Professional Documents

Culture Documents

Manual Maq Coser Stefi

Uploaded by

Felix AravenaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual Maq Coser Stefi

Uploaded by

Felix AravenaCopyright:

Available Formats

3.

N o t line

P o s s i b l e r e a s o n s : t h e b o t t o m line r u n o u t , t h r e a d i n g m i s t a k e s , n e e d l e w e a r t h e w r o n g

sewing machine operation manual

o r d i d n ' t r e a c h t h e p o s i t i o n , n e e d l e b e n d i n g d e f o r m a t i o n , c l o t h is n o t s u i t a b l e ( t o o t h i c k , t o o

thin, too soft o r t o o h a r d ) , n e e d l e is n o t s t a n d a r d . A U s e n o t e , p l e a s e b e s u r e t o a b i d e b y it

Solution: replace t h e bobbin of the bottom line, replace t h e original 9 0 / 1 4# m a c h i n e

USEOF: 0"2O1 B'202 0* 301 B ' 302 H'306

needle,install needle correctly a n d tighten thimble screw , replace the right fabrics,

r e p l a c e s e w i n g t h r e a d o f t h e o r i g i n a l f a c t o r y . t h r e a d i n g this n e e d l e in t h e right d i r e c t i o n , 1 .Insert the power or replace needles, please put the power on the closed position.

the needle must be through f r o m left t o right d i r e c t i o n . 2 . P l e a s e k e e p t h e m a c h i n e o u t o f t h e r e a c h o f c h i l d r e n , if c h i l d r e n u s e t h e m a c h i n e , m u s t b e

monitored by an adult.

4. Break

3. A f t e r u s e , t h e s w i t c h p l a c e o n t h e c l o s e d p o s i t i o n , a n d u n p l u g t h e p o w e r c o r d .

P o s s i b l e r e a s o n s : line is t o o t i g h t , t h e line b u t t o n is t o o t i g h t , f a b r i c is n o t a p p r o p r i a t e

4. Please do not collapse or reform the native .

( t o o t h i c k a n d t o o h a r d ) , s e w i n g t h r e a d is n o t s u i t a b l e , w i t h o u t t u r n i n g t h e h a n d w h e e l

5. T h e b o t t o m line, t h e s u r f a c e line h a s b e e n i n s t a l l e d b u t T h e b o b b i n of b o t t o m line

b e f o r e b o o t i n g , t h r e a d i n g is n o t c o r r e c t , n e e d l e is n o t s t a n d a r d , t h e b o t t o m l i n e a f t e r t h e

machine without cloth, do not open the power switch.

b o b b i n stuck wire, b r o k e n n e e d l e b o b b i n sets h a v e burrs, h o o k píate h a v e burr, pinhole Short pole

6. B e f o r e s t a r t i n g s e w i n g , p l e a s e t u r n t h e h a n d w h e e l t o

h a v e b u r r o r partial n e e d l e , n e e d l e is n o t in p l a c e , t h e t h r e a d c l a m p , t h r e a d i n g s p r i n g o r

m a k e needle to go through the cloth (boot after the

receive pole threading have burr.

h a n d w h e e l going smoothly ) , to avoid crashing

S o l u t i o n : relax t h e line b u t t o n , r e p l a c e t h e b o b b i n , r e p l a c e t h e s t a n d a r d 9 0 / 1 4 #

machine needle.

machine needle of the original factory jnstalled needle correctly a n d tighten thimble screw ,

7. A f t e r t h e m a c h i n e p l u g g i n g line o r t h e b o b b i n s e t s o f

replace the right fabric, replace t h e s e w i n g t h r e a d t h e o f o r i g i n a l f a c t o r y , t h r e a d in t h e

m o v e m e n t or for other reasons (that is,machine w a s

right d i r e c t i o n a g a i n , m u s t g o t h r o u g h t h e n e e d l e f r o m left to right d i r e c t i o n . r e d u c e burr

fixed or the h a n d w h e e l cann't work after booting),

w i t h f i n e s a n d p a p e r t o m a k e it s m o o t h l y . o p e r a t i n g t h e m a c h i n e Correctly.

shall be cut off p o w e r immediately , to put everything

5. B a d line the bottom line s m o o t h l y b e f o r e b o o t i n g , o t h e r w i s e it w i l l damage

P o s s i b l e r e a s o n s : t h e b o b b i n o f line is s t u c k e d , t h e b o b b i n o f t h e b o t t o m w a s s t u c k e d , the machine and power transformer.

line is t o o t i g h t o r t o o l o ó s e , n e e d l e is b e n d i n g d e f o r m a t i o n , t h r e a d i n g p o s i t i o n is w r o n g o r 8. L i n e fault c a n s l o v e a s " c o n v e n t i o n a l fault ".if c a n

i n a p p r o p r i a t e , c l o t h is n o t i n a p p r o c p r i a t e ( t o o s o f t a n d t h i n ) . not solve, please contact the dealers where y o u b u y

S o l u t i o n : install c o v e r line core then pulí b a c k , m a k e t h e b o b b i n of t h e line operating the machine.

flexiablly, c o o r d í n a t e f a c e line elastic a d j u s t m e n t k n o b , m a k e t h e b o t t o m line e v e n ,

VáZero degrees Celsius above the environment Sample graph 201

replace needle and thread again, change the suitable fabric.

6 F i r i n g pin,needle breakagePossible reasons: loóse presserfoot, needle loóse ,stitching

line b u t t o n t o o c i ó s e , b o o t w h e n n e e d l e is e n t e r into f a b r i c , n e e d l e n o t l a b , pulí w h e n they 1 The main c o m p o n e n t s and a c c e s s o r i e s

leave.Stay without turning the h a n d w h e e l , shuttle back a n d forth after the core set of shift

F i x e d line | Line button

a n d t i e line o r l i n e s d i d n o t h a n d l e b u t t u r n t h e h a n d w h e e l o r b o o t . N e e d l e is n o t i n s t a l l e d ,

n e e d l e is l o ó s e . Thread clamp piece

Solution: replace a n d correct to install machine needle and tighten the thimble screw, The bobbin of line

r e l a x e d line b u t t o n , r e p l a c e c o m f o r t a b l e fabric, adjust t h e b o b b i n c o v e r location, o p é r a t e short pole

the machine corectly.

7.Can't turn the handwheel

P o s s i b l e r e a s o n s : it d o e s n o t h a n d l e a f t e r t i e l i n e o r l i n e s , l i n e i s b a d o r j a m m e d , l i n e

button too cióse, needle bending deformation, displacement, the bobbin presser.

Solution: r e p l a c e a n d ¡nstall m a c h i n e n e e d l e correctly , tighten the thimble screw,

t h r e a d e n a n d r e l a x e d line right button a g a i n , adjust t h e b o b b i n s e t position, s e t t h e b o b b i n

position be reference ( A - C)

power socket

The bobbin of

bottom line Hook píate í\Pedal socket

Sample graph 301

L a m p , knife for matching function

Attachment Threading device X1 Belt line T h e bobbin X 2

Empty The bobbin X2 Needle X1

The power suppIy/Pedal (Selected Purchase)

The bobbin Set Normal position T h e bobbin Set Shift position T h e bobbin S e t Shift position

4 1

2 Threading method 1 .Press the w o u n d by the finger according to C o u n t e r clockwise

rotation, the w o u n d will be ejected automatically .

1 .Surface line

2.Put the e m p t y bobbin winding s t e m , not tight, (available

P l e a s e r e f e r t o f i g u r e 1 t o 7 , it i s w i t h t h e bobbin

in r o d c o i l w i n d i n g l a y e r t i s s u e ) t o p p o l e , i n s e r t t h e l i n e

o f l i n e a n d l i n e w h e n y o u g e t i t . If u s e t h e l i n e b a l l w h a t

ball, a n d t h e line o n t h e b o b b i n c l o c k w i s e a r o u n d f o u r

b u y f r o m m a r k e t , p l e a s e pulí out t h e f i x e d pole w h i c h

to five laps.

is o n t h e r o o f of m a c h i n e , i n s e r t t h e line i n t o t h e f i x e d

3 W i t h y o u r Índex finger b e t w e e n light c a n c e l t h e ball a n d

p o l e , W i r e l i n e d i r e c t i o n is c l o c k w i s e , a n d t h e n t h r e a d

t h e b o b b i n t h r e a d , a s s h o w n in f i g u r e ( 3 ) T u r n o n t h e p o w e r

a c c o r d i n g to f i g u r e 1 to 7.

switch can be winding, winding don't exceed the bobbin

í & T h e s h o r t p o l e w i t h l i n e is b e e n p u l l e d o u t ,if t o o t i g h t ,

edge

y o u c a n u s e t h e s c r e w d r i v e r t o p r y it o u t .

4. Turn off t h e p o w e r switch to stop w h e n a r o u n d the f u l l ,

2.The bottom line

cut the line, r e m o v e the b o b b i n a n d the line ball.

P r e s s the b o b b i n c o v e r by t h e left f i n g e r s , left out.

5. P r e s s t h e f i x e d line p o l e , t h e w i n d i n g r o d into t h e h a n d

P u t t h e b o b b i n in a line in t h e h o o k . C u t t h e b o b b i n threac Sample graph 301

wheel and the clockwise rotation.

keep about 5 c m long on the panel.Then put the bobbin c

^ O n the operation of the winding, banning a sewing machine needle

f r o m left to right b a c k to p l a c e .

or charge on the pole.

Sample graph 202

Clamp down socket

6 T h e r e p l a c e m e n t of the needle

3 Put cloth method and sewing operation

T h e m a c h i n e i s u s e d f o r 9 0 / 1 4 # c o n s o l é n e e d l e , it i s s u g g e s t e d t h a t

1 .Rotate the h a n d w h e e l according to the direction of the arrow, put the needle to the with the original machine needle.

highest position. 1 Pulí t h e e x t e r n a l p o w e r s u p p l y first, to a v o i d t o u c h s w i i c h to

2. L e t t h e p r e s s e r f o o t lift, p u t f a b r i c u n d e r t h e p r e s s e r f o o t l e v e r . scratches accidentally .

Needle bar

3. L o w e r p r e s s e r f o o t lift r o d . 2 T u r n the h a n d w h e e l to the a p p r o p r i a t e height of t h e m a c h i n e n e e d l e .

4 . R o t a t e t h e h a n d w h e e l 1-2 l a p s a c c o r d i n g t o t h e d i r e c t i o n o f t h e a r r o w , t o m a k e the 3 U n s c r e w t h e t h i m b l e s c r e w , pulí n e e d l e d o w n o u t .

needle through fabric (boot after hand wheel goling smoothly) 4 T h e p l a ñ e o f t h e n e w m a c h i n e n e e d l e b a r o n t h e p i n h o t e in t h e

5. P r e s s t h e p o w e r s w i t c h , t h e n y o u c a n start s e w i n g . d i r e c t i o n o f t h e t h i m b l e s c r e w i n s e r t i o n m a c h i n e , a n d p u s h it t h r o u g h .

6. T h e s p e e d s w i t c h c a n select 5.Tighten thimble screw.

7 . S e w i n g is c o m p l e t e d , t u r n o f f t h e p o w e r s w i t c h , t u r n t h e h a n d w h e e l , lift n e e d l e , lift t h e ¿SNeedle direction must be correct a n d appropriate tignten thimble screw, to

p r e s s e r foot lifting r o d . r e m o v e the cloth then cut the stitches. a v o i d n e e d l e fall a c c i d e n t .

Sí If t h e c l o t h i s d i f f i c u l t t o r e m o v e , y o u c a n t u r n t h e h a n d w h e e l , t h e n c a n r e m o v e the

ifabric easily. 7 T h e use of pedal p o w e r switch

4 The adjustment of the stitch Inside t h e pedal j a c k foot switch plug into the m a c h i n e , y o u c a n use the pedal switch instead

o f t h e p h o n e p r e s s t h e p o w e r s w i t c h . C o n t r o l s w i t c h is s e w n w i t h t h e f e e t , h a n d s f r e e a n d e a s y

T h e n o r m a l l i n e m a r k a s s h o w n in f i g u r e ( 2 A ) , t h e l i n e a n d t h e b o t t o m l i n e is u n i f o r m

operation.

t i g h t n e s s . l f t h e l i n e m a r k a s s h o w n in f i g u r e . S h o w n in ( 2 B ) , t h e b o t t o m l i n e is a s t r a i g h t

í s í U s e d t o pulí t h e p l u g t o pulí o u t , t o a v o i d t o u c h i n g t h e s w i t c h a c c i d e n t , t h e u s e o f t h e f o o t is

l i n e , it m e a n s l i n e i s t o o l o ó s e , w i l l a d j u s t l i n e b u t t o n b y c l o c k w i s e s c r e w i n g , i n c r e a s e t h e

not adjustable speed.

t h r e a d c l a m p p r e s s u r e until the b o t t o m line a n d the line elastic fit.lf the line m a r k as shown

8 The power converter

in f i g u r e (2 - C ) , t h e l i n e is a s t r a i g h t l i n e , t h e n l i n e is t o o t i g h t , t h a t is , t h e l i n e knob

c o u n t e r c l o c k w i s e rotation slowly, r e d u c e the p r e s s u r e of s u r f a c e line until the b o t t o m line, External p o w e r supply p a r a m e t e r s for 6-8 v D C (direct current) rated output, rated current 1 a

line e l a s t i c fit. or higher, polarity - plug t y p e for 2.1 * 5.5.The input v o l t a g e to m e e t the u s e a c p o w e r s u p p l y

Síln a d j u s t a b l e elastic, pay attention to s e e the s u r f a c e line w h e t h e r e x t r u s i ó n from v o l t a g e , insert the plug into the unit of the p o w e r c o n v e r t e r s o c k e t hole c a n be u s e d .

T h r e a d c l a m p d e v i c e , s u c h as e m e r g e n c e w a n t s to put the c a r d return line clip b e t w e e n . í K W h e n i n s e r t t h e p o w e r . p a y a t t e n t i o n t o t h e s w i t c h in "off" p o s i t i o n

W h e n t h e l i n e is a p p r o p r i a t e , t h e m o r e l o ó s e t h e b e t t e r , t o a v o i d d i s c o n n e c t i o n . A d j u s t

a c c o r d i n g to fabric thickness. 9 Cdnventional fault

1 .No electricity

Face l i n e — P o s s i b l e r e a s o n s : t h e e x t e r n a l p o w e r s u p p l y p o w e r o r p l u g is w r o n g , p o w e r d a m a g e .

A A A A A-

Cloth Solution: replace power.

J [

bottom line-

^—i «. I v > u u u u u= 2Jumper

A • B C Possible reasons: improper needle bending d e f o r m a t i o n , cloth (too thick, too thin,too soft a n d

5 The bobbin winding method h a r d ) , t h r e a d i n g is w r o n g , t h e w r o n g n e e d l e o r d o e s n o t r e a c h t h e d e s i g n a t e d p o s i t i o n , s e w i n g

t h r e a d is n o t a p p r o p r i a t e , t h e n e e d l e is n o t s t a n d a r d

W i n d i n g b a r in t h e m a c h i n e is u s e d f o r e m p t y t h e b o b b i n w i n d i n g , in g e n e r a l , w i n d i n g Solution: replace the original factory or 90/14 # standard machine needle, tighten thimble

lever on the f u s e l a g e h a n d w h e e l n e e d to w i n d the b o b b i n of b o t t o m line, please follow s c r e w a n d installed correctly, replace the right fabrics, replace the sewing thread of original

the following steps: factory.

You might also like

- Agfa Billy 1Document13 pagesAgfa Billy 1anon_420986037No ratings yet

- Montage KB 6 UKDocument2 pagesMontage KB 6 UKJosé SilvaNo ratings yet

- Catalogo Llave Foster 58-93rDocument40 pagesCatalogo Llave Foster 58-93rwfcenda2603No ratings yet

- ATreatiseontheArtofBreadMaking 10266279Document242 pagesATreatiseontheArtofBreadMaking 10266279RedDongleGamesNo ratings yet

- Unit 1 - Use of EnglishDocument10 pagesUnit 1 - Use of EnglishNấm HươngNo ratings yet

- AdlerJunior12 Triump Typewriter ManualDocument6 pagesAdlerJunior12 Triump Typewriter Manualrajesh2kakkasseryNo ratings yet

- ThePhilosophyofNietzsche 10041533Document293 pagesThePhilosophyofNietzsche 10041533didoNo ratings yet

- Vacuum Cleaner Eurotec EU5420 User ManualDocument4 pagesVacuum Cleaner Eurotec EU5420 User Manualcostin5No ratings yet

- AShortHistoryofthePrintingPress 10254129Document95 pagesAShortHistoryofthePrintingPress 10254129ZERO LOTNo ratings yet

- Lower-Limb Orthotics: Melvin Stills, C - ODocument10 pagesLower-Limb Orthotics: Melvin Stills, C - OCalugareanu MadalinaNo ratings yet

- The Complete Works of Mark TwainDocument411 pagesThe Complete Works of Mark TwainAlbinuta SmartNo ratings yet

- Zorki 4 ManualDocument18 pagesZorki 4 ManualPaul Grayson WombleNo ratings yet

- ThinkingFeelingDoing 10316119Document305 pagesThinkingFeelingDoing 10316119jurebieNo ratings yet

- FilipinoPopularTales 10030063Document494 pagesFilipinoPopularTales 10030063Voltaire Von AlvarezNo ratings yet

- AKG BX5 ManualDocument18 pagesAKG BX5 Manualmartin.mk-vhweb.deNo ratings yet

- Vivitar v3000s PDFDocument13 pagesVivitar v3000s PDFJennyfer NessieNo ratings yet

- Vaporeon: Find Me On EtsyDocument7 pagesVaporeon: Find Me On Etsymikka100% (1)

- The 4 Keys To A Great StartDocument9 pagesThe 4 Keys To A Great StartjohnNo ratings yet

- 45: C H E C K P R O N O U N Reference For AgreementDocument3 pages45: C H E C K P R O N O U N Reference For AgreementSari NurdianiNo ratings yet

- 1 s2.0 S0007850607613870 MainDocument6 pages1 s2.0 S0007850607613870 MainThi Phuong Thanh LeNo ratings yet

- Rope ReevingDocument8 pagesRope ReevingKS CheeNo ratings yet

- Readings On The History and System of The Common Law - Roscoe PoundDocument646 pagesReadings On The History and System of The Common Law - Roscoe PoundpajorocNo ratings yet

- Luther Halsey Gulick - Muscle BuildingDocument101 pagesLuther Halsey Gulick - Muscle BuildingMadalinaNo ratings yet

- Bending & Buckling of Partially Embedded Piles Davisson & Robinson 1965Document4 pagesBending & Buckling of Partially Embedded Piles Davisson & Robinson 1965chutton681No ratings yet

- Informations - Informationen - Informazioni - Notes: 3selht.s AquaticusDocument3 pagesInformations - Informationen - Informazioni - Notes: 3selht.s Aquaticusspektro_siktNo ratings yet

- Chem 110 Lab ManualDocument24 pagesChem 110 Lab ManualBxhsh HdhshsshNo ratings yet

- ABM Mohd Amaan SheikhDocument2 pagesABM Mohd Amaan SheikhMohd Amaan SheikhNo ratings yet

- FirstYearMathematics 10000987Document254 pagesFirstYearMathematics 10000987jurebieNo ratings yet

- Earthology 10502211Document226 pagesEarthology 10502211jurebieNo ratings yet

- Burda 1969.11Document177 pagesBurda 1969.11Надежда Кузнецова100% (2)

- TheChildrensFirstBookofPoetry 10184763Document227 pagesTheChildrensFirstBookofPoetry 10184763Afshan Quela Bonayon LiggayuNo ratings yet

- AHandbookofOrchestration 10030498Document161 pagesAHandbookofOrchestration 10030498leonorrllopessNo ratings yet

- International Society For Soil Mechanics and Geotechnical EngineeringDocument10 pagesInternational Society For Soil Mechanics and Geotechnical EngineeringFatma ElhussienNo ratings yet

- Passages 1 3rd WK AkDocument12 pagesPassages 1 3rd WK Akbahareh changiNo ratings yet

- Can, Could, Be Able ToDocument1 pageCan, Could, Be Able ToRolando ValenciaNo ratings yet

- ACompleteAlgebratoAccompanyRaysSeriesofMathematics 10000526Document365 pagesACompleteAlgebratoAccompanyRaysSeriesofMathematics 10000526jurebieNo ratings yet

- Cambridge English Vocabulary For FCEDocument133 pagesCambridge English Vocabulary For FCEmiseleNo ratings yet

- AComputerProgramforDoingTediousAlgebraSymb66 10286714Document56 pagesAComputerProgramforDoingTediousAlgebraSymb66 10286714Kumar RaamanathanNo ratings yet

- EarlyHistoryofFraternalBeneficiarySocietiesinAmerica 10000921Document263 pagesEarlyHistoryofFraternalBeneficiarySocietiesinAmerica 10000921aureliabadeaNo ratings yet

- VascoDaGama 10298532Document425 pagesVascoDaGama 10298532Geff AuguisteNo ratings yet

- AManualofArtisticAnatomy 10097437Document207 pagesAManualofArtisticAnatomy 10097437K extreme GamerNo ratings yet

- Festivals: Origin and Background of Bihu FestivalDocument23 pagesFestivals: Origin and Background of Bihu FestivalJohn HuttonNo ratings yet

- SteamTurbines 10308766Document282 pagesSteamTurbines 10308766FazliJaafarNo ratings yet

- PracticalInstructionHowtoAlterIllFittingGarmentsandHowtoHandleTryOns 10847050 PDFDocument111 pagesPracticalInstructionHowtoAlterIllFittingGarmentsandHowtoHandleTryOns 10847050 PDFShoaib AzizNo ratings yet

- Emigre 24 Fei NemanDocument3 pagesEmigre 24 Fei NemanSarmiento AbregoNo ratings yet

- Fate Cheat Sheet CardsDocument1 pageFate Cheat Sheet CardsВикторNo ratings yet

- Morse Code AssignmentDocument4 pagesMorse Code AssignmentShahbaz ZafarNo ratings yet

- Minute 16 Camera InstructionsDocument17 pagesMinute 16 Camera InstructionsJonnoNo ratings yet

- Hfe JBL l300 en Alt ScanDocument13 pagesHfe JBL l300 en Alt ScanthomasNo ratings yet

- UniversalisminAmerica 10458337Document561 pagesUniversalisminAmerica 10458337jurebieNo ratings yet

- Abnormality in AlternatorDocument18 pagesAbnormality in AlternatorSunil SinghNo ratings yet

- The Genesis of QuantaDocument38 pagesThe Genesis of Quantapriyanshu gangwarNo ratings yet

- TheNegrosOrigin 10855281Document39 pagesTheNegrosOrigin 10855281iluubooks20No ratings yet

- Group Tuesday 21st Litterature PresentationDocument25 pagesGroup Tuesday 21st Litterature PresentationMark Jhurich CabusuraNo ratings yet

- ViolinsandViolinMakers 10146406Document206 pagesViolinsandViolinMakers 10146406David BastosNo ratings yet

- English Fof AcadsDocument65 pagesEnglish Fof AcadsdeejoyalcanzoNo ratings yet

- Challenge 2 Activity 4 Worksheet, Plazo Hasta El Viernes 07 de Octubre 4 PM Deben Completar El Taller Y Lo Suben A La PlataformaDocument4 pagesChallenge 2 Activity 4 Worksheet, Plazo Hasta El Viernes 07 de Octubre 4 PM Deben Completar El Taller Y Lo Suben A La PlataformaNicolás SolerNo ratings yet

- System Descr MAB ModulesDocument10 pagesSystem Descr MAB ModulesMareks LezevskisNo ratings yet

- DEC AlphaServer 2x00 Technical SummaryDocument24 pagesDEC AlphaServer 2x00 Technical SummaryMario RossiNo ratings yet

- Bicotest Model T272 - High Resistance Cable Fault LocatorDocument2 pagesBicotest Model T272 - High Resistance Cable Fault LocatorDEEPAK KUMARNo ratings yet

- EM-II Lab ManualDocument53 pagesEM-II Lab Manualrv_andeNo ratings yet

- LabPro Dispenser LeafletDocument2 pagesLabPro Dispenser LeafletazhaniNo ratings yet

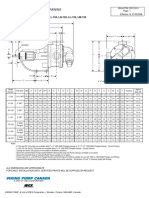

- Dimensiones de Bomba Viking L124Document1 pageDimensiones de Bomba Viking L124nerio gerardinoNo ratings yet

- Service: ManualDocument33 pagesService: ManualAckerman RinconNo ratings yet

- Pareto Problem LVDocument11 pagesPareto Problem LVRezhaNo ratings yet

- Part EngineDocument55 pagesPart EngineMarlon MontenegroNo ratings yet

- JBL LX 2000 SUB Service ManualDocument12 pagesJBL LX 2000 SUB Service ManualFrancoNo ratings yet

- Technology and Livelihood Education: Home EconomicsDocument9 pagesTechnology and Livelihood Education: Home EconomicsJacquilyn Dela Cruz100% (1)

- Mtap2 PresentationDocument31 pagesMtap2 PresentationtoilalongNo ratings yet

- 1.067 MTS CAPE GAGUE ELECTRIC LOCO MOTIVES DESIGNED BY SIEMENS BO-BO-BO Schmal - QR 3800 SchmalspurlokomotiveDocument4 pages1.067 MTS CAPE GAGUE ELECTRIC LOCO MOTIVES DESIGNED BY SIEMENS BO-BO-BO Schmal - QR 3800 SchmalspurlokomotivenmrNo ratings yet

- PDF 2 SD Control Ts97Document32 pagesPDF 2 SD Control Ts97Ehab KamalNo ratings yet

- 20N40 PDFDocument6 pages20N40 PDFJignesh PrajapatiNo ratings yet

- Led LCD TV Tcon Panel Repair GuideDocument601 pagesLed LCD TV Tcon Panel Repair Guidepedro perezNo ratings yet

- Sale Prices Valid Through February 28, 2015Document52 pagesSale Prices Valid Through February 28, 2015Benjamin DoverNo ratings yet

- Gage and Absolute Pressure Transducers: Special FeaturesDocument4 pagesGage and Absolute Pressure Transducers: Special Featuresaemis2010No ratings yet

- Ms 881Document32 pagesMs 881Mlam MlamNo ratings yet

- Dodge RAM Truck 2002 Workshop Repair Manual - Transmission and Transfer CaseDocument502 pagesDodge RAM Truck 2002 Workshop Repair Manual - Transmission and Transfer CaseLuis Ramon Arguello Real100% (1)

- B1 RC18 User GuideDocument20 pagesB1 RC18 User Guideharold_anilloNo ratings yet

- Auto Switch 1Document2 pagesAuto Switch 1deepak_singla227No ratings yet

- Theory2021-22-IC5I - IAU Teaching PlanDocument2 pagesTheory2021-22-IC5I - IAU Teaching Planrashmi patilNo ratings yet

- Method Statement FF Piping System Pipes - DotxDocument9 pagesMethod Statement FF Piping System Pipes - DotxBader ShrbajiNo ratings yet

- Katko Switches Technical Information AllDocument10 pagesKatko Switches Technical Information AllSanishka NiroshanNo ratings yet

- Marine TechDocument28 pagesMarine TechMichael OwingsNo ratings yet

- Valvula Reguladoras Pilotados DANFOSSDocument2 pagesValvula Reguladoras Pilotados DANFOSSJurandir Laureano SILVA JUNIORNo ratings yet

- Bicicleta Estatica Proteus PecDocument10 pagesBicicleta Estatica Proteus Pecpracticante.biomedicamedellinNo ratings yet

- MAGNETISM & ElectromagnetismDocument47 pagesMAGNETISM & ElectromagnetismJames SarkerNo ratings yet

- Solar Powered Mobile Charger Using Buck ConverterDocument4 pagesSolar Powered Mobile Charger Using Buck ConverterArvind RebelNo ratings yet