed LoadsDocument1 pageNgineering Preadsheets - Co.uk: Analysis of Equal Span Continuous Beams With Uniformly Distributed Loadsjakeer7No ratings yet

- IS 6926 1996 (Core Drilling) PDFDocument12 pagesIS 6926 1996 (Core Drilling) PDFsiidharthkmahajanNo ratings yet

- 2.3 - Geobrugg Spiral Rope AnchorDocument4 pages2.3 - Geobrugg Spiral Rope AnchorArmand J RomeroNo ratings yet

- Two Way Slabs PDFDocument5 pagesTwo Way Slabs PDFmathuNo ratings yet

- Bridge Deck Erection TechniquesDocument27 pagesBridge Deck Erection TechniquesSailaja VempatiNo ratings yet

- Detail Design of RCC Solid Slab For Span 10.6M For Minor Bridge at Ch. 11+120Document17 pagesDetail Design of RCC Solid Slab For Span 10.6M For Minor Bridge at Ch. 11+120siddharth yadavNo ratings yet

- Mean Flange Thickness T Overall Depth DDocument3 pagesMean Flange Thickness T Overall Depth DAkhil BabuNo ratings yet

- NG design analysisDocument4 pagesNG design analysisAnonymous sfkedkymNo ratings yet

- Naag Chandeshwar Bridge-ModelDocument1 pageNaag Chandeshwar Bridge-ModelManvendra NigamNo ratings yet

- SOLID SLAB 8m Span - 16+888Document7 pagesSOLID SLAB 8m Span - 16+888designbridgeeng geo groupNo ratings yet

- Amit Gupta: Himanshu SharmaDocument1 pageAmit Gupta: Himanshu SharmaSaurabh PandeyNo ratings yet

- Capability Report 2022Document21 pagesCapability Report 2022Akhilendra Pratap SinghNo ratings yet

- 3 Detail-1: Reference Drawings / NotesDocument2 pages3 Detail-1: Reference Drawings / NotesTarun MauryaNo ratings yet

- Live Load Analysis: 70R WheelDocument433 pagesLive Load Analysis: 70R WheelShashank SrivastavaNo ratings yet

- DN Nagar Mandala: Viaduct Layout Plan For Pier No. P1 To P18Document1 pageDN Nagar Mandala: Viaduct Layout Plan For Pier No. P1 To P18naba1577No ratings yet

- Bylor Temporary Works Design Cat 1: TWR: HFXDocument48 pagesBylor Temporary Works Design Cat 1: TWR: HFXOvidiu AlexoaeNo ratings yet

- DESIGN OF PLATE GIRDERS USING IS:800-2007Document45 pagesDESIGN OF PLATE GIRDERS USING IS:800-2007Afia S HameedNo ratings yet

- Abutment Type Selection AlgorithmDocument264 pagesAbutment Type Selection Algorithmpabro123No ratings yet

- Testing Spreadsheet Vs LRFD Tables: Truss Tr23 YP 29-Dec Sample ConnectionDocument4 pagesTesting Spreadsheet Vs LRFD Tables: Truss Tr23 YP 29-Dec Sample Connectionvijay10484No ratings yet

- Ilfs-Nagpur Metro-cn-1011-Details of Steel I Girder at Platform Level-17m SpanDocument1 pageIlfs-Nagpur Metro-cn-1011-Details of Steel I Girder at Platform Level-17m SpanrohitNo ratings yet

- Pre-Casting, Pre-Tensioning & Launching of Full Span Super-Structure in IndiaDocument2 pagesPre-Casting, Pre-Tensioning & Launching of Full Span Super-Structure in IndiafaumijkNo ratings yet

- 003.beam Design DocumentDocument59 pages003.beam Design Documentmathu100% (1)

- VBSL - Comments Plan & ProfileDocument2 pagesVBSL - Comments Plan & Profiledilip kumarNo ratings yet

- Curved BeamsDocument7 pagesCurved BeamsVicky MunienNo ratings yet

- FF Report-244-443........Document200 pagesFF Report-244-443........Harish Kumar GiriNo ratings yet

- Rly. Platform DrawingDocument1 pageRly. Platform DrawingAtul Kumar MishraNo ratings yet

- Design of Anchorage ZoneDocument6 pagesDesign of Anchorage ZoneSambhav PoddarNo ratings yet

- Case:: 12 Construction Stage Trans Seismic CaseDocument9 pagesCase:: 12 Construction Stage Trans Seismic CaseMadhurimaMitraNo ratings yet

- Br. No. 276-1 97919Document1 pageBr. No. 276-1 97919Krushana GiteNo ratings yet

- Optimization PSC Bridge An ExampleDocument13 pagesOptimization PSC Bridge An Exampleani4576No ratings yet

- Bearing layout and erection details of girderDocument1 pageBearing layout and erection details of girderRavpreet SinghNo ratings yet

- Prestressed Concrete Girder Continuity ConnectionDocument6 pagesPrestressed Concrete Girder Continuity ConnectionagnayelNo ratings yet

- All Hands Meeting 03 Sep 2019Document39 pagesAll Hands Meeting 03 Sep 2019Parikshit JoshiNo ratings yet

- Steel Support StructureDocument40 pagesSteel Support Structuremsiddiq1No ratings yet

- Chinyalisaur Bridge Presentation 12.03.12Document17 pagesChinyalisaur Bridge Presentation 12.03.12rims26No ratings yet

- PCC Return Wall PDFDocument3 pagesPCC Return Wall PDFNavarun VashisthNo ratings yet

- CSM Adac L&T 0h02 1 DesignDocument27 pagesCSM Adac L&T 0h02 1 Designtamim2014No ratings yet

- 001.gad Bow String Steel Bridge 200 M SpanDocument1 page001.gad Bow String Steel Bridge 200 M SpanManvendra NigamNo ratings yet

- 0007-SIL-019035-C-HP-16-DC-0007-R0-Design of First Floor BeamsDocument37 pages0007-SIL-019035-C-HP-16-DC-0007-R0-Design of First Floor BeamsHunny VermaNo ratings yet

- Issued For Information Issued For Approval: NotesDocument1 pageIssued For Information Issued For Approval: NotesAnkurAgarwalNo ratings yet

- Drawing List Seb Typical Details: Drawing No. Drawing TitleDocument26 pagesDrawing List Seb Typical Details: Drawing No. Drawing Titlevrajan1988No ratings yet

- Interpreter of MaladiesDocument50 pagesInterpreter of MaladiesmahakNo ratings yet

- Indian Railway Standard Code for Design of Bridge Substructures and FoundationsDocument64 pagesIndian Railway Standard Code for Design of Bridge Substructures and FoundationsNeha Singh100% (1)

- Standard Girder Girder Flange 5%Document4 pagesStandard Girder Girder Flange 5%Sharyn PolleyNo ratings yet

- Engineering Vol 69 1900-06-08Document33 pagesEngineering Vol 69 1900-06-08ian_newNo ratings yet

- Proposed ROB design documentDocument22 pagesProposed ROB design documentAkhil BabuNo ratings yet

- Bridge DesignDocument265 pagesBridge DesignJohnNo ratings yet

- GAD Drawings PDFDocument24 pagesGAD Drawings PDFVibekananda MohantyNo ratings yet

- IM Angul Railways PIF IIDocument52 pagesIM Angul Railways PIF IIarmaanNo ratings yet

- The World Bank: Uttarakhand Disaster Recovery ProjectDocument14 pagesThe World Bank: Uttarakhand Disaster Recovery Projectvicky rawatNo ratings yet

- GSPL203-73-1513 R-0Document37 pagesGSPL203-73-1513 R-0api-3846497No ratings yet

- SERC - Laced Reinforced ConcreteDocument11 pagesSERC - Laced Reinforced ConcretejrasankarNo ratings yet

- Match Cast TechniqueDocument15 pagesMatch Cast Techniquesukit_uiucNo ratings yet

- Owh My GopaDocument1 pageOwh My GopaKonten LimaNo ratings yet

- Hisense RSAG7.820.1535 SuperThin LED TV PSU SchematicDocument1 pageHisense RSAG7.820.1535 SuperThin LED TV PSU SchematicArlene B. NoceteNo ratings yet

- Catalog JD PDFDocument280 pagesCatalog JD PDFhydeer 1340% (5)

- New H Lland O: Pumpe Za Vodu I Ulje Water & Oil PumpsDocument18 pagesNew H Lland O: Pumpe Za Vodu I Ulje Water & Oil PumpsJasminM dooNo ratings yet

- CTP Engine Oil & Fuel Filters: New CTP Replacement Parts For Heavy EquipmentDocument3 pagesCTP Engine Oil & Fuel Filters: New CTP Replacement Parts For Heavy EquipmentMarlon Geronimo100% (1)

- Product Line: Caterpillar Machines, Engines and Work ToolsDocument24 pagesProduct Line: Caterpillar Machines, Engines and Work Toolsagegnehutamirat100% (1)

- Construction Equipment GuideDocument66 pagesConstruction Equipment Guideweston chegeNo ratings yet

- Kobelco Sk200 8 Excavator Parts Catalog ManualDocument5 pagesKobelco Sk200 8 Excavator Parts Catalog ManualWahyu Yudi100% (2)

- Tower Crane Mci 85a B Potain Tower Crane MC 125Document4 pagesTower Crane Mci 85a B Potain Tower Crane MC 125Nelson Benjamin Mendez LorenzoNo ratings yet

- Construction Equipment & Machinery Spare PartsDocument7 pagesConstruction Equipment & Machinery Spare PartsAjay SastryNo ratings yet

- Schedule PeralatanDocument1 pageSchedule PeralatanHendra FebriantNo ratings yet

- Data HoseDocument20 pagesData Hoseajiesoko2No ratings yet

- PT. RIUNG TECHNICAL ANALYSIS REPORTDocument47 pagesPT. RIUNG TECHNICAL ANALYSIS REPORTRohmat adenibrahimNo ratings yet

- Product Range: A Quick ReferenceDocument44 pagesProduct Range: A Quick Referencewirat9wisawaNo ratings yet

- Klasifikasi Pesawat Angkat Dan Pesawat Angkut: Oleh: Arief SuponoDocument80 pagesKlasifikasi Pesawat Angkat Dan Pesawat Angkut: Oleh: Arief SuponoAhmad MultidasaNo ratings yet

- Ir Filter TurboDocument2 pagesIr Filter TurbohayaNo ratings yet

- Drawbar - Bulldozer Komatsu D85ess-2 Work EquipmentDocument2 pagesDrawbar - Bulldozer Komatsu D85ess-2 Work EquipmentVolkzNo ratings yet

- SMKN 7 Semarang: Jalan PandansariDocument12 pagesSMKN 7 Semarang: Jalan PandansariHenri RivaldeNo ratings yet

- Site Diary: Project: Membina Jalan Perhubungan Desa Dari Koa Simoi Lama Ke Pos Lenjang, Lipis, PahangDocument2 pagesSite Diary: Project: Membina Jalan Perhubungan Desa Dari Koa Simoi Lama Ke Pos Lenjang, Lipis, Pahangtamimi_mohamedNo ratings yet

- Backhoe (709) (709FDS) (Boom & Dipperstick) - (S - N 270000101 & Above, A54M00101 & Above, 584100101 & Above, A5F300101 & Above) - BackhoeDocument4 pagesBackhoe (709) (709FDS) (Boom & Dipperstick) - (S - N 270000101 & Above, A54M00101 & Above, 584100101 & Above, A5F300101 & Above) - BackhoeFacu MarianiNo ratings yet

- Replacement Wear Parts For Caterpillar Machinery PDFDocument84 pagesReplacement Wear Parts For Caterpillar Machinery PDFEduardo Ariel BernalNo ratings yet

- Truck Crane - XCMG Crane - Foco Truck - Articulated - Telescopic Crane PDFDocument5 pagesTruck Crane - XCMG Crane - Foco Truck - Articulated - Telescopic Crane PDFboringNo ratings yet

- ESPLANADE THEATRE Biomimicry Sunidhi.n.prasadDocument45 pagesESPLANADE THEATRE Biomimicry Sunidhi.n.prasadsuniiNo ratings yet

- Mining Data 2022 ForecastDocument87 pagesMining Data 2022 ForecastWien Daniel SilaenNo ratings yet

- Populasi Unit Fleet 2010Document7 pagesPopulasi Unit Fleet 2010andra999No ratings yet

- Group 7 ExcavatorDocument42 pagesGroup 7 ExcavatorWired MindNo ratings yet

- 2008 Norscot CatalogDocument12 pages2008 Norscot CatalogAdriano Godinho100% (2)

- 1 - Pdfsam - JSN-20-008-LOP-WPS3-OS-001 Rev 00Document1 page1 - Pdfsam - JSN-20-008-LOP-WPS3-OS-001 Rev 00ibnu rizalNo ratings yet

- CATERPILLAR D4C and LGP, XL III TRACTOR BULLDOZER PARTS MANUAL BOOK CATALO083022Document4 pagesCATERPILLAR D4C and LGP, XL III TRACTOR BULLDOZER PARTS MANUAL BOOK CATALO083022Aldhi Brajamusti50% (2)

- Grove AT422 - 22 TonDocument4 pagesGrove AT422 - 22 TonMamour brshimNo ratings yet