Professional Documents

Culture Documents

Week 36 Quality Report

Week 36 Quality Report

Uploaded by

QMSOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Week 36 Quality Report

Week 36 Quality Report

Uploaded by

QMSCopyright:

Available Formats

Quality Report - Week # 36 (5.09.2022 - 11.09.

2022)

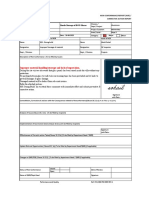

1.Field failure

Attribute to AIL /

Customer Model Failure Details QTY Corrective Action Customer/Unknown

NIL _ _ _ _ _ _

2.Customer returned Housings to AIL

Customer Model Reason for return QTY Corrective Action Attribute to AIL /

(To be filled by concern Dept head) Customer/Unknown

TML DL, JSR SRT REAR - 0104 Bottom boss shifted upto 30mm towards dome 1 Planned to provide sensor for proper seating of boss in housing in tack weld fixture AIL

3.Customer End Rejection/Rework

Customer Rejection Details Corrective Action taken Customer Concerns(Not considered in PPM) Corrective Action Disciplinary

(Reported in Portal and considered in PPM) Action

DANA,USA NIL NIL

Volvo truck-Thailand/ NIL NIL

Japan

DICV/AAM NIL NIL

TML DL,

Jamshedpur NIL NIL

TML DL Pune NIL NIL

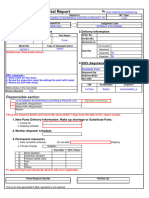

Customer-ID351190 Containment action:

NIL ----- Model -11.10HD 1) IBC leg corner weld to be covered and weld start to be done from seam weld .

Defects - RH Side IBC weld crack during U Bolt assembly. 2) RH Side V block center line corrected with shim. (One no. checked with CMM found ok.

Qty - 2 Nos. Corrective action: Fixture correction required. Under progress

VECV

Problem : Front cutout areaa burr found Containment action:

Model : VE3500

Part no : ISK7361 1. Reamer tool changed Immediately

NIL 2. Cut out burr Removed in Deburring area.

Qty : 1No

Reported on: 10.09.2022 Corrective action pending

SML NIL NIL

Mahindra NIL NIL

Problem : Housing inside metal burr

Model :980006

Qty : 1 no. 1.After rear cutout station Cleaning check point provided.

NIL Hsg No : H37686H22 2.Before inner plate welding inside holusing cleaning done and ensured. _

Plant : Chy

Date : 05.09.22

Problem : Front spigot diameter over size

Model :980006

Qty : 1 no. 1.Coolant flow provided in CNC Turning machine.

NIL Hsg No : H37640H22 2.80% of the tolerance fixed in Front spigot diameter gauge. _

Plant : Chy

Date : 05.09.22

DIPL-Oragadam

Problem : Drain plug Broken

Model : Ecomet (991999)

Qty : 1 no.

NIL Hsg No : E16327G22 1.Check and ensure the Torque 40-50 NM at Final inspection stage. If excess, to be released. _

Plant : E1

Date : 08.09.22

Problem : S cam brkt TPG NOGO Ans

Model : Ecomet (991999)

Qty : 1 no.

NIL Hsg No : E16275G22 1. Full Welding done in Fixture Bolt tightening condition at S cam brkt full welding stage. _

Plant : E1

Date : 08.09.22

DIPL-

Pant Nagar

You might also like

- Doosan DL450 Wheel Loader Service Repair Workshop ManualDocument10 pagesDoosan DL450 Wheel Loader Service Repair Workshop ManualManuals CE & Ag33% (3)

- Quality Report - Week #: 1.field FailureDocument2 pagesQuality Report - Week #: 1.field FailurebhavyaNo ratings yet

- Week 37 Quality ReportDocument3 pagesWeek 37 Quality ReportQMSNo ratings yet

- Week 35 Quality ReportDocument2 pagesWeek 35 Quality ReportQMSNo ratings yet

- Quality Report - Week #: 1.field FailureDocument2 pagesQuality Report - Week #: 1.field FailureBhavyaNo ratings yet

- Stock Level Change RequestDocument2 pagesStock Level Change RequestPatrick HillmanNo ratings yet

- Stock Level Change: MM - Inventory ManagementDocument2 pagesStock Level Change: MM - Inventory ManagementPatrick HillmanNo ratings yet

- Complaint AnalysisDocument8 pagesComplaint AnalysisJKP OperationNo ratings yet

- Week 39 Quality ReportDocument2 pagesWeek 39 Quality ReportQMSNo ratings yet

- SPCL Offer 9 (New) - 03.12.09Document55 pagesSPCL Offer 9 (New) - 03.12.09ptn999No ratings yet

- Stock Level Change RequestDocument2 pagesStock Level Change RequestPatrick HillmanNo ratings yet

- Stock Level Change: MM - Inventory ManagementDocument2 pagesStock Level Change: MM - Inventory ManagementPatrick HillmanNo ratings yet

- Supplier Corrective Action Report (Scar) : Characteristics Specification Actual RemarksDocument3 pagesSupplier Corrective Action Report (Scar) : Characteristics Specification Actual RemarksdysonNo ratings yet

- Load Calclations Slab TH 20cmDocument14 pagesLoad Calclations Slab TH 20cmMUHAMMAD AEMRNo ratings yet

- Zet Town Packing Summary JIO - JBV191M2!11!03-2024 Shift-BDocument1 pageZet Town Packing Summary JIO - JBV191M2!11!03-2024 Shift-Bsumit kumarNo ratings yet

- Rekayasa - BQ Pusri STG & Coal Boiler ProjectDocument18 pagesRekayasa - BQ Pusri STG & Coal Boiler ProjectSamuel SinagaNo ratings yet

- Stock Level Change: MM - Inventory ManagementDocument2 pagesStock Level Change: MM - Inventory ManagementPatrick HillmanNo ratings yet

- Lean Six Sigma 2022 - Nitrogen Improvement - AnalyseDocument80 pagesLean Six Sigma 2022 - Nitrogen Improvement - AnalyseSalman CnNo ratings yet

- Lean Six Sigma 2022 - Nitrogen Improvement - D&MDocument71 pagesLean Six Sigma 2022 - Nitrogen Improvement - D&MSalman CnNo ratings yet

- Cowp PDFDocument7 pagesCowp PDFScherraine Khrys CastillonNo ratings yet

- Noya - NCR - ISC-08Document2 pagesNoya - NCR - ISC-08Azam KhanNo ratings yet

- CAPADocument9 pagesCAPABalaji AnbazaganNo ratings yet

- Ae 2 PerformanceDocument4 pagesAe 2 PerformanceankitNo ratings yet

- Ae 2 PerformanceDocument4 pagesAe 2 PerformanceankitNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- Corrective and Preventive Action (8D) Report: Cust. Complaint Serial Number Cust. Complaint Ref. No. & DateDocument1 pageCorrective and Preventive Action (8D) Report: Cust. Complaint Serial Number Cust. Complaint Ref. No. & DateDeepak HoleNo ratings yet

- UntitledDocument12 pagesUntitledEnrico BishopNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- FD Tial: Servicetechnical ReportDocument11 pagesFD Tial: Servicetechnical Reportnhatnguyen101No ratings yet

- Skeipl-Qad-F-30 OplDocument5 pagesSkeipl-Qad-F-30 OplPreetam GiteNo ratings yet

- JMD Garden Exp Oct - 2018Document5 pagesJMD Garden Exp Oct - 2018monty.rajputNo ratings yet

- Mod-Itp-Ll - 005 - Pile HincasDocument2 pagesMod-Itp-Ll - 005 - Pile HincasalejandroNo ratings yet

- Quality Alert - Revised 2017Document4 pagesQuality Alert - Revised 2017Faraj KhanNo ratings yet

- 8D Gas Box Inlet - Dia 19.10mm LessDocument5 pages8D Gas Box Inlet - Dia 19.10mm LessRD PlcsNo ratings yet

- 2 - Borrow Area No-02Document2 pages2 - Borrow Area No-02sandeep singhNo ratings yet

- Accounting and Financial Management 1b Samplepractice Exam January 2015 AnswersDocument7 pagesAccounting and Financial Management 1b Samplepractice Exam January 2015 AnswersS MNo ratings yet

- CapaDocument10 pagesCapaBalaji AnbazaganNo ratings yet

- FA ReportDocument4 pagesFA ReportBudi ArtantoNo ratings yet

- IFC Closure Approval ReportDocument12 pagesIFC Closure Approval ReportAjayNo ratings yet

- Quality AlertDocument3 pagesQuality AlertPreetam GiteNo ratings yet

- General Formate of Estimation FinalDocument18 pagesGeneral Formate of Estimation Finalsaiful islamNo ratings yet

- Compliance Report JSW 2nd Reach StackerDocument2 pagesCompliance Report JSW 2nd Reach StackerPrem Kumar UpBrightNo ratings yet

- Stock Level Change: MM - Inventory ManagementDocument2 pagesStock Level Change: MM - Inventory ManagementPatrick HillmanNo ratings yet

- Capa Kipl Qa DT 23 24 9 03156Document16 pagesCapa Kipl Qa DT 23 24 9 03156Balaji AnbazaganNo ratings yet

- NCR Ref.# ILP2-001: Non-Conformity Report (NCR)Document1 pageNCR Ref.# ILP2-001: Non-Conformity Report (NCR)Naukhez A. KashifNo ratings yet

- 3511-A4-2 Iss1 ILLUMINATION WIRING Mk2020S BinnacleDocument1 page3511-A4-2 Iss1 ILLUMINATION WIRING Mk2020S BinnacleyanuNo ratings yet

- Quality Alert - Revised 2017Document2 pagesQuality Alert - Revised 2017Faraj KhanNo ratings yet

- 010-Reducing Agent SwitchingDocument91 pages010-Reducing Agent Switchingasri nurulNo ratings yet

- 165-4-DSE-015, Rev.0Document23 pages165-4-DSE-015, Rev.0Muhmmad udassirNo ratings yet

- Lab Test ReportDocument18 pagesLab Test ReportSumantrra ChattopadhyayNo ratings yet

- DEVIATION FORM - Pradeep MetalsDocument2 pagesDEVIATION FORM - Pradeep MetalsNitesh SrivastavaNo ratings yet

- Interim Inspection Report: Final Inspection of StructuresDocument5 pagesInterim Inspection Report: Final Inspection of StructuresAbdul RahmanNo ratings yet

- FAR 0214 ML4500 Lighting Tower Ver1Document2 pagesFAR 0214 ML4500 Lighting Tower Ver1K3LH BPPNo ratings yet

- Physical Targets and Achievements 2016-17 To 2019-2020Document3 pagesPhysical Targets and Achievements 2016-17 To 2019-2020Azhar AliNo ratings yet

- Stock Level Change: MM - Inventory ManagementDocument2 pagesStock Level Change: MM - Inventory ManagementPatrick HillmanNo ratings yet

- Load Calclations Beams (35X80) CMDocument11 pagesLoad Calclations Beams (35X80) CMMUHAMMAD AEMRNo ratings yet

- Basic Rate SheetDocument15 pagesBasic Rate Sheetraja shekarNo ratings yet

- Final OutputDocument3 pagesFinal OutputJudith DurensNo ratings yet

- Retail & Terminal: Engineering UnitDocument16 pagesRetail & Terminal: Engineering UnitElijah JohnNo ratings yet

- Observation Report - Mansoura#2 - RM6 Failure - Rev.00Document8 pagesObservation Report - Mansoura#2 - RM6 Failure - Rev.00TossonNo ratings yet

- AIoT Training Module Day 2 V1 10292020Document67 pagesAIoT Training Module Day 2 V1 10292020Louise Anjello MangahasNo ratings yet

- Maxxaudio v6 Technical Product BriefDocument10 pagesMaxxaudio v6 Technical Product BriefEleu Eduardo Mehret Scorsin FilhoNo ratings yet

- IEC61850 Ed2 Devices - EN - Rev1.6Document104 pagesIEC61850 Ed2 Devices - EN - Rev1.6huskeeNo ratings yet

- Diagrama de CabinaDocument274 pagesDiagrama de CabinaRodriguez Oswaldo100% (1)

- Atemperador ShiniDocument47 pagesAtemperador ShiniJulio Cesar Diaz RamosNo ratings yet

- Fee Management (Sourabh Verma)Document11 pagesFee Management (Sourabh Verma)Abhishek Singh (ABHISHEK SINGH)No ratings yet

- Noon PPDocument18 pagesNoon PPAlex ZodNo ratings yet

- Huawei OceanStor SNS2624 SNS3664 SNS3696E Data SheetDocument6 pagesHuawei OceanStor SNS2624 SNS3664 SNS3696E Data SheetdjsonicoNo ratings yet

- A2. Equipment Criticality RatingDocument3 pagesA2. Equipment Criticality RatingPeter IyereNo ratings yet

- SM-J111M Esquematico Completo Anibal Garcia IrepairDocument9 pagesSM-J111M Esquematico Completo Anibal Garcia IrepairSamir Sanchez GarnicaNo ratings yet

- V18 03 en Architecture TechnicalDocument20 pagesV18 03 en Architecture TechnicalOtavio CarvalhoNo ratings yet

- s1-pwn23-002 1Document10 pagess1-pwn23-002 1Ron Cedric GarciaNo ratings yet

- Event Management and Social Media Marketing: ISSN: 2454-132X Impact Factor: 4.295Document4 pagesEvent Management and Social Media Marketing: ISSN: 2454-132X Impact Factor: 4.295ShreyNo ratings yet

- Rocketfish AC/DC Combo Power Adapter: Rf-Bpracdc2Document16 pagesRocketfish AC/DC Combo Power Adapter: Rf-Bpracdc2dqrmxNo ratings yet

- Kaizen Continuous Improvement PhilosophyDocument69 pagesKaizen Continuous Improvement PhilosophyNur Alya Hidayah SairiNo ratings yet

- Dell 27 Monitor - E2720H Data SheetDocument4 pagesDell 27 Monitor - E2720H Data SheetShakilNo ratings yet

- Airline Reservation SystemDocument2 pagesAirline Reservation SystemKalyani NagarajanNo ratings yet

- SCADA Brochure ABB PDFDocument16 pagesSCADA Brochure ABB PDFAulia RahmanNo ratings yet

- KPI Assessment FormDocument2 pagesKPI Assessment FormRob Willestone100% (1)

- CAT6A Patch Cord 1m To 5mDocument2 pagesCAT6A Patch Cord 1m To 5mSajid KhanNo ratings yet

- Alakh Advertising & Publicity Pvt. Ltd.Document2 pagesAlakh Advertising & Publicity Pvt. Ltd.Alakh AdvtNo ratings yet

- Team Name: Andromeda: Instructor: Prof. Dr. Lawrence ChungDocument40 pagesTeam Name: Andromeda: Instructor: Prof. Dr. Lawrence ChungRomNo ratings yet

- C7950 SERIES: FeaturesDocument2 pagesC7950 SERIES: Features박만진No ratings yet

- CSS NC II Self CheckDocument8 pagesCSS NC II Self CheckJanice Conde PelaezNo ratings yet

- Z/Os, Z/VM and Platform Technology: Ibm Zseries April 2001 (Update)Document21 pagesZ/Os, Z/VM and Platform Technology: Ibm Zseries April 2001 (Update)gborja8881331No ratings yet

- OLGA Installation GuideDocument10 pagesOLGA Installation Guidepolaris44No ratings yet

- Lab 9: Javascript Web1201: Web Fundamentals: Rev 1.6.5 November, 2020Document34 pagesLab 9: Javascript Web1201: Web Fundamentals: Rev 1.6.5 November, 2020阿符的故事No ratings yet

- Fps MonitorDocument9 pagesFps MonitorMister TeeVeeNo ratings yet

- Geck Eri-2g CatalogueDocument2 pagesGeck Eri-2g CatalogueIan Kent BescoroNo ratings yet