Professional Documents

Culture Documents

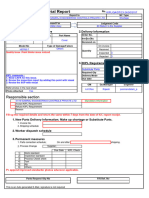

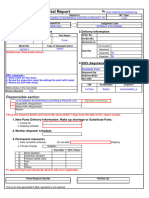

Quality Report - Week #: 1.field Failure

Quality Report - Week #: 1.field Failure

Uploaded by

BhavyaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quality Report - Week #: 1.field Failure

Quality Report - Week #: 1.field Failure

Uploaded by

BhavyaCopyright:

Available Formats

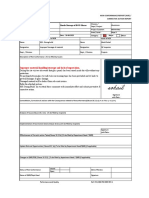

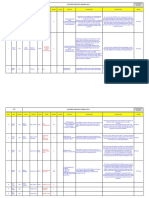

Quality Report - week # 33 (11.08.19 to 17.08.

19 )

1.Field failure

Attribute to AIL /

Customer Model Failure Details QTY Corrective Action Customer/Unknown

NIL

2.Customer returned Housings to AIL

Reason for return Attribute to AIL /

Customer Model QTY Corrective Action

(To be filled by concern Dept head) Customer/Unknown

HR210 housing(989036) 1

TML

979004 SRT HSG 6

AAM

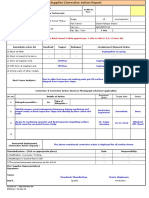

3.Customer End Rejection/Rework

Rejections Others Disciplinary

Customer Corrective Action

(Considered in PPM) (Not considered in PPM) Action

DANA,USA

Volvo truck-

Thailand/

Japan

1.Proof load operator advised to dont take brake flange machined housing to runout correction

Concentricity not ok 1 thru OPL to avoid FS excess runout.

2.Concentricity gauge 100% inspection implemented at final inspection stage

DICV/AAM

Banjo leak due to pin hole near 1)If any weld plugging rework carried out, immediate after leak to be checked and approved by

1 QA person. After certified by QAD further process will be done.2)Operator were advised to

drain plug avoid this type of rework and without QA approval.

TML DL,

Jamshedpur

TML DL Pune

VECV (CHY)

SML

Mahindra

DIPL-Oragadam

DIPL-

Pant Nagar

You might also like

- Vintage Rock #12 - 2014.07-08 PDFDocument115 pagesVintage Rock #12 - 2014.07-08 PDFpennyman100% (1)

- Quality Report - Week #: 1.field FailureDocument2 pagesQuality Report - Week #: 1.field FailurebhavyaNo ratings yet

- Week 37 Quality ReportDocument3 pagesWeek 37 Quality ReportQMSNo ratings yet

- Week 36 Quality ReportDocument3 pagesWeek 36 Quality ReportQMSNo ratings yet

- Week 35 Quality ReportDocument2 pagesWeek 35 Quality ReportQMSNo ratings yet

- 8D - Problem Resolution Report: Complaint No. Part Name Date Customer Problem Status New Repeated D-1 Problem DescriptionDocument2 pages8D - Problem Resolution Report: Complaint No. Part Name Date Customer Problem Status New Repeated D-1 Problem Descriptionpm metlabNo ratings yet

- Noya - NCR - ISC-08Document2 pagesNoya - NCR - ISC-08Azam KhanNo ratings yet

- 2953 Thrad TightDocument6 pages2953 Thrad TightRohit QualityNo ratings yet

- Inspection Test Plan For Eot CraneDocument4 pagesInspection Test Plan For Eot CraneBikash ShreshthaNo ratings yet

- 8D - Problem Resolution Report: Invoice No. Grade/ Size (MM) /condition Heat NoDocument2 pages8D - Problem Resolution Report: Invoice No. Grade/ Size (MM) /condition Heat Nopm metlabNo ratings yet

- QCD Dashboard : Server ns002/Workshare/2.ISO Department/QAQC HSE DashboardDocument2 pagesQCD Dashboard : Server ns002/Workshare/2.ISO Department/QAQC HSE Dashboardlemuel bacsaNo ratings yet

- Essae 20.06.20Document3 pagesEssae 20.06.20Parthiban DNo ratings yet

- IFC Closure Approval ReportDocument12 pagesIFC Closure Approval ReportAjayNo ratings yet

- Surface Finish Found 5.68ra Against Spe. 3.2ra On Ø60.0-0.3/-0.2mm ODDocument7 pagesSurface Finish Found 5.68ra Against Spe. 3.2ra On Ø60.0-0.3/-0.2mm ODBALACHANDAR SNo ratings yet

- Fuso Tem - 2022Document100 pagesFuso Tem - 2022abrahambelay92No ratings yet

- PfmeaDocument1 pagePfmeaSridhar DineshNo ratings yet

- Capa Kipl Qa DT 23 24 9 03157Document16 pagesCapa Kipl Qa DT 23 24 9 03157Balaji AnbazaganNo ratings yet

- 8D Example-NewDocument1 page8D Example-NewFR LMNo ratings yet

- Capa Kipl Qa DT 23 24 9 03156Document16 pagesCapa Kipl Qa DT 23 24 9 03156Balaji AnbazaganNo ratings yet

- LSS ProjectDocument88 pagesLSS ProjectQuality HosurNo ratings yet

- LeakageDocument1 pageLeakageSyed Owais Ali NaqviNo ratings yet

- ConcernsDocument4 pagesConcernsSrikanthNo ratings yet

- Ge Sill PFD PDFDocument1 pageGe Sill PFD PDFRavikumar BojjaNo ratings yet

- Complaint Summary All.2014Document15 pagesComplaint Summary All.2014Sameer SaxenaNo ratings yet

- Formato 8DDocument2 pagesFormato 8DALEJANDRONo ratings yet

- Vendor Document Review Sheet (DECAL) : J3 Program-Offsites & Utilities, Jamnagar, India Project TitleDocument6 pagesVendor Document Review Sheet (DECAL) : J3 Program-Offsites & Utilities, Jamnagar, India Project TitlenisargkedarNo ratings yet

- Draft Manpower Staffing Norms For Maintenance RegionsDocument2 pagesDraft Manpower Staffing Norms For Maintenance RegionsPuneet NirajNo ratings yet

- 850T - CPK ImprovementDocument11 pages850T - CPK ImprovementMansoor ShaikhNo ratings yet

- Online Feedback System 1921Document2 pagesOnline Feedback System 1921santosh kumarNo ratings yet

- Check Sheet Improved MT Inspection Procedure Report For C-0659Document3 pagesCheck Sheet Improved MT Inspection Procedure Report For C-0659Himanyu RafiqNo ratings yet

- CustomerDocument5 pagesCustomerMahmoud KhalifaNo ratings yet

- Asset Integrity Daily ReportDocument1 pageAsset Integrity Daily Reportعصمت ضيف اللهNo ratings yet

- Asset Integrity Daily ReportDocument1 pageAsset Integrity Daily Reportعصمت ضيف اللهNo ratings yet

- CapaDocument10 pagesCapaBalaji AnbazaganNo ratings yet

- Joint Inspection Report MechanicalDocument8 pagesJoint Inspection Report MechanicalRohan SharmaNo ratings yet

- S200 Acifm MNT 30 RPT XXXXXXX 02015Document2 pagesS200 Acifm MNT 30 RPT XXXXXXX 02015fayasibrahimkuttyNo ratings yet

- Visit Report - 312Document4 pagesVisit Report - 312Vinay YadavNo ratings yet

- Checklist For Blinds & CurtainsDocument1 pageChecklist For Blinds & Curtainsashutosh65361No ratings yet

- QP-QA-05-Control of Non-Conforming ProductDocument2 pagesQP-QA-05-Control of Non-Conforming ProductDebkanta DasNo ratings yet

- CMR For 2gs Am CrackDocument7 pagesCMR For 2gs Am CrackKumaravelNo ratings yet

- Supplier Technical Audit Report Example GMRDocument8 pagesSupplier Technical Audit Report Example GMRMohammad Faraz AkhterNo ratings yet

- Six Steps To Successful Repair of GT ComponentsDocument13 pagesSix Steps To Successful Repair of GT ComponentsThanapaet RittirutNo ratings yet

- Sacmi MeenaDocument1 pageSacmi MeenaKrishnendu GhoshNo ratings yet

- 12M PM Das Bombas de IncendioDocument4 pages12M PM Das Bombas de IncendioMarciokronembergerNo ratings yet

- Six Sigma - Reduction of Downtime - RE Mill-2 - NewDocument76 pagesSix Sigma - Reduction of Downtime - RE Mill-2 - NewKiruthiga VelmuruganNo ratings yet

- PFMEA OF ABB TankDocument12 pagesPFMEA OF ABB Tankrohit mathanker100% (3)

- Control Plan - Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Document4 pagesControl Plan - Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Himanshu MishraNo ratings yet

- CAPADocument9 pagesCAPABalaji AnbazaganNo ratings yet

- DG System - Log Data, Records, Observations & AnalysisDocument6 pagesDG System - Log Data, Records, Observations & AnalysisMohammed SajjadNo ratings yet

- TECH IT - Presentation Tata PowerDocument8 pagesTECH IT - Presentation Tata Powergoudappa6No ratings yet

- PDS - Carburetor Failure Boxer 150Document7 pagesPDS - Carburetor Failure Boxer 150Byron Pablo CalderonNo ratings yet

- Contractor Approved Typical Inspection Plan: Classification - INTERNALDocument10 pagesContractor Approved Typical Inspection Plan: Classification - INTERNALMohamed Reda Hussein SengarNo ratings yet

- Customer Quality Complain List 2015Document16 pagesCustomer Quality Complain List 2015Sameer SaxenaNo ratings yet

- Time Limits/Maintenance Checks Time Limits Inspection/Check: Maintenance Manual (Rev G12) 05-10-00 (Rev Apr 1/15)Document6 pagesTime Limits/Maintenance Checks Time Limits Inspection/Check: Maintenance Manual (Rev G12) 05-10-00 (Rev Apr 1/15)Nathaniel LuraNo ratings yet

- Acd Si 004Document6 pagesAcd Si 004Massimo FumarolaNo ratings yet

- Approved - Booster QapDocument1 pageApproved - Booster QapSebanti BanerjeeNo ratings yet

- Problem CT Over DCM 10 210509 1Document4 pagesProblem CT Over DCM 10 210509 1Arief NurhakikiNo ratings yet

- Xfmea Report Sample - Process FMEA: in Addition To This Summary, This Report Includes The Following FormsDocument8 pagesXfmea Report Sample - Process FMEA: in Addition To This Summary, This Report Includes The Following Formssenzo scholar100% (1)

- BN7I ProjectDocument19 pagesBN7I ProjectRathikaNo ratings yet

- Cis-Sp-18-Customer Complaints HandlingDocument5 pagesCis-Sp-18-Customer Complaints HandlingVaibhav Gadhawe100% (1)

- Trees of IndiaDocument6 pagesTrees of IndiaKonstantino LeoNo ratings yet

- Nano FiltersDocument18 pagesNano FiltersN Vinod babuNo ratings yet

- Apa 7TH Edition Format ExampleDocument11 pagesApa 7TH Edition Format ExampleCory StephensonNo ratings yet

- Math - 4 7 - Preamble - 2010 D 441 en 5Document23 pagesMath - 4 7 - Preamble - 2010 D 441 en 5Panagiotis SotiropoulosNo ratings yet

- Bond Valuation JiteshDocument83 pagesBond Valuation Jiteshjitesh_talesaraNo ratings yet

- 08 Evidence PlanDocument2 pages08 Evidence PlanGlenn TotzNo ratings yet

- Art Integration Lesson Plan-FinalDocument5 pagesArt Integration Lesson Plan-Finalapi-331699633No ratings yet

- A Bibliographical, Antiquarian and Picturesque Tour in France and Germany, Volume Three by Dibdin, Thomas Frognall, 1776-1847Document182 pagesA Bibliographical, Antiquarian and Picturesque Tour in France and Germany, Volume Three by Dibdin, Thomas Frognall, 1776-1847Gutenberg.orgNo ratings yet

- New Section: Jeff Is Quite Tall. Karl Is The Same Height As JeffDocument6 pagesNew Section: Jeff Is Quite Tall. Karl Is The Same Height As JeffIbrahim MahmoudNo ratings yet

- Sunrise SB9 Read OnlyDocument113 pagesSunrise SB9 Read OnlyAhmed SalahNo ratings yet

- IS EN 14476 - 2013 A1 2015 ResumenDocument12 pagesIS EN 14476 - 2013 A1 2015 ResumenLuciano QuinteroNo ratings yet

- Keystroke DynamicsDocument6 pagesKeystroke DynamicsrasbiakNo ratings yet

- BMW CAR m5 E34Document8 pagesBMW CAR m5 E34Gonzalo PerazaNo ratings yet

- Bliss Manufacturing Company Internal Lab Scope: Laboratory PersonnelDocument2 pagesBliss Manufacturing Company Internal Lab Scope: Laboratory PersonnelsachNo ratings yet

- 2021 Yr11 Task 1 Business Report FINALDocument3 pages2021 Yr11 Task 1 Business Report FINALTaha Kafil-HussainNo ratings yet

- Joy To Live EbookDocument417 pagesJoy To Live Ebookmarkuswolf11No ratings yet

- Action Research ProjectDocument7 pagesAction Research Projectapi-584022287No ratings yet

- Amm Tasks Airbus A 319 320 321Document6 pagesAmm Tasks Airbus A 319 320 321Jose HomoNo ratings yet

- Lecture 10: Power-Flow Studies: Instructor: Dr. Gleb V. Tcheslavski Contact: Office HoursDocument28 pagesLecture 10: Power-Flow Studies: Instructor: Dr. Gleb V. Tcheslavski Contact: Office HoursAn00pgadzillaNo ratings yet

- AIR Modeller - Issue 73 (2017 08-09)Document68 pagesAIR Modeller - Issue 73 (2017 08-09)604457060100% (1)

- Tests of Significance Notes PDFDocument12 pagesTests of Significance Notes PDFManish KNo ratings yet

- Ice Cream Cones Manufacturing and Production Project ReportDocument22 pagesIce Cream Cones Manufacturing and Production Project Reportwww.projecreportinfo.comNo ratings yet

- Knowles McCarthy Jones Rowse 2011Document13 pagesKnowles McCarthy Jones Rowse 2011Da Josh MarienellaNo ratings yet

- (123doc) - A-Qualitative-Study-Of-Project-Based-Learning-In-MainstreamDocument12 pages(123doc) - A-Qualitative-Study-Of-Project-Based-Learning-In-MainstreamThai ThuyNo ratings yet

- Mas 4 Reporting 1Document86 pagesMas 4 Reporting 1Er FernandezNo ratings yet

- GuitarDocument37 pagesGuitarramonphillipycNo ratings yet

- Evaluation Studyof MPLSNetwork Potencyin Yemen NetDocument13 pagesEvaluation Studyof MPLSNetwork Potencyin Yemen NetAdham AliNo ratings yet

- All QuestionDocument37 pagesAll QuestionOUSMAN SEIDNo ratings yet

- Panasonic TH42PA20ADocument80 pagesPanasonic TH42PA20AgondifNo ratings yet