Professional Documents

Culture Documents

04-LEK 1050 - 9.625 Casing & Cement Adjusted For HALL Stage Tool

Uploaded by

Drilling Engineering ChannelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

04-LEK 1050 - 9.625 Casing & Cement Adjusted For HALL Stage Tool

Uploaded by

Drilling Engineering ChannelCopyright:

Available Formats

5

RIG: Viking 118 WELL: LEK-1050 DATE: DCE 2021

Run & Cementing the 9-5/8”casing

Well Control: Lessons learnt: KPI :

Primary barrier ( Mwt) In OH record P/U & S/D wt each RIH Speed : 10 jts /hr including fill

a) PVT for monitoring 50 m to compare against T& D up time.

b) Return flow Sensor simulation. Best Record: Ahmed Riami: 18

c) MWT recording No stoppage in OH W/O STDs /hr

Secondary Barrier (Tested Pumping.

BOP, Well control X-over, Stock of inflow to be on site for

FOSV). any stuck.

Annular BOP closing

pressure to be adjusted.

Notes:

13 3/8 shoe 497 m

12 ½ TD section 1264 mMD 64° Inc

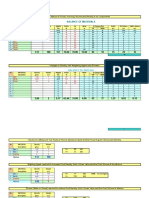

Casing tally LEK-1050

KOP 790 mMD

1. In case of losses keep filling the well Through Kill line.

2. Pull wear bushing

3. Flush & Wash BOP’s

4. Rig up the Volant CRT casing running tool. Function test tool.

5. MU F.Shoe, Float Collar and Landing collar. Thread lock all joints & test floats.

6. RIH with 9-5/8” casing to the 13-3/8” casing shoe. (41 joints = 531m.) Fill

casing every 5 joints.

7. Use Safety Calmp until string wt is 7 kdan.

8. Continue to RIH casing to joint number 63 (813m.) Call Halliburton cementer 1

hour before you need them

Regards

Mahmoud Boraey / Bader Hinaie

Drilling supervisors, LEK-1050

5

9. Pick up 9-5/8” cement DV with the winch & soft sling and make up in the

casing in the rotary table with a chain tong. MSIPC Stage Tool (3.24 m). ( under

direct supervision from Hall Cementer).

10.Circulation test with 1 m3/min rate check if there is any leaks.

11.Continue to RIH w/ 9-5/8” casing with joint number 96 + 1 Jts R2 (1261.5

meters.)

12.Max S/D Wt 10 Kdan. In case of S/D , P/U Free and turn pumps on 1.2 M3/min

and wash down setting Max pressure to 8000 Kpa ( work string by jerking).

13.Follow Darg Sheet attached. If large difference circulate BU with 1.5 M/Hr

while working string up and down.

14.Pick up Landing Joint & 13-3/8” X 9-5/8” casing hanger. Ensure hanger is fully

engaged to running tool. Confirm RT isn’t over torqued. . (B/O then M/U at

2000 ft.lb)

15.Drain BOP. Wash down with 1 m3/min while Landing HGR very slowly

returns through SOV to cellar.

16.Land the casing hanger. Pressure test the casing hanger against the annular to

8500 KPA for 15 minutes with chart and flat line. Have all hand tools ready.

17.Circulate one full cycle at 1.2 m3/min. (Pressure should be steady)

18.Meanwhile circulation Hold PJSM and rig up Halliburton cement head and

lines.

19.Flush lines with water and pressure test lines to 3500 kPa low and 21000

high for 5 / 15 min each.

20. Circulate another full cycle at 1.2 m3/min with no shutdowns and continue

circulation till cement team is ready to pump.

Cementing Stage 1 & 2

1. While circulating prepare the mix fluid for the single slurry. Only add

retarder once given the go ahead from the DSV.

Note: Cementer to take two (2) 5kg samples of dry cement.

Two (2) samples of 3 liters each of mix fluid.

Five (5) liters of mud & spacer.

Regards

Mahmoud Boraey / Bader Hinaie

Drilling supervisors, LEK-1050

5

Two (2) containers of Four (4) liters of Mix water.

Two (2) Samples of cement from lead, tail & single slurries.

One (1) KG or liter of cement additives.

1st Stage cement job:

1. Pump 10.0 m3 fresh water at 1 m3/min. With rig pump 533 strokes

2. Halliburton to begin mixing cement. Check density using a pressurized mud

balance. Proceed when density is +/- 0.2 kPa/m.

3. Pump +/- 28.8 m3 of 1.42 SG/ 13.8 KPA/M lead slurry fly mixed at 1

m3/min.( Mix fluid 23.25 m3)

4. Pump +/- 14.5 m3 of 1.90 SG / 18.6 KPA/M tail slurry fly mixed at .8

m3/min. ( Mix fluid 8.6 m3)

5. Drop the displacement plug, to be witnessed by HAL and DSV. Verify that

the plug has launched using the indicator. Do not flush lines to the floor –

want to have 0.5 to 1 bbl of cement behind plug.

6. Pump 3.2 m3 fresh water at 1.4 m3/min. Cement unit.

7. Pump +/- 45.6 m3 WBM @ 1 m3/min with rig pump (2414 strokes).

(with Rig pump, total displacement is 48.8 m3. We can pump extra 0.5 m3 if

required. (27 strokes)

8. Bump the plug Continue pressuring up to 14,000 kPa and complete a 30

minute casing test.

Bleed off, check floats at the cement unit.

a. If the floats and latch down plug fail to hold, try repeatedly bleeding off

pressure quickly then repumping volume to try flush and activate valves.

b. If this fails close in well at cement head and WOC for 2 hours, then check

for flow. If still flowing WOC in 1 hour intervals and recheck.

c. Have kill line connected to one side outlet and keep the other side open

Regards

Mahmoud Boraey / Bader Hinaie

Drilling supervisors, LEK-1050

5

2nd Stage Cement Job:

1. Bleed off pressure

2. Start filling Annulus with 0.5 M3/min keeping the other side of SOV’s Open.

3. Open up cement head, drop the ‘bomb’ opening plug, wind in the pin, load

the closing plug and close cement head. To be witnessed by HAL cement

and DSV.

3. Wait 10 minutes for the free fall plug to land in the MSIPC tool. No response

will be seen at surface. a. Plug falls at 61 meters per minute.

4. Apply 1,500 kPa in 3 minutes increments until reaching 5930 kPa or 860 psi

with the cement unit to slide the sleeve to allow pressure to inflate the packer.

Note: 5930 kPa or 860 psi is differential pressure and may be lower or greater

depending on well conditions.

5. Increase pressure in 1500 kPa increments and wait 3 minutes before increasing

the pressure each time. This is to allow the inflatable packer to fully extrude and

inflate. b. Continue until burst disk rupture pressure of 12410 kPa or 1800 psi.

7. Establish circulation to ensure that ports are open and free. Pump minimum 1

bottoms up with the rig pumps. (17.3 m3 Annulus volume.) (920 strokes). Till hole

is clean.

Count the strokes it takes to get returns from the SOV’s to calculate how low

the cement dropped in the 13-3/8” & 9-5/8” annulus.

7. Pump 5.0 m3 fresh water at 1 m3/min with RIG PUMP (266 strokes).

8. Begin mixing cement. Check density using a pressurized mud balance. Proceed

when density is +/- 0.2 kPa/m.

9. Pump +/- 18.1 m3 of 1.90SG / 18.6 KPA/M single slurry fly mixed at .8 m3/min.

( Mix fluid: 10.65 M3)

** Allow Excess CMT to fill previous Annulus as TOP fill.

10. Drop closing plug and close cement head. To be witnessed by HAL and DSV.

11. Pump 3.2 m3 fresh water at 0.8 m3/min with CEMENT UNIT.

Regards

Mahmoud Boraey / Bader Hinaie

Drilling supervisors, LEK-1050

5

12. Pump +/- 14.4 m3 WBM at 1.0 m3/min with Rig pump (761 stks)

TOTAL disp: 17.59 m3.

14. Bump the plug with a pressure of +/- 11,361 kPa or 1647 psi

At this time the closing plug will shear and move down closing the ports.

16. Continue pressuring up to 14,000 kPa and complete a 30 minute casing test.

17. Bleed off and check for back flow, rig down cement head, wash up cement

unit, complete job packet and get DSV to sign documentation before leaving

location.

Note:

Wear all PPE at all times, Follow JSA’s for operations & utilize the PTW for all jobs,

Isolations & confined spaces. TRIC cards & Hazard Observation cards to be used

every day by all personnel. Stop work authority to be encouraged. The 9

Halliburton life r6ules & 12 PDO life rules to be followed at all times.

Regards

Mahmoud Boraey / Bader Hinaie

Drilling supervisors, LEK-1050

You might also like

- HackSpace - June 2021Document116 pagesHackSpace - June 2021Somnath100% (1)

- The Electricity Wiring RegulationDocument239 pagesThe Electricity Wiring Regulationgodson50% (2)

- SP 1106Document26 pagesSP 1106Drilling Engineering ChannelNo ratings yet

- Pilot StudyDocument11 pagesPilot StudySatya Prakash80% (5)

- Rate of ChangeDocument22 pagesRate of ChangeTrisha MariehNo ratings yet

- Well Control Data Sheet: Well: All Values in Have To Be EnteredDocument11 pagesWell Control Data Sheet: Well: All Values in Have To Be Enteredmiguel rojasNo ratings yet

- Section 02 Tubulars-ConnectionsDocument55 pagesSection 02 Tubulars-ConnectionsDrilling Engineering ChannelNo ratings yet

- 09 Plug Setting Best PractisesDocument1 page09 Plug Setting Best Practiseshamora33No ratings yet

- BOP Control UnitDocument102 pagesBOP Control UnitDrilling Engineering ChannelNo ratings yet

- Primary Cementing CalculationsDocument40 pagesPrimary Cementing CalculationsMostafa ElghifaryNo ratings yet

- (Pdo Oman) Electrical Safety Specs.Document56 pages(Pdo Oman) Electrical Safety Specs.KT MENON100% (7)

- IJPC 13 4 Hormone Replacement TherapyDocument92 pagesIJPC 13 4 Hormone Replacement TherapyMatiasNo ratings yet

- Casing & Cementing ConventionalDocument1 pageCasing & Cementing ConventionalDeepak TandonNo ratings yet

- WELL DATADocument3 pagesWELL DATAscrbdgharaviNo ratings yet

- Santos 7'' HPC and TAMCAP Assembly - Running Procedure - Rev.3Document13 pagesSantos 7'' HPC and TAMCAP Assembly - Running Procedure - Rev.3TonyNo ratings yet

- Kill Sheet IWCFDocument2 pagesKill Sheet IWCFMaria FernandaNo ratings yet

- Exercise 4 AnswersDocument12 pagesExercise 4 AnswersadeelsnNo ratings yet

- Cementing Program For The 13 38 Inch CasingDocument40 pagesCementing Program For The 13 38 Inch CasingMarvin OmañaNo ratings yet

- 13 38 in TP-194 (HAS-2) Cement Program V1Document21 pages13 38 in TP-194 (HAS-2) Cement Program V1hakoubNo ratings yet

- Spot Heavy MudDocument1 pageSpot Heavy MudstevebeardsleyNo ratings yet

- Solution SellingDocument18 pagesSolution Sellingvikramgulati13090% (1)

- Drilling Fluids Guide for Well ConstructionDocument21 pagesDrilling Fluids Guide for Well ConstructionFernando AybarNo ratings yet

- Example 7in Liner 2 Stage Cementing ProcedureDocument2 pagesExample 7in Liner 2 Stage Cementing ProcedureYougchu LuanNo ratings yet

- Hole Cleaning: Downhole Motors in Deviated WellsDocument13 pagesHole Cleaning: Downhole Motors in Deviated WellsJairo CortesNo ratings yet

- Plugback Sidetracks - Off Cement PlugsDocument4 pagesPlugback Sidetracks - Off Cement PlugsAdel Ahmed AlkhaligyNo ratings yet

- Rules of Thumb To Improve High-Angle Hole CleaningDocument29 pagesRules of Thumb To Improve High-Angle Hole CleaningjalalNo ratings yet

- CAPS LESSON PLAN, KAHOOT QUIZ, PPT VIDEODocument3 pagesCAPS LESSON PLAN, KAHOOT QUIZ, PPT VIDEOMandisa MselekuNo ratings yet

- Tutorial Sheet No.3: Leak Off Test and MAASPDocument14 pagesTutorial Sheet No.3: Leak Off Test and MAASPali jabbarNo ratings yet

- Tg-374 18.625in Cement Rev No. 1Document3 pagesTg-374 18.625in Cement Rev No. 1Lessly Lorena Apala RamirezNo ratings yet

- Cameron Flange Slide RuleDocument1 pageCameron Flange Slide RuleDrilling Engineering ChannelNo ratings yet

- Pilot testing for contamination issuesDocument25 pagesPilot testing for contamination issuesEjaz ul Haq kakar100% (1)

- Casing and Formation DamageDocument4 pagesCasing and Formation DamageManthan MarvaniyaNo ratings yet

- Measure Science AccuratelyDocument41 pagesMeasure Science AccuratelyAnthony QuanNo ratings yet

- NLOG GS PUB 1387 Cementing EOWRDocument61 pagesNLOG GS PUB 1387 Cementing EOWRWilson WanNo ratings yet

- TVD & Kill Weight CalculationsDocument40 pagesTVD & Kill Weight Calculationsfrancisryan4519No ratings yet

- AVIARA ENERGY CORP Well Drilling ApplicationDocument1 pageAVIARA ENERGY CORP Well Drilling ApplicationstevebeardsleyNo ratings yet

- Pilot Test: ScientificDocument12 pagesPilot Test: ScientificHomam MohammadNo ratings yet

- Squeeze ProcedureDocument4 pagesSqueeze Proceduresaa6383No ratings yet

- Surge and swab pressure calculationsDocument2 pagesSurge and swab pressure calculationsSyed IrtazaNo ratings yet

- Drill String 1 DISDocument1 pageDrill String 1 DISpiies85No ratings yet

- Off-Bottom Drilling PracticesDocument3 pagesOff-Bottom Drilling PracticesAdel Ahmed AlkhaligyNo ratings yet

- CMT Programm Spd18a-07 - 3Document9 pagesCMT Programm Spd18a-07 - 3nabiNo ratings yet

- 12 Casing Running Speed - QuartzDocument1 page12 Casing Running Speed - QuartzRebarNo ratings yet

- Basic DrillingDocument65 pagesBasic DrillingAboZaidNo ratings yet

- Game Plan Adc-12 at Shyb-479 16" Hole 06/20/2014Document2 pagesGame Plan Adc-12 at Shyb-479 16" Hole 06/20/2014Mohamed AbozeimaNo ratings yet

- Liner Cementing GuidelinesDocument2 pagesLiner Cementing GuidelineszapspazNo ratings yet

- Tutorial Sheet No - 4Document23 pagesTutorial Sheet No - 4ali jabbarNo ratings yet

- 05 - SRB Hydraulic ProgramsDocument22 pages05 - SRB Hydraulic ProgramsnelsonhugoNo ratings yet

- Lab Test - AM - 17.5 - 01Document1 pageLab Test - AM - 17.5 - 01tungxuanbrNo ratings yet

- TCP-DST-01 String Diagram Rajian-07 PDFDocument1 pageTCP-DST-01 String Diagram Rajian-07 PDFRizwan FaridNo ratings yet

- OVERPULLDocument3 pagesOVERPULLscrbdgharaviNo ratings yet

- Field Fluids QaqcDocument38 pagesField Fluids QaqcscrbdgharaviNo ratings yet

- Stuck Pipe in CTD OperationsDocument5 pagesStuck Pipe in CTD OperationsAdel Ahmed AlkhaligyNo ratings yet

- Settling Plug Mixing ProcedureDocument8 pagesSettling Plug Mixing ProcedureKamel TouahriaNo ratings yet

- Surge - Swab ProgramDocument1 pageSurge - Swab ProgramHenry BritoNo ratings yet

- BP Shell Chevron Conocophillips Marathon Total Schlumberger Imperial College, London Heriot Watt University, Edinburgh (Anywhere in Article)Document42 pagesBP Shell Chevron Conocophillips Marathon Total Schlumberger Imperial College, London Heriot Watt University, Edinburgh (Anywhere in Article)Doppler KenzoNo ratings yet

- Mud Plan CalculationsDocument6 pagesMud Plan CalculationsHarjan Philipp C. GopaldasNo ratings yet

- He-E10 Well MontageDocument1 pageHe-E10 Well MontageSaeid OrangiNo ratings yet

- Programa Completo Completacion InicialDocument23 pagesPrograma Completo Completacion InicialAlejandro JaramilloNo ratings yet

- GOK-12 Wellbore Cementing ReportDocument5 pagesGOK-12 Wellbore Cementing Report-BloodSeeker-No ratings yet

- AM DRLG Report 19-12-2017Document336 pagesAM DRLG Report 19-12-2017Islam AtifNo ratings yet

- Well DataDocument5 pagesWell Datamohamed elshemyNo ratings yet

- Spe62752 Viscous Pill InfoDocument1 pageSpe62752 Viscous Pill InfoAkkassin AbdullayevNo ratings yet

- Balance of Materials: Density of A Mixture of Fluids, Knowing Volume and Density of Its ComponentsDocument2 pagesBalance of Materials: Density of A Mixture of Fluids, Knowing Volume and Density of Its ComponentsRebarNo ratings yet

- Drilling BHA - General AssemblyDocument3 pagesDrilling BHA - General AssemblyAdel Ahmed AlkhaligyNo ratings yet

- Alaska Drilling and Wells Recommended Practice: CTD Drilling FluidDocument4 pagesAlaska Drilling and Wells Recommended Practice: CTD Drilling FluidAdel Ahmed AlkhaligyNo ratings yet

- Module 06 - Cause of Kick, Indicator & Warning SignDocument10 pagesModule 06 - Cause of Kick, Indicator & Warning SignDChristiono Ayah QueenNo ratings yet

- PillsDocument4 pagesPillsbestman82No ratings yet

- Kill Sheet: Prerecorded Infromation Pump Strokes RequiredDocument17 pagesKill Sheet: Prerecorded Infromation Pump Strokes RequiredscrbdgharaviNo ratings yet

- CT Coveyed PerforatingDocument4 pagesCT Coveyed PerforatingAdel Ahmed AlkhaligyNo ratings yet

- Game Plan Cement 13 3/8Document2 pagesGame Plan Cement 13 3/8Mohamed AbozeimaNo ratings yet

- OPEN Hole 3 Cement Plug Job Procedures. 9900-9150: Operation SequenceDocument1 pageOPEN Hole 3 Cement Plug Job Procedures. 9900-9150: Operation SequenceMohammed Ali YoussefNo ratings yet

- 03-LEK-1050 Drill 12.25 Inch SectionDocument4 pages03-LEK-1050 Drill 12.25 Inch SectionDrilling Engineering ChannelNo ratings yet

- Wash PipeDocument60 pagesWash PipemohamedNo ratings yet

- Upd ReseumeDocument2 pagesUpd ReseumeDrilling Engineering ChannelNo ratings yet

- Petroleum Development Oman L.L.C. Health, Safety and Environment Specification for Activities Near Overhead Power LinesDocument17 pagesPetroleum Development Oman L.L.C. Health, Safety and Environment Specification for Activities Near Overhead Power LinesDrilling Engineering ChannelNo ratings yet

- Engineering DrawingDocument1 pageEngineering DrawingDrilling Engineering ChannelNo ratings yet

- Jet Size 7x15 & 2X16: Bit Ser - NoDocument4 pagesJet Size 7x15 & 2X16: Bit Ser - NoDrilling Engineering ChannelNo ratings yet

- Hydraulics Programme: Wellbore Mud PropertiesDocument2 pagesHydraulics Programme: Wellbore Mud PropertiesDrilling Engineering ChannelNo ratings yet

- Independent Third-Party Review ProcessDocument12 pagesIndependent Third-Party Review ProcessDrilling Engineering ChannelNo ratings yet

- Particle Physics Brick by Brick - Atomic and Subatomic Physics Explained... in LEGO - Dr. Ben Still (Firefly Books 2018 9781844039340 Eng)Document177 pagesParticle Physics Brick by Brick - Atomic and Subatomic Physics Explained... in LEGO - Dr. Ben Still (Firefly Books 2018 9781844039340 Eng)KonstantineNo ratings yet

- Dispersion of Carbon Nanotubes in Water and Non-Aqueous SolventsDocument41 pagesDispersion of Carbon Nanotubes in Water and Non-Aqueous SolventsSantiago OrtizNo ratings yet

- Chapter 6 Physics LabDocument3 pagesChapter 6 Physics Labraquelloveswow0% (1)

- Large Generators WEBDocument16 pagesLarge Generators WEBMaycon MaranNo ratings yet

- Educ 580 - Edpuzzle PD HandoutDocument3 pagesEduc 580 - Edpuzzle PD Handoutapi-548868233No ratings yet

- Belotero Intense LidocaineDocument7 pagesBelotero Intense LidocaineAnnaNo ratings yet

- MJP Rate Schedule for Water Supply Pipeline ProjectDocument6 pagesMJP Rate Schedule for Water Supply Pipeline ProjectJalal TamboliNo ratings yet

- Lembar Jawaban Skillab Evidence Based Medicine (Ebm) Nama: Rafika Triasa NIM: 040427223270003Document11 pagesLembar Jawaban Skillab Evidence Based Medicine (Ebm) Nama: Rafika Triasa NIM: 040427223270003Yahya Darmais FaridNo ratings yet

- Avago Fiber Optic ComponentsDocument8 pagesAvago Fiber Optic ComponentsGerardo BaltaNo ratings yet

- Repport Btech FinalDocument49 pagesRepport Btech FinalSuzelle NGOUNOU MAGANo ratings yet

- XFARDocument14 pagesXFARRIZA SAMPAGANo ratings yet

- Catanduanes State University: Page 1 of 12Document12 pagesCatanduanes State University: Page 1 of 12Jonah reiNo ratings yet

- Unit IV - CPU Scheduling and Algorithm Section 4.1 Scheduling Types Scheduling ObjectivesDocument18 pagesUnit IV - CPU Scheduling and Algorithm Section 4.1 Scheduling Types Scheduling ObjectivessmsaranyaNo ratings yet

- MF ISIN CodeDocument49 pagesMF ISIN CodeshriramNo ratings yet

- TEFL I Course Prepares Students to Teach EnglishDocument8 pagesTEFL I Course Prepares Students to Teach EnglishErma DomosNo ratings yet

- Water TreatmentDocument6 pagesWater TreatmentSantiago LarrazNo ratings yet

- Exercise 1: Chọn đáp án đúng:: Buổi 9: Động từ khuyết thiếu (Modal verb)Document6 pagesExercise 1: Chọn đáp án đúng:: Buổi 9: Động từ khuyết thiếu (Modal verb)Huyền HồNo ratings yet

- Urbanclap 160731135642Document20 pagesUrbanclap 160731135642Kaustav Dey100% (1)

- B1 UDO Trace LogDocument14 pagesB1 UDO Trace LogCh M KashifNo ratings yet

- (MATH1013) (2016) (F) Midterm Wsuab 41338Document9 pages(MATH1013) (2016) (F) Midterm Wsuab 41338陳希程No ratings yet

- English Assignment Team:: Devia Annisa E. E44190045 2. TB. Aditia Rizki E44190027 3. Tedi Irfan Jelata E44190028Document3 pagesEnglish Assignment Team:: Devia Annisa E. E44190045 2. TB. Aditia Rizki E44190027 3. Tedi Irfan Jelata E4419002856TB. Aditia RizkiNo ratings yet